Академический Документы

Профессиональный Документы

Культура Документы

Bbse3006 1112 05-Ventilation

Загружено:

Invisiblesp123Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bbse3006 1112 05-Ventilation

Загружено:

Invisiblesp123Авторское право:

Доступные форматы

Dr. Sam C. M.

Hui

Department of Mechanical Engineering

The University of Hong Kong

E-mail: cmhui@hku.hk

Mechanical and Natural Ventilation

BBSE3006: Air Conditioning and Refrigeration II

http://www.hku.hk/bse/bbse3006/

Sep 2011

Contents

Basic Concepts

Ventilation Requirements

Natural Ventilation

Mechanical Ventilation

Design Factors

Basic Concepts

What is Ventilation ( )?

The process by which fresh air is introduced and

ventilated air is removed

Primary aim: to preserve the qualities of air

May also be used to lower temperature & humidity

Natural ventilation

By means of purpose-provided aperture (such as

openablewindows, ventilators and shafts) and the

natural forces of wind and temperature-difference

pressures

Natural ventilation (e.g. cross ventilation )

(Source: Environmental Protection Department)

Basic Concepts

Two categories of natural ventilation:

Controlled natural ventilation

Intentional displacement of air through specified

openings such as windows, doors, and ventilators by

using natural forces

Usually controlled to some extent by the occupant

Infiltration (air leakage into a building)

Uncontrolled random flow of air through unintentional

openings driven by wind, temperature-difference

pressures and/or appliance-induced pressures across the

building envelope

Basic Concepts

Mechanical (or forced) ventilation

By means of mechanical devices, such as fans

May be arranged to provide either supply, extract

or balanced ventilation for an occupied space

Exfiltration

Leakage of indoor air out of a building through

openings (similar to infiltration)

When indoor space is at higher (+ve) pressure than

outdoor

Mechanical ventilation (extract ventilation)

(Source: Environmental Protection Department)

What will happen if the windows are closed?

1. Outdoor air

2. Supply air

3. Indoor air

4. Transferred air

5. Extract air

6. Recirculation air

7. Exhaust air

8. Secondary air

9. Leakage

10. Infiltration

11. Exfiltration

12. Mixed air

Analysis of air flow

Ventilation Requirements

Ventilation for supporting life

Maintain sufficient oxygen in the air

Prevent high concentration of carbon dioxide

Remove odour, moisture & pollutants

Poor ventilation and indoor air quality

Impact on human health & productivity

CO

2

as an index of air quality

< 1,000 ppm, corresponds to fresh air 7 l/s/person

< 800 ppm, corresponds to fresh air 10 l/s/person

Ventilation to remove pollutants and moisture

(Source: Environmental Protection Department)

* Remember, source control is usually more effective than ventilation

Ventilation system design should avoid intake of vehicle exhaust

(Source: Environmental Protection Department)

* Also ensure outdoor air intake is of adequate quality

Ventilation Requirements

Purposes of ventilation

Maintain human comfort and health

Provide sufficient air/oxygen for human/livestock

Provide sufficient air/oxygen for processes

Remove products of respiration and bodily odour

Remove contaminants or harmful chemicals

Remove heat generated indoor

Create air movement (feeling of

freshness/comfort)

Ventilation Requirements

For removal of indoor pollution

Estimate production rates of all known pollutants

Select the largest ventilation rate for design

Standards & guides, e.g. ASHRAE Standard

62.1 and CIBSE Guide B2

Prescriptive procedure and analytical procedure

In Hong Kong, the related building regulation

e.g. Building (Ventilating Systems) Regulations --

Chapter 123J

Ventilation Requirements

Ventilation calculations

For general mechanical ventilation:

Ventilation Rate (m

3

/h) = Air Change Rate (/h) x Room

Volume (m

3

)

Ventilation Rate (m

3

/s) =Ventilation Rate (m

3

/h) / 3600

For calculating fresh air ventilation rates

Fresh air rate (m

3

/s) = Fresh air rate per person (l/s/p) x

number of occupants

Ventilation effectiveness

Depend on ventilation strategy, air distribution

method, room load & air filtration

Changes in the minimum ventilation rates in the USA

Current: ASHRAE 62.1-2010 (10 L/s/person)

(Source: ASHRAE)

Ventilation Requirements

Determinethe requiredventilation rate (Q):

(a) Maximum allowable concentration of

contaminants (C

i

)

C

i

= C

o

+ F / Q

(b) Heat generation inside the space (H)

Q = H / [c

p

x x (T

i

T

o

)]

(c) Air change rates (ACH)

Q = V x ACH / 3.6

Natural Ventilation

For air to move into and out of a building, a

pressure differenceis required

Resistance to air flow through the building will

affect the actual air flow rate

The pressure difference is caused by:

Wind effect

Stack or chimney effect

Combination of both wind and stack effects

Pressure effect from

stack ventilation

Pressure effect from wind

Natural Ventilation

Wind effect

Air flow around a building

Wind pressure +vewindward side, -veleeward side

Wind pressure depends on:

Wind speed and direction

Location and surrounding environment

Shape of the building

Wind pressure on building surfaces

2

2

1

w p o w

v C P P =

(Source: ASHRAE Handbook Fundamentals 2005)

Natural Ventilation

Stack effect: air movement due to temp.

difference between indoor and outdoor

Flow of air in vertical direction and along the path

of least resistance

Winter: air flowing up; Summer: air flowing down

A neutral pressure level (NPL) exists where the

interior and exterior pressures are equal

Pressure difference due to stack effect is given by:

o

o i

neutral i neutral i o s

T

T T

h h g h h g P

= = A ) ( ) ( ) (

(Source: ASHRAE Handbook Fundamentals 2005)

Neutral pressure level is not necessarily at the middle height

(Source: ASHRAE Handbook Fundamentals 2005)

Each floor is separate and independent

(Source: ASHRAE Handbook Fundamentals 2005)

Floors are connected by a shaft and openings

Natural Ventilation

Combined effect of wind and temp. difference

Most commonly found

Pressures due to each effect are added together

The relative importance of wind and stack

pressures depends on:

Building height

Internal resistance to vertical air flow

Location and flow resistance of openings

Local terrain and immediate shielding

Combined effect of wind and thermal forces

(Source: ASHRAE Handbook Fundamentals 2005)

Natural Ventilation

Infiltration uncontrolled air flow through

building envelope driven by pressures from:

Wind

Temp. difference between indoor and outdoor

Operation of mechanical exhaust

Characteristics determined by:

Measuring air leakage of building envelope

Typical leakage rates (residential) = 6 to 10 ACH

at 50 Pa pressure difference

Natural Ventilation

Building air leakage (e.g. at cracks)

A measure of air tightness of building envelope

Expressed as (effective) air leakage area

Varies with design, construction, season and age

No simple relationship with air exchange rate

Air leakage may be determined by:

Pressurisationtesting

Tracer gas measurement

Natural Ventilation

Ratings for air tightness may be found for

whole building (e.g. leakage class A, B, C, D)

Exterior walls and windows usually important

Air leakage area per component, per unit surface

area, or per unit length of crack or sash

Infiltration rate may be calculated by:

2

W

e

V B T A

A

Q

+ A =

Natural Ventilation

Three main types of natural ventilation

Single-sided ventilation

Cross ventilation

Passive stack ventilation

Passive stack ventilation (PSV)

(Source: Building Services Handbook)

Stack Ventilation Analysis

gH

T

T T

A c q

o

o i

d B

|

|

.

|

\

|

= 2

*

where

2 2

2 *

/ 1 / 1 / 1

t b

A A A + =

Stack ventilation rate q

B

through

two openings is:

the Neutral Plane Level h

N

is:

H

A A

A

h

t b

t

N

2 2

2

+

=

H

A

b

A

t

T

i

T

o

q

B

q

B

h

N

and C

d

= discharge coefficient for

opening, C

d

= 0.61 for sharp-edge orifice.

Natural Ventilation

Solar-induced ventilation

Relied upon the heating of part of the building

fabric by solar irradiation resulting into a greater

temp. difference, hence larger air flow

Three devices are often used:

Trombe wall

Solar chimney

Solar roof

(Source: Awbi (1998))

(Source: Awbi (1998))

(Source: Awbi (1998))

Cross flow natural ventilation with a solar chimney

Solar chimney with thermal insulation

Mechanical Ventilation

Mechanical ventilation

Movement of air through a building using fan

power

Ability to control the air flows

Two types:

Unbalanced systems

Air is either supplied or extracted

Balanced systems

Air is supplied and extracted simultaneously

Mechanical Ventilation

Design principles:

1. Exhaust close to pollutant

generation

2. Effective local extracts

3. Supply to the breathing zone

4. Supply air to clean areas

5. More extract from dirty

areas

6. Transfer air from clean to

dirty areas

Mechanical Ventilation

Extract ventilation, e.g.

Commercial kitchens

Toilets and bathrooms

Underground carparks

Factories or industrial buildings

Localisedindustrial extraction

Supply ventilation

Can be used to ensure adequate supply of outside

air, e.g. in boiler house ventilation

Kitchen

hood

Makeup air

Dinning area

Supply air

Return air

Makeup air unit

HVAC unit

Kitchen exhaust

Kitchen

Example of kitchen ventilation system

Mechanical Ventilation

Industrial ventilation

An important method for reducing employee

exposures to airborne contaminants

Dilution systems:

Reduce the concentrations of contaminants released in a

work room by mixing with air flowing through the room

Local exhaust ventilation (LEV):

Capture or contain contaminates at their source before

they escape into the workplace environment

Mechanical Ventilation

Supply and extract (balanced) systems

Central air handling unit (AHU) with separate

supply and extract fans

A heat recovery device can also be incorporated

Energy implications & efficient ventilation

Heat recovery

Demand controlled ventilation (DCV)

User control ventilation

Ventilation system balancing

Design Factors

Benefits of natural ventilation

Can save substantial energyby decreasing or

eliminating the need for HVAC

May improve indoor air qualityif outdoor air

quality is good and air exchange rate is high

Buildings with well-designed natural ventilation

systems often provide very comfortable and

pleasant environmentsfor the occupants

People may increase their work productivitywhen

they can open and close windows and vary the

natural ventilation rate in their workspace

Design Factors

Key factors affecting natural ventilation:

Depth of space with respect to ventilation openings

Ceiling height

Thermal mass exposed to the air

Location of building and possible air pollutants

Heat gain

Climate, e.g. outdoor temperature or wind velocity

Passive cooling

Technologies or design features used to cool

buildings without power consumption

Design strategies of natural ventilation

(Source: Pennycook, K., 2009. The Illustrated Guide to Ventilation)

Design Factors

Suitabilityof natural ventilation

Most suited to:

Buildings with a narrow plan or atria with floor plate

width of 15 m or less

Sites with minimal external air and noise pollution

Open plan layouts

Not suited to:

Buildings with a deep floor plan

Buildings that require precise temp. & humidity control

Buildings with individual offices or small spaces

Buildings with continual heat loads above 3540 W/m

2

Locations with poor air quality

Design Factors

Natural ventilation -- basicprinciples for

sizing and placing openings:

The area of the opening at intake must be equal to

or 25% smaller than the area of opening for

exhaust

Air flow will take the line of least resistance so

follow the flow line to check for dead spots (areas

where fresh air does not go)

Consider security, privacy and noise transfer

Design Factors

Design for natural ventilation (contd)

Flow caused by wind is affected by:

Average wind speed

Prevailing wind direction

Seasonal & daily variation in wind speed and direction

Local obstructing objects, e.g. nearby buildings & trees

Position and characteristics of openings

Distribution of surface pressure coefficients for the

wind

Design Factors

Design for natural ventilation (contd)

Flow caused by thermal forces

where

Q = air flow rate (m

3

/s)

K = discharge coefficient for the opening (usually assumed to be 0.65)

A = free area of inlet openings (m

2

)

h = height from lower opening (mid-point) to neutral pressure level (m)

T

i

= indoor air temperature (K)

T

o

= outdoor air temperature (K)

Design Factors

Hybridventilation (or mixed mode ventilation)

= Natural ventilation + Mechanical ventilation

Use themat different time of the dayor seasonof

the year

Usuallyhave a control system to switchbetween

natural and mechanical modes

Combine the advantagesof bothto satisfythe

actual ventilation needsand minimise energy

consumption

Hybrid ventilation concepts

Low pressure

mechanical ventilation

Demand-controlled

mechanical ventilation

Constant air flow

mechanical ventilation

Mechanical ventilation Natural ventilation

Air infiltration through

cracks

Openablewindows,

supply and exhaust

grilles

Self-regulating supply

and exhaust grilles

Demand-controlled

natural ventilation

Design Factors

Main hybrid ventilation principles:

(1) Natural and mechanical ventilation

Two fully autonomous systems with control

strategy to switch between them, or use one system

for some tasks and the other system for other tasks

For example, natural ventilation in intermediate

seasons and mechanical ventilation during

midsummer; or systems with mechanical

ventilation during occupied hours and

natural ventilation for night cooling

Design Factors

Main hybrid ventilation principles: (contd)

(2) Fan-assisted natural ventilation

A natural ventilation system combined with an

extract or supply fan

It covers natural ventilation systems that, during

periods of weak natural driving forces or periods

of increased demands, can enhance pressure

differences by mechanical (low-pressure) fan

assistance

Design Factors

Main hybrid ventilation principles: (contd)

(3) Stack- and wind-assisted mechanical

ventilation

A mechanical ventilation system that makes

optimal use of natural driving forces

It covers systems with very small pressure losses,

where natural driving forces can account for a

considerable part of the necessary pressure

Is it feasible to use

Natural Ventilation?

If situation prevents this,

is it feasible to use

Mechanical Ventilation?

If situation prevents this,

is it feasible to use

Hybrid/Mixed Mode Ventilation?

If situation prevents this,

is it feasible to use

Cooling and Heating

(without humidity control)?

If situation prevents this,

is it feasible to use

Full Air Conditioning

(with humidity control)?

Increasing:

energy

consumption

capital cost

running costs

maintenance

complexity

Ventilation design hierarchy

Further Reading

Air Movement and Natural Ventilation [Web-

based lecture by Dr. Sam C. M. Hui]

http://arch.hku.hk/teaching/lectures/airvent/

Ventilation [www.bsenotes.com]

http://www.arca53.dsl.pipex.com/index_files/venta.htm

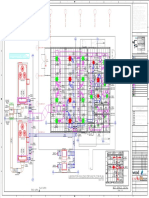

Design guidelines

Design examples

Ventilation drawings

Вам также может понравиться

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationОт EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationРейтинг: 1 из 5 звезд1/5 (1)

- Mebs6008 1415 05-Space Air Diffusion IДокумент72 страницыMebs6008 1415 05-Space Air Diffusion Iahtin618Оценок пока нет

- Bbse3006 1011 05-Waterside01Документ60 страницBbse3006 1011 05-Waterside01starykltОценок пока нет

- Acoustic of Green BuildingsДокумент7 страницAcoustic of Green BuildingsJuan DupezhОценок пока нет

- MECH3423 1516 09-HVAC Water-Side SystemsДокумент60 страницMECH3423 1516 09-HVAC Water-Side Systemsahtin618Оценок пока нет

- Air Conditioning and RefrigerationДокумент28 страницAir Conditioning and Refrigerationdubaisrinivasulu100% (1)

- MEBS6006 1516 01-IntroДокумент66 страницMEBS6006 1516 01-Introahtin618100% (1)

- Naturalighting 2Документ61 страницаNaturalighting 2Dannie RelacionОценок пока нет

- 1234 Burj Dubai Stack Effect Passive Stack Effect Mitigation Measures in The Design of The Worlds Tallest Building PDFДокумент7 страниц1234 Burj Dubai Stack Effect Passive Stack Effect Mitigation Measures in The Design of The Worlds Tallest Building PDFRaviNagiОценок пока нет

- Modelit: Tutorial 1Документ3 страницыModelit: Tutorial 1U0U0IОценок пока нет

- Hvac Load Calculation PDFДокумент20 страницHvac Load Calculation PDFkamel0% (1)

- IES Daylight and Thermal Comfort Analysis (Firrdhaus)Документ25 страницIES Daylight and Thermal Comfort Analysis (Firrdhaus)Firrdhaus Sahabuddin100% (1)

- Apachesim Ve 2014 Session A Training Notes PDFДокумент23 страницыApachesim Ve 2014 Session A Training Notes PDFKa Hung LeungОценок пока нет

- Apache HVACДокумент360 страницApache HVACRaffaele100% (1)

- VRF Thesis EditedДокумент69 страницVRF Thesis EditedMurtaza Sabir50% (2)

- Ventilation: The Design and Delivery of Low Carbon BuildingsДокумент15 страницVentilation: The Design and Delivery of Low Carbon BuildingsMallinatha PNОценок пока нет

- Atrium Ventilation StrategyДокумент13 страницAtrium Ventilation Strategykevinbovo0% (1)

- 2022-Air-To-Water Heat Pumps - Review and Analysis of The Performance Gap Between In-Use and Product Rated Performance PDFДокумент21 страница2022-Air-To-Water Heat Pumps - Review and Analysis of The Performance Gap Between In-Use and Product Rated Performance PDFCojanu ClaudiuОценок пока нет

- CTV003Документ20 страницCTV003Sujani MaarasingheОценок пока нет

- Apachehvac: Training Notes - Part 1Документ31 страницаApachehvac: Training Notes - Part 1joe1256100% (1)

- Assignment MechanicalДокумент5 страницAssignment MechanicalSoufiane RamdaniОценок пока нет

- Energy Modeling2Документ66 страницEnergy Modeling2noveОценок пока нет

- HVAC - Space Heating SystemsДокумент114 страницHVAC - Space Heating Systemsnitin guptaОценок пока нет

- Bioclimatic Design at The Site Planning Scale: By: Donald Watson & Kenneth LabsДокумент47 страницBioclimatic Design at The Site Planning Scale: By: Donald Watson & Kenneth Labskiran tatipudiОценок пока нет

- Mechanical System Integration in High Rise Building 2019-06-16Документ32 страницыMechanical System Integration in High Rise Building 2019-06-16Tharangi MunaweeraОценок пока нет

- Natural VentilationДокумент3 страницыNatural VentilationGeeryl Tayone100% (1)

- Heat Loading Calculation MethodsДокумент16 страницHeat Loading Calculation Methodsnavabnavab786Оценок пока нет

- Mebs6006 1112 10-Airside SystemДокумент40 страницMebs6006 1112 10-Airside Systemsimoncarter313Оценок пока нет

- Building ScienceДокумент34 страницыBuilding ScienceEvon LowОценок пока нет

- Mebs6000 1011 06 Sewage DisposalДокумент72 страницыMebs6000 1011 06 Sewage DisposalJack LiОценок пока нет

- Refr Sys DesignДокумент13 страницRefr Sys Designعبدالله عمرОценок пока нет

- Dynamic Daylight Performance Metrics For Sustainable Building DesignДокумент26 страницDynamic Daylight Performance Metrics For Sustainable Building DesignNur Nasuha SalamОценок пока нет

- Smart Innovation Systems For Indoor Environmental Quality (IEQ)Документ13 страницSmart Innovation Systems For Indoor Environmental Quality (IEQ)shahriz amriОценок пока нет

- South Bank Decentralised Energy-Feasibility Report - Feb 09Документ58 страницSouth Bank Decentralised Energy-Feasibility Report - Feb 09maxmanfrenОценок пока нет

- Green Building Store MVHR Brochure-File032484Документ9 страницGreen Building Store MVHR Brochure-File032484Anthi ValavaniОценок пока нет

- Building Science 1: Thermal Comfort ReportДокумент60 страницBuilding Science 1: Thermal Comfort ReportChristopher Ng Man KingОценок пока нет

- 383 NO28 EnergyModeliing 2013Документ23 страницы383 NO28 EnergyModeliing 2013Parvez SaifОценок пока нет

- Plea Note 3 Thermal ComfortДокумент68 страницPlea Note 3 Thermal ComfortIgnacio Fernández Solla100% (1)

- High Performance BuildingДокумент21 страницаHigh Performance BuildingPallab MukherjeeОценок пока нет

- SPD4121 1617 05-Load PDFДокумент60 страницSPD4121 1617 05-Load PDFMukti WibowoОценок пока нет

- Advances in Building EnergyДокумент268 страницAdvances in Building EnergyAmjad PervazОценок пока нет

- Building Envelope: Envelopes For Climate TypesДокумент9 страницBuilding Envelope: Envelopes For Climate Typesdhanya1995Оценок пока нет

- Load CalcculationДокумент46 страницLoad CalcculationAzher MemonОценок пока нет

- Bbse2001 1011 Elect02Документ48 страницBbse2001 1011 Elect02kelvincmlauОценок пока нет

- Portfolio Led Catalog BroДокумент56 страницPortfolio Led Catalog BroJaimasa100% (1)

- LEED 201 Presentation Materials-Dec2010Документ109 страницLEED 201 Presentation Materials-Dec2010Ata Atef100% (1)

- 291 Natural Ventilation of Tall Buildings Options and Limitations PDFДокумент8 страниц291 Natural Ventilation of Tall Buildings Options and Limitations PDFNaman JainОценок пока нет

- Wadas of Pune: Name: Neha S. Dere Std/Div: Fourth Year/D Subject: Conservation of ArchitectureДокумент9 страницWadas of Pune: Name: Neha S. Dere Std/Div: Fourth Year/D Subject: Conservation of Architectureneha dereОценок пока нет

- Designbuilder // Energyplus Designbuilder // Energyplus: Tutorial #1'Документ66 страницDesignbuilder // Energyplus Designbuilder // Energyplus: Tutorial #1'rxp2007Оценок пока нет

- Energy Efficiency: Power Quality and Utilisation GuideДокумент11 страницEnergy Efficiency: Power Quality and Utilisation Guidedavid.spiderweb3961100% (6)

- CTV046 HvacДокумент21 страницаCTV046 Hvacbookslover1Оценок пока нет

- Bbse2008 - 1112 - 06-Mechanical and Natural VentilationДокумент58 страницBbse2008 - 1112 - 06-Mechanical and Natural Ventilationahtin618Оценок пока нет

- MECH3423 - 1516 - 08-Mechanical and Natural VentilationДокумент53 страницыMECH3423 - 1516 - 08-Mechanical and Natural Ventilationahtin618Оценок пока нет

- Mechanical and Natural VentilationДокумент43 страницыMechanical and Natural VentilationSudhanshu Mandlik100% (1)

- Mech VentДокумент88 страницMech VentMedha GuptaОценок пока нет

- Building Natural VentilationДокумент49 страницBuilding Natural Ventilationnadeem UddinОценок пока нет

- Natural Ventilation: Lesson - 7 Env - Science For BuildingДокумент49 страницNatural Ventilation: Lesson - 7 Env - Science For Buildingxahidlala100% (1)

- Mebs7014 2223 05Документ78 страницMebs7014 2223 05Yuki ChanОценок пока нет

- Fundamentals of HVACR 2012 SamHui 02Документ16 страницFundamentals of HVACR 2012 SamHui 02Merrel RossОценок пока нет

- Environmental Control Systems 1 VentilationДокумент39 страницEnvironmental Control Systems 1 VentilationTauseef AhmadОценок пока нет

- ..Las Science 6 Quarter 3 Week 6 7Документ4 страницы..Las Science 6 Quarter 3 Week 6 7EvelynMartinezОценок пока нет

- Concrete Block Partition WallДокумент25 страницConcrete Block Partition WallKripa PanjariОценок пока нет

- BS 3M 60-1998 (ISO 7169-1998) ScanДокумент21 страницаBS 3M 60-1998 (ISO 7169-1998) ScandokuОценок пока нет

- EV314 RCC Design 2: Taha AlesawyДокумент48 страницEV314 RCC Design 2: Taha AlesawySam KhorОценок пока нет

- MEB18010-Test 3Документ15 страницMEB18010-Test 3MustafaОценок пока нет

- Kirloskar 6R1080TA 21-40Документ20 страницKirloskar 6R1080TA 21-40Niten GuptaОценок пока нет

- Compact Track Loader: Parts ManualДокумент144 страницыCompact Track Loader: Parts ManualAleks BubaevОценок пока нет

- Troubleshooting The Positive Displacement RotaryДокумент4 страницыTroubleshooting The Positive Displacement Rotaryابو المعالي الهمامОценок пока нет

- Seismic Response of RC Building Structures Using Capacity Spectrum Method With Included Soil FlexibilityДокумент8 страницSeismic Response of RC Building Structures Using Capacity Spectrum Method With Included Soil Flexibilityshivaji.sarvadeОценок пока нет

- Special Repair of Biswa Dehat Link RoadДокумент15 страницSpecial Repair of Biswa Dehat Link Roadamit singhОценок пока нет

- Velocity StringsДокумент2 страницыVelocity StringsCarlos LiscanoОценок пока нет

- Design For Manufacturability For CNC MachiningДокумент4 страницыDesign For Manufacturability For CNC Machiningviorelu99Оценок пока нет

- 01CBO Procurement Manual EnglishДокумент86 страниц01CBO Procurement Manual EnglishfeteneОценок пока нет

- Heritage Architecture (Ivatan House)Документ45 страницHeritage Architecture (Ivatan House)Hazel Acidre100% (1)

- Standard Drawing 3901 Concrete Barriers F Shape Profile May 2019Документ1 страницаStandard Drawing 3901 Concrete Barriers F Shape Profile May 2019Amr Adel HameedОценок пока нет

- Weichai Engine PrintДокумент52 страницыWeichai Engine PrintKo ZayОценок пока нет

- Wilshire Grand CenterДокумент11 страницWilshire Grand Centerapi-350784733Оценок пока нет

- BQ 13 Street Lighting and Traffic PDFДокумент11 страницBQ 13 Street Lighting and Traffic PDFNurly SafОценок пока нет

- IHC Merwede: Case StudyДокумент2 страницыIHC Merwede: Case StudytsaipeterОценок пока нет

- Me301 - FinalДокумент2 страницыMe301 - FinalkhalidОценок пока нет

- CPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookДокумент93 страницыCPVC Fire Sprinkler Products: Installation Instructions & Technical HandbookLuiz Fernando SilvaОценок пока нет

- AISC Properties DatabaseДокумент7 страницAISC Properties DatabaseShekh Muhsen Uddin AhmedОценок пока нет

- De La Cruz, J. C., Del Campo, J. M., & Colorado, D. (Mayo de 2014)Документ7 страницDe La Cruz, J. C., Del Campo, J. M., & Colorado, D. (Mayo de 2014)Jorge GonzalezОценок пока нет

- Development of A Device For Brazing Copper Pipes in HVAC InstallationsДокумент8 страницDevelopment of A Device For Brazing Copper Pipes in HVAC InstallationsJournal of Interdisciplinary PerspectivesОценок пока нет

- Construction Document Sheet Numbers and Sheet OrderДокумент5 страницConstruction Document Sheet Numbers and Sheet Orderkajale_shrikant2325Оценок пока нет

- Finite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsДокумент14 страницFinite Element Based Dynamic Analysis of Multilayer Fibre Composite Sandwich Plates With Interlayer DelaminationsAhmet EcevitОценок пока нет

- BS 1722-13 1978 - Chain Link Fences For Tennis Court SurroundsДокумент10 страницBS 1722-13 1978 - Chain Link Fences For Tennis Court SurroundsAnoyОценок пока нет

- Medium Voltage Composite InsulatorsДокумент14 страницMedium Voltage Composite Insulatorsdeepthik27Оценок пока нет

- A B C D E: Laboratory Building Ground Floor PlanДокумент1 страницаA B C D E: Laboratory Building Ground Floor PlanEmre ÇilОценок пока нет

- Monitoring Shop Drawing MVACДокумент2 страницыMonitoring Shop Drawing MVACEko Indra SaputraОценок пока нет