Академический Документы

Профессиональный Документы

Культура Документы

Compressed Air Engine

Загружено:

George OliverАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Compressed Air Engine

Загружено:

George OliverАвторское право:

Доступные форматы

Compressed air engine

Hello to all, I just wanted to show a project I was proud of. It isn't quite a robot, but it does incorporate a Basic Stamp 2 and some solenoids! I did this project for my 5th year in high-school. The project was very lose on the subjects, so I decided to build a compressed air engine. This is only my first prototype and due to some $ limitations, I couldn't make it any better. The Objective of my project was to build a prototype of an engine that could replace a conventional combustion engine. Since the compressed air engine needs lot's of... You guessed it, compressed air, I figured I was better to plan for something like and 18 wheeler or a city bus since they have lot's of space. So the first step is to build air muscles. I used some 30 mm in diameter air muscles. These are roughly able to lift 150 pounds while contracting 27% of their length. To say the truth I kinda guesstimated the lift capacity because I didn't have a way to test the muscle with 150 pounds. I used the stats from Shadow Robot (http://www.shadowrobot.com/airmuscles/techspec.shtml). Here is my nicely done muscle 30mm (but it's less efficient) next to the mini-muscles :

This was also more practical for all the calculations that I will show later. So I made a Basic Stamp 2 breadboard to control valves (http://forums.trossenrobotics.com/showthread.php?t=1250&hig hlight=solenoid+basic+sta mp&page=15 thread)

This was a huge milestone for me, I, for the first time, managed to do something concrete with a micro-controller. Thanks to all of you! Wouldn't have been possible without you guys! Then I made the frame. I decided to make the frame a triangle since it can't move. For example, a square could become a parralelogram if you push hard enough. I used 6 * 24 inch metal sheets (2 inches * 24 inches * 1/8 inch). Used long screws with nuts to hold the double layer of metal and some big spacers and the corners of the triangles. These were used to hold the air muscles. Here is the image of the frame :

Here is the image of the air muscle that is efficient on the frame : (although very ugly)

So I put it all together. I used 1 second intervals to open the valves. So, the engine does 1 turn in three seconds, or 20 RPM. After calculating the torque, I figured out that the engine was producing a measly 0.15 horsepower! But after reading about the combustion engine, I learned that Enrico Bernardi (who built the first combustion engine) engine only produced 0.024 CV, so it's not that bad. My engine could produce a lot motor power, all I needed was better valve (that pass more air) because the ones I had took about 1 second to fill the artificial muscle. But those are about 500$... Here is a video.

So the motor breaks down at the end because I used a metal piece that was too small. (won't make that error again!) Calculations : These are estimates made with the data I found.

The green cylinders in the 3D models are compressed air reservoirs made of carbon fiber. I made three models : 18 wheelers : I estimated with a 32 muscle motor : Amount of compressed air : 5200 liters. Adds a total of 850 kg to the 18 wheels. It can run over 300km and reduces the cost of fuel of 30% to 80% depending on the truck.

City Bus : Amount of compressed air : 3300 liters. Adds a total of 500 kg to the bus, which is about the same weight as the hybrid buses in my city. It can run over 200km and reduces the cost of fuel of 65% to 75% depending on the conditions.

UPS style truck: Amount of compressed air : 1800 liters. Doesn't add any weight.

It can run over 200km and reduces the cost of fuel of 65% to 70% depending on the conditions.

I gave in a 30 000 word "Rapport" explaining pretty much everything (the problem is it's in French.) What do you guys think? Sam

Last edited by sam; 09-03-2009 at 08:59 PM.

Вам также может понравиться

- Unit Iv - Pumps and TurbinesДокумент10 страницUnit Iv - Pumps and TurbinesGeorge OliverОценок пока нет

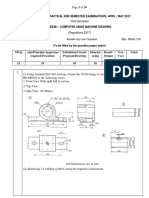

- 13154S15 - Engineering Graphics Pre SemДокумент1 страница13154S15 - Engineering Graphics Pre SemGeorge OliverОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- MCQ Aim/Principle/Apparatus Required/procedure Tabulation/Circuit/ Program/Drawing Dimensi Oning Result/ Output Viva-Voce TotalДокумент21 страницаMCQ Aim/Principle/Apparatus Required/procedure Tabulation/Circuit/ Program/Drawing Dimensi Oning Result/ Output Viva-Voce TotalGeorge OliverОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- MCQ Aim/Principle/Apparatus Required/procedure Tabulation/Circuit/ Program/Drawing Dimensi Oning Result/ Output Viva-Voce TotalДокумент20 страницMCQ Aim/Principle/Apparatus Required/procedure Tabulation/Circuit/ Program/Drawing Dimensi Oning Result/ Output Viva-Voce TotalGeorge OliverОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Me 2353 - Finite Element Analysis: Unit 1Документ14 страницMe 2353 - Finite Element Analysis: Unit 1Shridhar SrinivasanОценок пока нет

- 12154E64AP - Unconventional Machining ProcessesДокумент4 страницы12154E64AP - Unconventional Machining ProcessesGeorge OliverОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Me8691-Computer Aided Design and ManufacturingДокумент2 страницыMe8691-Computer Aided Design and ManufacturingGeorge Oliver100% (3)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Basic Civil and Mechanical-Unit-3-Power Plants-Support Notes-V+Документ19 страницBasic Civil and Mechanical-Unit-3-Power Plants-Support Notes-V+SathishОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- BCMДокумент25 страницBCMGeorge OliverОценок пока нет

- Ucmp QB PTДокумент4 страницыUcmp QB PTGeorge OliverОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Two Mark Engineering Metrology and MeasurementsДокумент5 страницTwo Mark Engineering Metrology and MeasurementsGeorge Oliver.DОценок пока нет

- Renewable Sources of Energy Question BankДокумент2 страницыRenewable Sources of Energy Question BankGeorge Oliver100% (1)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 2 Marks: 1.distinguish Between Space Diagram and Free Body DiagramДокумент4 страницы2 Marks: 1.distinguish Between Space Diagram and Free Body DiagramGeorge OliverОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- FM and SM Lab ManualДокумент87 страницFM and SM Lab ManualGeorge OliverОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Theory of Metal CuttingДокумент3 страницыTheory of Metal CuttingGeorge Oliver100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Numerical Methods QB 11148S51B 12148S51BДокумент10 страницNumerical Methods QB 11148S51B 12148S51BGeorge OliverОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Engineering Metrology & InstrumentsДокумент28 страницEngineering Metrology & InstrumentsJobanjit SinghОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- PRIST UNIVERSITY-Application For Railway Concession Form For Students Going On VacationДокумент1 страницаPRIST UNIVERSITY-Application For Railway Concession Form For Students Going On VacationGeorge OliverОценок пока нет

- Energy Conservation Question BankДокумент11 страницEnergy Conservation Question BankGeorge OliverОценок пока нет

- Solar Question BankДокумент6 страницSolar Question BankGeorge Oliver100% (2)

- Manuf SyllabusДокумент96 страницManuf SyllabusGeorge OliverОценок пока нет

- B.Tech. Mechanical Engineering Question BankДокумент8 страницB.Tech. Mechanical Engineering Question BankGeorge OliverОценок пока нет

- Engineering Metrology & InstrumentsДокумент28 страницEngineering Metrology & InstrumentsJobanjit SinghОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Bio Energy Conversion Question BankДокумент6 страницBio Energy Conversion Question BankGeorge OliverОценок пока нет

- Prist Pondy Dept of MechДокумент14 страницPrist Pondy Dept of MechGeorge OliverОценок пока нет

- Manufacturing TechnologyДокумент34 страницыManufacturing TechnologyGeorge OliverОценок пока нет

- Customer's Name: 2. Particular's of Bank Account: A. Bank Name: B. Branch NameДокумент1 страницаCustomer's Name: 2. Particular's of Bank Account: A. Bank Name: B. Branch NameGeorge OliverОценок пока нет

- Safety Study MaterialДокумент40 страницSafety Study MaterialGeorge OliverОценок пока нет

- M.tech Technical Writing Guidelines-Annexure 1Документ11 страницM.tech Technical Writing Guidelines-Annexure 1George OliverОценок пока нет

- Advances in Solar Drying Systems for Agricultural and Marine ProductsДокумент14 страницAdvances in Solar Drying Systems for Agricultural and Marine ProductsGeorge OliverОценок пока нет

- Service Bulletin: Cfe738 Turbofan Aircraft EngineДокумент9 страницService Bulletin: Cfe738 Turbofan Aircraft EngineVikrant RajputОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- MB 190 WMДокумент866 страницMB 190 WMjose guara100% (1)

- Varajet 2 Carburetor Manual GuideДокумент3 страницыVarajet 2 Carburetor Manual GuideWilber Manasés100% (1)

- Question PaperДокумент3 страницыQuestion PaperParanthaman RamanОценок пока нет

- Work Description - 9-Series Engine: Program 96Документ74 страницыWork Description - 9-Series Engine: Program 96KingОценок пока нет

- SIT Cayenne 08 GB PDFДокумент143 страницыSIT Cayenne 08 GB PDFВадим ТертицаОценок пока нет

- Motor 1AZ-FE OverhaulДокумент29 страницMotor 1AZ-FE OverhaulfredhОценок пока нет

- PC130 Part Cat NewДокумент312 страницPC130 Part Cat NewsatyaОценок пока нет

- I.C. Engines QP-1Документ1 страницаI.C. Engines QP-1Sriramulu JaichandarОценок пока нет

- Error CodesДокумент14 страницError CodesJeff SmartassОценок пока нет

- EPBook20 2016Документ80 страницEPBook20 2016Lex Giovanni Pitol CamachoОценок пока нет

- GutsДокумент552 страницыGutsroparts cluj100% (1)

- PERKINS 1103A 33G ElectropaK PN1780 PDFДокумент2 страницыPERKINS 1103A 33G ElectropaK PN1780 PDFMarketing IBLОценок пока нет

- Fiat Doblo 2010-2021Документ102 страницыFiat Doblo 2010-2021wezawezaОценок пока нет

- Competency Based Learning Material: Servicing Diesel Fuel InjectorДокумент26 страницCompetency Based Learning Material: Servicing Diesel Fuel Injectorgillian marbebeОценок пока нет

- Piston SkirtДокумент2 страницыPiston SkirtAmmar OmranОценок пока нет

- Diesel Engine Fundamentals HandbookДокумент125 страницDiesel Engine Fundamentals HandbookBobi Pitrop100% (3)

- MST Ks Catalogue WebДокумент180 страницMST Ks Catalogue WebMiguel Gutierrez100% (2)

- Hoffman: Spotmaster Spotting Boards and Cabinets - The Most Complete Range of Spotting Systems!Документ2 страницыHoffman: Spotmaster Spotting Boards and Cabinets - The Most Complete Range of Spotting Systems!NugagodaОценок пока нет

- Service Manual Models Mercury/Mariner 40-45-50-50 BigfootДокумент599 страницService Manual Models Mercury/Mariner 40-45-50-50 BigfootCarsten LarsenОценок пока нет

- Nanni 6.420 TDi Marine Diesel 6cylДокумент16 страницNanni 6.420 TDi Marine Diesel 6cylAlbertoJim90Оценок пока нет

- Tilt Cylinder S150 Parts List & SpecsДокумент3 страницыTilt Cylinder S150 Parts List & SpecsSIA Stats RENTОценок пока нет

- Mitsubishi Evo ECU PinoutsДокумент2 страницыMitsubishi Evo ECU PinoutsDavid AlanocaОценок пока нет

- Miguel Filipe Vieira Batista Miguel - Batista@tecnico - Ulisboa.pt Instituto Superior Técnico, Universidade de Lisboa, Portugal November 2016Документ9 страницMiguel Filipe Vieira Batista Miguel - Batista@tecnico - Ulisboa.pt Instituto Superior Técnico, Universidade de Lisboa, Portugal November 2016Marco Raneo PezzanoОценок пока нет

- RX8 Short Manual 2007 PDFДокумент7 страницRX8 Short Manual 2007 PDFgk218Оценок пока нет

- GENERATOR TECHNICAL SHEETДокумент7 страницGENERATOR TECHNICAL SHEETThanh Trúc Đặng HuỳnhОценок пока нет

- B20D Parts Manual Section 2 EngineДокумент76 страницB20D Parts Manual Section 2 EngineerickbothaОценок пока нет

- C11 ACERT BrochureДокумент2 страницыC11 ACERT Brochurepeakwealth0% (1)

- Troubleshooting-Data: FH 12 380 Model: Motor: D12A 380 / ABS 4 ChannelДокумент1 страницаTroubleshooting-Data: FH 12 380 Model: Motor: D12A 380 / ABS 4 ChannelSurena RafiОценок пока нет

- E110a - Cylinder BlockДокумент6 страницE110a - Cylinder BlockbennieОценок пока нет

- The Grid: The Fraying Wires Between Americans and Our Energy FutureОт EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureРейтинг: 3.5 из 5 звезд3.5/5 (48)

- Handbook on Battery Energy Storage SystemОт EverandHandbook on Battery Energy Storage SystemРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Nuclear Energy in the 21st Century: World Nuclear University PressОт EverandNuclear Energy in the 21st Century: World Nuclear University PressРейтинг: 4.5 из 5 звезд4.5/5 (3)

- Asset Integrity Management for Offshore and Onshore StructuresОт EverandAsset Integrity Management for Offshore and Onshore StructuresОценок пока нет

- Guidelines for Implementing Process Safety ManagementОт EverandGuidelines for Implementing Process Safety ManagementОценок пока нет

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет