Академический Документы

Профессиональный Документы

Культура Документы

Chapter 7-STEERING System (EngineeringDuniya - Com)

Загружено:

mukesh3021Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Chapter 7-STEERING System (EngineeringDuniya - Com)

Загружено:

mukesh3021Авторское право:

Доступные форматы

Steering Systeml

1

Chapter 7

Steering system

7. 1 INTRODUCTION

Primary function of the steering system is to achieve angular motion of the

front wheels to negotiate a turn. This is done through linkage and steering gear

which convert the rotary motion of the steering wheel into angular motion of the

front road wheels. Secondary functions of steering system are :

I. To provide directional stability of the vehicle when going straight ahead. .

2. To provide perfect steering condition, i.e., perfect rolling motion of the road

wheels at all times.

3. To facilitate straight ahead recovery after completing a turn.

4. To minimize tyre wear.

Till recently all vehicles were steered by turning the front wheels in the

desired directions, with the rear: wheels following. However, lately all-wheel-

steering has been designed and employed in some selected vehicles. Here only

front wheel steering would be discussed which is being used universally till today.

The requirements of a good steering system are:

1. The steering mechanism should be very accurate and easy to handle.

2. The effort required to steer should be minimal and must not be Tiresome to the

driver. .

3. The steering mechanism should also provide directional stability. This

Implies that the vehicle. Should have a tendency to return to its straight ahead

Position after turning.

7.2 Components of a Steering system- Steering linkages

1.Rigid axle Suspension

Steering Systeml

2

2.Independent Suspension

Different types of steering linkages

Steering Systeml

3

7.3 Steering axis (or kingpin) inclination

Kingpins are inclined inward at the top. The centre line of the ball joints (or

kingpin) is inclined to the vertical. This inclination is called steering axis

inclination or ball joint angle for ball joint systems. It is called kingpin inclination

for kingpin systems.

The steering axle inclination in the

present day vehicles ranges from

3.5-8.5

0

and its average value is 5

0

.

Kingpin inclination is usually built

into the axle ends. This inclination

has the effect of placing the turning

point at the centre of the tyre tread

instead of inside the wheel. This

makes possible more stable steering as the wheel has the tendency to swing

around the kingpin when it strikes a bump.

Kingpin inclination has a pronounced effect on the steering effort and return

ability. As the front wheels are turned around an inclined steering axis or kingpin,

the front of the vehicle is lifted. This lifting of the vehicle is experienced as the

turning effort when the turn is executed and exhibits itself as recovery force when

the steering wheel is released. In this way it helps to provide steering stability. It

also reduces steering effort especially when the vehicle is stationary. In addition,

it reduces tyre wear.

Camber

The front wheels are generally not mounted parallel to each other. Camber is the

angle of inclination of the front wheel tyre with respect to the vertical. Camber

provided may be positive or negative.

Steering Systeml

4

When the wheel tilt is outward i.e. when the distance between the top of the

wheels is greater than the distance at the ground, the camber is positive. This

positive camber is built into the wheel spindle by forming the spindle with a

downward tilt.

When the tilt of the front wheel tyre to the vertical is inward, the wheels are closer

together at the top than at the bottom, the camber is negative.

The amount of the tilt of the front wheel tyre is measured in degrees from the

vertical. This measurement is called camber angle. If the wheels are vertical to

the road, the condition is referred to as zero camber.

Camber is built into the front wheels for the following reasons

1. To place the load more nearly on the inner bearing of the wheel.

2. To avoid reverse camber (wheels leaning inward at the top) as the spindle

parts wear.

3. To reduce the side thrust on the kingpin.

4. To compensate the centre of the wheel rotation plane being outside of the

centre line of the kingpin.

The camber angle is generally less than 3

0

. A cambered wheel tries to roll

around the point defined by the intersection of the inclined axis of the tyre and

ground. A cambered wheel must, therefore, be forced to roll around a point

defined by the intersection of the inclined axis of the tyre and ground. A

cambered wheel must, therefore, be forced to roll straight ahead, and unless

camber is equal on both wheels, an imbalance of restraining forces results.

Steering Systeml

5

When a camber exists, the restrained tyre also scrubs on the road. This is

because; the tyre is compelled to follow the path straight down the road when its

geometric rotation tendency is to roll in a circle about the tyres inclined axis and

the ground. Therefore, zero camber is desired to eliminate the tyre wear caused

by this scrubbing action.

If the camber of the front wheel is set at zero in the manufacturing process, the

effects of bearing clearances, axle deflection due to load after installation in the

vehicle, and dynamic operating loads will results in negative camber during

vehicle operation. Since the camber change with load, a slight amount of positive

camber is usually incorporated in the front axle during fabrication. This results in

a net camber of approximately zero when the vehicle is operated in normal

design load.

Caster

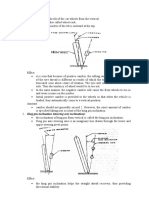

Figure below shows a side view of the caster angle formed between the vertical

line and the knig pin inclination. Depending upon the manner in which the king

pin is tilted, the caster may be of two different natures. Viz. positive caster and

negative caster. The purpose of negative caster is to

- produce directional stability

- to avoid or minimize the tendency of wheel wander

- Avoid shimmy (i.e. oscillation of the front wheels).

Steering Systeml

6

7.4 Toe-in and Toe-out

Figure 1

Figure 2

in the initial setting of the front wheels, carried out in the industry or the repairing

garage, the front wheels are set closer at their front than at their rear at their

stationary state when viewed from the top, as shown in the figure 2a. The

difference in the amount of B and A is called toe-in i.e. B-A = toe-in. The opposite

of it is the setting of the wheels as shown in the figure 2B in which the fronts of

the front wheels are far-off than their rears. This is toe-out whose value is equal

to the difference between A and B. Thus A-B = Toe-out.

Purpose: - The toe-in is provided on all kinds of vehicle. The purpose of

providing toe-in is to offset the tendency of wheel rolling.

i.) On the curves due to the limitation of correct steering,

ii.) Due to possible play in the steering linkages,

iii.) Due to the camber effect

Steering Systeml

7

The toe-out is provided to counter the tendency of the inward rolling of the

wheels

i.) Due to the soil condition on agricultural land

ii.) On account of side thrusts

The amount of toe-in varies from 0 to 6 mm on different vehicles. It is 2 to 4 mm

on Maruti 800 car, up to 6 mm on Swaraj Mazda, but 0 mm on Ashok Leyland

Comet.

7.5 Center point steering

With a standard axle the point of intersection of the king pin axis with ground is

different from the centre point of the tyre contact path as shown in figure (a). This

result in heavy steering because the wheel has to be moved along the king pin

axis in an arc of radius equal to the king pin off-set (called the scrub radius).

Moreover, this also results in larger bending stress on stub axle and king pin.

In order to avoid this, the wheel and the king pin are arranged to reduce the king

pin off-set. When the king pin off-set is eliminated, i.e. outer line of the wheel

Steering Systeml

8

meets the centerline of the king pin at the road surface, the condition is termed

as center-point steering. This is shown in figure b.

Center point steering results in much reduced steering effort and seems to be

ideal. However the spread effect of the pneumatic tyres causes the wheels to

scrub and give hard steering and tyre wear. so slide rolling action is provided by

arranging the king pin off-set to be 10 to 25 percent of the tyre tread width.

Scrub Radius or king pin offset radius:

The action points of tractive force and the road resistance are shown in the

above figure. The tractive force F

Tr

acts at a point A while the road resistance

R

RO

at the point B. The distance between these two points is called scrub radius.

It is expressed in mm.

Effects:

Wheels are turned away from rolling straight due to the torque. The torque

is created on account of tractive force and the road resistance acting in

different lines of action and opposite directions. This torque is of opposite

nature: clockwise and anti-clockwise in the two cases shown in figure (a)

and (c)

The tendency of toe-in and toe-out is produced in cases of negative and

positive scrub radii. Respectively.

When the tractive force and the road resistance act in the same line of

action, the torque is not produced. The effects of toe in and toe out are

also not experienced by the vehicle. The front wheels move straight in this

case, and the conditions of true centre point steering is achieved.

Preferred choice:

Among these cases, the case shown in figure c is most preferred but with

smaller scrub radius. Generally AB = 8 to 12 mm is preferred. A value greater

than this, will invite a larger torque wheel to turn the wheel. Consequently, the

Steering Systeml

9

load on the steering linkage and the suspension system will increase

unnecessarily. This will result in greater wear of parts, unequal braking on the

front, uncomfortable and unsafe driving.

7.6 STEERING GEARBOX

1. Worm and Sector Steering Gear

The worm sector is a fractional part of the worm-wheel as shown in the figure

and is often mounted above the worm. Since the worm sector is smaller than the

worm-wheel, it is cheaper and easier to install and also occupies less space.

2. Worm and worm wheel

The worm wheel is carried in bearings in

the cast iron case. The case is made in

halves. The outer end of the spindle which

carries the worm wheel is squared to

receive the drop arm. The drop arm is

connected by the drag link to a steering

arm fixed to one of the stub axles. As

such any motion given to the worm wheel

will result in the motion of the stub axle. The worm wheel meshes with the worm.

Steering Systeml

10

The worm is keyed on to a tubular shaft which is carried in two thrust bearings in

the casing. The tubular shaft at its upper end carries the steering wheels. The

two thrust bearings position the worm in the axial direction. The upper thrust

bearing abuts against the casing. The lower thrust bearings abut against the nuts

which is screwed into the casing and locked by a lock nut. This provides an

adjustment for eliminating the end play of the worm.

3. Cam and roller

As the cam rotates the roller is compelled to follow the helix of the groove and in

doing so causes the rocker shaft to rotate, thus moving the drop arm as shown in

the figure.

The contour of the cam is designed to match the arc made by the roller, so

maintaining a constant depth of mesh and evenly distributing the load and wear

on the mating parts.

Steering Systeml

11

4. Cam and the Peg

Attached to the rocker arm is a taper peg which engages in the cam as shown in

the figure. When the cam rotates, the peg moves along

the groove causing the rocker shaft to rotate.

Steering Systeml

12

5. Re-circulating Ball

The circulating ball steering mechanism is an improved version of the now

obsolete worm and nut. The balls are contained in a half nut and transfer tube as

shown in the figure. As the cam, or worm, rotates the ball pass from one side of

the nut through the transfer tube to the opposite side as the nut cannot turn, any

movement of the balls along the track of the cam carries the nut along with it and

rotates the rocker shaft. This type of box is efficient because of the small friction

Steering Systeml

13

6. Rack and pinion

A pinion, mounted on the end of the steering shaft, engages with a rack which

has ball joints at each ends to allow for the rise and fall of the wheels. Tie-rods

connect the ball joints to the stub-axles. Rotary movement of the steering wheel

causes sideways movement of the rack which is directly conveyed to the wheels.

With the previous steering systems, the off-side wheel, on a right hand drive car,

is steered directly, while the near-side wheel is driven through the linkage, so that

wear in the steering joints affects the near side the most; this does not occur with

the rack and pinion steering. The latter arrangement provides a sufficiently low

gear reduction for light saloon and sports cars and, when power assisted is

suitable for heavier motor vehicles.

Steering Systeml

14

Steering Systeml

15

Steering Systeml

16

LAW OF STEERING

o

o 0

P

Q

S R

I

l

w

Figure 1.

Let & be the angle made by inner and outer stub axles.

l = Wheel base

w = Distance between pivot of front axle

Cot =

PI

OI

Cot =

QI

OI

Cot Cot =

PI QI PQ w

OI OI l

= =

This is called fundamental equation for correct steering. Mechanisms which fulfill

this equation is called steering gears mechanism.

Types of steering gear:

1. Davis Steering gear

2. Ackerman steering gear

Steering Systeml

17

Ackerman steering gear

PQNM constitute a 4 bar mechanism. Conditions for correct gearing is satisfied

at three different positions:

1.) Vehicle turns to right,

2.) Vehicle turns to left,

3.) Steered on straight path

Sin ( + ) =

y z

r

+

Sin ( =

y z

r

Sin ( + ) + Sin ( ) =

2y

r

or Sin ( + + + + ) + Sin ( ) = 2 Sin ( (( (Ref. fig. 2)

o

0

y

y

z

z

r

y

r

w

Distance between pivots

Track rod

(track arm radius)

P

Q

M

N

Figure 2.

Steering Systeml

18

Cot =

PI PG GI

HI HI

+

=

Cot =

QI QG IG

HI HI

=

Cot Cot =

2 2 IG GQ

HI QR

= =

2( )

2

w

w

l l

= and hence satisfying the law of steering

Refer to figure 3.

P

S R

l

w

G I Q

H

o

0

True

steering

curve

Figure 3.

Steering Systeml

19

Turning circle radius (TCR)

o

o 0

P

Q

N M

l

w

R

R

R

if

of

or

ri

a

Figure 4.

R

All wheels rotate about a common center along different turning curves.

TCR of outer front wheel

R

of

=

sin 2

l a w

| |

+

|

\ .

TCR of inner front wheel

R

if

=

sin 2

l a w

| |

|

\ .

TCR of outer rear wheel

R

or

= l cot +

2

a w | |

|

\ .

TCR of inner rear wheel

R

ir

= l cot

2

a w | |

|

\ .

Steering Systeml

20

Minimum radius definition

As per society of auto engines TCR is the radius of arc described by the center of

the track made by the outer front wheel of the vehicle when making its shortest

turn

R

of

=

2

2

2

sin tan 2

l lw a w

w

(

| |

+ + + (

|

( \ .

Problems:

Problem 1. A vehicle has pivot pins 1.4 m apart. Length of each track arm

is 0.2 m and track rod is behind front axle and is 1.3 m long.

Determine the wheel base which will give true rolling for all wheels when

the vehicle is turning so that inner wheel stub axle is 60

0

to the centerline

of the vehicle.

Solution:

= 90 - 60 = 30

0

w = 1.4 m d = 1.3 m

r = 0.2 m

Sin =

1.4 1.3

2 2 0.2

w d

r

=

= 14.4775

0

Sin ( + ) Sin ( + ) = 2 sin

Substituting for and in the above equation

= 26.05

0

For correct steering

Cot Cot =

w

l

Cot 26.05

0

Cot 30 =

1.4

l

Steering Systeml

21

Therefore wheel base l = 4.46 m

Problem 2 A motor car has a wheel base of 2.75 m and pivot center of

1.08 m. The front and rear wheel track is 1.23 m. Calculate the correct angle

of outside lock and turning circle radius of the outer front and inner rear

wheels when the angle of inside lock is 40

0

.

Solution:

Cot Cot =

w

l

Cot =

1.08

2.75

- Cot 40

Therefore angle of outer lock = 32.25

0

.

Turning circle radius of outer front wheel

R

of

=

sin 2

l a w

| |

+

|

\ .

=

2.75 1.23 1.08

sin32.25 2

| |

+

|

\ .

= 5.07 m

Turning circle radius of inner rear wheel

R

ir

= l cot

2

a w | |

|

\ .

=

2.75 1.23 1.08

tan 40.25 2

| |

|

\ .

= 3.2 m

Steering Systeml

22

Exercise 7

1. WhaL are Lhe prlmary and secondary funcLlons of sLeerlng sysLem?

2. WhaL ls Lhe requlremenL of good sLeerlng sysLem?

3. uraw and name Lhe parLs of a SLeerlng llnkage for lndependenL suspenslon sysLem.

4. WrlLe shorL noLe on wlLh a neaL skeLch a) klng pln lncllnaLlon b) Camber c) casLer d)

1oe-ln and Loe-ouL.

3. uraw and explaln worklng of Worm and worm wheel of a sLeerlng sysLem.

6. Lxplaln wlLh a neaL skeLch worklng of 8ack and plnlon sLeerlng sysLem

7. WhaL are Lhe laws of sLeerlng sysLem? Lxplaln

Вам также может понравиться

- Wheel AlignmentДокумент45 страницWheel AlignmentViswajith Vm100% (1)

- Chapter 5 - SteeringДокумент15 страницChapter 5 - SteeringLalith Koushik Ganganapalli100% (1)

- Steering System AEДокумент46 страницSteering System AEShubham GuptaОценок пока нет

- Camber Caster Toe 7 PagesДокумент7 страницCamber Caster Toe 7 PagesTeresa HollidayОценок пока нет

- Auto Service Technician Level3 PDFДокумент29 страницAuto Service Technician Level3 PDFArun PrasathОценок пока нет

- Why Do Cars Need AlignmentДокумент17 страницWhy Do Cars Need Alignmentochrerocker100% (1)

- Winalign Software: Quick Reference GuideДокумент89 страницWinalign Software: Quick Reference GuideValuador CjaОценок пока нет

- MLR-Steering and Suspension PDFДокумент86 страницMLR-Steering and Suspension PDFJhay AirgelAlegriaОценок пока нет

- Steering SystemДокумент37 страницSteering SystemSandeep Magapu100% (1)

- Cattle Farming Meat Processing PlantДокумент88 страницCattle Farming Meat Processing Plantkebamo watumoОценок пока нет

- Camber, Caster and Toe ExplainedДокумент8 страницCamber, Caster and Toe ExplainedAbhishek Sharma100% (1)

- 02 BPCrankshaftДокумент129 страниц02 BPCrankshaftrajishrrrОценок пока нет

- B0C9N1GYXJДокумент81 страницаB0C9N1GYXJClintus VictoriyaОценок пока нет

- Professional Tool Set in Aluminum Case, 149 PCS.: Item # 15501Документ10 страницProfessional Tool Set in Aluminum Case, 149 PCS.: Item # 15501HERRAPROОценок пока нет

- (Bhiku - Matre) 13-Traction and Transport Devices PDFДокумент33 страницы(Bhiku - Matre) 13-Traction and Transport Devices PDFNamrataMeenaОценок пока нет

- How Differential WorksДокумент23 страницыHow Differential Worksjohnplaya1234100% (1)

- Automobile Engineering: Steering SystemДокумент50 страницAutomobile Engineering: Steering SystemKarne Dheeraj KumarОценок пока нет

- Steering Systems: 4.1 Axle-Beam Steering SystemДокумент12 страницSteering Systems: 4.1 Axle-Beam Steering SystemCallGRОценок пока нет

- Construction of A Constant Mesh Gear BoxДокумент21 страницаConstruction of A Constant Mesh Gear BoxAmare Eshetie0% (1)

- Effect of Wheel Geometry Parameters On Vehicle SteeringДокумент8 страницEffect of Wheel Geometry Parameters On Vehicle SteeringRudrendu ShekharОценок пока нет

- Bump Steer by Longacre RacingДокумент5 страницBump Steer by Longacre RacingFotis FotopoulosОценок пока нет

- Gearboxes in AutomobilesДокумент34 страницыGearboxes in AutomobilesPrashant PatilОценок пока нет

- Steering GeometryДокумент4 страницыSteering GeometryAnanya BhardwajОценок пока нет

- Automotive Transmission SystemДокумент94 страницыAutomotive Transmission SystemTanzim Rafat AyonОценок пока нет

- See Figures 1 Thru 7: Suspension SystemДокумент28 страницSee Figures 1 Thru 7: Suspension SystembalajigandhirajanОценок пока нет

- Suspension Front 4wdДокумент12 страницSuspension Front 4wdAnimemanuel MuñozОценок пока нет

- Function of Steering SystemДокумент19 страницFunction of Steering SystemTeju LoveОценок пока нет

- Differential and Drive AxlesДокумент38 страницDifferential and Drive AxlesShivam Wankhede100% (2)

- Clutches Transmissions and Drive 10Документ53 страницыClutches Transmissions and Drive 10Napau AdelinОценок пока нет

- Studyguide Suspension and SteeringДокумент44 страницыStudyguide Suspension and Steeringmonikaneha123100% (1)

- 2013 Fork Rockshox Service ManualДокумент83 страницы2013 Fork Rockshox Service ManualXc Cristi0% (1)

- Operators Manual 500 SeriesДокумент36 страницOperators Manual 500 SeriesAutochthon GazetteОценок пока нет

- Vehicle Dynamics ProДокумент15 страницVehicle Dynamics ProChirag D PatelОценок пока нет

- Bump SteerДокумент5 страницBump SteerHimanshu RajputОценок пока нет

- Katalog Motorů 2015 BriggsДокумент72 страницыKatalog Motorů 2015 BriggsnialabersoОценок пока нет

- Engine Suspension: Issue 1Документ8 страницEngine Suspension: Issue 1ruanОценок пока нет

- SAC Brake Training: Simplex Air Cam Drum Brake Exploded ViewДокумент19 страницSAC Brake Training: Simplex Air Cam Drum Brake Exploded ViewAnonymous gTerattFpQ100% (1)

- Leaf SpringДокумент52 страницыLeaf Springrachit chourasiaОценок пока нет

- OvalCrewChief101 v5Документ7 страницOvalCrewChief101 v5darakof258Оценок пока нет

- Steering SystemДокумент15 страницSteering SystemSatya NarayanaОценок пока нет

- Project Report: - Suspension SystemДокумент33 страницыProject Report: - Suspension SystemAnil KumarОценок пока нет

- Air Brake SystemsДокумент48 страницAir Brake SystemsBaD BoYОценок пока нет

- Corner Weights 4 PagesДокумент4 страницыCorner Weights 4 PagesTeresa HollidayОценок пока нет

- How Manual Transmissions WorkДокумент7 страницHow Manual Transmissions Workbishal.sonarОценок пока нет

- Air Brake ModuleДокумент80 страницAir Brake ModuleShahzad ahamadОценок пока нет

- Handout T1124F-1511 3869 OnB-Bus-DAS-SRS TN PDFДокумент142 страницыHandout T1124F-1511 3869 OnB-Bus-DAS-SRS TN PDFlequangthongОценок пока нет

- V2 3 6 Final Gear and Differential GearДокумент44 страницыV2 3 6 Final Gear and Differential GearDwy Bagus NОценок пока нет

- Shimano Disk BrakeДокумент1 страницаShimano Disk Brakehayleymorris24Оценок пока нет

- 12-Piece T-Star Bit Socket Set, Extra Short, T8 - T60: Item # 5098Документ22 страницы12-Piece T-Star Bit Socket Set, Extra Short, T8 - T60: Item # 5098HERRAPROОценок пока нет

- DrivetrainsДокумент27 страницDrivetrainsArthur AyresОценок пока нет

- Chapter 7-STEERING System-1 PDFДокумент22 страницыChapter 7-STEERING System-1 PDFShivam AgarwalОценок пока нет

- STEERING AND SUSPENSION SYSTEMSДокумент24 страницыSTEERING AND SUSPENSION SYSTEMSvijay bnОценок пока нет

- Steering SystemДокумент32 страницыSteering Systemaashish koiralaОценок пока нет

- AE, Steering Geometry, Unit-IIIДокумент9 страницAE, Steering Geometry, Unit-IIIVenkat ReddyОценок пока нет

- Steering SystemДокумент14 страницSteering SystemRaghav NanyaОценок пока нет

- Front Axle - Steering GeometryДокумент50 страницFront Axle - Steering GeometryNaveen Vachipalli0% (1)

- 2 - Module 3Документ13 страниц2 - Module 3Vinit TyagiОценок пока нет

- Wheel - Alignment HandoutsДокумент21 страницаWheel - Alignment HandoutsJih Yan Lai50% (2)

- 17me655 Module 3.1Документ23 страницы17me655 Module 3.1VinayakОценок пока нет

- Steering System Components and PrinciplesДокумент13 страницSteering System Components and PrinciplesMidhun SukumaranОценок пока нет

- Safety HandbookДокумент17 страницSafety HandbookRakesh JunnurОценок пока нет

- Strength of MaerialsДокумент45 страницStrength of MaerialsShivakumar PatilОценок пока нет

- 00107Документ9 страниц00107mukesh3021Оценок пока нет

- Shop Safety PolicyДокумент21 страницаShop Safety Policymukesh3021Оценок пока нет

- Laboratory Manual Physics - 1: AGH University of Science and Technology in Cracow Department of ElectronicsДокумент3 страницыLaboratory Manual Physics - 1: AGH University of Science and Technology in Cracow Department of Electronicsmukesh3021Оценок пока нет

- Convocation Adv Sept 13Документ1 страницаConvocation Adv Sept 13mukesh3021Оценок пока нет

- StabilityДокумент5 страницStabilityJenelia Jojo50% (2)

- LM FluidMechanicsLabДокумент0 страницLM FluidMechanicsLabmukesh3021Оценок пока нет

- CNC Programming - PdfdsfdsДокумент27 страницCNC Programming - PdfdsfdsArie JuliantoОценок пока нет

- Experiment - 08 - Determination of Meta-Centric HeightДокумент3 страницыExperiment - 08 - Determination of Meta-Centric HeightAshish YadavОценок пока нет

- Impact of A Jet: Experiment 4Документ6 страницImpact of A Jet: Experiment 4Eye IqbalОценок пока нет

- Types of Boilers PDFДокумент5 страницTypes of Boilers PDFJosé RubioОценок пока нет

- Fluid Mechanics Ans Machinery - Lab ManualДокумент76 страницFluid Mechanics Ans Machinery - Lab ManualVikram Puttenahalli Nagesh GowdaОценок пока нет

- Boilers and Thermic Fluid HeatersДокумент54 страницыBoilers and Thermic Fluid HeatersParin PatelОценок пока нет

- Fluid Friction in Liquids Laboratory ManualДокумент16 страницFluid Friction in Liquids Laboratory Manualmukesh3021Оценок пока нет

- Fluids Lab ManualДокумент67 страницFluids Lab Manualkalyan_aubeОценок пока нет

- Mechanics of Fluids Laboratory: A Manual For TheДокумент52 страницыMechanics of Fluids Laboratory: A Manual For Theturnip331100% (1)

- Advt ES2 03 2013EДокумент1 страницаAdvt ES2 03 2013Emukesh3021Оценок пока нет

- PublicationsДокумент11 страницPublicationsmukesh3021Оценок пока нет

- Fluids Lab Venturi Meter - 4Документ5 страницFluids Lab Venturi Meter - 4augur886Оценок пока нет

- Fluid Mechanics Hydraulics Lab ManualДокумент24 страницыFluid Mechanics Hydraulics Lab Manualsawmag123Оценок пока нет

- 1373090220Документ14 страниц1373090220mukesh3021Оценок пока нет

- EAS361 LabManual Fall2004 r3Документ41 страницаEAS361 LabManual Fall2004 r3mukesh3021Оценок пока нет

- Flued Mechanics & MachineryДокумент4 страницыFlued Mechanics & Machinerymukesh3021Оценок пока нет

- Centrifugal Pump Test Rig: Fluid Mechanics and Hydraulics LabДокумент6 страницCentrifugal Pump Test Rig: Fluid Mechanics and Hydraulics Labmukesh3021Оценок пока нет

- Laboratory ManualДокумент10 страницLaboratory Manualmukesh3021100% (1)

- Fluid Mechanics (2003)Документ6 страницFluid Mechanics (2003)mukesh3021Оценок пока нет

- Pert Time/ Cost: An Aid To Agribusiness ManagementДокумент62 страницыPert Time/ Cost: An Aid To Agribusiness ManagementPangga TolentinoОценок пока нет

- CPMДокумент15 страницCPMViktor AnastasovskiОценок пока нет

- Operators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 TractorsДокумент44 страницыOperators Manuel International Cub Cadet 72, 104, 105, 124, ZND 125 Tractorsfundreamer1Оценок пока нет

- Instrument Check List PDFДокумент9 страницInstrument Check List PDFBrijesh Srivastav100% (1)

- Temp Card PBMДокумент18 страницTemp Card PBMRemil CastañedaОценок пока нет

- Relationship of Personal Growth Initiative With Self-EfficacyДокумент12 страницRelationship of Personal Growth Initiative With Self-Efficacyeva pandanaОценок пока нет

- Physics PP1Документ22 страницыPhysics PP1Tamoya ShirleyОценок пока нет

- CRE Notes 14 Intro To CSTRsДокумент11 страницCRE Notes 14 Intro To CSTRsYayan IndrayaniОценок пока нет

- ZuulДокумент20 страницZuulBajjiVaraОценок пока нет

- Extrusion Course MaterialДокумент43 страницыExtrusion Course MaterialIncharge Training and Placement CellОценок пока нет

- CPA Review School Philippines Final Exam GuideДокумент14 страницCPA Review School Philippines Final Exam GuideAzureBlazeОценок пока нет

- Fraction As A Part of A WholeДокумент4 страницыFraction As A Part of A WholeWennyОценок пока нет

- Design of RCC Structure: Department of Civil Engineering Diploma Section 3 YEAR - 5 Semester 2020 - 2021Документ6 страницDesign of RCC Structure: Department of Civil Engineering Diploma Section 3 YEAR - 5 Semester 2020 - 2021Tapabrata2013Оценок пока нет

- Water TreatmentДокумент123 страницыWater TreatmentkaranОценок пока нет

- Analyzing Java OutOfMemory Problems With IBM Heapdump FacilityДокумент10 страницAnalyzing Java OutOfMemory Problems With IBM Heapdump FacilityNarendra ChoudaryОценок пока нет

- Mod 2 BA PhysicsДокумент412 страницMod 2 BA PhysicsBenitoKameloОценок пока нет

- Chapter1 Det10013Документ30 страницChapter1 Det10013che syakirОценок пока нет

- LeadGuitar Method 2 PDFДокумент69 страницLeadGuitar Method 2 PDFsjlerman100% (2)

- Guitarjamz Ultimate Tab ManualДокумент4 страницыGuitarjamz Ultimate Tab ManualweazelzbОценок пока нет

- Rational Numbers ListДокумент4 страницыRational Numbers ListnishagoyalОценок пока нет

- Bond Strength of Electrical Insulating Varnishes by The Twisted-Coil TestДокумент3 страницыBond Strength of Electrical Insulating Varnishes by The Twisted-Coil TestAmer AmeryОценок пока нет

- Direct Electrical Arc Ignition of Hybrid Rocket MotorsДокумент91 страницаDirect Electrical Arc Ignition of Hybrid Rocket MotorsHyan GontijoОценок пока нет

- DG 09 006-E 12-09 HELENOS IДокумент61 страницаDG 09 006-E 12-09 HELENOS IBalu MОценок пока нет

- Finalterm Exam-TOA PDFДокумент2 страницыFinalterm Exam-TOA PDFEnayat KhanОценок пока нет

- Finding the Force and Center of Pressure on a Submerged Plane SurfaceДокумент12 страницFinding the Force and Center of Pressure on a Submerged Plane SurfaceSudheer Kumar JnvОценок пока нет

- Functional Specification Document (Template)Документ11 страницFunctional Specification Document (Template)Madiha Malik50% (2)

- Chemistry Module 1: Identifying Properties of MatterДокумент10 страницChemistry Module 1: Identifying Properties of MatterROMEОценок пока нет

- Soil Stabilization of Road by Using Spent WashДокумент7 страницSoil Stabilization of Road by Using Spent WashInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- Signature FileДокумент28 страницSignature FileLaxmi BlossomОценок пока нет

- (The Routledge Philosophers) David Cunning - Descartes-Routledge (2023)Документ425 страниц(The Routledge Philosophers) David Cunning - Descartes-Routledge (2023)Hasan sabbah Alamutharemeyn100% (1)

- In 2014 Dub Tarun Founded A Firm Using 200 000Документ1 страницаIn 2014 Dub Tarun Founded A Firm Using 200 000Let's Talk With HassanОценок пока нет

- Annotated Birthday 3.javaДокумент2 страницыAnnotated Birthday 3.javaTasnim MahiОценок пока нет