Академический Документы

Профессиональный Документы

Культура Документы

SEO-OPTIMIZED SPECIFICATION TITLE FOR SCHARFENBERG COUPLERS

Загружено:

Sumit ShyamalИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SEO-OPTIMIZED SPECIFICATION TITLE FOR SCHARFENBERG COUPLERS

Загружено:

Sumit ShyamalАвторское право:

Доступные форматы

DA LWAYS

SPECIFICAno

FOR

SCH FE BE G CO PLERS &D W GEA

OR

ELEC RIC ULTIPLE UNIT RO LING STOCK

FOR

CALCUTTA &BO Y S BURBA SERVICE

BROADG UGE

1676 mm

SP CIFICA ION 0.61- B - 36/ ev.68-1

( Eeo S CTED OVE BER 2004)

ISSUED BY

RESEARCH DESIG S & STA DARDS ORGANISATION

INISTRY OF RAILWAYS

AI< AGAR,

Leo -2260

Specification No. 61-B-36/Rev. 68/1

INDIAN RAILWAYS

SPECIFICATION FOR SCHARFENBERG COUPLERS AND DRAW GEAR

FOR

AC I DC EMU STOCK FOR CALCUTTA & BOMBAY SUBURBAN

SERVICES

BROAD GAUGE

1 SCOPE:

i) This specification covers the design. manufacture and supply of

Scharfenberg Couplers and Draw Gear for 4-car AC or 3-car DC

EMU Stock.

ii) The coupling and draw gear arrangement at the outer ends of

each 4-car/3--car unils shall be SUItable for filbng of

Scharfenberg Automatic Coupler that meet the

given ,n Appendix 'A'. These end couplers shall be sunable for

coupling with AC I DC Locomotives provided with screw

coupling & side buffers either by using special Transition Gear

(Adopter) or by removing the automatic head and replacing by

pot and draw screw.

iii) All intermediate couplers in the 4-car l3-car units shall be of the

semi-permanent type.

iv) The Contractor shall develop a design based on sound

engineenng practice and submit general arrangement and

wor1<ing drawings and all technical data to concerned railway

organization or Coach builders and to ROSa I Lucknow for

approval before commencing manufacture.

v) This specification IS Intended to indude everything requisite to

the manufacture of the coupler. notwlthstanding that everything

reqUIred may not be mentioned herein.

2. GENERAL DESIGN FEATURES:

I) The fiXIng of coupler to underlrame shall be by bolts I welding.

The IODng arrangement and underframe cutaways shall be

Idenhcal for all couplers (end and ,ntermediate).

II) The draft gear housing shan be capable of taking either rubber

spnngs or nng springs, and identical spnng packs shall be used

for both end and intermedIate couplers

IIi) The draft I buffing spnngs shall be of natural or synthehc rubber,

avaIlable in India.

iv) The attachment of the draw hook to the draft gear shall be

designed so that it can be conveniently replaced by automatic

Scharfenberg heads, without alteration 10 any other part of the

coupler or draft gear.

v) The location of the pivot pin centre line of couplers shall not

exceed 707 mm from headstock face, and should preferably be

the same for both end and intermediate couplers.

vi) The distance between the headstocks of adjacent coaches shall

be 800 mm when semi-permanent couplers are fitted, and not

less than 964 mm for the end couplers when fitted with

automatic heads.

vii) The semi-permanent couplers shall be provided with

arrangement for coupling of brake pipes. If required provision

should also be made for coupling of electrical cables for which

76 electrical contacts should be catered for.

viii) The Air Brake connections shall tuttil the requirements given in

Appendix 'B'.

3. MAIN REQUIREMENTS:

i) The couplers shall have a rated draft capacity of not less than

34 tonnes and buff capacity not less than 800 mkg. The stroke

of Buffing Gear shall be restricted to 75 mm and the Sill

Pressure shalt not exceed 50.000 kg. under buffing impacts of

800 mkg intensity.

ii) The couplers shall allow coupled coaches to negotiate curves of

radius 152.4 metres and shall be capable of passage in either

direction over standard 1 in BY:! turnouts, and shall function

satisfactorily with a 75 mm difference in headstock heights of

adjacent coaches.

iii) The couplers shall be tight lock, and shall not develop slack in

selVice.

4. TESTS:

The coupler assembly excluding the rubber draft gear shall withstand

tensile loads of 70 to.mes and compressive loads of 100 tonnes without

any permanent deformation and tensile or compressive loads of 150

tonnes without fracture.

5. CONTRACTORS' RESPONSIBILITY:

The Contractor shall assist the coach builders in the fitting, testing and

commissioning of these couplers, and shall be responsible for their

satIsfactory worKing, and for any failure due to defective tfesign or

materials for a period of two years from date of their placement in

service He shall replace, free of c o s ~ all parts damaged or found

defechve dunng the period of guarantee

The Contractor shall be responsible for the execution of the contract

slnctly In accordance WIth the lanns of thIS speClficalJon and the

Standard Conditions of Contract as may be applICable

6 INSTRUCTIONAL MANUALS:

The Contractor han supply repair manuals, onslnJclional booklets and

spare parts lisl for these couplers.

7 CONTRACT DRAWINGS:

The Iisl of contract drawlClgs for ScIIarfenberg couplers and their

assemblies 's given on Appendix 'C'

*****

APPENDIX 'A' TO SPECIFICATION

No. 61 - B - 361Rev. 68-1

ADDITIONAL REQUIREMENTS FOR FITMENT OF AUTOMATIC

SCHARFENBERG COUPlER HEADS

1 The automatic head when fllted shall be generally to

Scharfenberg Org. 40.6n(O).

2 Automatic coupling heads shall provide for automatic

coupling of brake pipes and have provision for subsequent

fitting of automatic electrical contacts.

3. The automatic heads shall be capable of uncoupling through

hand operated lever. This lever shall Qrve a visual indication

of the coupler position and may be set in the open, neutral or

closed position. The lever shall be easily accessible for

operation and shall allow for frtting of pneumallC release from

drive(s cab at a later date.

4 AutomatIC coupling shall take place satisfactorily when

coaches are brought together at speeds between 1 kmlh and

15 kmlh.

5. The gathering range shall be 75 mm. Vertically on eMer Side

and 264 mm horizontally on either side of centre line of the

coupler.

6. It should be possible to couple Scharfenberg automatic

heads with standard IRS draw hookS through a transition

gear adaptor Schaku automatic I IRS draw hook which

should be obtainable on demand.

APPENDIX 'B' TO SPECIFICATION

No. 61- B - 36/Rev. 68-1

NOTES ON BRAKE REQUIREMENTS FOR AUTOMATIC COUPLERS

(WITH AIR CONNECTIONS)

a) Brake pipe connection to be 1" 8.S.P. - wooong pressure 4.922 kglcm

2

.

b} MalO reservoir connection to be %" B S P - wooong pressure 7 031 kg/enr.

c) Brake pipe 10 be dosed onty at uncoupled ends.

d) Main reservoir pipe to be closed only at uncoupled ends

e) In the event of an unwanted uncoupling between coach the brake pipe

connection on both halves of the traWl must be vented to the atmosphere The

malO reservoir shoukt preferabty (but not essentialty) seal on both halves of the

train under these circumstances.

f} Provision must be made on the c o u p ~ adjaCeOt to the Driving Cabs of the

control trailers and the motor coach for a comection (112" Of 3/8' 8.S.P.) to the

brake pipe pressure switch.. This connection must be taken from the brake pipe

contained wrthin the coupler. Thus the pressure SWttch at both ends of the train

Will be sUbjected to the atmospheric pressure but at all Intermediate points down

the train Will be subjected to brake pipe pressure

g) As there will be relative movement between the coupler and the main frame.

flexible hose connections will be required for the brake pipe, the main reservoir

pipe and (where fiUed) the pressure swrtch pipe.

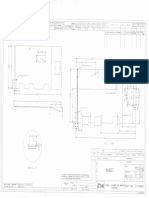

APPENDIX 'C' TO SPECIFICATION

No. 61- B - 36/Rev. 68-1

LIST OF DRAWINGS FOR SCHARFENBERG COUPLERS

AND THEIR ASSEMBLIES

1- Semi-permanent Intermediate Coupfer End 'A' 40.586 (0) '-'

a) Rubber Draft Gear 40.586.06 (2) '-

b) Bearing Bracket 40.586.07 (3)

2. Semi-permanent Intermediate Coupler End 'B' 40.587 (0) \

a) Rubber Draft Gear 40.586.06 (2)

b) Bearing Bracket 40.586.07 (3)

3. Fully Automatic CouDler 40.672 (0)

a) Automatic Coupler Head 40.663 (1)

~

Coupler Head 40.640.01 (1)

ii) Air Pipe coupling for majo air reservoir Pipe 40.370.04 (1)

iii) Air Pipe Coupling with valve for brake pipe 40.663.03 (2)

assembly

Iv) Stem with Spring Sleeve 40.371.02 (3)

b) Draw & Buff Gear 40.588 (0)5

I) Rubber Draft Gear

40.586.06 (2) '"

ii) Bearing Bracket with support 40.588.07 (2) v

iii) Centering carrier 40.1000.10 (2)

Вам также может понравиться

- p2 - Guerrero Ch13Документ40 страницp2 - Guerrero Ch13JerichoPedragosa88% (17)

- M&C PCN 102-2009Документ11 страницM&C PCN 102-2009Sumit Shyamal100% (1)

- Is 1570Документ164 страницыIs 1570Sumit Shyamal63% (8)

- John PFTДокумент231 страницаJohn PFTAlexander Santiago ParelОценок пока нет

- Geometric Dilution of Precision ComputationДокумент25 страницGeometric Dilution of Precision ComputationAntonius NiusОценок пока нет

- Research of William Wells at HarvardДокумент10 страницResearch of William Wells at HarvardARGHA MANNAОценок пока нет

- Qa LHB Bogie RepairДокумент6 страницQa LHB Bogie RepairSriram SubramanianОценок пока нет

- Carriage Watering PPT 21-3-2013 ModifiedДокумент27 страницCarriage Watering PPT 21-3-2013 Modifiedmkg90Оценок пока нет

- Specif BVCM 18.4.17Документ10 страницSpecif BVCM 18.4.17kapilparyaniОценок пока нет

- LHB Monograph PDFДокумент60 страницLHB Monograph PDFVijay Ranjan KumarОценок пока нет

- Quality Audit of Bogie OverhaulДокумент24 страницыQuality Audit of Bogie OverhaulEnd End100% (1)

- 1483772168068-C&W STC SC Hand BookДокумент472 страницы1483772168068-C&W STC SC Hand BookMani YuviОценок пока нет

- Irca Part 4Документ6 страницIrca Part 4Vikash100% (2)

- Must Change Item During ROH & POHДокумент25 страницMust Change Item During ROH & POHRakesh JainwalОценок пока нет

- Recommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysДокумент75 страницRecommended Practice FOR Welded Fabrication in Wagons: Government of India Ministry of RailwaysAMIT KUMAR100% (1)

- Air Brake System of LHBДокумент86 страницAir Brake System of LHBAbhishek patelОценок пока нет

- Indian Railways Bogie Brake Van Check SheetsДокумент13 страницIndian Railways Bogie Brake Van Check SheetsVijay KumarОценок пока нет

- Incentive Scheme 21 JET 1Документ39 страницIncentive Scheme 21 JET 1Saptarshi PalОценок пока нет

- LATEST RWF-Prop-1-cast-vs-forge-modifiedДокумент8 страницLATEST RWF-Prop-1-cast-vs-forge-modifiedDevarshi GaurОценок пока нет

- DAR FormsДокумент18 страницDAR FormsAmitabh Narula0% (1)

- Maintenance of Freight Stock Air Brake SystemsДокумент199 страницMaintenance of Freight Stock Air Brake SystemsKamaljyoti Deka100% (1)

- List of RDSO Coaching DrawingsДокумент21 страницаList of RDSO Coaching DrawingsShubhav Manav0% (2)

- Advanced Bogie Brakes Improve Safety and EfficiencyДокумент5 страницAdvanced Bogie Brakes Improve Safety and EfficiencyAndy AcousticОценок пока нет

- South East Central Railway (SECR) Bilaspur Mechanical Vocational Training Report 1-Haxxo24 I IДокумент42 страницыSouth East Central Railway (SECR) Bilaspur Mechanical Vocational Training Report 1-Haxxo24 I Ihaxxo24Оценок пока нет

- LVPH BPC ValidityДокумент4 страницыLVPH BPC ValidityJeetendra Singh ChauhanОценок пока нет

- Joining Time RuleIndian RailwaysДокумент9 страницJoining Time RuleIndian Railwayssaurabh guptaОценок пока нет

- Pamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFДокумент9 страницPamphlet On Arrangement of Springs in Various Casnub Trolleys Fitted On Air Brake Wagon PDFNiKhil GuPtaОценок пока нет

- A REPORT ON REVIEW OF MAINTENANCE PERIODICITY OF ICF AND LHB COACHE (1) VHVVДокумент39 страницA REPORT ON REVIEW OF MAINTENANCE PERIODICITY OF ICF AND LHB COACHE (1) VHVVsubashritunalco100% (1)

- GDR Check TimeДокумент12 страницGDR Check TimeMurali KrishnanОценок пока нет

- CBCДокумент52 страницыCBCOmaroMohsenОценок пока нет

- RCFДокумент16 страницRCFAmitShuklaОценок пока нет

- Model Question Paper for selection of Instructors in STC/KGPДокумент77 страницModel Question Paper for selection of Instructors in STC/KGPDeepak DohareОценок пока нет

- Raebarille 2Документ45 страницRaebarille 2Sachin GautamОценок пока нет

- 1514285051142-Rehresher Course Book PDFДокумент99 страниц1514285051142-Rehresher Course Book PDFSaptarshi Pal100% (1)

- ICF Bogie OverhaulingДокумент10 страницICF Bogie OverhaulingSaptarshi PalОценок пока нет

- 1434529208729-UST Testing IRДокумент59 страниц1434529208729-UST Testing IRPM LOgsОценок пока нет

- Train Detention Particulars Observations: Train. No 17612 AWB-RU Detained at NKDO On 17/8/19 For 10"Документ8 страницTrain Detention Particulars Observations: Train. No 17612 AWB-RU Detained at NKDO On 17/8/19 For 10"frenz2kiranОценок пока нет

- DBOOK wdg4Документ13 страницDBOOK wdg4RUDHRESH KUMAR SОценок пока нет

- TRF DrawingsДокумент4 страницыTRF DrawingssivaОценок пока нет

- CMT Lab FunctionДокумент10 страницCMT Lab FunctionmajjisatОценок пока нет

- PP FastenersДокумент10 страницPP FastenersyesbeeОценок пока нет

- Oscillation Trial Report No. R.D.S.O T.G MT-1321 F Rev.-0 Dated 29.01.2013 Amendment NilДокумент53 страницыOscillation Trial Report No. R.D.S.O T.G MT-1321 F Rev.-0 Dated 29.01.2013 Amendment NilraОценок пока нет

- Pro - Guard Meterial G&SR, Comme, Airbrake, BitbankДокумент63 страницыPro - Guard Meterial G&SR, Comme, Airbrake, BitbankAvinash ArjunОценок пока нет

- Course Book Mse MJR Iii Workshop PDFДокумент133 страницыCourse Book Mse MJR Iii Workshop PDFPratap Singh GangwarОценок пока нет

- Schedule of Dimensions - Bansal PDFДокумент52 страницыSchedule of Dimensions - Bansal PDFMahmood MuftiОценок пока нет

- Draft Handbook On Air Brake System of LHB CoachesДокумент189 страницDraft Handbook On Air Brake System of LHB Coachesnikunjsingh04Оценок пока нет

- Final Specification - STR No. WD-40-LWLH25 Bogie-K-class Dated 26-02-16Документ61 страницаFinal Specification - STR No. WD-40-LWLH25 Bogie-K-class Dated 26-02-16ksvinyk7193Оценок пока нет

- Question Bank East Coast RailwayДокумент123 страницыQuestion Bank East Coast RailwayVenkat KondamudiОценок пока нет

- Coaches and Wagons Codification and Numbering System: R.Venkatachari SR - Lecturer/C&W STC/SCДокумент32 страницыCoaches and Wagons Codification and Numbering System: R.Venkatachari SR - Lecturer/C&W STC/SCmaharshi DaddyОценок пока нет

- Safety UnusualsДокумент3 страницыSafety Unusualspower controlОценок пока нет

- Type of WagonsДокумент24 страницыType of WagonsCaspian DattaОценок пока нет

- MJR MSE LLL DSL BookДокумент147 страницMJR MSE LLL DSL Bookbalaji817150Оценок пока нет

- Revised Maintenanace Instruction FIBA-23!06!2020Документ7 страницRevised Maintenanace Instruction FIBA-23!06!2020meenaashutoshОценок пока нет

- Specification No. MP-0.41.00.03 SIDE BUFFERДокумент12 страницSpecification No. MP-0.41.00.03 SIDE BUFFERnasirzeal990Оценок пока нет

- Final Report On Examination Time For Diffrent Rake LengthДокумент45 страницFinal Report On Examination Time For Diffrent Rake LengthRakesh JainwalОценок пока нет

- Annual Report 2010-2011 PublicationsДокумент14 страницAnnual Report 2010-2011 PublicationsspnaikОценок пока нет

- EMU - 0167 - Rev 4 - 15Документ138 страницEMU - 0167 - Rev 4 - 15Prasad AthavaleОценок пока нет

- Fabricated BogieДокумент16 страницFabricated BogiemailbkraoОценок пока нет

- (IRFCA) Indian Railways FAQ - Acronyms and Abbreviations - II PDFДокумент8 страниц(IRFCA) Indian Railways FAQ - Acronyms and Abbreviations - II PDFGaurang singhОценок пока нет

- C&W Objective Question Bank PDFДокумент45 страницC&W Objective Question Bank PDFRaghubir KumarОценок пока нет

- CBC Couplers: A Report On LHB and Wagon CbcsДокумент10 страницCBC Couplers: A Report On LHB and Wagon CbcsWheel Bogie Parel WSОценок пока нет

- FIBA TestsДокумент33 страницыFIBA TestsRishika RОценок пока нет

- CTRBДокумент98 страницCTRBAlok AmanОценок пока нет

- Bvzi (Design-C) Check SheetДокумент13 страницBvzi (Design-C) Check SheetManoj BairwaОценок пока нет

- Scanned by CamscannerДокумент10 страницScanned by CamscannerChandrashekhar KalyankarОценок пока нет

- MR Num4-EnДокумент14 страницMR Num4-EnaminardakaniОценок пока нет

- CEOWB 636312348195127173 English Bilingual Form8AДокумент2 страницыCEOWB 636312348195127173 English Bilingual Form8ASumit ShyamalОценок пока нет

- Is 3063Документ11 страницIs 3063Sumit ShyamalОценок пока нет

- Created by TIFF To PDF Trial Version, To Remove This Mark, Please Register This SoftwareДокумент1 страницаCreated by TIFF To PDF Trial Version, To Remove This Mark, Please Register This SoftwareSumit ShyamalОценок пока нет

- IRS T 29-2016: Cast Manganese Steel Crossings SpecificationДокумент44 страницыIRS T 29-2016: Cast Manganese Steel Crossings SpecificationSumit Shyamal100% (1)

- Is 2896-1979Документ12 страницIs 2896-1979Sumit ShyamalОценок пока нет

- Reaffirmed 2012 Standard Page Intentionally BlankДокумент16 страницReaffirmed 2012 Standard Page Intentionally BlankSumit ShyamalОценок пока нет

- Is 228 - 24Документ6 страницIs 228 - 24cuteamit2Оценок пока нет

- Is - 814 - 1991 (Part-1)Документ16 страницIs - 814 - 1991 (Part-1)Sumit Shyamal100% (1)

- Is-10810 53Документ4 страницыIs-10810 53Sumit ShyamalОценок пока нет

- Indian Standard " QQ+ 72: Methods 0-F Test For Cables Bk-At FIRN'Документ2 страницыIndian Standard " QQ+ 72: Methods 0-F Test For Cables Bk-At FIRN'Sumit ShyamalОценок пока нет

- Reaffirmed Standards HistoryДокумент3 страницыReaffirmed Standards HistorySumit ShyamalОценок пока нет

- Is 2707-1982Документ12 страницIs 2707-1982Sumit ShyamalОценок пока нет

- Reaffirmed 2008 and 2003Документ11 страницReaffirmed 2008 and 2003Sumit ShyamalОценок пока нет

- RDSO specification for epoxy-PU painting system of railway assetsДокумент33 страницыRDSO specification for epoxy-PU painting system of railway assetsSumit Shyamal50% (2)

- Revised Spec. No.C 9202 R3Документ28 страницRevised Spec. No.C 9202 R3Sumit ShyamalОценок пока нет

- Is 1030-1998Документ8 страницIs 1030-1998Sumit ShyamalОценок пока нет

- Is 2016Документ13 страницIs 2016Sumit Shyamal100% (1)

- Is 1363 (Part 1)Документ10 страницIs 1363 (Part 1)Sumit ShyamalОценок пока нет

- Is 1363 (Part 1)Документ10 страницIs 1363 (Part 1)Sumit ShyamalОценок пока нет

- SEO-OPTIMIZED SPECIFICATION TITLE FOR SCHARFENBERG COUPLERSДокумент7 страницSEO-OPTIMIZED SPECIFICATION TITLE FOR SCHARFENBERG COUPLERSSumit Shyamal100% (1)

- C K514Документ15 страницC K514Sumit ShyamalОценок пока нет

- Spec. no.C-9202-R2 - Oct 08Документ32 страницыSpec. no.C-9202-R2 - Oct 08Sumit ShyamalОценок пока нет

- Schaku Coupler - ICF Des..Документ20 страницSchaku Coupler - ICF Des..Sumit Shyamal33% (3)

- Is 1239 Part 12004 DetailsДокумент1 страницаIs 1239 Part 12004 DetailsSumit ShyamalОценок пока нет

- Unitary Small Air-Conditioners and Air-Source Heat Pumps (Includes Mixed-Match Coils) (RATED BELOW 65,000 BTU/H) Certification ProgramДокумент65 страницUnitary Small Air-Conditioners and Air-Source Heat Pumps (Includes Mixed-Match Coils) (RATED BELOW 65,000 BTU/H) Certification ProgramAmer GaladОценок пока нет

- Löwenstein Medical: Intensive Care VentilationДокумент16 страницLöwenstein Medical: Intensive Care VentilationAlina Pedraza100% (1)

- 2020 - Audcap1 - 2.3 RCCM - BunagДокумент1 страница2020 - Audcap1 - 2.3 RCCM - BunagSherilyn BunagОценок пока нет

- Basics of Duct DesignДокумент2 страницыBasics of Duct DesignRiza BahrullohОценок пока нет

- Hercules SegersДокумент15 страницHercules SegerssuneelaamjadОценок пока нет

- Nysc Editorial ManifestoДокумент2 страницыNysc Editorial ManifestoSolomon Samuel AdetokunboОценок пока нет

- Book 7 More R-Controlled-VowelsДокумент180 страницBook 7 More R-Controlled-VowelsPolly Mark100% (1)

- List of StateДокумент5 страницList of StatedrpauliОценок пока нет

- Trabajo de Investigación FormativaДокумент75 страницTrabajo de Investigación Formativalucio RОценок пока нет

- Amniotic Membrane in Oral and Maxillofacial SurgeryДокумент13 страницAmniotic Membrane in Oral and Maxillofacial SurgerySooraj SОценок пока нет

- Manuais - 727312 - manuais-Raios-X AXR - 77000001249Документ72 страницыManuais - 727312 - manuais-Raios-X AXR - 77000001249Hosam Ahmed HashimОценок пока нет

- Lay Out New PL Press QltyДокумент68 страницLay Out New PL Press QltyDadan Hendra KurniawanОценок пока нет

- Export - Import Cycle - PPSXДокумент15 страницExport - Import Cycle - PPSXMohammed IkramaliОценок пока нет

- Operating Instructions: Blu-Ray Disc™ / DVD Player BDP-S470Документ39 страницOperating Instructions: Blu-Ray Disc™ / DVD Player BDP-S470JhamОценок пока нет

- Ace3 1122.03 GB PDFДокумент16 страницAce3 1122.03 GB PDFArpit VermaОценок пока нет

- Online Music QuizДокумент3 страницыOnline Music QuizGiang VõОценок пока нет

- Design of Steel Structures Handout 2012-2013Документ3 страницыDesign of Steel Structures Handout 2012-2013Tushar Gupta100% (1)

- Edexcel A2 Biology 6BI06Документ7 страницEdexcel A2 Biology 6BI06abhayОценок пока нет

- Exercise C: Cocurrent and Countercurrent FlowДокумент6 страницExercise C: Cocurrent and Countercurrent FlowJuniorОценок пока нет

- SWOT AnalysisДокумент6 страницSWOT Analysishananshahid96Оценок пока нет

- Costos estándar clase viernesДокумент9 страницCostos estándar clase viernesSergio Yamil Cuevas CruzОценок пока нет

- Theatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THДокумент18 страницTheatre Arts I 9 - 12 Grade Beginning Theatre Students: TH THAppleSamsonОценок пока нет

- (V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsДокумент7 страниц(V) 2020-Using Extensive Reading in Improving Reading Speed and Level of Reading Comprehension of StudentsMEYTA RAHMATUL AZKIYAОценок пока нет

- Popular Tools CatalogДокумент24 страницыPopular Tools CatalogCarbide Processors IncОценок пока нет

- COP2251 Syllabus - Ellis 0525Документ9 страницCOP2251 Syllabus - Ellis 0525Satish PrajapatiОценок пока нет

- PH Miracle Complete Whole Body Alkalizing Program-1201724Документ20 страницPH Miracle Complete Whole Body Alkalizing Program-1201724joao carlos100% (1)