Академический Документы

Профессиональный Документы

Культура Документы

Dimensional Analysis Exersice

Загружено:

Allen HuangОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dimensional Analysis Exersice

Загружено:

Allen HuangАвторское право:

Доступные форматы

Assignment 1 Material Balance, Dimensionless Analysis and Similarity

NOTE: Due date: submitted in class on Tuesday 9 April before lecture starts. Question 1: FeS2 is roasted to Fe3O4 and SO2 in a flash roaster. FeS2 occurs in a pyrite ore, which in this case analyses 48%S. If the air supply is controlled at 10kg air/kg ore, calculate the expected exit gas analysis.

Pyrite ore Air

Fe3O4

Waste Gas

Question 2: 100 tons of hard lead (98%Pb, 2%Sb) are melted in a steel kettle and then treated with 2 tons of PbO. The products are (1) a slag consisting of PbO and Sb2O3, analyzing 20%Sb, (2) a PbSb alloy of lowered Sb content and negligible oxygen content. Calculate the % Sb in the final alloy. The reaction involved is: 3PbO + 2Sb(in Pb) = Sb2O3 +3 Pb Question 3: Thermal stress developed in continuously cast ingots: The thermal stress developed in the centre of a continuously cast cooling ingot is a function of its shape and the following independent variables: E modulus of elasticity coefficient of linear thermal expression initial temperature difference between cooling medium and melting point of metal L characteristic linear dimension of ingot h heat transfer coefficient of cooling medium at surface of ingot k thermal conductivity of ingot C thermal capacity of ingot density of metal t time from start of cooling (i.e. distance from mould/downward velocity of ingot) LH Latent heat of metal Using Buckinghams theorem, or otherwise, show by dimensional analysis what form the unknown physical equation relating to the pertinent variables must take. In an industrial process, a 6-inch diameter steel ingot was found to develop an acceptable maximum stress after 4 min. What process variables would you adjust to ensure that this stress would not be

exceeded in a similar steel, whose thermal conductivity was 9/10 times that of the steel investigated? In particular, what diameter must the mould have, and at which time will maximum thermal stress be developed? Question 4: A model of a soaking pit (or reheat) furnace has been proposed so that gas flow patterns generated in a new one-way fired pit design can be optimized for uniform convective heat flow to the reheating ingots. Develop an expression showing how the gas velocity at any given point within the system is related to the length L, and width W, of the pit, the combusted gas (i.e. burnt oxygen fuel mixture) flow rate G0, and the mean density and viscosity of these combusted gases. In order to model the system at the one-fifth scale, it is proposed that water, rather than cold air, be used as the fluid medium. Comment on this proposal and recommend the inlet gas and water flows and other dimensions that would be required to simulate the following set of conditions expected for the prototype.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 14 09 07 SolutionsДокумент1 страница14 09 07 SolutionsAllen HuangОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Ac R030L CoДокумент6 страницAc R030L CoAllen HuangОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Evaluation MethodsДокумент1 страницаEvaluation MethodsAllen HuangОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Evaluation MethodsДокумент1 страницаEvaluation MethodsAllen HuangОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Enrolment StatementДокумент1 страницаEnrolment StatementAllen HuangОценок пока нет

- Assignment1 Q1Документ1 страницаAssignment1 Q1Allen HuangОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Iterative method order of convergence and error estimationДокумент4 страницыIterative method order of convergence and error estimationAllen HuangОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Assignment1 Q1Документ1 страницаAssignment1 Q1Allen HuangОценок пока нет

- Assignment1 Q1Документ1 страницаAssignment1 Q1Allen HuangОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- Dimensional Analysis ExersiceДокумент2 страницыDimensional Analysis ExersiceAllen HuangОценок пока нет

- Dimensional Analysis ExersiceДокумент2 страницыDimensional Analysis ExersiceAllen HuangОценок пока нет

- Assignment 1 (Recovered)Документ8 страницAssignment 1 (Recovered)Allen HuangОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Energy Balances ExplainedДокумент34 страницыEnergy Balances ExplainedAllen HuangОценок пока нет

- MeasurIT Flexim Fastening Parts 0910Документ5 страницMeasurIT Flexim Fastening Parts 0910cwiejkowskaОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Anchor Bolt Design Using Anchor ReinforcementДокумент8 страницAnchor Bolt Design Using Anchor Reinforcementtiger_lxfОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Helical gear units specs and dimensionsДокумент75 страницHelical gear units specs and dimensionsamir_tstfrm1Оценок пока нет

- Seahawk Cement Unit 2300 BHP AC Electric: Available OptionsДокумент2 страницыSeahawk Cement Unit 2300 BHP AC Electric: Available Optionsbruce lianОценок пока нет

- Pressure Testing ChecklistДокумент3 страницыPressure Testing Checklistjerin100% (3)

- 1190 1Документ88 страниц1190 1TONОценок пока нет

- Split Case LRДокумент8 страницSplit Case LRmartin.rubenОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Clayton RajaДокумент7 страницClayton RajaSrinivasm SriniОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Mechanical, Plumbing, Electrical Materials ListДокумент3 страницыMechanical, Plumbing, Electrical Materials ListMohamedОценок пока нет

- Grease Sampling SetДокумент4 страницыGrease Sampling SetMoustapha SeyeОценок пока нет

- Small Bore Metric Seals CatalogДокумент64 страницыSmall Bore Metric Seals CatalogLeroy AraoОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- 003 001 Brasz 2003Документ109 страниц003 001 Brasz 2003Anonymous YBTHsR24U4Оценок пока нет

- Shuttlewagon Commander ManualДокумент21 страницаShuttlewagon Commander ManualDecebalusII100% (2)

- High-Strength Epoxy Grouting SystemДокумент6 страницHigh-Strength Epoxy Grouting SystemGihasAbdОценок пока нет

- D 6Документ47 страницD 6gilmer flores mamaniОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Piping Isometric ChecklistДокумент21 страницаPiping Isometric ChecklistNguyen Anh Tung50% (2)

- Industrial Project Report (WPS)Документ79 страницIndustrial Project Report (WPS)Khairil Anwar MuhajirОценок пока нет

- Bujii Opel BenzinaДокумент2 страницыBujii Opel BenzinaCata Stefan0% (1)

- Catalog 40 Spare PartsДокумент54 страницыCatalog 40 Spare PartsMiticaVladОценок пока нет

- 33Документ40 страниц33farida2020Оценок пока нет

- PDF - Download - GEA - Flex-Geko PDFДокумент16 страницPDF - Download - GEA - Flex-Geko PDFEvangelos SotiriouОценок пока нет

- Altronics DC-CPU IOM 06-1988 PDFДокумент22 страницыAltronics DC-CPU IOM 06-1988 PDFSMcОценок пока нет

- Single Aisle Maintenance Practice Training Manual CFM56 Engine Run Up Course (M70) ChecklistsДокумент28 страницSingle Aisle Maintenance Practice Training Manual CFM56 Engine Run Up Course (M70) ChecklistsLucas GabrielОценок пока нет

- P730 Brochure ENДокумент2 страницыP730 Brochure ENVictor GalarzaОценок пока нет

- Eu 3800Документ2 страницыEu 3800Fernando MilmanОценок пока нет

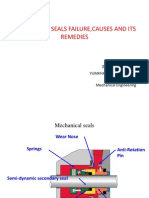

- MECHANICAL SEALS FAILURE CAUSESДокумент26 страницMECHANICAL SEALS FAILURE CAUSESFaruque Khan Yumkhaibam100% (6)

- Operating Manual - Dehumidifier TTK 31 EДокумент17 страницOperating Manual - Dehumidifier TTK 31 EEşanu ViorelОценок пока нет

- Thermal Breakage and Impact Strength of Tempered GlassДокумент7 страницThermal Breakage and Impact Strength of Tempered GlassMartinBalanagОценок пока нет

- Overview of Drilling OperationДокумент106 страницOverview of Drilling OperationTemitope BelloОценок пока нет