Академический Документы

Профессиональный Документы

Культура Документы

10 Cum - Day

Загружено:

Abhijit MondalОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

10 Cum - Day

Загружено:

Abhijit MondalАвторское право:

Доступные форматы

TECHNICAL OFFER A.

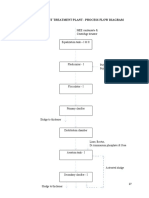

Introduction:The treatment system considered herewith for the treatment of effluent generated from kitchen, toilet and other sources. Our treatment process consists of primary collection followed by anaerobic treatment process based on anaerobic sludge blanket process with special microorganism and completely underground in civil works. B. Effluent Quantity:The generation of effluent has been considered from kitchen, canteen, restaurant, bar, banquet hall etc. and office as well, if any. Design flow considered B-1. Raw Effluent Quality:Raw pH BOD, mg/l TSS, mg/l Oil & Grease,mg/l B-2. Treated Water Quality:The treated water characteristics as per P.C.B norms will be as follows: pH BOD, mg/l TSS, mg/l Oil & Grease,mg/l PCB. C. Treatment Philosophy: We have considered High Rate Flexible Digester (HRFD) method for treatment of the sanitary wastewater or in other words the treatment will follow the principle of Anaerobic Sludge Blanket Process. In this process the whole waste is passed through the anaerobic tank where the EM will be dosed on a fixed dosing pattern. The Anaerobic unit will then be filled the millions of small granules or particles of sludge consisting of bacterial strains of EM. (1) 6.5 7.5 < 20 < 30 <10 effluent characteristic is considered 7.5 8.5 300 (max) 400 (max) 50 to have the following characteristic: - 10 cum/day (maximum)

We do not stand guarantee for any other parameters except the above as per the norms of

These sludge particles are held in a blanket and provide a large surface area on which organic matter are attached and undergo bio-digestion or biodegradation. A high solid retention time (SRT) occurs within the tank. The total treatment process and the operation involve no usage of mechanical equipment, less manpower requirement and ease of operation. D. Treatment Methodology: The removal of BOD, TSS, Bad Odour and E-Coli will be done for sewage and for canteen wastewater in proposed anaerobic tank followed by filter by dosing of EM in a proper dosing pattern, which will be provided by us. The bacterial strains of EM will form a sludge blanket at the bottom of the tank within 20 25 days time after which the load on the tanks will come down substantially. The clear water then overflows from the top of the tank to the Treated Effluent Sump from where it will be pumped through filters to the final discharge point. E. Treatment Programme of EM: For initial stabilization we recommend 10 liters followed by 4 liters per month as preventive maintenance dose. Progressive stages of developments after of EM. F. Treatment Programme: The initiation of EM treatment programme will start in the presence of our and your technical personnel and adequate training will be given to your personnel during commissioning. The total conditioning will take around 24 weeks times. G-1. Progressive Stages: Within 3 to 7 days of starting the EM programme, bad odor will get reduced significantly. After a week bad odor will be completely eliminated. Commencing from the 2nd week onwards the BOD, TSS, E-Coli values will reach an optimum level of treatment and these factors have to be adjusted by proper dosing pattern of EM by weekly monitoring the test results. By 4th week BOD, TSS etc. will start achieving the desired levels of pollution parameters. G-2. G-3. Connected Power Operating Power Bacteria Culture 2.98 KW 1.19 KW/Hr 10 Lit for commissioning & stabilization

G-4.

Area Required for STP-

6Mx3M (2)

H. Scope of Work:H.1 Civil (Customer Scope): SL. No. a. Civil Bar Screen Chamber Dimension (L x W x Ht), m b. Construction Collection Sump Capacity Dimension (L x W x SWD), m c. Construction Anaerobic Tank Capacity Dimension (L x W x SWD), m d. Construction Filter Feed Tank Capacity Dimension (L x W x SWD), m Construction Note: Invert level has been considered as (-1.00) m below ground level. Description 01 No. 0.8 x 0.8 x 1.5 RCC underground 01 No. 2 Cum 1.2 x 0.8 x 2.0 RCC underground 01 No. 18 Cum 2.0 x 3.0 x 3.0 RCC underground 01 No. 9 Cum 2.0 x 1.5 x 3.0 RCC underground

(3)

H.2 Mechanical & Electrical (Unitech Scope): Sl. No. a. Item Transfer Pump Type Capacity Head Power b. Make Filter Feed Pump Type Capacity Head Power c. Make Pressure Sand Filter with sand media Capacity Diameter Height Construction d. Make Activated Carbon Filter Capacity Diameter Height Construction e. f. g. h. Make Piping & Valves Make of Pipes & Valves Electrical Cabling Starter Panel Microorganism for commissioning & stabilization. Description 02 Nos. (1w+1s) Dry Motor Submersible 2 cum/hr 10 MWC 1 HP (each) CNP/ Kirloskar / DP/Equv. 02 Nos. (1w+1s) Open well Submersible 2 cum/hr 20 MWC 1 HP (each) Kirloskar/ Grundfos/ Equv. 01 No. 2 Cum/Hr (max) 350 mm 1800 mm PVC / FRP Aventura /Pentair/Unitech/ Equv. 01 No. 2 Cum/Hr (max) 400 mm 1800 mm PVC / FRP Aventura / Pentair/Unitech/Equv. 01 Lot PVC & PP 01 Lot. 01 No. As Required

(4)

Commercial Proposal

(A)

Price Our price for design & engineering, supply of mechanical & electrical items as per our scope of work mentioned in our offer would be Rs.5,50,000/- ( five lacs fifty thousand only) exclusive of all taxes and duties. However, tax @4% VAT/C.S.T would be charged extra as actual. Payment Terms: i) 30% mobilization advance along with the order. ii) 60% against pro-forma invoice prior to dispatch. iii) 5% after completion of erection at site. iv) Balance 5% after commissioning of plant or within three months from the date of completion of erection work at site, whichever is earlier. Delivery Period We shall deliver the material within 02 (two) months from the date of receipt of your techno-commercial clear order along with advance.

(B)

(C)

(D) Validity Our offer shall remain valid up to 30.04.2010 and thereafter it will be subject to our confirmation. (E) Exclusion: i) All Civil works at site. ii) Erection and placing all the equipment at the respective foundation. iii) Any other mechanical/ electrical/ instrumentation works not considered in our offer. iv) Power supply & connection to Starter Panel. v) Labors, operators, chemicals and consumables for trial run & normal operation of plant. vi) Service water line at ETP. vii) Laboratory Testing and PCB approval. viii) Roads, Pathway, Drain, Boundary Wall, Fencing etc, if required. ix) All other works not specified in our scope of work. (F) Guarantee: We offer our guarantee both for equipment and quality. Our supplied equipments are guaranteed for a period of (1) one year from the date of supply against any manufacturing defects. Any parts found defective within the guarantee period shall be repaired or replaced free of cost.

(5)

Вам также может понравиться

- Water Treatment Plant Performance Evaluations and OperationsОт EverandWater Treatment Plant Performance Evaluations and OperationsОценок пока нет

- Municipal Wastewater Treatment: Evaluating Improvements in National Water QualityОт EverandMunicipal Wastewater Treatment: Evaluating Improvements in National Water QualityОценок пока нет

- Chapter 4 StudentДокумент48 страницChapter 4 StudentMaster-s Hero-sОценок пока нет

- 02 Overview of Drinking Water TreatmentДокумент36 страниц02 Overview of Drinking Water TreatmentCharlie CB PortnerОценок пока нет

- WEEM 3510 Water and Wastewater Lab ManualДокумент65 страницWEEM 3510 Water and Wastewater Lab ManualMichael Huisa Taipe100% (1)

- Wastewater IrrigationДокумент28 страницWastewater IrrigationZindai WazirОценок пока нет

- BIONICS - DR - Parameswari. PHD Agri., Bionics Enviro Tech, NanozymeДокумент26 страницBIONICS - DR - Parameswari. PHD Agri., Bionics Enviro Tech, NanozymeK SASIKUMAR100% (1)

- MEMBRANE PROCESSES: FILTRATION, APPLICATIONS AND CLASSIFICATIONДокумент35 страницMEMBRANE PROCESSES: FILTRATION, APPLICATIONS AND CLASSIFICATIONArie Ikhwan SaputraОценок пока нет

- Disinfection Methods for Water TreatmentДокумент6 страницDisinfection Methods for Water TreatmentAriff JasniОценок пока нет

- Lesson Plan: How Do We Clean Polluted Water?Документ15 страницLesson Plan: How Do We Clean Polluted Water?Tarun MattaparthyОценок пока нет

- Drinking Water Sludge Recovery Feb 2011Документ2 страницыDrinking Water Sludge Recovery Feb 2011Fernando GarcíaОценок пока нет

- Investigation Anaerobic Processes Septic Tank Wastewater TreatmentДокумент5 страницInvestigation Anaerobic Processes Septic Tank Wastewater TreatmentSaj Bhai100% (1)

- ADF Health Manual Vol 20, Part8, Chp2Документ18 страницADF Health Manual Vol 20, Part8, Chp2Ahmad Usman Tahir100% (2)

- Household Water Treatment and StorageДокумент15 страницHousehold Water Treatment and StorageOxfamОценок пока нет

- Report TreatmentPond PDFДокумент10 страницReport TreatmentPond PDFSérgio Dos SantosОценок пока нет

- Treatment of Industrial WastewaterДокумент42 страницыTreatment of Industrial WastewaterchanlalОценок пока нет

- Constructed WetlandДокумент2 страницыConstructed WetlandKartika Rahmayani DjauhariОценок пока нет

- Active Sludge PDFДокумент8 страницActive Sludge PDFDark_KiroОценок пока нет

- Water Softening ProcessДокумент29 страницWater Softening ProcessAbo-Khaled MohammedОценок пока нет

- Nitrates Removal StrategiesДокумент12 страницNitrates Removal Strategiesharoon_siyech_enggОценок пока нет

- Basic Environmental Engineering Lecture on Secondary Treatment MethodsДокумент56 страницBasic Environmental Engineering Lecture on Secondary Treatment MethodsRagib Nur Alam ShuvoОценок пока нет

- Monitoring, Operation and Control of Ion Exchange Plant: Mel HallДокумент73 страницыMonitoring, Operation and Control of Ion Exchange Plant: Mel HallefasaravananОценок пока нет

- Loc 2 WastewaterДокумент62 страницыLoc 2 WastewaterPatricia Jayshree Samuel Jacob100% (1)

- Single Cell Protein Production A Review PDFДокумент12 страницSingle Cell Protein Production A Review PDFseharОценок пока нет

- Operation and Control of STPДокумент11 страницOperation and Control of STPHari Krishna.MОценок пока нет

- Stages Water Treatment ProcessДокумент2 страницыStages Water Treatment Processglo lipaodОценок пока нет

- Tertiary TreatmentДокумент26 страницTertiary TreatmentNirra IndriiОценок пока нет

- Enpro Project ReportДокумент51 страницаEnpro Project ReportYadav VirendraОценок пока нет

- SCP as Dietary Supplement: Neutraceutical SurveyДокумент20 страницSCP as Dietary Supplement: Neutraceutical SurveyStephen MooreОценок пока нет

- Biotower FundamentalsДокумент40 страницBiotower Fundamentalsram1987_rajaОценок пока нет

- Chapter-1: 1.1 Waste Water Treatment PlantДокумент39 страницChapter-1: 1.1 Waste Water Treatment PlantKalyan Reddy AnuguОценок пока нет

- Unit-III Secondary Treatment Processes-Suspended Growth: Instructor: Prof. (DR.) Gaurav Saini Sharda UniversityДокумент66 страницUnit-III Secondary Treatment Processes-Suspended Growth: Instructor: Prof. (DR.) Gaurav Saini Sharda UniversityAkbar Hamid100% (1)

- Development of Advanced Water Treatment Using Microbubbles - Pan Li - 2006Документ149 страницDevelopment of Advanced Water Treatment Using Microbubbles - Pan Li - 2006cristian muozОценок пока нет

- Introduction BODДокумент4 страницыIntroduction BODShaoline LungaoОценок пока нет

- CH 4 Sewage TreatmentДокумент134 страницыCH 4 Sewage TreatmentGetu BogaleОценок пока нет

- Principles and Practices of Reverse OsmosisДокумент9 страницPrinciples and Practices of Reverse OsmosisMohamadОценок пока нет

- Waste Stabilisation PondsДокумент8 страницWaste Stabilisation PondsIndrie AgustinaОценок пока нет

- Topic Quiz QA Wastewater Treatment Dec 04.2021Документ4 страницыTopic Quiz QA Wastewater Treatment Dec 04.2021Julie Anne Cristales100% (1)

- Adapatation of WWTP Warm Climates CH WalderДокумент8 страницAdapatation of WWTP Warm Climates CH WalderChokri ChakiirОценок пока нет

- Flow Over A Rectangular and Vee NotchesДокумент7 страницFlow Over A Rectangular and Vee NotchesfarahanisiliasОценок пока нет

- Treatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorДокумент8 страницTreatment of Pre-Treated Textile Wastewater Using Moving Bed Bio-Film ReactorIna SitaОценок пока нет

- Water TreatmentДокумент29 страницWater TreatmentSubhamay BarmanОценок пока нет

- Iare Ce Iwwt Lecture Notes 2Документ101 страницаIare Ce Iwwt Lecture Notes 2SHEKHARОценок пока нет

- Solving Operation Problems For Wastewater Treatment Plants in Cold ClimateДокумент3 страницыSolving Operation Problems For Wastewater Treatment Plants in Cold ClimateShakeel ShahОценок пока нет

- Introduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationДокумент33 страницыIntroduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationAgus WitonoОценок пока нет

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsДокумент34 страницыWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanОценок пока нет

- Problems of Drinking Water in Rural AreaДокумент14 страницProblems of Drinking Water in Rural AreaRoumyadeep ChakrabortyОценок пока нет

- Managing Food Industry Waste EffluentsДокумент5 страницManaging Food Industry Waste EffluentsAbiodun GbengaОценок пока нет

- 9.6.2023 - Shorthand Notes On Sewage Sludge Treatment and DisposalДокумент17 страниц9.6.2023 - Shorthand Notes On Sewage Sludge Treatment and DisposalLucas AgumbaОценок пока нет

- Thickened Sludge Volume from Aeration WasteДокумент3 страницыThickened Sludge Volume from Aeration WasteKai Faha LukumОценок пока нет

- Tertiary TreatmentДокумент45 страницTertiary TreatmentsunitaudayОценок пока нет

- Study Guide: Activated SludgeДокумент18 страницStudy Guide: Activated Sludged4321100% (1)

- Chapter 5Документ23 страницыChapter 5Tefera TemesgenОценок пока нет

- STP PDFДокумент16 страницSTP PDFhumaidjafriОценок пока нет

- Project Semester ReportДокумент60 страницProject Semester ReportPrabhjot Singh TinnaОценок пока нет

- Module 2 - Water TreatmentДокумент56 страницModule 2 - Water TreatmentGorgeous boiОценок пока нет

- Raw Water Treatment (Group 1)Документ34 страницыRaw Water Treatment (Group 1)AMIRAH AFIQAH BINTI ABDUL RAHIM MKK211007Оценок пока нет

- Seminar Om MBRДокумент7 страницSeminar Om MBRઅવિનાશ મીણા100% (1)

- Effluent Treatment Plant - Process Flow DiagramДокумент45 страницEffluent Treatment Plant - Process Flow DiagramAmarnath PОценок пока нет

- Faid Akandeowoo IT ReportДокумент18 страницFaid Akandeowoo IT ReportfaidakandeОценок пока нет

- Tutorial 1 SolutionsДокумент14 страницTutorial 1 SolutionsGeorge KoroОценок пока нет

- Hydrology and Water Resource MGT For Winter NarmДокумент83 страницыHydrology and Water Resource MGT For Winter NarmBekam BekeeОценок пока нет

- Energy For Sustainable Development: Serhat KucukaliДокумент9 страницEnergy For Sustainable Development: Serhat KucukaliAlejandro Duvan Lopez RojasОценок пока нет

- Sri Lankan Bottled Water Industry Overview: January 2020Документ10 страницSri Lankan Bottled Water Industry Overview: January 2020TgemunuОценок пока нет

- MWSS PlanДокумент1 страницаMWSS Planruby ultrAОценок пока нет

- Syllabus B Civil AMIEДокумент23 страницыSyllabus B Civil AMIEPankaj ChetiaОценок пока нет

- List of Indian Cities On RiversДокумент51 страницаList of Indian Cities On RiversSougata RoyОценок пока нет

- Indonesia - Seminar - ChikamiДокумент29 страницIndonesia - Seminar - Chikamiibnu Sina ForvalОценок пока нет

- 2.1 Types of Dams and Introduction Lecture Two (II)Документ44 страницы2.1 Types of Dams and Introduction Lecture Two (II)MuletaОценок пока нет

- Mci 1Документ34 страницыMci 1NAMITHA M RОценок пока нет

- Sustainable Rural Water, Sanitation and Hygiene Project PROPOSALДокумент13 страницSustainable Rural Water, Sanitation and Hygiene Project PROPOSALLawrence WatssonОценок пока нет

- TASET Introduction 201808Документ18 страницTASET Introduction 201808Mubeen NavazОценок пока нет

- Build storm water drainage systemДокумент4 страницыBuild storm water drainage systemJessa Mae CatabayОценок пока нет

- Wastewater Treatment Methods ComparisonДокумент54 страницыWastewater Treatment Methods ComparisonPamela MendozaОценок пока нет

- Wastewater Flow Rate: Chapter II: Wastewater Engineering CE 524Документ31 страницаWastewater Flow Rate: Chapter II: Wastewater Engineering CE 524Rushed AlamaОценок пока нет

- 04 - PFMA Process Out-BriefingДокумент42 страницы04 - PFMA Process Out-BriefingMimicry TarnОценок пока нет

- Lower Course LandformsДокумент17 страницLower Course LandformsTanatswa BenhuraОценок пока нет

- Well Water BasicsДокумент5 страницWell Water Basicsbontu gadisaОценок пока нет

- Advanced Series in Agricultural Sciences 8Документ163 страницыAdvanced Series in Agricultural Sciences 8conwenaОценок пока нет

- Hydrogeological Processes in Karst TerranesДокумент422 страницыHydrogeological Processes in Karst TerranesAbdullah Cem Koç100% (1)

- ReferencesДокумент5 страницReferencesMazzel May PacatanОценок пока нет

- Network Modelling For Road-Based Faecal Sludge ManagementДокумент9 страницNetwork Modelling For Road-Based Faecal Sludge ManagementEddiemtongaОценок пока нет

- Water AnalysisДокумент3 страницыWater AnalysisElprince MidoОценок пока нет

- Name: Anastazia Jagdeo Student Number: 500637954 Course: ES8901Документ4 страницыName: Anastazia Jagdeo Student Number: 500637954 Course: ES8901anastazia67Оценок пока нет

- CDP of Nashik Municipal Corporation water projectsДокумент39 страницCDP of Nashik Municipal Corporation water projectsPranav. ThubeОценок пока нет

- Process Calculations - 1 MLD - SBRДокумент164 страницыProcess Calculations - 1 MLD - SBRRAJ100% (8)

- MS-0041015 Test Request FormДокумент1 страницаMS-0041015 Test Request FormLIRIS BT RAWIОценок пока нет

- DPR2Документ247 страницDPR2Tenders TGSPLОценок пока нет

- Please Upload The Question Paper Together With Your Answers: Mid-Term Test SolutionДокумент7 страницPlease Upload The Question Paper Together With Your Answers: Mid-Term Test Solutionsui sui mangОценок пока нет