Академический Документы

Профессиональный Документы

Культура Документы

Part 2 Checklist - Boat Safety Scheme

Загружено:

ibrafeeuОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Part 2 Checklist - Boat Safety Scheme

Загружено:

ibrafeeuАвторское право:

Доступные форматы

part 2 checklist | Boat Safety Scheme

Boat Examination

Stay Safe

About Us

Contact Us

Arranging The Examination part 2 - inboard engines

Private Boats part checklist part 2 checklist

Non-private Boats

Boats with gas

part 3 - electrical installations

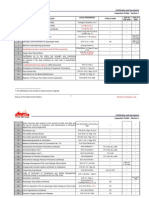

part 2 checklist

2.1 filling pipe taken to deck level filling pipe arranged to prevent fuel entering any part of the boat

part 4 - electrically propelled vessels part 5 - outboard & portable engines

2.2 part 6 - fire prevention & extinguishing equipment part 7 - LPG installations part 8 - appliances, flueing & ventilation part 9 - pollution part 10 - hire boats & safety features

filling pipe of prescribed minimum internal diameter* filling pipe of non-kinking material filling pipe suitable for use with petrol filling pipe of suitable material for use with fuel oil filling pipe connected with leakproof joints to the top of the tank filling pipe connected with leakproof joints to the screwcap or plate deck filling connection outside coaming filling pipe adequately supported filling pipe of minimum practicable length filling pipe joints/connections readily accessible

2.3

deck connections minimise risk of cross contamination deck connections clearly marked 'PETROL' deck connections clearly marked 'PETROIL' deck connections clearly marked 'PARAFFIN' deck connections clearly marked 'DIESEL' deck connections clearly marked 'LPG BUTANE/PROPANE' deck connections clearly marked 'WATER' deck connections clearly marked 'PUMP OUT' deck connections clearly marked 'RINSE OUT'

http://www.boatsafetyscheme.org/boat-examination/non-private-boats/part-2-inboard-engines/part-2-checklist[25/12/2012 10:19:12]

part 2 checklist | Boat Safety Scheme deck connections are marked on deck fitting or immediately beside deck connections

2.4

vent pipe of minimum practicable length vent pipe fitted* vent pipe has the prescribed minimum internal diameter vent pipe fitted at highest point of fuel tank vent pipe connected with leakproof joints vent pipe of non-kinking material vent pipe of suitable material for use with petrol vent pipe of suitable material for use with fuel oil

2.5

vent pipe extended to at least the height equal of the deck filling connections open end of the vent pipe fitted in a position where no danger will be incurred from escaping fuel or vapour vent pipe fitted with an effective prescribed flame arrester vent pipe's flame arrester mesh less than 11/linear centimetre vent pipe's total area of gauze clear openings less than cross section of air pipe

2.6

fuel tank properly secured fuel tank as low as practicable fuel tank of a suitable non-corrosive material fuel tank sufficiently fire resistant (BS 476 Part 20) fuel tank marked to indicate pressure test (0.25kg/cm2)* fuel tank's joints/seams efficiently made to sustain pressure test

2.7

petrol/paraffin tank larger than 2.5 litres is more than 1 metre from engine/heating appliances and insulated by an efficient fireproof baffle

2.8

tube sight - not gauge glass/plastic* fitted fuel level indicator doesn't allow escape of fuel or vapour if damaged* fitted dipstick - calibrated* fitted dipstick - gas tight* dipstick - can't strike bottom of tank*

http://www.boatsafetyscheme.org/boat-examination/non-private-boats/part-2-inboard-engines/part-2-checklist[25/12/2012 10:19:12]

part 2 checklist | Boat Safety Scheme

2.9

fuel tank accessible for inspection fuel tank connections readily accessible for inspection

2.10

fuel tank effectively bonded to deck filling connection fuel tank effectively bonded to an earth point

2.11

fuel tank's drain valve suitable*

2.12

fuel supply lines - connections through top, or as near as practicable to top, of tank* gravity feed system - cock/valve fitted to tank return fuel line - connections through top, or as near as practicable to top, of tank*

2.13

fixed fuel pipe copper/stainless steel/aluminium alloy or for diesel only mild steel fuel pipe fixed clear of exhaust system fuel pipe fixed clear of heating apparatus fuel pipe adequately supported balance pipe fitted only in diesel fuelled installation balance pipe of suitable material balance pipe fitted with valves attached to tank* balance pipe valves constructed to remain leakproof when operated

2.14

flexible tubing not approved outside the engine compartment flexible tubing suitable for the fuel used flexible tubing of a minimum practicable length flexible tubing bore greater than half its outside diameter flexible tubing of reinforced/fire resisting quality (BS EN ISO 7840/DIN 4798) fuel pipe connections permanently charged with fuel - efficient screwed/compression/cone/brazed/flanged joints

2.15

2.16

fuel filters suitable for marine use fuel filters of fire resistant quality

2.17

fuel cock fitted

http://www.boatsafetyscheme.org/boat-examination/non-private-boats/part-2-inboard-engines/part-2-checklist[25/12/2012 10:19:12]

part 2 checklist | Boat Safety Scheme

fuel cock fitted as near as possible to the fuel tank fuel cock readily accessible fuel cock location clearly marked fuel cock immediately accessible from steering position or there are means of operating main cock from steering position petrol cock can be opened from steering position

2.18 2.19

fuel pipes installed above bilge water level carburettor fitted with drip tray carburettor drip tray spirit tight carburettor drip tray covered with copper/brass gauze carburettor drip tray has flame arresting mesh carburettor drip tray mesh soldered to the tray all around carburettor drip tray removable or fitted with emptying cock air intake fitted with flame trap or air filter

2.20

engine securely installed

2.21

engine - means of reversing operable from steering position* engine stop control located as near to steering position as practicable

2.22

engine tray made of a suitable material engine tray sides carried as high as practicable* engine tray fitted beneath engine/gear box engine tray prevents oil escaping into vessel/overboard engine tray's fixed bilge pump fitted in oil tight area

2.23

engine cylinders effectively cooled exhaust system effectively cooled exhaust pipe effectively lagged or shielded

2.24

silencer - exhaust noise effectively suppressed

2.25

pressure system - current pressure system certificate boiler - current pressure system insurance policy

http://www.boatsafetyscheme.org/boat-examination/non-private-boats/part-2-inboard-engines/part-2-checklist[25/12/2012 10:19:12]

part 2 checklist | Boat Safety Scheme

boiler - LPG installation complies with Part 7 of these Standards boiler - fuel system does not complies with Part 2 of these Standards

2.26

LPG engines - installation complies with LPGA Code of Practice No. 18 LPG engines - no dual fuel system

Check List items in bold are Mandatory Check List items in italic are Advisory *EXEMPTION AVAILABLE

The Boat Safety Scheme is owned by the Canal & River Trust and Environment Agency It is supported and promoted by the Association of Inland Navigation Authorities The Scheme is administered by Canal & River Trust which is registered charity in England and Wales (1146792) Search | Contact us | Terms & Conditions

http://www.boatsafetyscheme.org/boat-examination/non-private-boats/part-2-inboard-engines/part-2-checklist[25/12/2012 10:19:12]

Вам также может понравиться

- Small Vessel Operator Proficiency Training CourseДокумент9 страницSmall Vessel Operator Proficiency Training CourseibrafeeuОценок пока нет

- SeamanshipF Boatswain, RopeworkДокумент15 страницSeamanshipF Boatswain, Ropeworkheincpaing100% (2)

- OverUnity Lead Acid Battery Switching Circuit - Self Battery ChargingДокумент8 страницOverUnity Lead Acid Battery Switching Circuit - Self Battery ChargingpranalarОценок пока нет

- Edit 1 ....Документ100 страницEdit 1 ....Brahim YEKHLEF100% (1)

- Fire Control Plan IMO SymbolДокумент13 страницFire Control Plan IMO SymbolAkshay A KumarОценок пока нет

- Deckwatchkeeping Part 2Документ15 страницDeckwatchkeeping Part 2ibrafeeu67% (3)

- Crude Oil Washing 2Документ8 страницCrude Oil Washing 2Subir BairagiОценок пока нет

- 2012-04 ST Gangway SafetyДокумент3 страницы2012-04 ST Gangway SafetykhavihongОценок пока нет

- Wellington County Fire Training SCBA PresentationДокумент25 страницWellington County Fire Training SCBA PresentationbenonОценок пока нет

- ISM-Code MaintenanceДокумент3 страницыISM-Code MaintenanceghwertpОценок пока нет

- Different Types of Fire Extinguishers Used On ShipsДокумент13 страницDifferent Types of Fire Extinguishers Used On Shipsstamatis100% (1)

- BTM Course HandoutДокумент49 страницBTM Course Handoutibrafeeu100% (1)

- MCA Masters Guide PDFДокумент213 страницMCA Masters Guide PDFgary wilsonОценок пока нет

- IMO Resolution 1050 - Entry Into Enclosed Spaces PDFДокумент14 страницIMO Resolution 1050 - Entry Into Enclosed Spaces PDFpgupta71Оценок пока нет

- Japanese Pilot Association Pilot Ladders - v3Документ72 страницыJapanese Pilot Association Pilot Ladders - v3Manoj VarrierОценок пока нет

- Code of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7От EverandCode of Safe Working Practices for Merchant Seafarers Consolidated 2015 edition, including amendments 1-7Оценок пока нет

- Elementary First Aid IntroductionДокумент29 страницElementary First Aid Introductionibrafeeu0% (1)

- The ISM Code Development Implementation and Legal AspectsДокумент47 страницThe ISM Code Development Implementation and Legal AspectsOdumoduChigozieUzoma100% (1)

- Personal Safety & Social Responsibilities Workbook: Written by Barry BarnesДокумент86 страницPersonal Safety & Social Responsibilities Workbook: Written by Barry BarnesNautas NautasОценок пока нет

- Code of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)От EverandCode of Safe Working Practices for Merchant Seafarers: Consolidated edition (incorporating amendments 1-6)Оценок пока нет

- SOLAS Pilot LadderДокумент8 страницSOLAS Pilot LadderManoj VarrierОценок пока нет

- Familiarization Bridge and EquipmentДокумент30 страницFamiliarization Bridge and Equipmentsimon_midjaja100% (1)

- Pilot Transfer Arrangements For Panama CanalДокумент6 страницPilot Transfer Arrangements For Panama CanalMeleti Meleti MeletiouОценок пока нет

- CAA Revision Notes PDFДокумент26 страницCAA Revision Notes PDFarek100% (1)

- Prevention of Marine Litter PollutionДокумент35 страницPrevention of Marine Litter Pollutionrmb2007Оценок пока нет

- Recovery of Persons From The Water Guidelines For The Development of Plans and ProceduresДокумент6 страницRecovery of Persons From The Water Guidelines For The Development of Plans and ProceduresClive MalliaОценок пока нет

- ISM Code and Guidelines On Implementation of The ISM Code 2010Документ3 страницыISM Code and Guidelines On Implementation of The ISM Code 2010Juan Miguel TorresОценок пока нет

- Training and Drills in ShipДокумент2 страницыTraining and Drills in Shipsmoj09Оценок пока нет

- Guidelines Enclosed Space Entry and Rescue DrillsДокумент8 страницGuidelines Enclosed Space Entry and Rescue DrillsvdevivОценок пока нет

- Detailed Syllabu Ssubstaiion DesignДокумент10 страницDetailed Syllabu Ssubstaiion Designwaqqar shaikhОценок пока нет

- Slide 1Документ18 страницSlide 1Dave Benedick Lariosa ApagОценок пока нет

- ISM CODE GUIDANCE Rec41rev5Документ63 страницыISM CODE GUIDANCE Rec41rev5ChetanОценок пока нет

- Fuels 1 SlidesДокумент19 страницFuels 1 Slidesengr_saifОценок пока нет

- Redefining Riser-Guard System For Fixed Offshore PlatformsДокумент5 страницRedefining Riser-Guard System For Fixed Offshore PlatformsJACKОценок пока нет

- USKUP - Emcy Procedures ContainerДокумент28 страницUSKUP - Emcy Procedures ContainerAlran Eric CifraОценок пока нет

- Life Raft, Kits and ProcedureДокумент14 страницLife Raft, Kits and Procedurejaber hasan talalОценок пока нет

- PSC Pocket ChecklistДокумент16 страницPSC Pocket Checklistparamjyot_sabharwalОценок пока нет

- International Safety Management (Ism) CodeДокумент10 страницInternational Safety Management (Ism) CodeVivek GaneshОценок пока нет

- CDI-Marine Inspection Procedures Section 4 - Rev07 2024Документ8 страницCDI-Marine Inspection Procedures Section 4 - Rev07 2024Quốc Tiến TrịnhОценок пока нет

- Recognised Security Organisation Instruction 1 2018 PDFДокумент21 страницаRecognised Security Organisation Instruction 1 2018 PDFHamzah HinduanОценок пока нет

- Code For Investigating AccidentsДокумент40 страницCode For Investigating Accidentsmoe_htwe_1Оценок пока нет

- Fire Fighting On BoardДокумент13 страницFire Fighting On BoardAnton Valentin100% (1)

- US Environmental Protection Agency National Pollution Discharge Elimination System Vessel General PermitДокумент37 страницUS Environmental Protection Agency National Pollution Discharge Elimination System Vessel General PermitHarbinder SinghОценок пока нет

- LifeboatДокумент74 страницыLifeboatSumit SinhaОценок пока нет

- PT 980410 Fundamental and Installation TR - W PDFДокумент63 страницыPT 980410 Fundamental and Installation TR - W PDFMet PichborameyОценок пока нет

- 4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210Документ13 страниц4 Albert Embankment London Se1 7Sr Telephone: 020 7735 7611 Fax: 020 7587 3210Sanjeewa DelgodaОценок пока нет

- Passenger Ship Outbreak Management Manual AppendixДокумент82 страницыPassenger Ship Outbreak Management Manual AppendixNestor Matus100% (1)

- Masters Handbook Isle of ManДокумент33 страницыMasters Handbook Isle of ManMeraj Ahmed Haidri100% (1)

- NEW MaritimeSafetyCatalogue2018Документ52 страницыNEW MaritimeSafetyCatalogue2018nhatly106Оценок пока нет

- Life Rafts & FittingsДокумент5 страницLife Rafts & FittingsmetallourgosОценок пока нет

- MSC Circ 810Документ4 страницыMSC Circ 810waleedyehiaОценок пока нет

- MSC 1-Circ 1447-GuidelinesForTheDevelopmentOfPlansAndProceduresForRecoveryOfPersonsFromTheWater (Secretariat) PDFДокумент4 страницыMSC 1-Circ 1447-GuidelinesForTheDevelopmentOfPlansAndProceduresForRecoveryOfPersonsFromTheWater (Secretariat) PDFFaris HarunОценок пока нет

- Basic Fire Fighting CourseДокумент4 страницыBasic Fire Fighting CourseBevan Balingit0% (1)

- Vanguard - Hook Release SystemДокумент2 страницыVanguard - Hook Release Systemnavalzero910Оценок пока нет

- Frequently Asked Questions Update 20 Feb 2009Документ1 страницаFrequently Asked Questions Update 20 Feb 2009Riaz AhmedОценок пока нет

- International Maritime Organization: I:/ASSEMBLY/21/RES/884Документ40 страницInternational Maritime Organization: I:/ASSEMBLY/21/RES/884MasterPie1950100% (1)

- L. List of Certificates and Documents Required To Be Carried On Board Ships Rev18Документ6 страницL. List of Certificates and Documents Required To Be Carried On Board Ships Rev18ncharala100% (1)

- MMC - 201 ASI Correction of Deficiencies Found in ASI Inspections PDFДокумент2 страницыMMC - 201 ASI Correction of Deficiencies Found in ASI Inspections PDFNguyen Huu TriОценок пока нет

- 4 - GMDSS.1-CIRC.22 GMDSS Master Plan PDFДокумент201 страница4 - GMDSS.1-CIRC.22 GMDSS Master Plan PDFTran HoangОценок пока нет

- Lifeboat ChecklistДокумент12 страницLifeboat ChecklistmfazioliОценок пока нет

- Musters and Drills and On-Board Training & Instruction: Manx Shipping NoticeДокумент7 страницMusters and Drills and On-Board Training & Instruction: Manx Shipping NoticeAnkit Khokhar100% (1)

- 24 6 2011 Port SecurityДокумент112 страниц24 6 2011 Port SecurityFiroze Zia Hussain100% (1)

- Commercial Yacht Code - LY3Документ192 страницыCommercial Yacht Code - LY3naufragatoОценок пока нет

- Personal Safety & Social Responsibility (PSSR) STCW-95Документ2 страницыPersonal Safety & Social Responsibility (PSSR) STCW-95Kunal Nagal100% (1)

- What Is Ship Oil Pollution Emergency PlanДокумент2 страницыWhat Is Ship Oil Pollution Emergency PlanMyat Kaung50% (2)

- VHF Communication Urgency & SafetyДокумент9 страницVHF Communication Urgency & SafetyoLoLoss m100% (1)

- ISGOTT 6 Breakdown of POI For InspectorsДокумент4 страницыISGOTT 6 Breakdown of POI For InspectorsSam BОценок пока нет

- Bwmp-Model Ballast Water Management Plan-IntertankoДокумент42 страницыBwmp-Model Ballast Water Management Plan-IntertankoThurdsuk NoinijОценок пока нет

- Section 10 Storage of Liquid Fuels, Lubricating, Hydraulic and Thermal Oils As Well As Oily ResiduesДокумент4 страницыSection 10 Storage of Liquid Fuels, Lubricating, Hydraulic and Thermal Oils As Well As Oily ResiduesbuturcasОценок пока нет

- KMS MicroДокумент3 страницыKMS MicroibrafeeuОценок пока нет

- FAO Small VSL StabilityДокумент64 страницыFAO Small VSL StabilityibrafeeuОценок пока нет

- Deck Seamanship and Shipboard Safety: NS 101 Captain N. A. ReedДокумент14 страницDeck Seamanship and Shipboard Safety: NS 101 Captain N. A. Reedibrafeeu83% (6)

- Pub92 MHSQE Guide PDFДокумент53 страницыPub92 MHSQE Guide PDFibrafeeuОценок пока нет

- Overview of Gas-Handling FacilitiesДокумент6 страницOverview of Gas-Handling FacilitiesMatthew AdeyinkaОценок пока нет

- The Molecular Symmetry GroupДокумент24 страницыThe Molecular Symmetry GroupWippetsxzОценок пока нет

- Gas Turbines Siemens InteractiveДокумент24 страницыGas Turbines Siemens InteractiveFernando Bolivar PОценок пока нет

- QFT OutlinesДокумент42 страницыQFT OutlinesBrandon StephensОценок пока нет

- Tutorials On MachinesДокумент2 страницыTutorials On Machinesjenniferi_7Оценок пока нет

- Exs PDFДокумент8 страницExs PDFIchsan DachiОценок пока нет

- Techno Economic Analysis and Environmental Impact of EVДокумент13 страницTechno Economic Analysis and Environmental Impact of EVNikeshManandharОценок пока нет

- Lion TamingДокумент3 страницыLion TamingtnvОценок пока нет

- Single Axis Solar Panel Tracking Using PLC and Scada: Team Members Project GuideДокумент14 страницSingle Axis Solar Panel Tracking Using PLC and Scada: Team Members Project GuideSai PrashanthОценок пока нет

- 034 Drazu Olweny Kazoora ASA2015Документ10 страниц034 Drazu Olweny Kazoora ASA2015Lubega JumaОценок пока нет

- Pulse Generator G M: ContinuousДокумент5 страницPulse Generator G M: ContinuousMoi MohemedОценок пока нет

- g26q250 Furnance ManualДокумент52 страницыg26q250 Furnance ManualHaoxian FengОценок пока нет

- Engine Starting ProceduresДокумент6 страницEngine Starting ProceduresSuresh RajroyceОценок пока нет

- S9 Q4 Hybrid Module 5 Week 6 How Heat Transfer and Energy Transformation Make Heat EngineДокумент16 страницS9 Q4 Hybrid Module 5 Week 6 How Heat Transfer and Energy Transformation Make Heat EngineSally CustodioОценок пока нет

- Inox Spare Parts - PPT by Trebu PDFДокумент20 страницInox Spare Parts - PPT by Trebu PDFAP Advisory BVОценок пока нет

- V.Senthil Me WWW - Chennaituitions.in: Page 1 of 6Документ6 страницV.Senthil Me WWW - Chennaituitions.in: Page 1 of 6saranyakathiravan100% (1)

- Phy ProjectДокумент15 страницPhy ProjectSPS KUSHWAHAОценок пока нет

- Design of Mechanical Drive For Diesel Engine Test Rig: BackgroundДокумент10 страницDesign of Mechanical Drive For Diesel Engine Test Rig: BackgroundAyuguОценок пока нет

- SMPR Manual GBДокумент64 страницыSMPR Manual GBDang Ngoc VungОценок пока нет

- QCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCДокумент20 страницQCVN 09 2017 BXD ENGLISH Unofficial Translation by VGBCTrần TùngОценок пока нет

- John Thompson Europac Boiler BrochureДокумент2 страницыJohn Thompson Europac Boiler BrochureHafid NaufalОценок пока нет

- Fluid MoversДокумент10 страницFluid MoversNishit KumarОценок пока нет

- Generator Working and Dynamic Testing: P. A. Amilkanthwar Dy. Chief Engineer (Testing) MSPGCL, KoradiДокумент27 страницGenerator Working and Dynamic Testing: P. A. Amilkanthwar Dy. Chief Engineer (Testing) MSPGCL, KoradiAhemadОценок пока нет

- Internal Combustion Engines and Turbomachinery Milano BovisaДокумент6 страницInternal Combustion Engines and Turbomachinery Milano BovisaaminardakaniОценок пока нет