Академический Документы

Профессиональный Документы

Культура Документы

Lab Preservation 2

Загружено:

Sikin SikinАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lab Preservation 2

Загружено:

Sikin SikinАвторское право:

Доступные форматы

TITLE : THE DRYING OF BANANA FRUIT OBJECTIVE Drying the banana fruit to measure its moisture content using

moisture analyzer. INTRODUCTION Those days, food preservation is commonly used by the ancestors to extend shelf life of food in which to inhibit microbiological and biochemical changes. However, preservation of food products in food industry nowadays has been well-developing, especially with the high technology equipments. There are a number of aims to be achieved by the industry such as to increase variety in the diet by providing a range of attractive flavors, colors, aromas and texture in food. Besides that, it is to provide nutrients required for health and also to generate income for the manufacturing company (Fellows, 2000). In food industry, they developed many types of food products in order to reached the demands from the customer and also competitors from others manufacturer. In fact, people nowadays prefer simple food but has adequate amount of nutrients, convenient to eat and also make us full by undergoes some principle of food preservation, for instances are drying, size reduction, extrusion and many more. Drying process is an alternative technique to reduce the water content in food. Water activities encourage the growth of microorganisms in foods. In drying process, heat has important influences on food processing where it is the most practical way of extending the shelf life of foods by removing water to inhibit deterioration. There are many types of fruits that can undergo drying process such as guavas, mangoes and

also bananas. In this experiment, bananas are used as sample to determine it drying process by cut them into slices with equal thickness. The purpose of drying may be carried out in the absence of oxygen in order to protect the components of foods that are easily oxidized (Fellows, 2000). Foods have a low thermal conductivity which becomes lower as the food dries and a thin layer of food is thus needed to conduct heat rapidly, without causing heat damage. MATERIALS AND INSTRUMENTS 1. Guava 2. Acetic acid 3. Calcium Chloride 4. Sugar 5. Plastic bag 6. Distilled water METHODS Firstly, the guava that we need to blanch was washed cleanly. Then the guava was peeled and cutted in cube shape with the width 1cm3. The cube shapes guava is then divided into three parts. One part is used raw while the second part was boiled at 80oC and the third part of guava was boiled at 100oC. After that, the guava was soaked in the salt water with the 12% concentration for a week. While the process of soaking, the guava was pressed with the water containing in the plastic bag. After one week, the guava was taken out and then immersed in the Calcium Chloride with the 0.4% in concentration. The water with the sugar concentration of 40% was heated. After that, 7. Beaker 8. Cutting board 9. Balancer 10. Knife 11. Hot plate

the vinegar and the 0.2% Calcium Chloride was added into the guava and the cooled to 70oC. Then, the guava was arranged in the clean and dry bottle until full and then closed tightly. The bottle was then heated in the boiling water for 6 minutes. Then, we observe the taste of the guava. RESULTS: Initials weight: Materials Banana (with skin) Banana (without skin) Aluminium foil Tray Alumiium foil + Tray + Banana Weight (g) 217.05 114.05 3.070 1730 1760

Moisture content: Time taken: 5 minutes Moisture analyzer tray weight: 2.584g Moisture contents Initial Final Percentage (%) 73.83 13.27

Weight changes of banana in the dehydrator: Time (hours) Weight 1.76 (kg) 1.75 1.75 1.75 1.75 1.75 1 2 3 4 5 6

DISCUSSION Based on the results and graph obtained, it can be seen that the moisture content of bananas decreased from 73.83% to 13.27% in 6 hours. For the first six hours of drying, the weight of the banana plus the tray is 1.76kg, and for every next 1 hour, the weight recorded is constant which is 1.75kg.

This means that the dehydration of bananas is completed only in 2 hours. The constant temperature might be caused by too long exposure of the bananas to the surrounding temperature. Plus, the result obtained might be affected by temperature of dehydrator itself and also the thickness of each slice of bananas. The higher the temperature of the dehydrator, the shorter time to complete the process of dehydration of banana slices. The thickness of banana slices also influenced the process of dehydration. The thicker the slices of banana, the longer the time to complete the dehydration of the banana. In this experiment, natrium metabisulfite acts as antimicrobial preservative, inhibiting the growth of fungi and bacteria. Plus, it is also an antioxidant, decreasing the amount of oxygen in a substance and thus preventing the enzymatic browning especially in fruits. It also functions as bleaching agent. Natrium metabisulfite is a crystalline powder that is white to yellow in color. It is soluble in water. Another names for natrium metabisulfite are pyrosulphurous acid or disodium salt. Another sulfites that can be used exactly the same way as natrium metabisulfite is sodium sulfite, sodium bisulfate and also potassium metabisulfite. There are many types of preservatives that can be used but some of them are dangerous and has been banned in country such as Australia. The preservatives that should be avoided by people who are having cardiovascular disease, asthma, conjunctivitis and emphysema are calcium sulfite or sulphur dioxide. Besides drying, the bananas can be preserved by smoking, or it can be preserved by making banana jam (canning). It can also be fried to extend their life shelf. The

efficient way of drying the bananas is by drying them with food dehydrator instead of traditional ways- using sunlight. This is because if the weather is not good enough for drying, the quality of dried banana will be low. The quality is said to be good if the colour of the banana is brownish-yellow. Plus, the drying of the bananas is effective by using food dehydrator rather than sunlight because of its shorter time, less cost and high quality of control and hygiene (Dasuki, 1992). In addition, pisang emas, pisang raja and pisang ambon are types of bananas that can be used to be preserved by drying. This is because of its colour and moisture content. But of course, if the bananas are high in water content, the time taken to be dried might be much higher. CONCLUSION As for conclusion, we can state that the banana need to be decrease their moisture content until 15 20% which this percentage were the most suitable to reduce the microbiological activity and also extend it shelf life. Moreover, this process must have an accurate usage of drying time which helps to increase the quality of dried banana. In addition, we must also know how to use the correct technique of drying for dried banana by using the dehydrator instead of dry it under the sunlight. REFERENCE Rika. 2003. Pengaruh Suhu dan Lama Pengeringan Pisang Terhadap Mutu Sale Pisang. http://digilib.itb.ac.id/gdl.php?mod=browse&op=read&id=jiptumm-gdl-s1-2003henimudias-238. Retrieved on 20th MARCH. 2012

Вам также может понравиться

- Lab 2Документ11 страницLab 2api-300103665Оценок пока нет

- Drying Characteristics of Mango Slices Using The Refractance Window™ Technique PDFДокумент7 страницDrying Characteristics of Mango Slices Using The Refractance Window™ Technique PDFcedu126Оценок пока нет

- Tray Dryer Final ReportДокумент13 страницTray Dryer Final ReportHaziq AzliОценок пока нет

- Tutorial 1 - Application With SolutionsДокумент8 страницTutorial 1 - Application With SolutionsMARLIANAОценок пока нет

- Condensation in Drop and Film FormДокумент5 страницCondensation in Drop and Film FormAshish VermaОценок пока нет

- ChE Industrial Chem Manual Final - 002Документ37 страницChE Industrial Chem Manual Final - 002rossangel35Оценок пока нет

- Jar Test Lab Report Level 2Документ14 страницJar Test Lab Report Level 2syaaa0% (1)

- Determination of The Heat Capacity of A CalorimeterДокумент8 страницDetermination of The Heat Capacity of A CalorimeterVictor NyarugweОценок пока нет

- Cooling Tower ReportДокумент11 страницCooling Tower Reportbae zazОценок пока нет

- Climbing Film GanganДокумент20 страницClimbing Film GanganAdeniran Joshua50% (2)

- Final Proposal Etp ExampleДокумент11 страницFinal Proposal Etp ExampleAfif IzwanОценок пока нет

- Lab Report CMT 450 Tray DryerДокумент3 страницыLab Report CMT 450 Tray DryerJohanОценок пока нет

- Questions (Cod Lab Report)Документ1 страницаQuestions (Cod Lab Report)putriyusairah_91Оценок пока нет

- Colling Tower: Mechanical Lab / Exp. NO.Документ10 страницColling Tower: Mechanical Lab / Exp. NO.Dalal Salih100% (1)

- A Theory of Dropwise CondensationДокумент187 страницA Theory of Dropwise CondensationJuvy A. BalbaronaОценок пока нет

- Measurement of The Drag Coefficients of Spherical ParticlesДокумент10 страницMeasurement of The Drag Coefficients of Spherical Particlessr3shОценок пока нет

- Tray Dryer Objectives: Calculate The Percentage Moisture Content of Wet Rice Husk Removed in A Rotary Drier byДокумент4 страницыTray Dryer Objectives: Calculate The Percentage Moisture Content of Wet Rice Husk Removed in A Rotary Drier byHajra AamirОценок пока нет

- Exp 3 DNSДокумент10 страницExp 3 DNSEmelya NatraОценок пока нет

- Gas UnitДокумент4 страницыGas UnitZalina SamsuddinОценок пока нет

- Report Case Study FluidДокумент11 страницReport Case Study FluidAnisalya JamriОценок пока нет

- Discussion Exp 1 Plate & FrameДокумент1 страницаDiscussion Exp 1 Plate & FrameNur AsiahОценок пока нет

- Crystallization (Latest)Документ31 страницаCrystallization (Latest)Lin Xian XingОценок пока нет

- Practical Manual of Extrusion Technology FST-608 (Dr. Faiz)Документ16 страницPractical Manual of Extrusion Technology FST-608 (Dr. Faiz)Ayesha SafdarОценок пока нет

- Experiment 1 Introduction and ConclusionДокумент3 страницыExperiment 1 Introduction and ConclusionMaiSakurajima100% (1)

- Lab Report Alka-SeltzerДокумент2 страницыLab Report Alka-SeltzerHingaffersОценок пока нет

- The Avanced CRYOSCOPE 4D3Документ111 страницThe Avanced CRYOSCOPE 4D3Miguel CapassoОценок пока нет

- CPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportДокумент9 страницCPB 20104 Mass Transfer 2 UniKL MICET Experiment 2: Tray Dryer Full Lab ReportSiti Hajar MohamedОценок пока нет

- Experiment 2 - Forced Draft Cooling TowerДокумент14 страницExperiment 2 - Forced Draft Cooling TowerSonia YuОценок пока нет

- Exp.5 - Bacteria CountДокумент6 страницExp.5 - Bacteria Countمحمد أمير لقمان0% (1)

- Lab Report 1 Particle Size Analysis of SДокумент8 страницLab Report 1 Particle Size Analysis of SMohammad Sayim0% (1)

- (Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Документ11 страниц(Unit Operations Laboratory-2) : Name: Siraj Ali Aldeeb ID: 3214118Siraj AL sharifОценок пока нет

- Latent Heat of Vaporization of EthanolДокумент5 страницLatent Heat of Vaporization of EthanolMel DyОценок пока нет

- Physical Chem 1 (Combined)Документ35 страницPhysical Chem 1 (Combined)Yit JuanОценок пока нет

- Oecd 202 211 Daphnia MagnaДокумент0 страницOecd 202 211 Daphnia MagnaHeidita SanchezОценок пока нет

- Lab Report Chm207Документ6 страницLab Report Chm207zack wanОценок пока нет

- Lab Report Exp 4 (Siti Nuraziemah Binti Azmy - 2021373309)Документ7 страницLab Report Exp 4 (Siti Nuraziemah Binti Azmy - 2021373309)SITI NURAZIEMAH AZMYОценок пока нет

- Experiment Manual - Liquid-Liquid ExtractionДокумент24 страницыExperiment Manual - Liquid-Liquid ExtractionStolen RememberОценок пока нет

- CH 3510: Mechanical Operations Lab: B Narasimhan: CH11B043 Naveenraaj K.P: CH11B044 Raghuveer P: CH11B045Документ7 страницCH 3510: Mechanical Operations Lab: B Narasimhan: CH11B043 Naveenraaj K.P: CH11B044 Raghuveer P: CH11B045aravind1997muraliОценок пока нет

- Supercritical Fluid Cleaning: Fundamentals, Technology and ApplicationsОт EverandSupercritical Fluid Cleaning: Fundamentals, Technology and ApplicationsSamuel P. SawanОценок пока нет

- CELCHA2 Study GuidesДокумент7 страницCELCHA2 Study GuidesEsther100% (1)

- Drying: Merry Jessah S. TorresДокумент6 страницDrying: Merry Jessah S. TorresFrancis Val FranciscoОценок пока нет

- Liquid Liquid ExtractionДокумент36 страницLiquid Liquid ExtractionamirnimoОценок пока нет

- Determination of PHДокумент5 страницDetermination of PHFath Bond50% (2)

- National Institute of Molecular Biology and Biotechnology University of The Philippines, Diliman, Quezon CityДокумент12 страницNational Institute of Molecular Biology and Biotechnology University of The Philippines, Diliman, Quezon CityCeruleanBeingОценок пока нет

- Mass Transfer Lab ManualДокумент29 страницMass Transfer Lab ManualPrajwal ChavanОценок пока нет

- Determination of Biological Oxygen Demand (BOD) in Waste Water - Pharmaceutical GuidelinesДокумент3 страницыDetermination of Biological Oxygen Demand (BOD) in Waste Water - Pharmaceutical GuidelinesIrfan SalimОценок пока нет

- Fst359 Experiment 3 Rice FlourДокумент11 страницFst359 Experiment 3 Rice Flourfatin umairahОценок пока нет

- Crystallisation and PrecipitationДокумент19 страницCrystallisation and PrecipitationNestorОценок пока нет

- Exp 1 Reynolds' NumberДокумент7 страницExp 1 Reynolds' NumberDonna Mae Ramos GalaezОценок пока нет

- Lead PoisoningДокумент17 страницLead PoisoningParvez X GulОценок пока нет

- Lab Report GCДокумент8 страницLab Report GCAyish MataОценок пока нет

- LabreportДокумент3 страницыLabreporttaylor100% (1)

- Dew Point - Thermo 2 Lab Report B1 (DEW POINT)Документ5 страницDew Point - Thermo 2 Lab Report B1 (DEW POINT)Taqqi HaiderОценок пока нет

- Lab Report Osmosis FinalДокумент12 страницLab Report Osmosis Finaloda_px_mcrОценок пока нет

- Conclusion CPP Bubble Cap DistillationДокумент2 страницыConclusion CPP Bubble Cap DistillationAhmad KhalidОценок пока нет

- Fila Table MathДокумент1 страницаFila Table Mathfarhan aliОценок пока нет

- HTL-04 Thermal Conductivity of LiquidДокумент2 страницыHTL-04 Thermal Conductivity of Liquidvindiesel9222Оценок пока нет

- SpectroscopДокумент104 страницыSpectroscopSikin SikinОценок пока нет

- TT 0309Документ2 страницыTT 0309Sikin SikinОценок пока нет

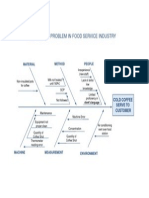

- Ishikawa DiagramДокумент1 страницаIshikawa DiagramSikin SikinОценок пока нет

- Universiti Malaysia Sabah: Senarai Semak Latihan IndustriДокумент3 страницыUniversiti Malaysia Sabah: Senarai Semak Latihan IndustriSikin SikinОценок пока нет

- (Your Name & Full Address) (Date) : Li Placement Application Cover Letter SampleДокумент2 страницы(Your Name & Full Address) (Date) : Li Placement Application Cover Letter SampleSikin SikinОценок пока нет

- (Company's Name & Full Address) : UMS/SSMP6.8/600-3/15/1 (Date)Документ1 страница(Company's Name & Full Address) : UMS/SSMP6.8/600-3/15/1 (Date)Sikin SikinОценок пока нет

- RUJUKANДокумент2 страницыRUJUKANSikin SikinОценок пока нет

- EnumerationДокумент7 страницEnumerationSikin Sikin100% (1)

- Lab YogurtДокумент6 страницLab YogurtSikin Sikin0% (1)

- Serial Dilution MethodДокумент3 страницыSerial Dilution Methoddraneesh75% (4)

- Lab SauerkrautДокумент6 страницLab SauerkrautSikin Sikin100% (2)

- Eastern and Western Cookery SinopsisДокумент9 страницEastern and Western Cookery SinopsisSikin SikinОценок пока нет

- Microbiology Lab 3Документ6 страницMicrobiology Lab 3Sikin SikinОценок пока нет

- Lab Preservation 1Документ7 страницLab Preservation 1Sikin SikinОценок пока нет

- Physical ProposalДокумент1 страницаPhysical ProposalJasmine Kaur 2K21/MSCCHE/23Оценок пока нет

- Electrodialysis and Electrodialysis Reversal: Manual of Water Supply PracticesДокумент63 страницыElectrodialysis and Electrodialysis Reversal: Manual of Water Supply PracticesWilmer David Quispe HaroОценок пока нет

- Concept Map: Lab Review: Sodium: 136 - 145 Meq/L Potassium: 3.5 - 5.0 Meq/LДокумент2 страницыConcept Map: Lab Review: Sodium: 136 - 145 Meq/L Potassium: 3.5 - 5.0 Meq/LKingsMan SSGОценок пока нет

- Unit 5 Organic Chemistry ReactionsДокумент9 страницUnit 5 Organic Chemistry ReactionsRobbing_Hood100% (1)

- Loki's DMT ExtractionGuide PDFДокумент27 страницLoki's DMT ExtractionGuide PDFOriginal Peoples100% (1)

- MSDS NaohДокумент9 страницMSDS NaohtalhawasimОценок пока нет

- CLIN PHARM - Fluids and ElectrolytesДокумент11 страницCLIN PHARM - Fluids and ElectrolytesAlodia RazonОценок пока нет

- Kimia F4 Akhir Tahun SBP 2008Документ65 страницKimia F4 Akhir Tahun SBP 2008Mustakimah Muhamad100% (5)

- CSEC Chemistry January 2012 P032Документ7 страницCSEC Chemistry January 2012 P032AshleyОценок пока нет

- Grade X - Teaching Notes: Metals and Non-Metals GlossaryДокумент25 страницGrade X - Teaching Notes: Metals and Non-Metals GlossaryAkshith KottaОценок пока нет

- APFLU SYRUP Chlorphenamine Maleate BP 0.5mg Paracetamol BP 120 MG and Vitamin C 50mg PILДокумент2 страницыAPFLU SYRUP Chlorphenamine Maleate BP 0.5mg Paracetamol BP 120 MG and Vitamin C 50mg PILJo NoutОценок пока нет

- Owner: PMC: Contractor: Project:: Dangote Refinery and Petrochemicals ProjectДокумент161 страницаOwner: PMC: Contractor: Project:: Dangote Refinery and Petrochemicals ProjectMonaОценок пока нет

- Physics - Numericals - APPLIED PHYSICS - ENGINEERING 1st YearДокумент16 страницPhysics - Numericals - APPLIED PHYSICS - ENGINEERING 1st YearManas Upadhyaya Telecommunication EngineeringОценок пока нет

- Batch Reactor ExpДокумент12 страницBatch Reactor ExpJack AndreasОценок пока нет

- Indigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnДокумент4 страницыIndigo Prodn. From Phenyl-Glycine Carboxylic Acid Salt - by Fusion in Mixed Potassium Hydroxide and Sodium Hydroxide Melt, Then OxidnCillian CreedonОценок пока нет

- CBSE Class 7 Science The Language of Chemistry Exam Notes: IntroductionДокумент8 страницCBSE Class 7 Science The Language of Chemistry Exam Notes: Introductionanika varshneyОценок пока нет

- BITSAT Practise TestsДокумент336 страницBITSAT Practise Testssiddharth1996Оценок пока нет

- Oral Rehydration SaltsДокумент3 страницыOral Rehydration SaltsKadek Adit WiryadanaОценок пока нет

- Cambridge IGCSE: CHEMISTRY 0620/51Документ8 страницCambridge IGCSE: CHEMISTRY 0620/51ÙИΚNOWN ΔSSΔSSłÑОценок пока нет

- Daniel Venne-What I Have Learned About Water PDFДокумент70 страницDaniel Venne-What I Have Learned About Water PDFGlenn PintorОценок пока нет

- عبدالله الحذيفيДокумент620 страницعبدالله الحذيفيAbdullahОценок пока нет

- Chemistry MRSM 2008Документ73 страницыChemistry MRSM 2008kenwoo1978Оценок пока нет

- NOTES Acid Bases and SaltsДокумент18 страницNOTES Acid Bases and SaltsRaghav JiОценок пока нет

- SDS Oxido de CalcioДокумент4 страницыSDS Oxido de CalcioMadrazo Esquivel AquilesОценок пока нет

- Chem152 Lab 6Документ6 страницChem152 Lab 6api-277000361Оценок пока нет

- Anatomy and Physiology Module 2Документ16 страницAnatomy and Physiology Module 2JayR MendonesОценок пока нет

- S and P BlockДокумент9 страницS and P BlockShasvat JainОценок пока нет

- Gold Recovery MethodsДокумент90 страницGold Recovery MethodsAlejandra Gómez100% (1)

- SDS - Crosstrans 206 - 0Документ6 страницSDS - Crosstrans 206 - 0omidОценок пока нет

- EZ Mulz 1475 TDS 1Документ2 страницыEZ Mulz 1475 TDS 1Dinesh babuОценок пока нет