Академический Документы

Профессиональный Документы

Культура Документы

Eld Brochure

Загружено:

EstuardoAИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Eld Brochure

Загружено:

EstuardoAАвторское право:

Доступные форматы

Worldwide ACE Liability Insurance Product Certications available: BG-PRFZERT 88 TV CERTIFICATE NIPPON KAIJI KYOKAI LLOYDS REGISTER DET

NORSKE VERITAS

European Lifting Devices The art of making hooks

ELD - Division of the Feat Group SpA that is specialized in hot forging is a leader in design, application engineering and production of wire rope ttings, grade 8 chain accessories, blocks and OEM components.

www.featgroup.com

Lifting and Wire Rope Accessories.

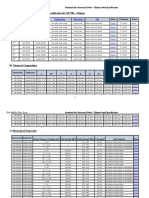

According to EN 1677.

High resistance safety catch

Swivel Hooks. Hooks New improved model. The changes are the result of many years of experience and millions of pieces sold. Lifting capacity from 0.8 tons up to 30 tons. A large number of possible applications. Two congurations are available: with and without under-load rotation. Series 168 and 167.

Strictly controlled Alloy and Carbon steel from the best Italian steel mills. For high performances also at low temperatures, and for longer lifespan.

Light and heavy duty bearings

Eye Hook 101 series

General recommendations about Lifting Components.

Single Master Link and Sub-Assembly: 151-302 series. Grade 8 Chain: 180 series.

You can get the warning and application instructions of our products by contacting ELD technical department or by downloading them yourself from internet together with the updated catalogue. ELD distributors have to be concerned that end-users are knowledgeable with, use, inspection and maintenance of our products. O.E.M.s that install ELD lifting components on their machines, are responsible for their correct application. ELD lifting devices must always be used in full compliance with the manufacturers instructions and with the regulations in force.

Do not make modications without specic approval by the ELD technical ofce. Do not exceed the Working Load Limit. Shock loading must be avoided. Fitness, positioning and grip of the loads must always be checked before lifting operations. Markings and ID tags must never be altered. The WLL must be adequately reduced in case of severe and corrosive environments. In these operating conditions and in the presence of possible wear or damage, it is necessary to have a comprehensive examination made by a qualied inspector.

A complete range of accessories for one or more leg chain slings according to EN 818-4.

Improper use can create a seriously dangerous situation for the safety of exposed persons.

Our lifting accessories are supplied in ELD standard color Matt Red. Other colors available with manufacturing batch size.

Spare Parts always available in stock

Grade 8 Chain Fittings. According to EN 1677.

Clevis Hook: 179 series

Self Locking Hooks for the highest safety: Eye 102, Clevis 103, Swivel 105 and 106, series.

Il BG-PRFZERT 88 is proof of the specic competence own by ELD. We are committed to supplying a reliable product which is in full compliance with industry norms.

Precise machining and controlled heat treatment in order to obtain a real fatigue resistance.

Clevis and Eye Grab Hooks: 184 and 183 series Connecting link: 181 series.

Bottom Blocks of all sizes

and geometries, from the simplest to the most complex.

The special bottom blocks are manufactured in a dedicated department. A team of engineers has achieved an International reputation in the sector of: overhead, mobile, tower, marine, offshore cranes and in the problem solving connected to the lifting eld in general. The design and the relating calculations of bottom blocks are developed by maintaining a constant dialogue with the customer, focusing on the nal application of the product in order to obtain the best overall result. All products are developed in conformity with F.E.M. 1.001 norms and following the latest and most important national and international required rules.

ELD Standard Overhead Craneblock from one up to four sheaves, (1UB 1UB, 1HB 1HB, 1HA series series) the simplest and most tested solution

a4

Bow Shackle Screw Pin and Safety Bolt: 122 123 series Plain Swivel underload 118 series

We can adapt our standard components to new applications.

C and U series

Our patented Weld-On Bucket Hooks made in Sweden, are well known all over the world.

Also available option with greaser on rotating elements

Sliding Choker Hook 112 series.

We can manufacture acture pebatches of special accessories s in drop forged steel, complete with design and inspection test in order to fulll specic requirements of the customers.

The chemical analysis of steel, the heat treatment and the controls imposed by the norms are scrupulously respected. Quality accepts no compromises.

We can offer various compact solutions for motorized blocks.

We can supply a single item or serial production in order to obtain the best quality-price ratio.

Hook Block for steel mill.

ELD is the Division of FEAT Group SpA which specializes in hooks and other components for the lifting industry. Feat is located in the Milano area which is known as a worldwide leader in engineered steel hot forgings for high performance and safety applications. FEAT makes use of technologically advanced closed die mechanical presses which are automated using robots. The combination of ELDs engineering expertise in designing lifting components and the production forging expertise of FEAT, allows us to supply a superior product in compliance with industrial norms and the highest quality standards.

The information contained in this brochure is for commercial and illustrative use only. The photos and data may vary with the actual product. For more information please contact our technical ofce or consult our ofcial catalogue. ELD is a dynamic company and its range of products can be modied or integrated as necessary per customer requirements, or changes to industry standards. ELD guarantees quick deliveries by keeping in stock all of the standard items shown in this brochure. ELD International distributors are carefully selected directly by our head ofce and are required to uphold the highest lever of professionalism. Thanks to a vertical organization it is always possible to develop strategic projects directly with company owners. Our board direction and engineers are always available for offering technical and production assistance. ELD can offer customized solutions for important clients. The technical co-operation with customers is essential in order to develop a nal product which fully fullls the application required. Unhealthy, risky and difcult maintenance areas; Extreme temperature, explosive and chemical aggressive zones; Intensive cycles of work and exposure to severe weather conditions, are just some of the elements to be kept into consideration when designing a block or special lifting accessory.

Forged Lifting Components

either raw pieces or machined ready to be assembled.

Faithful compliance with the most widespread and reliable norm, the DIN 15400.

Typical products destined to OEM and to companies that are specialized in maintenance and after market service

Large stocks of DIN 15401 / 15402 Single and Ramshorn Hooks and DIN 1541 Suspensions are available.

Drop forged Cross Heads

We can supply up to Nr 250, in strength class P / T and V

Shank machining according to customers drawing on demand

Final surface treatment for extreme applications and explosive areas. (paint, galvanic coating, nickel-copper plating).

High performing Sheaves in forged steel up to 500 mm diameter. Possibility for special treatment for increasing throat hardness and high resistance bearings.

The quality of the nal product is strongly inuenced by the skill of the forger. Feat Group is historically recognized - from the most well known brands as a reference supplier in the steel forming sector.

ELD guarantees the traceability of all products through a marking code for the forgings and ID tags for the hook blocks. Each code is linked to its own certicate which is available (by means of a password) in the web site and recorded in our databases. The conformity certicate contains data relating to the manufacturing batch, as well as the material chemical and mechanical properties in compliance with industry norms. We can issue special inspection certicates for additional controls, and welcome external inspectors when requested.

Our quality system imposes rigid production cycles and 100% visual inspection before packaging. Destructive and non destructive tests and metallurgical analysis on forgings are carried out in the central lab of Feat. ELD is internally equipped with dedicated machines for tests on the nal product: Manufacturing Proof Test, 20,000 Cycle Fatigue Test and Tensile Strength Test.

Once the hook reaches the breaking load limit it withstands a strong deformation but does not break.

Technicians

use

modern

Computer

Aided

Design,

forging

simulation

software,

and

Finite

Element

Modeling.

E.L.D. EUROPEAN LIFTING DEVICES Division of FEAT GROUP S.p.A. Via Portoni, 205 - 21044 Cavaria con Premezzo (VA) - ITALY Tel. +39 0331.73571 Fax +39 0331.219933 Sito Web: www.featgroup.com - e-mail: eld@featgroup.com

www.targetadv.it

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- AS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection StandardsДокумент7 страницAS/NZS 3008.1.1 Amendment 1 Aug 2011 Cable Selection Standardslastwest1Оценок пока нет

- AMS-2249-Chemical Check Analysis LimitsДокумент6 страницAMS-2249-Chemical Check Analysis LimitsSinan Yıldız100% (1)

- RCC Water Tank Construction TenderДокумент12 страницRCC Water Tank Construction Tendersurya0588Оценок пока нет

- Add Your Own Custom Logo To A Drafting Sheet in Solidworks: 5 Aug, 2017 04:40 PMДокумент12 страницAdd Your Own Custom Logo To A Drafting Sheet in Solidworks: 5 Aug, 2017 04:40 PMEstuardoAОценок пока нет

- Ueeek.!: Ma, R, Al ,,,,,,,,,,.Документ5 страницUeeek.!: Ma, R, Al ,,,,,,,,,,.EstuardoAОценок пока нет

- Consejos de AlimentacionДокумент40 страницConsejos de AlimentacionEstuardoAОценок пока нет

- 02theoretical Context PDFДокумент12 страниц02theoretical Context PDFEstuardoAОценок пока нет

- JLAB APPROVED ABBREVIATIONS AND ACRONYMSДокумент100 страницJLAB APPROVED ABBREVIATIONS AND ACRONYMSJuan OvalleОценок пока нет

- Entropy 16 04489 PDFДокумент8 страницEntropy 16 04489 PDFEstuardoAОценок пока нет

- JLAB APPROVED ABBREVIATIONS AND ACRONYMSДокумент100 страницJLAB APPROVED ABBREVIATIONS AND ACRONYMSJuan OvalleОценок пока нет

- Engineering Drawing & CAD Standards Mechanical Design/CAD Program C. Bales, M. VlamakisДокумент24 страницыEngineering Drawing & CAD Standards Mechanical Design/CAD Program C. Bales, M. VlamakisRajasekaran VtОценок пока нет

- JLAB APPROVED ABBREVIATIONS AND ACRONYMSДокумент100 страницJLAB APPROVED ABBREVIATIONS AND ACRONYMSJuan OvalleОценок пока нет

- The Men America Left BehindДокумент4 страницыThe Men America Left BehindEstuardoAОценок пока нет

- 14-0430 Sow PDFДокумент6 страниц14-0430 Sow PDFEstuardoAОценок пока нет

- 2 CДокумент23 страницы2 CHoo WooОценок пока нет

- Spr11blackstock PDFДокумент16 страницSpr11blackstock PDFEstuardoAОценок пока нет

- Morowitz BandP 1987 PDFДокумент5 страницMorowitz BandP 1987 PDFEstuardoAОценок пока нет

- Rivet Handbook: Blind Rivets GuideДокумент15 страницRivet Handbook: Blind Rivets GuidenextreaderОценок пока нет

- 10 1 1 135Документ6 страниц10 1 1 135Navaneetha SattarОценок пока нет

- Fasteners ScrewДокумент79 страницFasteners ScrewChristopher BeckОценок пока нет

- 06 08 029 PDFДокумент10 страниц06 08 029 PDFEstuardoAОценок пока нет

- Creo 2011Документ40 страницCreo 2011Little AyaОценок пока нет

- 1 AAM Body-StructuresДокумент84 страницы1 AAM Body-StructuresZander_100% (1)

- Welding Jumbo Shapes: The AISC SpecificationsДокумент12 страницWelding Jumbo Shapes: The AISC SpecificationsamokhtaОценок пока нет

- Technical Standards For Air Conditioning, Heating, and Refrigeration TechnologyДокумент10 страницTechnical Standards For Air Conditioning, Heating, and Refrigeration TechnologyEstuardoAОценок пока нет

- Introduction To Engineering Heat TransferДокумент74 страницыIntroduction To Engineering Heat Transferpkpnitian_152297088Оценок пока нет

- Straightness, Circularity, CylindricityДокумент18 страницStraightness, Circularity, CylindricityKarthik Ram0% (1)

- Is ScopeRational ALGДокумент3 страницыIs ScopeRational ALGEstuardoAОценок пока нет

- Grey Cast Iron CompositionДокумент4 страницыGrey Cast Iron CompositionJigar M. UpadhyayОценок пока нет

- Southco Push To Close Latches - Paddle Latch Series, Medium and Large SizesДокумент2 страницыSouthco Push To Close Latches - Paddle Latch Series, Medium and Large SizesEstuardoAОценок пока нет

- How To Test Mass Air Flow (MAF) SensorДокумент2 страницыHow To Test Mass Air Flow (MAF) SensorEstuardoAОценок пока нет

- General Galvanizing (Continuous Galvanizing: Performance & ConditionДокумент2 страницыGeneral Galvanizing (Continuous Galvanizing: Performance & ConditionEstuardoA100% (1)

- Hot Dip Galvan Neal EdДокумент6 страницHot Dip Galvan Neal EdEstuardoAОценок пока нет

- Chapter 11-Refrigeration CyclesДокумент24 страницыChapter 11-Refrigeration CyclesAbas S. AcmadОценок пока нет

- Micro Electro Mechanical Systems: S. MeenatchisundaramДокумент15 страницMicro Electro Mechanical Systems: S. MeenatchisundaramkksundariОценок пока нет

- Astm C 639-2001 PDFДокумент3 страницыAstm C 639-2001 PDFzeqs9Оценок пока нет

- Test Report: H.D.G. Bolts, Nuts & Plain WasherДокумент1 страницаTest Report: H.D.G. Bolts, Nuts & Plain WasherSumanta AdhikariОценок пока нет

- 3 PoleДокумент3 страницы3 PoleSejahtra AbadiОценок пока нет

- ProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Документ1 страницаProductSpec HS2.4S HS3.75S HSZ2.4S HSZ3.75S HSD2.55S1Araujo Felipe AndrésОценок пока нет

- Specification For Gas Fired Boiler PDFДокумент7 страницSpecification For Gas Fired Boiler PDFmjmehta81Оценок пока нет

- Masterpact NW-NTДокумент184 страницыMasterpact NW-NTCarito Ahumada100% (1)

- HD8765 47 PDFДокумент109 страницHD8765 47 PDFArsenie GeorgeОценок пока нет

- KSB Influence of Pumps On Energy ConsumptionДокумент14 страницKSB Influence of Pumps On Energy Consumption@sssОценок пока нет

- CarouselДокумент2 страницыCarouselCatalin AlexandruОценок пока нет

- Cement Properties and Testing MethodsДокумент22 страницыCement Properties and Testing Methodsankit kasanaОценок пока нет

- Cat 03a en Compact Conductor System VKS10Документ25 страницCat 03a en Compact Conductor System VKS10quang.an185Оценок пока нет

- Smart Axis Automatic Chasing Machine ManualДокумент38 страницSmart Axis Automatic Chasing Machine Manualvser19Оценок пока нет

- 423-Renolin CLP-1Документ1 страница423-Renolin CLP-1Moutaz IsmailОценок пока нет

- AIGOSTAR 300000HFA Panini Maker NoticeДокумент9 страницAIGOSTAR 300000HFA Panini Maker NoticeSYLVIEОценок пока нет

- Quality Metrics For Aerospace: Tim Robertson PQA Nasa/JplДокумент20 страницQuality Metrics For Aerospace: Tim Robertson PQA Nasa/Jplnikhil jОценок пока нет

- Technical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHДокумент77 страницTechnical & Service Manual: Sap-Krv93Eh + Sap-Crv93Eh SAP-KRV123EH + SAP-CRV123EHpht12345Оценок пока нет

- Comparison Between Vacuum and SF6 Circuit BreakerДокумент12 страницComparison Between Vacuum and SF6 Circuit BreakerecsanyiОценок пока нет

- Adeka Introduction Portfolio GeneralДокумент19 страницAdeka Introduction Portfolio Generalladislav_hipolОценок пока нет

- ZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Документ8 страницZF Astronic Bus Repair Manual Level 1-2-1337 751 101 2003Bette98% (48)

- Standard Specification For GB 700Документ12 страницStandard Specification For GB 700Ma'arif Nuzul AddibОценок пока нет

- 2015 Oil Seals by Design Web CatalogueДокумент341 страница2015 Oil Seals by Design Web CatalogueEUROPARTS67% (3)

- Utilization of Waste Plastic in Manufacturing of Paver BlocksДокумент4 страницыUtilization of Waste Plastic in Manufacturing of Paver BlocksAragorn RingsОценок пока нет

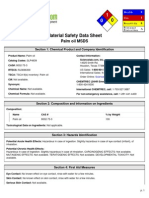

- Palm Oil MSDSДокумент5 страницPalm Oil MSDSCaliche Omn100% (1)

- Madpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Документ7 страницMadpenguin - Ca-Tutorial Use An Old Inkjet Printer To Learn Servo Motor Control With EMC2 Part 2Rudi AribowoОценок пока нет

- AMMIE 2023 Conference on Advanced Materials and ManufacturingДокумент9 страницAMMIE 2023 Conference on Advanced Materials and ManufacturingrjОценок пока нет