Академический Документы

Профессиональный Документы

Культура Документы

Stiffened Seat Connection

Загружено:

Uttam Kumar GhoshАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stiffened Seat Connection

Загружено:

Uttam Kumar GhoshАвторское право:

Доступные форматы

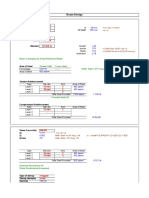

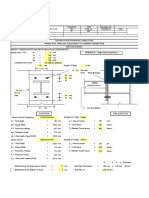

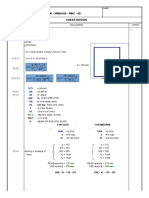

Design of Beam End Connection Type : Stiffened Seat Connection (Welded) Part : Floor Elevation : Reference drawing no.

: Connection marked in the drawing :

Input data Beam end reaction "R" (kN) Supported beam section Supporting media (flange/web of column) Supporting media specification Thickness of seat plate assumed Assumed depth of seat plate (mm) 280 ISMB 550 Flange of column ISMB 250 20 200

12 mm Gap

Member properties ( Ref. : SP-6, Part-1, Bureau of Indian Standard ) 11 5 Supported beam D (mm) 550 tw (mm) 11.2 h2 (mm) 41.25 b (mm) Supporting column tf (mm) 12.5 tw (mm) 6.9 h2 (mm) 27.95 b (mm) Analysis & design Safe crippling length of web B = R Fbr*tw

150 125

tf (mm)

19.3

h2

(Ref. Page 87 of IS : 800, 1984)

Here, R = Beam end reaction, Fbr= Permissible bearing strength of web = 187.5 Mpa So, B= 133.3 mm From the figure it is clear that b = B - 3h2 (As per IS : 800, b 0.5*B) b = 61.89 mm < 0.5* B So let's consider b = 66.67 mm Asuming a clearance of 12 mm between the beam end & column, width of seat plate required = 66.67 + 12 = 78.67 mm, Use 90 mm The thickness of seat plate may be kept equal to that of beam flange. So the assumed thickness of seat plate is The stiffening plate thickness should at least be equal to that of beam web, that is OK

Fig. - 1 : Stiffened Seat Connection

11.2 mm, so provide 12 mm thick vertical plate.

Page 1 of 4

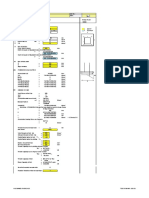

Design of Beam End Connection Type : Stiffened Seat Connection (Welded) Part : Floor Elevation : Reference drawing no. : Connection marked in the drawing :

Welds Flange width of beam = 150 mm & flange width of column = y1= 77.97 mm & 125 mm, Use 125 mm length seat plate. 12 125 Ixx= 2214425 mm3 On a stiffening seat, the length of eccentricity e is measured from the edge of the stiffening plate. 56.67 mm & M = 15866.667 kN-mm R Vertical shear on welds qv = = 545.8 N/mm per mm length L Horizontal shear on welds qh = M*y1 Ixx = 558.7 N/mm per mm length = 781 N/mm y2 So, e = y1 (Here L is the total length of welds ) X 200 X 12 Fig. - 2 : Welds of Stiffened Seat Note : Theoritically the maximum stress in weld will occur at the bottom of weld, but it is considered that the nature of connection doesn't permit a compression failure. An ISA 100 X 100 X 6 mm clip angle is used at the top to restrain the beam laterally

From Fig. - 2 it can be obtained that

y2= 122.0 mm

Resultant shear per unit length of weld q = (qv2+qh2)

As these welds are made in workshop, allowable shear stress may be taken as 108 N/mm 2 as per IS : 816. Now, if the size of weld is S S X 108 = q So, S = 10.23 mm 2 Therefore, use 12 mm size welds.

Page 2 of 4

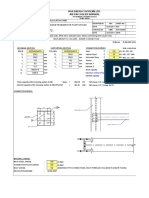

ROLLED STEEL I SECTIONS: PROPERTIES

Reference : SP-6, Part-1, Bureau of Indian Standard

Section ISMB 100 ISMB 125 ISMB 150 ISMB 200 ISMB 250 ISMB 300 ISMB 350 ISMB 400 ISMB 450 ISMB 500 ISMB 550 ISMB 600

w Kg/m 11.5 13.4 15 25.4 37.3 46.1 52.4 61.6 72.4 86.9 104 123

a cm2 14.7 17 19.1 32.3 47.6 58.7 66.7 78.5 92.3 111 132 156

D mm 100 125 150 200 250 300 350 400 450 500 550 600

b mm 70 70 75 100 125 140 140 140 150 180 190 210

tf mm 7.5 8 8 10.8 12.5 13.1 14.2 16 17.4 17.2 19.3 20.8

tw mm 4.5 5 5 5.7 6.9 7.7 8.1 8.9 9.4 10.2 11.2 12

Ix cm4 252 445.1 717.6 2235.4 5131.6 8985.7 13630.3 20458.4 30390.8 45218.3 64893.6 91813

Iy cm4 35.4 38.5 46.8 150 334.5 486.3 537.7 622.1 834 1369.8 1833.8 2651

S: PROPERTIES

Indian Standard

rx cm 4.14 5.16 6.13 8.32 10.4 12.4 14.3 16.2 18.2 20.2 22.2 24.2

ry cm 1.55 1.51 1.57 2.15 2.65 2.86 2.84 2.82 3.01 3.52 3.73 4.12

Zx cm3 50.4 71.2 95.7 224 410 599 779 1020 1350 1810 2360 3060

Zy cm3 10.1 12.5 30 53.5 69.5 76.8 88.9 111 152 193 252

h2 mm 17.6 18.1 18.3 23.65 27.95 29.9 31 32.8 35.4 37.95 41.25 45.15

ISA 150 X 150 X 12 ISA 150 X 150 X 18

34.6 50.8

735.4 1048.9

Вам также может понравиться

- Combined FootingДокумент15 страницCombined FootingAbhishek GuptaОценок пока нет

- Design of Pilecap - Is CodeДокумент9 страницDesign of Pilecap - Is CodeazjrolОценок пока нет

- PURLIN - DESIGN - AS - PER - IS - CODE LatestДокумент22 страницыPURLIN - DESIGN - AS - PER - IS - CODE Latestnitin chaudharyОценок пока нет

- Is 800-2007 Interpretation by INSDAGДокумент15 страницIs 800-2007 Interpretation by INSDAGnilesh_yerawar100% (1)

- Spread Sheet of Plate Girder-Is800-2007Документ3 страницыSpread Sheet of Plate Girder-Is800-2007yedida v r aviswanadhОценок пока нет

- Flat Slab 6 X 6 Ext PNLДокумент5 страницFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- Circular Water Tank Design: Capacity of Tank Free Board Total HeightДокумент2 страницыCircular Water Tank Design: Capacity of Tank Free Board Total HeightyasirjurabaОценок пока нет

- Crack Width Check For Water Tank BaseДокумент4 страницыCrack Width Check For Water Tank BaseShamim Ahsan ZuberyОценок пока нет

- Chequered DesignДокумент2 страницыChequered DesignSaravana N100% (1)

- RC WALLS & Base Raft Design-R2Документ96 страницRC WALLS & Base Raft Design-R2Moideen Sunaif Mustafa100% (1)

- Beam To Beam Bolted Moment End Plate Connection - Sample Calculation (As 4100)Документ4 страницыBeam To Beam Bolted Moment End Plate Connection - Sample Calculation (As 4100)Tiam MarapeОценок пока нет

- RCC Cantilever Slab DesignДокумент1 страницаRCC Cantilever Slab DesigndaxeshОценок пока нет

- Chequered Plate 1250mm-cДокумент28 страницChequered Plate 1250mm-casvenk309100% (3)

- Shear Conection Design - IS 800-2007Документ4 страницыShear Conection Design - IS 800-2007Swapnil ToraskarОценок пока нет

- Pile Cap DesignДокумент9 страницPile Cap DesignSayantan Paul100% (1)

- Combined Footing Design SheetДокумент28 страницCombined Footing Design SheetSuhas Mangalore100% (1)

- Steel Connection - IS CodeДокумент4 страницыSteel Connection - IS CodeAmit Ghosh75% (4)

- Is800 2007Документ8 страницIs800 2007Abhijit Hazarika25% (4)

- Precast StaircaseДокумент65 страницPrecast StaircasepravinОценок пока нет

- Design of Composite Floor System Using Profiled SheetsДокумент2 страницыDesign of Composite Floor System Using Profiled SheetsArya AsokanОценок пока нет

- JSPL SectionsДокумент7 страницJSPL SectionsDebasish MondalОценок пока нет

- Design of Column For Biaxial BendingДокумент5 страницDesign of Column For Biaxial BendingJitendra Kumar100% (1)

- Design of Combined FootingДокумент23 страницыDesign of Combined Footingsameed malik100% (1)

- Design of Pipe Pedestals:: (IS: 456, PP - No.66)Документ6 страницDesign of Pipe Pedestals:: (IS: 456, PP - No.66)Bhaskar ReddyОценок пока нет

- Steel Bridge DesignДокумент56 страницSteel Bridge Designnavin263Оценок пока нет

- Class A LoadingДокумент120 страницClass A LoadingAakash RastogiОценок пока нет

- Design of Welded Splice Connection (DET.-D-04) : From Staad OutputДокумент10 страницDesign of Welded Splice Connection (DET.-D-04) : From Staad Outputvikas WaghmareОценок пока нет

- Cap PlateДокумент18 страницCap PlateVinoth KumarОценок пока нет

- Water Tank Design (Aci 318-05)Документ8 страницWater Tank Design (Aci 318-05)arnoldОценок пока нет

- Water Tank Design As Per Moody ChartДокумент5 страницWater Tank Design As Per Moody Chartarif_rubin100% (1)

- Composite Slab DesignДокумент6 страницComposite Slab DesignFranklyn GenoveОценок пока нет

- Design of Steel ConnectionsДокумент34 страницыDesign of Steel ConnectionsMashudha Sulthana100% (1)

- Water Tank-Underground-SwapnilДокумент52 страницыWater Tank-Underground-Swapnilneeraj0% (1)

- Grade SlabДокумент16 страницGrade SlabVinay Kumar100% (3)

- Box Culvert-Structural DesignДокумент5 страницBox Culvert-Structural Designsiva100% (1)

- Design and Detailing For Earthquake Loads: IS 800: 2007 SECTION 12Документ21 страницаDesign and Detailing For Earthquake Loads: IS 800: 2007 SECTION 12Anshul SoniОценок пока нет

- Design of Base PlateДокумент14 страницDesign of Base PlateSunidhi ItagiОценок пока нет

- End Plate Beam To Column Moment ConnectionДокумент84 страницыEnd Plate Beam To Column Moment Connectionakshay chauhanОценок пока нет

- Welded Splice ConnectionДокумент14 страницWelded Splice Connectionamitkukna0% (1)

- Corbel Design Spreadsheet To ACI318Документ6 страницCorbel Design Spreadsheet To ACI318LAU TOОценок пока нет

- Bolted Splice DesignДокумент8 страницBolted Splice DesignAnonymous sfkedkymОценок пока нет

- Connection DesignДокумент94 страницыConnection DesignAnand.5100% (1)

- 1 Design Code: Loading Considerations SR No DescriptionДокумент4 страницы1 Design Code: Loading Considerations SR No DescriptionVishal TiwariОценок пока нет

- Angle Brace ConnectionДокумент20 страницAngle Brace Connectionmaheshbandham100% (1)

- Design of 1.50KL OH Tank 9M Staging PDFДокумент21 страницаDesign of 1.50KL OH Tank 9M Staging PDFshivanandarcotОценок пока нет

- Moment Connection Beam Column IS BS SECTION FOR IS800Документ27 страницMoment Connection Beam Column IS BS SECTION FOR IS800JANMESHОценок пока нет

- Bolted Cover Plate Splice Connection B1Документ4 страницыBolted Cover Plate Splice Connection B1ikanyu79Оценок пока нет

- 1 - Inputs: Project Name: Title of Report: 180xx R0yy Input Variable Name Units Symbol Value Formula & InformationДокумент17 страниц1 - Inputs: Project Name: Title of Report: 180xx R0yy Input Variable Name Units Symbol Value Formula & InformationSurya PratapОценок пока нет

- Shear Connection Beam To Beam by Fin Plate by Is CodeДокумент37 страницShear Connection Beam To Beam by Fin Plate by Is CodeStructural SpreadsheetsОценок пока нет

- Purlin Cleat 220908Документ24 страницыPurlin Cleat 220908kalpanaadhi100% (2)

- CorbelДокумент4 страницыCorbelAnand SoniОценок пока нет

- Extended Fin Plate Connection - LRFDДокумент22 страницыExtended Fin Plate Connection - LRFDkalpanaadhiОценок пока нет

- Design of Splice ConnectionДокумент4 страницыDesign of Splice ConnectionJustinОценок пока нет

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Документ3 страницыAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Sheikh Mizanur RahmanОценок пока нет

- 11stiffened Seat ConnectionДокумент5 страниц11stiffened Seat ConnectionAjit SinghОценок пока нет

- 1.0 Beam DesignДокумент8 страниц1.0 Beam Designklynchelle100% (1)

- 1.0 Beam DesignДокумент17 страниц1.0 Beam DesignklynchelleОценок пока нет

- Q&A - Mughal DynastyДокумент5 страницQ&A - Mughal DynastyUttam Kumar GhoshОценок пока нет

- Wood and Armer MethodДокумент1 страницаWood and Armer MethodUttam Kumar GhoshОценок пока нет

- Period of TransitionДокумент9 страницPeriod of TransitionUttam Kumar GhoshОценок пока нет

- Crane DesignДокумент3 страницыCrane DesignUttam Kumar GhoshОценок пока нет

- Section 10 ExemptДокумент2 страницыSection 10 ExemptUttam Kumar GhoshОценок пока нет

- Thrust Block DesignДокумент2 страницыThrust Block DesignUttam Kumar Ghosh100% (2)

- Design of Concrete CorbelДокумент2 страницыDesign of Concrete CorbelUttam Kumar GhoshОценок пока нет

- Design Parameters - Concrete Is 456Документ5 страницDesign Parameters - Concrete Is 456Uttam Kumar GhoshОценок пока нет

- Is Steel SectionДокумент38 страницIs Steel SectionUttam Kumar GhoshОценок пока нет

- Lap DevelopmentДокумент4 страницыLap DevelopmentUttam Kumar GhoshОценок пока нет

- Temperature Moment Calculation: H + K A +a +a KДокумент2 страницыTemperature Moment Calculation: H + K A +a +a KUttam Kumar GhoshОценок пока нет

- Shear With TensionДокумент1 страницаShear With TensionUttam Kumar GhoshОценок пока нет

- Settlement - CalculationДокумент2 страницыSettlement - CalculationUttam Kumar GhoshОценок пока нет

- SK-001 R0Документ1 страницаSK-001 R0Uttam Kumar GhoshОценок пока нет

- Bearing Capacity of Soil As Per IS-6403:1981: Input DataДокумент1 страницаBearing Capacity of Soil As Per IS-6403:1981: Input DataUttam Kumar GhoshОценок пока нет

- Chimney FootingДокумент3 страницыChimney FootingUttam Kumar GhoshОценок пока нет

- Circular Hollow Concrete ColumnДокумент3 страницыCircular Hollow Concrete ColumnUttam Kumar GhoshОценок пока нет

- Pile Load For 10 PilesДокумент3 страницыPile Load For 10 PilesUttam Kumar GhoshОценок пока нет

- Design of Unburned Clinker Silo Based On BS EN 1991-4:2006Документ4 страницыDesign of Unburned Clinker Silo Based On BS EN 1991-4:2006Uttam Kumar GhoshОценок пока нет

- Design Lined CanalsДокумент2 страницыDesign Lined CanalsUttam Kumar GhoshОценок пока нет

- For NB 300: Stress Diagram Is Drawn Only For Load Case-1Документ7 страницFor NB 300: Stress Diagram Is Drawn Only For Load Case-1Uttam Kumar GhoshОценок пока нет

- Design of Concrete CorbelДокумент2 страницыDesign of Concrete CorbelUttam Kumar GhoshОценок пока нет

- Steel Silo Quantity EstimationДокумент4 страницыSteel Silo Quantity EstimationUttam Kumar Ghosh100% (1)

- 1.5DL+1.5LL 1.5DL+1.5WLX+ 1.5DL+1.5WLX-1.5DL+1.5WLZ+ 1.5DL+1.5WLZ - 1.2DL+1.2LL+1.2WLX+ 1.2DL+1.2LL+1.2WLX - 1.2DL+1.2LL+1.2WLZ+ 1.2DL+1.2LL+1.2WLZДокумент1 страница1.5DL+1.5LL 1.5DL+1.5WLX+ 1.5DL+1.5WLX-1.5DL+1.5WLZ+ 1.5DL+1.5WLZ - 1.2DL+1.2LL+1.2WLX+ 1.2DL+1.2LL+1.2WLX - 1.2DL+1.2LL+1.2WLZ+ 1.2DL+1.2LL+1.2WLZUttam Kumar GhoshОценок пока нет

- Stair Wall JointДокумент3 страницыStair Wall JointUttam Kumar GhoshОценок пока нет

- For NB 300: Stress Diagram Is Drawn Only For Load Case-1Документ7 страницFor NB 300: Stress Diagram Is Drawn Only For Load Case-1Uttam Kumar GhoshОценок пока нет

- Stair Wall JointДокумент3 страницыStair Wall JointUttam Kumar GhoshОценок пока нет

- Construction JointДокумент3 страницыConstruction JointUttam Kumar GhoshОценок пока нет

- Base Mom ServiceДокумент1 страницаBase Mom ServiceUttam Kumar GhoshОценок пока нет

- 13C09-008-BBS-001 R0Документ2 страницы13C09-008-BBS-001 R0Uttam Kumar GhoshОценок пока нет

- Steel Pipes C1 C2Документ1 страницаSteel Pipes C1 C2arya asusОценок пока нет

- Brosur GalvalumДокумент6 страницBrosur GalvalumariefОценок пока нет

- Rajat Report On Folding TableДокумент21 страницаRajat Report On Folding TableRajat Thakur0% (1)

- Finit Element Analysis MatlabДокумент3 страницыFinit Element Analysis MatlabAntehun MekonnenОценок пока нет

- Drawing 4.Документ1 страницаDrawing 4.tiyaniОценок пока нет

- United States Patent: (45) Date of Patent: Aug - 21, 2018Документ22 страницыUnited States Patent: (45) Date of Patent: Aug - 21, 2018RiskaОценок пока нет

- Cement Equipment PartsДокумент4 страницыCement Equipment Parts奥世迈拓Оценок пока нет

- Building Structures NotesДокумент23 страницыBuilding Structures Notestwinkle4545Оценок пока нет

- Failure Analysis of Steam Pipe Flange Gasket: Wei Liu and Hehui WangДокумент4 страницыFailure Analysis of Steam Pipe Flange Gasket: Wei Liu and Hehui WangKelvin IbrahimОценок пока нет

- Test-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oДокумент2 страницыTest-IV (Spring, 2015) ME 308 (Heat and Mass Transfer) : o o o o o 2 oKrishnaJaiswal0% (1)

- Cellsite Project: Detailed Design Drawing Greenfield SiteДокумент27 страницCellsite Project: Detailed Design Drawing Greenfield SiteSanday YurfoОценок пока нет

- MATRIX - SCOPE OF SERVICES & Option 1Документ22 страницыMATRIX - SCOPE OF SERVICES & Option 1Cộng đồng Quản lý Xây dựngОценок пока нет

- TEGДокумент12 страницTEGMiloslav Steinbauer100% (1)

- Notes: Electromagnetic InductionДокумент88 страницNotes: Electromagnetic InductionArkaОценок пока нет

- Retaining Wall With Up To 2 Wall Segments: CRSI Example 1 9'-0" HighДокумент1 страницаRetaining Wall With Up To 2 Wall Segments: CRSI Example 1 9'-0" HighAnthony GravagneОценок пока нет

- Mass Timber Construction ManualДокумент81 страницаMass Timber Construction ManualA WebОценок пока нет

- Thermostatic Expansion Valve TroubleshootingДокумент3 страницыThermostatic Expansion Valve TroubleshootingAbdullah HamidОценок пока нет

- Laundry GroupДокумент65 страницLaundry Groupotim timothy williamsОценок пока нет

- SEI FEDRO Guidelines For Integral BridgesДокумент6 страницSEI FEDRO Guidelines For Integral BridgesÁlvaro SerranoОценок пока нет

- DNV RP F106Документ32 страницыDNV RP F106sharif339Оценок пока нет

- Guide To Welding Hot Dip Galvanized Steel v1.0Документ15 страницGuide To Welding Hot Dip Galvanized Steel v1.0pkannanОценок пока нет

- Material Data Sheet Stainless Steel Sheet Aisi 301Документ2 страницыMaterial Data Sheet Stainless Steel Sheet Aisi 301Andrea MartinezОценок пока нет

- Transportation Hub - Sample WorkДокумент17 страницTransportation Hub - Sample WorkMohamed LabibОценок пока нет

- Lecorbusier Tropical Designs PDFДокумент8 страницLecorbusier Tropical Designs PDFglai RamosОценок пока нет

- DE - CM 402 BFT.v02 PDFДокумент13 страницDE - CM 402 BFT.v02 PDFDaryanto GultomОценок пока нет

- Manual T4A3S-B PDFДокумент40 страницManual T4A3S-B PDFCesar Calle JimenezОценок пока нет

- RYfnnd 7 LQ 1180612121529Документ206 страницRYfnnd 7 LQ 1180612121529Bickey LakhaОценок пока нет

- RSW Chiller VKДокумент2 страницыRSW Chiller VKzhyhhОценок пока нет

- Experimental Evaluation of A Solid Desiccant System Integrated With Cross Flow Maisotsenko Cycle Evaporative CoolerДокумент12 страницExperimental Evaluation of A Solid Desiccant System Integrated With Cross Flow Maisotsenko Cycle Evaporative CoolerkashifОценок пока нет

- Cebex 305: Constructive SolutionsДокумент4 страницыCebex 305: Constructive SolutionsBalasubramanian AnanthОценок пока нет