Академический Документы

Профессиональный Документы

Культура Документы

Handling and Use of Sulfur Hexafluoride Gas

Загружено:

ممشطОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Handling and Use of Sulfur Hexafluoride Gas

Загружено:

ممشطАвторское право:

Доступные форматы

Handling and Use of Sulfur Hexafluoride Gas

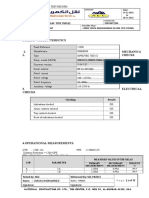

Contents Section I. II. III. PURPOSE SCOPE POLICY A. B. IV. V. Sulfur Hexafluoride Gas Decomposition Gasses and Solid By-products Page 2 2 2 2 3 3 4 4 4 5 6 7

DEFINITIONS PROCEDURE A. B. C. D. E. Handling of Sulfur Hexafluoride Gas - Central Facilities Handling of Sulfur Hexafluoride Gas - Districts Filling Equipment with Sulfur Hexafluoride Gas Removal of Sulfur Hexafluoride Gas from In-Service Equipment Removal of Hazardous Solid By-products

This document is provided for informational purposes only for co-partners of the U.S. Environmental Protection Agencys SF6 Emissions Reduction Partnership for Electric Power Systems. It is not intended as legal advice. Neither Northeast Utilities nor any of its subsidiaries or affiliates make any warranties or guarantees as to its sufficeincy or adequacy for any purpose and are not liable for any use or misuse of this material.

Handling and Use of Sulfur Hexafluoride Gas

I.

PURPOSE This procedure establishes safe working practices for handling sulfur hexafluoride (SF6) gas. It specifies methods for handling of SF6 gas and removal, handling, and disposal of hazardous by-products.

II.

SCOPE The following departments are affected by this procedure: Transmission & Distribution Maintenance Substation Construction General Construction & Maintenance

III.

POLICY A. Sulfur Hexafluoride Gas Clean SF6 gas is an inert, stable, colorless, odorless, nontoxic, nonflammable gas. It is approximately five times heavier than air and will displace air in confined areas. SF6 gas contains no oxygen and will not support life. Confined areas must be forceventilated when working with SF6 gas. The Occupational Safety and Health Administration (OSHA) regulation on air contaminants, 29 CFR 1910.1000, establishes that SF6 gas has no adverse effects when inhaled in the air at a Threshold Limit Value (TLV) of 1,000 ppm. DOT regulations require equipment containing SF6 gas at pressures greater than 39.6 psia to be certified to transport compressed gas. The Environmental Protection Agency has identified Sulfur Hexafluoride as a greenhouse gas with a global warming potential 23,900 times the effect of an equal mass of Carbon Dioxide and an atmospheric lifetime of 3,200 years. Northeast Utilities has entered a Memorandum of Understanding (MOU) with the EPA requiring monitoring and reporting of annual usage and leakage amounts. Under no circumstances should equipment pressurized with SF6 be voluntarily vented to

Page 2 of 8

Handling and Use of Sulfur Hexafluoride Gas

atmosphere. If discharge of small quantities is necessary for test purposes (i.e., contamination or moisture analysis, etc.), such discharge is to be kept to the minimum required to obtain a reading.

B. Decomposition Gasses and Solid By-Products When exposed to sustained or intense electrical arcs, SF6 gas decomposes to form sulfur-fluoride gases and metal-fluorides which are toxic. If moisture is present, the decomposition by-products may also include sulfur-oxyfluorides and hydrofluoric and sulfuric acids. The presence of these by-products can be readily detected by a white or gray powdery substance or a very pungent odor similar to rotten eggs. All in-service SF6 equipment shall be assumed to contain decomposition by-products. All employees shall wear the protective equipment specified in this procedure when removing gas or solid by-products. OSHA regulations on respiratory protective equipment, 29 CFR 1910.134, require that all employees wearing respiratory protective equipment be properly trained in the use of this equipment.

IV.

DEFINITIONS A. Processing Cart - a gas-handling unit equipped with a vacuum pump, storage tank(s), and filtration equipment necessary to recycle SF6 gas. 1. The storage tank(s) on these carts is either a large central reservoir or one or more DOT-approved cylinders. 2. Reservoir-equipped carts shall not be transported over public roadways if the gas pressure is above 25 psig, unless the cart is properly certified for transportation of compressed gas. B. Transfer Cart - a cart used to invert and/or heat gas cylinders when filling equipment to ensure the cylinder is thoroughly emptied.

Page 3 of 8

Handling and Use of Sulfur Hexafluoride Gas

V.

PROCEDURE A. Handling of Sulfur Hexafluoride Gas - Central Facilities. 1. All SF6 gas shall be obtained through a central facility. 2. The designated central facility is responsible for maintaining a log of all SF6 gas procurements and disbursals. The log shall include the weight of each bottle transported before shipment and after return from Districts. 3. SF6 gas shall be shipped only in DOT-approved cylinders. B. Handling of Sulfur Hexafluoride Gas - Districts. 1. SF6 gas shall not be voluntarily discharged into the atmosphere. 2. The Maintenance or Construction Supervisor shall request the amount of SF6 gas needed from the designated central facility. 3. The Maintenance or Construction Supervisor is responsible for maintaining a log for each cylinder provided. a) This log shall be retained with the cylinder, and indicate the location and nomenclature of the equipment being filled and weight of the cylinder before and after filling. b) The log shall be returned with the cylinder to the central facility when work is complete or the cylinder is empty. 4. Partially used or full cylinders may be retained at the work center at the discretion of the District Supervisor - Substation Equipment. The supervisor is responsible for maintaining the required logs and forwarding usage reports to the central facility upon request.

Page 4 of 8

Handling and Use of Sulfur Hexafluoride Gas

C. Filling Equipment with Sulfur Hexafluoride Gas 1. Obtain a SF6 Gas Processing or Transfer Cart as needs dictate. 2. Connect SF6 source to gas compartment valve. a) Processing cart (preferred method): (1) Connect hose to gas compartment valve and tighten all fittings. (2) Evacuate hose using vacuum pump. (3) Break vacuum using SF6 gas. (4) Open gas compartment valve. b) Transfer Cart/cylinder: (1) Loosely connect hose to gas compartment valve. (2) Partially open the gas cylinder valve. (3) Check for presence of SF6 gas in the vicinity of the connection to the gas compartment valve using an approved halogen leak detector. (4) Seal all fittings as soon as SF6 gas is detected. (5) Open gas compartment valve. 3. Fill and pressurize the equipment per manufacturers instructions. 4. Using an approved halogen leak detector, check the gas compartment and associated devices for any SF6 gas leaks into the atmosphere. 5. Repair all leaks to prevent discharge of SF6 gas. 6. Close gas compartment valve and source valve. 7. Disconnect hose from gas compartment valve and cap hose fitting. 8. Weigh all SF6 gas cylinders used to fill the equipment. a) Record final weight on cylinder log.

Page 5 of 8

Handling and Use of Sulfur Hexafluoride Gas

b) Record date, location, and equipment nomenclature on cylinder log. 9. Return all empty cylinders and appropriate logs to the central facility. D. Removal of Sulfur Hexafluoride Gas from In-Service Equipment. 1. Prior to removal of gas, check the gas compartment and associated devices for leaks using an approved halogen leak detector. a) Identify any components that must be repaired while SF6 gas is evacuated from equipment. b) Obtain replacement parts as necessary to repair leaks. 2. Attach the hose from the SF6 Processing Cart to the gas compartment valve. 3. Draw a vacuum on the hose to remove air and moisture. 4. Open the gas compartment valve. 5. Remove SF6 gas from the gas compartment via the processing cart filtration system as described in the processing cart operating/maintenance instruction booklet. 6. Draw a vacuum on the gas compartment to complete the SF6 gas removal process. 7. Break vacuum with nitrogen or dry air as applicable. 8. SF6 Gas that is to be reused on the same equipment may be kept in the processing cart until maintenance is complete. a) If equipment is to be retired from use, SF6 gas must be transferred to DOTapproved cylinders for return to the central facility. b) Cylinders of SF6 from retired equipment returned to central facility must include log indicating cylinder weight and the nomenclature of the equipment from which the gas was removed. c) Reservoir-equipped gas carts must not be transported over public roadways if gas pressure exceeds 25 psig unless the cart is properly certified for transportation of compressed gas.

Page 6 of 8

Handling and Use of Sulfur Hexafluoride Gas

9. Clean interior of equipment in accordance with section E prior to working on any internal parts. 10. When equipment is to be returned to service, seal all portholes and fittings. 11. Evacuate equipment using processing cart vacuum pump. 12. Break vacuum using SF6 gas. 13. Fill equipment in accordance with section A. E. Removal of Hazardous Solid By-Products 1. After the SF6 gas has been removed from the gas compartment and prior to opening the gas compartment's porthole(s), put on the following approved protective outerwear: a) clothing, protective, rainsuit, poly, x-large, yellow, 3 piece b) glove, safety, disposable, polyethylene, large, clear c) respirator, half-face or full-face, reusable, with two HEPA cartridges for organic vapor/acid gas (cartridge type F/C). d) goggles, chemical splash resistant, without vent, clear lens (if using half-face respirator) e) boot, pullover, disposable, for pcb and nuclear use, yellow, plastic 2. Open the porthole(s) to gain access to the gas compartment. 3. Before entry, ventilate gas compartment with a 50 cfm blower for at least one-half hour. 4. Test the compartment with an approved air monitor to verify a minimum of 20.9% oxygen and no presence of combustible gases or carbon monoxide. 5. Using an approved halogen leak detector, perform checks at various low points within the gas compartment to determine any presence of SF6 gas. 6. Continue ventilation in low point areas until the detector indicates that SF6 gas has been purged.

Page 7 of 8

Handling and Use of Sulfur Hexafluoride Gas

7. Continue ventilation while work is being performed. 8. Remove contaminated powdery deposits using an approved vacuum cleaner equipped with high-efficiency particle arresting (HEPA) filters. Note: These deposits must be removed promptly once the gas compartment is opened, since they readily absorb moisture, becoming corrosive and sticky, and making their removal more difficult. 9. Clean up any powdery residue using approved wipes. 10. Place powdery deposits contained in the vacuum cleaner disposal bag along with any wipes and other contaminated materials in a plastic waste bag. 11. Upon completion of repair and/or maintenance work, seal all portholes of the gas compartment. 12. Remove protective outerwear. 13. Place disposable coveralls, gloves, boots, and respirator cartridges, and any other contaminated materials in the plastic waste bag. 14. Secure bag with filament tape. 15. Place plastic waste bag in a 55 gallon drum. 16. Wash face and hands following completion of work and before eating or drinking. 17. Label the side of the drum with a Hazardous Waste sign and a Sulfur Hexafluoride Caution sign. 18. Leave the drum in a safe location at job site for proper disposal. a) Inform the Environmental Coordinator or the Environmental Administrator that a drum containing Hazardous Waste is at the job site and is ready for removal. b) The Environmental Coordinator/Administrator will make arrangements for disposal of the drum in accordance with federal and state regulations. c) The Environmental Coordinator/Administrator will retain copies of all manifests in a central file.

Page 8 of 8

Вам также может понравиться

- Street Lighting Installation Worker: Passbooks Study GuideОт EverandStreet Lighting Installation Worker: Passbooks Study GuideОценок пока нет

- Sf6 Gas Processing & RecoveryДокумент42 страницыSf6 Gas Processing & RecoveryJyoti Singh100% (1)

- Testing of Transformer Oil and Winding Temperature IndicatorsДокумент6 страницTesting of Transformer Oil and Winding Temperature IndicatorsK Vijay Bhaskar ReddyОценок пока нет

- Automatic Voltage Regulator Reg D E.eberleДокумент28 страницAutomatic Voltage Regulator Reg D E.eberleAnkur_soniОценок пока нет

- Siemens 7sd5Документ18 страницSiemens 7sd5BalajiОценок пока нет

- Enhancing SF6 Analysis - CIGREДокумент58 страницEnhancing SF6 Analysis - CIGREJoseph SumpaicoОценок пока нет

- Oltc RTCCДокумент6 страницOltc RTCCSuresh Kumar VengaliОценок пока нет

- Charging Method and EquipmentДокумент16 страницCharging Method and EquipmentlrpatraОценок пока нет

- Harmonic Filtering ReactorsДокумент6 страницHarmonic Filtering Reactorsvicky_doshi096004Оценок пока нет

- LCM500 Leakage Current Monitor: User GuideДокумент74 страницыLCM500 Leakage Current Monitor: User GuideThien Nguyen VanОценок пока нет

- 3-372-R008 Gas Density Sensor Test KitДокумент2 страницы3-372-R008 Gas Density Sensor Test Kitluangkok0% (1)

- Siemens Sirius Series Auxiliary CatalogДокумент8 страницSiemens Sirius Series Auxiliary CatalogJohn SerbianОценок пока нет

- Impedance MeasurementДокумент2 страницыImpedance MeasurementAhsan KaziОценок пока нет

- DELTA 4000: Reference Manual Applications GuideДокумент48 страницDELTA 4000: Reference Manual Applications GuidepetarlОценок пока нет

- Aut Section 0 - PMSДокумент44 страницыAut Section 0 - PMShari95Оценок пока нет

- Battery Testing GuideДокумент1 страницаBattery Testing GuidepeterОценок пока нет

- Controlled Switching of High-Voltage Circuit-BreakersДокумент8 страницControlled Switching of High-Voltage Circuit-BreakersBaris GurbuzОценок пока нет

- Bus Bar ArrangementsДокумент23 страницыBus Bar ArrangementsKarthik SsnongoleОценок пока нет

- Buchholz Relays PRINCIPLESДокумент9 страницBuchholz Relays PRINCIPLESBui VanluongОценок пока нет

- Omega Matrix 45 Users ManualДокумент92 страницыOmega Matrix 45 Users Manualamro galibОценок пока нет

- SF6 Gas Management Overview 2GNM110105.BДокумент8 страницSF6 Gas Management Overview 2GNM110105.BmersiumОценок пока нет

- Note Switchgear PDFДокумент36 страницNote Switchgear PDFNur FatihahОценок пока нет

- SF6 Transporation and SafetyДокумент13 страницSF6 Transporation and Safetylbk50Оценок пока нет

- Dry Transformer MaintenanceДокумент1 страницаDry Transformer MaintenanceWangun100% (1)

- Generator Maintenance ChecklistДокумент1 страницаGenerator Maintenance ChecklistVictorIjadunminiyiОценок пока нет

- RET670 Installation and Commissioning Manual PDFДокумент180 страницRET670 Installation and Commissioning Manual PDFWashington MunatsiОценок пока нет

- Fuse CharacteristicsДокумент31 страницаFuse CharacteristicsMouna NjОценок пока нет

- Braking Resistor FormulaДокумент72 страницыBraking Resistor FormulaAftandil QarmonОценок пока нет

- ALCAD HC+P - I&O InstructionДокумент2 страницыALCAD HC+P - I&O InstructionsiavoshsaifОценок пока нет

- Polarity Test of TransformerДокумент3 страницыPolarity Test of TransformerdebarshiОценок пока нет

- Transformer ReportДокумент39 страницTransformer ReportSHAROON SARDAR GHULAMОценок пока нет

- MV Switchgear CT Inspection and Test Procedure: October 2019Документ6 страницMV Switchgear CT Inspection and Test Procedure: October 2019sabamalar100% (1)

- Commissioning Numerical RelaysДокумент24 страницыCommissioning Numerical Relayslankesh_db100% (1)

- Design and Use of MV Current Limiting Fuses PDFДокумент30 страницDesign and Use of MV Current Limiting Fuses PDFBalamurugan ArumugamОценок пока нет

- 400 KB Circuit Breaker Installation Pro6Документ24 страницы400 KB Circuit Breaker Installation Pro6sanjayОценок пока нет

- Capacitors and ReactorsДокумент84 страницыCapacitors and ReactorsJalpeshLimbolaОценок пока нет

- Batteries For UPS PDFДокумент4 страницыBatteries For UPS PDFrajpre1213Оценок пока нет

- Tan-Delta TestДокумент2 страницыTan-Delta TestRakesh BabuОценок пока нет

- Atvus PRVДокумент6 страницAtvus PRVvipulpanchotiyaОценок пока нет

- Phase Displacement Between HV and LV WindingsДокумент8 страницPhase Displacement Between HV and LV WindingspawannhpcОценок пока нет

- Open-Delta or V-V ConnectionДокумент2 страницыOpen-Delta or V-V ConnectionbudituxОценок пока нет

- Lectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1Документ6 страницLectura 1 Design and Testing of Polymer Housed Surge Arresters Part 1William PinzonОценок пока нет

- Maintenance Manual - TD-TSP-0004-2A PDFДокумент19 страницMaintenance Manual - TD-TSP-0004-2A PDFSidhartha MallickОценок пока нет

- Bizu Teste Trafo Power Transformer Testing Brochure ENUДокумент32 страницыBizu Teste Trafo Power Transformer Testing Brochure ENUdiogoufrn-1Оценок пока нет

- Curriculam Vitae With CAДокумент5 страницCurriculam Vitae With CAshan1009Оценок пока нет

- 2011-LER-RC-Transformer Failure Due To Circuit-Breaker-Induced Switching TransientsДокумент12 страниц2011-LER-RC-Transformer Failure Due To Circuit-Breaker-Induced Switching Transientsjulio_nunes21Оценок пока нет

- Testing Equipment Manual PDFДокумент114 страницTesting Equipment Manual PDFSelva MaharajanОценок пока нет

- RMU HV SwitchgearДокумент28 страницRMU HV Switchgearmentong100% (2)

- Auxiliary Switch AdjustmentsДокумент3 страницыAuxiliary Switch Adjustmentsමාධව නදුන්මල්.Оценок пока нет

- Double Bus Single Breaker SchemДокумент4 страницыDouble Bus Single Breaker SchemR IsОценок пока нет

- Disconnector PDFДокумент8 страницDisconnector PDFgloby_pnbОценок пока нет

- TESAR Installation Use and Maintenance EngДокумент20 страницTESAR Installation Use and Maintenance EngceragonОценок пока нет

- sf6 Northeast PDFДокумент8 страницsf6 Northeast PDFradinalОценок пока нет

- Sf6 Handling ProcedureДокумент3 страницыSf6 Handling ProcedureRohith R NairОценок пока нет

- Osha 1910-101 Gases ComprimidosДокумент9 страницOsha 1910-101 Gases ComprimidosLaylla SilvaОценок пока нет

- SF6 Gas Safety PrecautionsДокумент4 страницыSF6 Gas Safety PrecautionssrzaОценок пока нет

- sf6 1Документ6 страницsf6 1engamsОценок пока нет

- PD History and FutureДокумент0 страницPD History and FutureممشطОценок пока нет

- Gas-Insulated Switchgear From 72.5 To 800 KV: Excellent Systems That Create Lasting ValueДокумент16 страницGas-Insulated Switchgear From 72.5 To 800 KV: Excellent Systems That Create Lasting ValueممشطОценок пока нет

- DCДокумент23 страницыDCممشطОценок пока нет

- 0909 Social AcceptanceДокумент6 страниц0909 Social AcceptanceممشطОценок пока нет

- Gas Insulated Transmission Lines GILДокумент2 страницыGas Insulated Transmission Lines GILممشط100% (1)

- Partial Discharge Detection For Gas-Insulated Switchgear in ServiceДокумент38 страницPartial Discharge Detection For Gas-Insulated Switchgear in ServiceممشطОценок пока нет

- Gis PDFДокумент28 страницGis PDFgloby_pnbОценок пока нет

- Management and Safe Handling Procedures For (Sf6) GasДокумент21 страницаManagement and Safe Handling Procedures For (Sf6) GasKhaled KhaledОценок пока нет

- HV Test MeasurementsДокумент11 страницHV Test Measurementsreza515heiОценок пока нет

- Circuit Breakers Timing Test SystemДокумент4 страницыCircuit Breakers Timing Test SystemSusan PintoОценок пока нет

- SF6 HandlingДокумент4 страницыSF6 HandlingممشطОценок пока нет

- HV Test MeasurementsДокумент11 страницHV Test Measurementsreza515heiОценок пока нет

- High Voltage TechniquesДокумент108 страницHigh Voltage Techniquesممشط75% (4)

- Circuit Breakers Timing Test SystemДокумент4 страницыCircuit Breakers Timing Test SystemSusan PintoОценок пока нет

- Power TransformerДокумент54 страницыPower TransformerممشطОценок пока нет

- الفحوصات الكهربائيةДокумент14 страницالفحوصات الكهربائيةMustafa MurshedОценок пока нет

- Circuit Breakers Timing Test SystemДокумент4 страницыCircuit Breakers Timing Test SystemSusan PintoОценок пока нет

- Section 1: Mechanical Check and Visual Inspection:: Testing Engineer Nour QC Maaden WitnessДокумент5 страницSection 1: Mechanical Check and Visual Inspection:: Testing Engineer Nour QC Maaden WitnessMourad BenderradjiОценок пока нет

- A F Af Af: Fault On Station AДокумент1 страницаA F Af Af: Fault On Station AممشطОценок пока нет

- Section 1: Mechanical Check and Visual Inspection:: Testing Engineer Nour QC Maaden WitnessДокумент5 страницSection 1: Mechanical Check and Visual Inspection:: Testing Engineer Nour QC Maaden WitnessMourad BenderradjiОценок пока нет

- Skin Effect Is DefinedДокумент2 страницыSkin Effect Is DefinedممشطОценок пока нет

- 2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredДокумент7 страниц2005 16 Autumn Wiring Matters Earthing Your Questions AnsweredAbhijeet KulkarniОценок пока нет

- Power TransformerДокумент54 страницыPower TransformerممشطОценок пока нет

- GISДокумент10 страницGISممشطОценок пока нет

- This Page Intentionally Left BlankДокумент1 страницаThis Page Intentionally Left BlankممشطОценок пока нет

- Symmetrical Fault Calculations: Example 17.14Документ1 страницаSymmetrical Fault Calculations: Example 17.14ممشطОценок пока нет

- SsДокумент1 страницаSsممشطОценок пока нет

- Unsymmetrical Fault Calculations: With The Help of Scientific Calculator, Can Be Directly Changed To and ViceДокумент1 страницаUnsymmetrical Fault Calculations: With The Help of Scientific Calculator, Can Be Directly Changed To and ViceممشطОценок пока нет

- Partial Discharge Display: (A) Void Point To Plane.: CB CBДокумент1 страницаPartial Discharge Display: (A) Void Point To Plane.: CB CBممشطОценок пока нет

- Children and Young People and The Climate Change ChallengeДокумент2 страницыChildren and Young People and The Climate Change ChallengeIstiqamah PurnomoОценок пока нет

- Msds Ammoniak UpdateДокумент9 страницMsds Ammoniak UpdateDiana Kamaliyah IОценок пока нет

- Annotated Bibliography Anna UpdatedДокумент3 страницыAnnotated Bibliography Anna Updatedapi-469896519Оценок пока нет

- Problem Statement FinalДокумент8 страницProblem Statement Finalapi-639340248Оценок пока нет

- Safety Data Sheet: Product Name: MOBIL RARUS 829Документ9 страницSafety Data Sheet: Product Name: MOBIL RARUS 829ChengОценок пока нет

- Simulation of A Vacuum Cooling System For The Phosphoric Slurry Flash Cooler 2157 7048.1000159Документ3 страницыSimulation of A Vacuum Cooling System For The Phosphoric Slurry Flash Cooler 2157 7048.1000159abdeljalil mansouriОценок пока нет

- Use of Formalin and Other Additives in FoodsДокумент2 страницыUse of Formalin and Other Additives in Foodsfaiz ariq azmi hkОценок пока нет

- Research Investigatory ProjectДокумент7 страницResearch Investigatory ProjectCharito GesiteОценок пока нет

- LevisorДокумент272 страницыLevisorrajuhaveriОценок пока нет

- Language Hub - B1 - Unit 6Документ2 страницыLanguage Hub - B1 - Unit 6Oviedo Rocío100% (1)

- AT6703 Question BankДокумент7 страницAT6703 Question BankJana garan.sОценок пока нет

- Safety Data Sheet (SDS) : 1. Product and Company IdentificationДокумент7 страницSafety Data Sheet (SDS) : 1. Product and Company Identificationjin100% (1)

- 13 Wet Scrubbing: A. Arrowsmith and N. F. AshtonДокумент2 страницы13 Wet Scrubbing: A. Arrowsmith and N. F. AshtonDHAVALESH AMОценок пока нет

- Boiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerДокумент9 страницBoiler Maintenance Checklist: Inspection and Safety Checks To Marine Steam BoilerChriscarl De LimaОценок пока нет

- Muhammad Rehan Dzaky Bing pg20 SoalДокумент6 страницMuhammad Rehan Dzaky Bing pg20 SoalHarRenFricker249Оценок пока нет

- Environment Degradation Is The Cost Justified.Документ25 страницEnvironment Degradation Is The Cost Justified.Anuj SharmaОценок пока нет

- Case Study-The Donora Smog 1948Документ9 страницCase Study-The Donora Smog 1948Denzil SeguntoОценок пока нет

- Bai Tap Tong Hop Unit 9 Tieng Anh Thi Diem 10Документ5 страницBai Tap Tong Hop Unit 9 Tieng Anh Thi Diem 10mai huongОценок пока нет

- Bharat Stage Emission StandardsДокумент7 страницBharat Stage Emission Standardspiyush tarsariyaОценок пока нет

- Safety Data Sheet: Section 1. IdentificationДокумент17 страницSafety Data Sheet: Section 1. IdentificationNICKYОценок пока нет

- 0433 CertiPUR-US Tech Guide 10.25Документ11 страниц0433 CertiPUR-US Tech Guide 10.25irwanchemОценок пока нет

- Environmental Chemistry: Air Pollution: The Atmospheric PressureДокумент42 страницыEnvironmental Chemistry: Air Pollution: The Atmospheric Pressuresayed Tamir janОценок пока нет

- LNG RegasificationДокумент16 страницLNG RegasificationCal100% (1)

- Ess Ee SampleДокумент28 страницEss Ee SampleRitika MittalОценок пока нет

- Green Concrete PresentationДокумент17 страницGreen Concrete PresentationSivaramakrishnan PОценок пока нет

- AlternativeFuel - Ashx Foir Cement PlantДокумент4 страницыAlternativeFuel - Ashx Foir Cement PlantRavindra BhatnagarОценок пока нет

- Usp - 1116 - Usp 36Документ11 страницUsp - 1116 - Usp 36Jusuf Hasan100% (1)

- CoV - Bulletin Green Buildings Policy For RezoningДокумент4 страницыCoV - Bulletin Green Buildings Policy For RezoningAakash GoliyanОценок пока нет

- Impact of Coal Based Power Plant of Rampal On The Sundarbans and Surrounding AreasДокумент11 страницImpact of Coal Based Power Plant of Rampal On The Sundarbans and Surrounding AreasNiloy BiswasОценок пока нет

- ANSI-AIHA Z9 Committee Recommendations for the Management, Operation, Testing and Maintenance of HVAC Systems - Maintaining Acceptable Indoor Air Quality in Nonindustrial Employee Occupancies through Dilution Venti.pdfДокумент49 страницANSI-AIHA Z9 Committee Recommendations for the Management, Operation, Testing and Maintenance of HVAC Systems - Maintaining Acceptable Indoor Air Quality in Nonindustrial Employee Occupancies through Dilution Venti.pdfSara Adnan100% (1)