Академический Документы

Профессиональный Документы

Культура Документы

A3150

Загружено:

Pham LongАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A3150

Загружено:

Pham LongАвторское право:

Доступные форматы

3150

PROGRAMMABLE, CHOPPERSTABILIZED, HALL-EFFECT SWITCH

The A3150JLT and A3150JUA programmable switches provide tooth/valley recognition in large gear-tooth sensing applications. Each sensor consists of a single element, chopper-stabilized Hall-effect IC that can be programmed to the desired magnetic switch point, optimizing sensor airgap and timing accuracy performance after final packaging. The small package can be easily assembled and used in conjunction with a wide variety of gear/target shapes and sizes. The two devices differ only in package style. The sensing technology used for this sensor is Hall-effect based. The sensor incorporates a single-element Hall IC that switches in response to magnetic signals created by a ferrous target. The programmability of the circuit eliminates magnet and system offsets such as those caused by tilt yet provides zero-speed detection capabilities without the associated running jitter inherent in classical digital solutions. A proprietary dynamic offset cancelation technique, with an internal high-frequency clock, reduces the residual offset voltage, which is normally caused by device overmolding, temperature dependancies, and thermal stress. This technique produces devices that have an extremely stable quiescent output voltage, are immune to mechanical stress, and have precise recoverability after temperature cycling. Many problems normally associated with low-level analog signals are minimized by having the Hall element and amplifier in a single chip. Output precision is obtained by internal gain adjustments during the manufacturing process and operate-point programming in the users application. This sensor system is ideal for use in gathering speed, position, and timing information using gear-tooth-based configurations. The A3150JLT/JUA are particularly suited to those applications that require accurate duty cycle control or accurate edge detection. The lower vibration sensitivity also makes these devices extremely useful for transmission speed sensing.

Continued next page

Data Sheet 27621.40

PTCT

PRELIMINARY INFORMATION

(subject to change without notice)

ABSOLUTE MAXIMUM RATINGS

at TA = 25C

Supply Voltage, VCC ........................... 26.5 V Reverse Supply Voltage, VRCC ............ -30 V Overvoltage Supply Current, ICC ..... 100 mA Magnetic Flux Density, B ............ Unlimited Output Current, IOUT ..... Internally Limited Output OFF Voltage, VOUT ................. 26.5 V Reverse Output Current, IROUT ......... -50 mA Operating Temperature Range, TA ............................... -40C to +115C Storage Temperature, TS ................... +170C

T C . U Y D L N O n R O P E sig D C e E d N U E w N R e I E n T F r N E o f O R 0 C S OR 25 I D F A3 se U

V

CC

GROUND

Dwg. PH-003-2

April 12, 1999

OUTPUT

SUPPLY

Always order by complete part number: the prefix 'A' + the basic four-digit part number + a suffix to indicate operating temperature range + a suffix to indicate package style, e.g., A3150JLT .

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

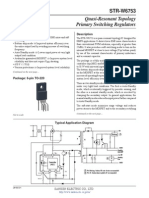

FUNCTIONAL BLOCK DIAGRAM

1 SUPPLY

REG. PROGRAM LOGIC OFFSET ADJUST

DYNAMIC OFFSET CANCELLATION

POWER-UP OUTPUT

SAMPLE & HOLD

LOW-PASS FILTER

3 CONTROL

CURRENT LIMIT <1 GROUND 2

Dwg. FH-020-3

Two package styles provide a magnetically optimized package for most applications. Suffix LT is a miniature SOT-89/TO-243AA transistor package for surface-mount applications; while suffix UA is a three-lead ultra-mini-SIP for through-hole mounting.

FEATURES AND BENEFITS

s Chopper Stabilized for Extremely Low Switch-Point Drift and Immunity to Mechanical Stress s Externally Programmed Switch Point s On-Chip Supply-Transient Protection s Output Short-Circuit Protection s Single-Chip Sensing IC for High Reliability s Small Mechanical Size s <50 s Power-On Time s Wide Operating Voltage Range s Defined Power-On State

115 Northeast Cutoff, Box 15036 Worcester, Massachusetts 01615-0036 (508) 853-5000 Copyright 2000, Allegro MicroSystems, Inc.

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

ELECTRICAL CHARACTERISTICS over operating voltage and temperature range (unless otherwise noted).

Limits Characteristic Supply Voltage Power-On State Low Output Voltage Output Current Limit Output Leakage Current Supply Current Symbol VCC POS VOUT(SAT) IOUTM IOFF ICC Test Conditions Operating, TJ < 165C After programming, VCC = 0 5 V IOUT = 20 mA VOUT = 12 V VOUT = 24 V Before programming, output OFF Before programming, output ON Reverse Supply Current Power-On Delay Output Rise Time Output Fall Time Clock Frequency Zener Voltage Zener Impedance IRCC ton tr tf fC VZ zz IZT = 100 A, TA = 25C IZT = 10 mA, TA = 25C VRCC = -30 V VCC > 5 V RL = 820 , CL = 20 pF RL = 820 , CL = 20 pF Min. 4.25 HIGH 65 27 Typ. HIGH 175 80 0.2 4.0 5.0 20 200 100 340 32 50 Max. 26 HIGH 400 95 10 7.0 8.0 -5.0 50 100 Units V mV mA A mA mA mA s ns ns kHz V

NOTE: Typical data is at VCC = 5 V and TA = +25C and is for design information only.

MAGNETIC CHARACTERISTICS over operating supply voltage and temperature ranges.

Limits Characteristic Operate Point Symbol BOP Test Conditions Programmable offset range Initial (before programming) Resolution BOP Hysteresis Bhys VCC = 14 V, after programming, BOP 500 G Min. 500 0 8.0 -35 5.0 Typ. 670 20 11 8.0 20 Max. 850 40 14 +35 35 Units G G G G G

NOTE: Typical data is at VCC = 5 V and TA = +25C and is for design information only.

www.allegromicro.com

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

TYPICAL ELECTRICAL CHARACTERISTICS

5.0

10 T A = +25C

4.0

SUPPLY CURRENT IN mA

SUPPLY CURRENT IN mA

B > B OP

V CC = 5 V

8.0

6.0 B > B OP 4.0 B < B RP 2.0

3.0 B < B RP

2.0

1.0 -50 -25 0 25 50 75 100 125 150

0 0 5 10 15 20 25

AMBIENT TEMPERATURE IN C

Dwg. GH-053-2

SUPPLY VOLTAGE IN VOLTS

Dwg. GH-041-2

300

I OUT = 20 mA V CC = 4.524 V

SATURATION VOLTAGE IN mV

200

100

0 -50

-25

25

50

75

100

125

150

AMBIENT TEMPERATURE IN C

Dwg. GH-040-4

115 Northeast Cutoff, Box 15036 Worcester, Massachusetts 01615-0036 (508) 853-5000

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

FUNCTIONAL DESCRIPTION

Chopper-Stabilized Technique. These devices use a proprietary dynamic offset cancellation technique, with an internal high-frequency clock to reduce the residual offset voltage of the Hall element that is normally caused by device overmolding, temperature dependencies, and thermal stress. This technique produces devices that have an extremely stable quiescent Hall output voltage, are immune to thermal stress, and have precise recoverability after temperature cycling. This technique will also slightly degrade the device output repeatability. The Hall element can be considered as a resistor array similar to a Wheatstone bridge. A large portion of the offset is a result of the mismatching of these resistors. The chopperstabilizing technique cancels the mismatching of the resistors by changing the direction of the current flowing through the Hall plate and Hall voltage measurement taps, while maintaining the Hall-voltage signal that is induced by the external magnetic flux. The signal is, then, captured by a sample-and-hold circuit. Operation. The output of these devices switches low (turns ON) when a magnetic field (south pole) perpendicular to the Hall sensor exceeds the operate point threshold (BOP). After turn-ON, the output is capable of sinking 25 mA and the output voltage is VOUT(SAT). When the magnetic field is reduced below the release point (BRP), the device output goes high (turns OFF). The difference in the magnetic operate and release points is the hysteresis (Bhys) of the device. This built-in hysteresis allows clean switching of the output even in the presence of external mechanical vibration and electrical noise. Applications. It is strongly recommended that an external bypass capacitor be connected (in close proximity to the Hall sensor) between the supply and ground of the device to reduce both external noise and noise generated by the chopper-stabilization technique. The simplest form of magnet that will operate these devices is a bar magnet with the south-seeking pole towards the branded surface of the device. Many other methods of operation are possible. Extensive applications information on magnets and Hall-effect sensors is also available in the Allegro Electronic Data Book AMS-702 or Application Note 27701, or

REG

B +V

HALL VOLTAGE

+

Dwg. AH-011-2

+V

VCC

OUTPUT VOLTAGE

B RP

B OP

VOUT(SAT)

0 0 FLUX DENSITY +B

Dwg. GH-007-2

SUPPLY

PTCT

0.1 F

CC

www.allegromicro.com

Dwg. EH-013

www.allegromicro.com

SAMPLE & HOLD

Dwg. EH-012

OUTPUT

SUPPLY

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

PROGRAMMING PROTOCOL

The A3150JLT and A3150JUA operate points are programmed by serially addressing the device through the supply terminal (pin1). After the correct operate point is determined, the device programming bits are selected and then a lock set to prevent any further (accidental) programming. Program Enable. To program the device, a sequence of pulses is used to activate/enable the addressing mode as shown in figure 1. This sequence of a VPP pulse, at least seven VPH pulses, and a VPP pulse with no supply interruptions, is designed to prevent the device from being programmed accidentally (for example, as a result of noise on the supply line).

VPP

PROGRAM ENABLE (AT LEAST 7 PULSES)

VPH VPL td(1) 0 td(1) td(0)

Figure 1 Program enable

Dwg. WH-013

PROGRAMMING PROTOCOL over operating temperature range.

Limits Characteristic Programming Voltage Symbol VPL VPH VPP Programming Current Pulse Width IPP td(0) td(1) tdP Pulse Rise Time Pulse Fall Time tr tf Max. supply current during programming OFF time between bits Enable, address, program, or lock bit ON time Program pulse ON time VPL to VPH or VPP VPH or VPP to VPL Description Minimum voltage during programming Min. 4.5 9.0 20 20 20 100 11 5.0 Typ. 5.0 10 23 250 300 Max. 5.5 11 25 Units V V V mA s s s s s

NOTE: Typical data is at TA = +25C and is for design information only.

115 Northeast Cutoff, Box 15036 Worcester, Massachusetts 01615-0036 (508) 853-5000

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

Address Determination. The operate point is adjustable in 64 increments. With the appropriate target or gear* in position, the 64 switch points are sequentially selected (figure 2) until the required operate point is reached. Note that the difference between the operate point and the release point (hysteresis) is a constant for all addresses. Set-Point Programming. After the desired set-point address is determined (0 through 63), each bit of the equivalent binary address is programmed individually. For example, as illustrated in figure 3, to program address code 5 (binary 000101), bits 1 and 3 need to be programmed. Each bit is programmed during the wide VPP pulse and is not reversible. Lock Programming. After the desired set point is programmed, the program lock is then activated (figure 4) to prevent further programming of the device.

ADDRESS N-2

ADDRESS N-1

td(0)

VPH VPL td(1) 0

Dwg. WH-014

Figure 2 Address determination

VPP

PROGRAM ENABLE

BIT 3 PROGRAM (000100) ADDRESS 4

PROGRAM ENABLE

VPH VPL td(1) 0 td(1) td(0) tdP

Figure 3 Set-point programming

VPP

PROGRAM ENABLE

LOCK PROGRAM (65 PULSES)

VPH VPL td(1) 0

Dwg. WH-016

td(1)

td(0)

tdP

Figure 4 Lock programming

* In application, the terms gear and target are often interchanged. However, gear is preferred when motion is transferred.

www.allegromicro.com

BIT 1 PROGRA

Dwg. WH-015

ADDRESS N (UP TO 63)

ADDRESS 0

ADDRESS 1

ADDRESS 2

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

CRITERIA FOR DEVICE QUALIFICATION

All Allegro sensors are subjected to stringent qualification requirements prior to being released to production. To become qualified, except for the destructive ESD tests, no failures are permitted. Qualification Test Biased Humidity (HAST) High-Temperature Operating Life (HTOL) Accelerated HTOL Test Method and Test Conditions TA = 130C, RH = 85% JESD22-A108, TA = 150C, TJ = 165C JESD22-A108, TA = 175C, TJ = 190C JESD22-A102, Condition C, TA = 121C, 15 psig MIL-STD-883, Method 1008, TA = 170C MIL-STD-883, Method 1010, -65C to +150C Test Length 50 hrs 408 hrs Samples 77 77 Comments VCC = VOUT = 5 V VCC = 24 V, VOUT = 20 V VCC = 24 V, VOUT = 20 V

504 hrs

77

Autoclave, Unbiased

96 hrs

77

High-Temperature (Bake) Storage Life Temperature Cycle

1000 hrs

77

500 cycles

77

Latch-Up

Pre/Post Reading Pre/Post Reading Pre/Post Reading

Electro-Thermally Induced Gate Leakage ESD, Human Body Model Electrical Distributions

CDF-AEC-Q100-002

x per test 30

Test to failure, All leads > TBD

Per Specification

115 Northeast Cutoff, Box 15036 Worcester, Massachusetts 01615-0036 (508) 853-5000

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

(0.005 [0.13 mm] die placement) Package Designator LT

ACTIVE AREA DEPTH 0.030" 0.76 mm NOM

SENSOR LOCATIONS

0.088" 2.24 mm 0.045" 1.14 mm

A

1 2 3

Dwg. MH-008-8

Package Designators UA and "UA-TL"

ACTIVE AREA DEPTH 0.018" 0.46 mm NOM

0.080" 2.04 mm

0.056" 1.44 mm

A

BRANDED SURFACE 1 2 3

Dwg. MH-011-9A

Although sensor location is accurate to three sigma for a particular design, product improvements may result in small changes to sensor location.

Allegro

www.allegromicro.com

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

PACKAGE DESIGNATOR 'LT'

(SOT-89/TO-243AA) Dimensions in Inches (for reference only) Dimensions in Millimeters (controlling dimensions)

0.181 0.173 0.072 0.064 0.167 0.155 0.102 0.090

0.063 0.055

0.0173 0.0138

4.60 4.40 1.83 1.62 4.25 3.94 2.60 2.29

1.60 1.40

0.44 0.35

0.090 0.084

2.29 2.13

0.047 0.035 0.059

BSC

0.0189 0.0142 0.0221 0.0173 0.118

BSC

Dwg. MA-009-3A in

1.20 0.89 1.50

BSC

0.48 0.36 0.56 0.44 3.00

BSC

Dwg. MA-009-3A mm

0.098 0.079 B A 0.031 0.102 0.181 3 0.047 0.031

TYP

2.5 2.0 B A 0.8 2.6 4.6 1.2 0.8

TYP

1 0.028

TYP

1 0.7

TYP

ads 1, 2, 3, and A Standard SOT-89 Layout ads 1, 2, 3, and B Low-Stress Version ads 1, 2, and 3 only Lowest Stress, But Not Self Aligning

Dwg. MA-012-3 in

Pads 1, 2, 3, and A Standard SOT-89 Layout Pads 1, 2, 3, and B Low-Stress Version Pads 1, 2, and 3 only Lowest Stress, But Not Self Aligning

Dwg. MA-012-3 mm

NOTE: Exact body and lead configuration at vendors option within limits shown.

115 Northeast Cutoff, Box 15036 Worcester, Massachusetts 01615-0036 (508) 853-5000

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

PACKAGE DESIGNATOR 'UA'

Dimensions in Inches (controlling dimensions)

0.164 0.159

Dimensions in Millimeters (for reference only)

4.17 4.04

45

0.062 0.058

45

1.57 1.47

0.122 0.117

45 0.031

3.10 2.97

45 0.79

0.085

MAX

2.16

MAX

0.640 0.600

0.0173 0.0138

16.26 15.24

0.44 0.35

SEE NOTE

0.0189 0.0142

SEE NOTE

0.48 0.36

0.050

BSC

Dwg. MH-014E in

1.27

BSC

Dwg. MH-014E mm

Surface-Mount Lead Form (Suffix '-TL')

0.095

0.005

2.41

0.13

0.002

MAX

0.051

MAX

0.004 08

MAX

0.020

MIN FLAT

Dwg. MH-015 in

0.10

MAX

08

0.51

MIN FLAT

Dwg. MH-015 mm

NOTES: 1. Tolerances on package height and width represent allowable mold offsets. Dimensions given are measured at the widest point (parting line). 2. Exact body and lead configuration at vendors option within limits shown. 3. Height does not include mold gate flash. 4. Recommended minimum PWB hole diameter to clear transition area is 0.035 (0.89 mm). 5. Where no tolerance is specified, dimension is nominal.

www.allegromicro.com

3150 PROGRAMMABLE, CHOPPERSTABILIZED, PRECISION, HALL-EFFECT SWITCH

The products described herein are manufactured under one or more of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283; 5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719; 5,686,894; 5,694,038; 5,729,130; 5,917,320; and other patents pending. Allegro MicroSystems, Inc. reserves the right to make, from time to time, such departures from the detail specifications as may be required to permit improvements in the performance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that the information being relied upon is current. Allegro products are not authorized for use as critical components in life-support appliances, devices, or systems without express written approval. The information included herein is believed to be accurate and reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringements of patents or other rights of third parties that may result from its use.

115 Northeast Cutoff, Box 15036 Worcester, Massachusetts 01615-0036 (508) 853-5000

Вам также может понравиться

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- A1250 DatasheetДокумент12 страницA1250 DatasheetAlexandre CalixtoОценок пока нет

- Ratiometric, Linear Hall-Effect Sensors For High-Temperature OperationДокумент13 страницRatiometric, Linear Hall-Effect Sensors For High-Temperature OperationLuiz JesusОценок пока нет

- Micropower, Ultra-Sensitive Hall Effect Switch - Farnell UkДокумент12 страницMicropower, Ultra-Sensitive Hall Effect Switch - Farnell Uklxz5101Оценок пока нет

- A1230 DatasheetДокумент17 страницA1230 DatasheetBruno Koch SchmittОценок пока нет

- Uc3842b 3843BДокумент10 страницUc3842b 3843Bbob75Оценок пока нет

- A132XДокумент10 страницA132XAndres CamachoiОценок пока нет

- Data SheetДокумент7 страницData SheetOvi PanteaОценок пока нет

- CA3080Документ12 страницCA3080yusufwpОценок пока нет

- Discontinued Product: Ratiometric Linear Hall Effect Sensor Ics For High-Temperature OperationДокумент13 страницDiscontinued Product: Ratiometric Linear Hall Effect Sensor Ics For High-Temperature OperationceferrruОценок пока нет

- Dse STR A6000mДокумент13 страницDse STR A6000mAlanОценок пока нет

- STRW6754Документ9 страницSTRW6754electronicaliderОценок пока нет

- Hall Effect Latch A1220LUA-T-IC SipДокумент14 страницHall Effect Latch A1220LUA-T-IC Sipwaseemanwar321Оценок пока нет

- 3132Документ7 страниц3132Wilson NgОценок пока нет

- STR W6735Документ14 страницSTR W6735proctepОценок пока нет

- STR W6053SДокумент14 страницSTR W6053SMarcos Rangel100% (1)

- Data SheetДокумент12 страницData SheetMarcoAntonioCamanTraihuelОценок пока нет

- STR W6000S Series Application NoteДокумент20 страницSTR W6000S Series Application NoteSutrisno OkОценок пока нет

- 000 1 L6380Документ9 страниц000 1 L6380Ishak Khan GulamОценок пока нет

- STR-A6151 STR-A6159: Universal-Input/13 or 16 W Flyback Switching RegulatorsДокумент7 страницSTR-A6151 STR-A6159: Universal-Input/13 or 16 W Flyback Switching RegulatorsmilebaleОценок пока нет

- STR S5707 STR S5708 DatasheetДокумент9 страницSTR S5707 STR S5708 DatasheetJose Gregorio Sanchez Araujo0% (1)

- CA3140Документ20 страницCA3140Brzata PticaОценок пока нет

- Chip Ca3098eДокумент12 страницChip Ca3098etopogigio240Оценок пока нет

- ACS713-Datasheet - Current Sensor ICДокумент14 страницACS713-Datasheet - Current Sensor ICphase90Оценок пока нет

- Allegro STR-W6765 PDFДокумент15 страницAllegro STR-W6765 PDFcomportОценок пока нет

- SG 3524Документ10 страницSG 3524Akhlaque ShamsiОценок пока нет

- Ca3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesДокумент19 страницCa3140, Ca3140A: 4.5Mhz, Bimos Operational Amplifier With Mosfet Input/Bipolar Output FeaturesRicardo Teixeira de AbreuОценок пока нет

- STR-A6151 STR-A6159: Universal-Input/13 or 16 W Flyback Switching RegulatorsДокумент7 страницSTR-A6151 STR-A6159: Universal-Input/13 or 16 W Flyback Switching RegulatorsVidal VelasquezОценок пока нет

- Datasheet STR 6757Документ11 страницDatasheet STR 6757Walter CarreroОценок пока нет

- ACS714Документ15 страницACS714connect2nsОценок пока нет

- A3423 Datasheet PDFДокумент10 страницA3423 Datasheet PDFRuannytha RibeiroОценок пока нет

- Features Description: FM IF SystemДокумент7 страницFeatures Description: FM IF Systemlu1agpОценок пока нет

- A 3423 Hall Effect EncordorДокумент9 страницA 3423 Hall Effect Encordortabassam7801Оценок пока нет

- Sla7024 26 29mДокумент12 страницSla7024 26 29mbashtavОценок пока нет

- PD Derated at 8.5mW/ For Temperature Above Ta 25 (When Mounted On A PCB 70.0mm×70.0mm×1.6mm)Документ5 страницPD Derated at 8.5mW/ For Temperature Above Ta 25 (When Mounted On A PCB 70.0mm×70.0mm×1.6mm)Osama YaseenОценок пока нет

- Sla7024m PDFДокумент12 страницSla7024m PDFEJASMANYОценок пока нет

- ACS712 DatasheetДокумент15 страницACS712 DatasheetHernan PorriniОценок пока нет

- STR W6735 DatasheetДокумент13 страницSTR W6735 DatasheetloagerОценок пока нет

- UDN2916Документ10 страницUDN2916ejoaomelchiorsОценок пока нет

- Sla7024m (Motor Driver)Документ13 страницSla7024m (Motor Driver)Franklin Miranda RoblesОценок пока нет

- STR W6753 DatasheetДокумент8 страницSTR W6753 DatasheetjgerabmОценок пока нет

- Ivc102 DatasheetДокумент15 страницIvc102 DatasheetChristian CândidoОценок пока нет

- 12 Volt Smps Circuit DiagramДокумент7 страниц12 Volt Smps Circuit DiagramAnura MaddumageОценок пока нет

- Ca3080, Ca3080A: 2Mhz, Operational Transconductance Amplifier (Ota) FeaturesДокумент11 страницCa3080, Ca3080A: 2Mhz, Operational Transconductance Amplifier (Ota) FeaturesToshang SharmaОценок пока нет

- 000 1 Ca3109Документ20 страниц000 1 Ca3109moongaboongaОценок пока нет

- Imprimir Datasheet 1Документ14 страницImprimir Datasheet 1Randy Siancas VelezОценок пока нет

- Sanyo Avm2751s Service ManualДокумент26 страницSanyo Avm2751s Service ManualKastaliaОценок пока нет

- A5800 and A5801: Discontinued ProductДокумент13 страницA5800 and A5801: Discontinued Productitamar_123Оценок пока нет

- FP 6291 V 070Документ11 страницFP 6291 V 070rems69Оценок пока нет

- 1 Performance DataДокумент9 страниц1 Performance DataYusep KurniaОценок пока нет

- Ca3080 Ca3080a Intersil PDFДокумент11 страницCa3080 Ca3080a Intersil PDFsomtchekusОценок пока нет

- SG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorДокумент10 страницSG3525A Pulse Width Modulator Control Circuit: 1% and The ErrorJayesh SuryavanshiОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsОт EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsРейтинг: 3.5 из 5 звезд3.5/5 (6)

- Renishaw Ballbar LaserДокумент21 страницаRenishaw Ballbar LaserPham LongОценок пока нет

- Mitsubishi Manual Fx5-40ssc AdvancedДокумент598 страницMitsubishi Manual Fx5-40ssc AdvancedPham LongОценок пока нет

- Handle PulseДокумент17 страницHandle PulsePham LongОценок пока нет

- NSK CAT E1102m B234-243Документ5 страницNSK CAT E1102m B234-243LeandroОценок пока нет

- CNC Advanced ConceptsДокумент100 страницCNC Advanced ConceptsPham LongОценок пока нет

- NSK CAT E1102m B234-243Документ5 страницNSK CAT E1102m B234-243LeandroОценок пока нет

- Yuasa International: Full 4 Axis vs. Programmable Indexer?Документ4 страницыYuasa International: Full 4 Axis vs. Programmable Indexer?Pham LongОценок пока нет

- NSK CAT E1102m B234-243Документ5 страницNSK CAT E1102m B234-243LeandroОценок пока нет

- TM A1000sw 063Документ36 страницTM A1000sw 063Pham LongОценок пока нет

- H PulseДокумент18 страницH PulsePham LongОценок пока нет

- H PulseДокумент18 страницH PulsePham LongОценок пока нет

- SU-matic Instruction ManualДокумент12 страницSU-matic Instruction ManualPham LongОценок пока нет

- G Code List OkumaДокумент10 страницG Code List OkumaPham Long50% (2)

- UE-42-09-fiber Optic Catalog Med PDFДокумент40 страницUE-42-09-fiber Optic Catalog Med PDFPham LongОценок пока нет

- GT User Manual Revision 1.10Документ66 страницGT User Manual Revision 1.10Pham LongОценок пока нет

- Tny267pn PDFДокумент24 страницыTny267pn PDFPham LongОценок пока нет

- Delta Ispsoft M en 20130118Документ617 страницDelta Ispsoft M en 20130118Daniel Iurck VosgerauОценок пока нет

- Micro Smart ManualДокумент455 страницMicro Smart ManualDaniel HilariОценок пока нет

- NX 10 For Engineering Design PDFДокумент207 страницNX 10 For Engineering Design PDFAnonymous EVAzqFeburОценок пока нет

- Radioactive PrincipleДокумент17 страницRadioactive PrincipleHenry LingОценок пока нет

- Parallel Port Interfacing Inpout32 DLL Source Code and TheoryДокумент2 страницыParallel Port Interfacing Inpout32 DLL Source Code and TheoryPham LongОценок пока нет

- 7mbp75ra060 PDFДокумент8 страниц7mbp75ra060 PDFPham LongОценок пока нет

- Analog Drive Configuration and Setup NotesДокумент3 страницыAnalog Drive Configuration and Setup NotesPham LongОценок пока нет

- Manual For USB To 9 Pin RS 232 Serial Adaptor PDFДокумент20 страницManual For USB To 9 Pin RS 232 Serial Adaptor PDFPham LongОценок пока нет

- 6sn1145 1aa01 0aa2 ManualДокумент485 страниц6sn1145 1aa01 0aa2 ManualjohnysonycumОценок пока нет

- CH 17 SCR IGBTДокумент14 страницCH 17 SCR IGBTPham LongОценок пока нет

- NextMove Input and Output CircuitДокумент2 страницыNextMove Input and Output CircuitPham LongОценок пока нет

- A F700 PID ControlДокумент8 страницA F700 PID ControlPham LongОценок пока нет

- Rs 232 For Ka CounterДокумент4 страницыRs 232 For Ka CounterPham LongОценок пока нет

- France: French HistoryДокумент16 страницFrance: French HistoryMyroslava MaksymtsivОценок пока нет

- Introduction To Streering Gear SystemДокумент1 страницаIntroduction To Streering Gear SystemNorman prattОценок пока нет

- Executive Education Portfolio Soft Copy-INSEADДокумент58 страницExecutive Education Portfolio Soft Copy-INSEADОля КусраеваОценок пока нет

- Bethany Getz ResumeДокумент2 страницыBethany Getz Resumeapi-256325830Оценок пока нет

- Linguistics: Chapter 1 - 10Документ41 страницаLinguistics: Chapter 1 - 10Ahmad A. JawadОценок пока нет

- Biomechanics of Advanced Tennis: January 2003Документ7 страницBiomechanics of Advanced Tennis: January 2003Katrien BalОценок пока нет

- Choose the Best WordДокумент7 страницChoose the Best WordJohnny JohnnieeОценок пока нет

- MSC Euribia - 2023-06-01Документ2 страницыMSC Euribia - 2023-06-01蔡國懷Оценок пока нет

- Long Run Average Cost (LRAC) : Economies of ScaleДокумент3 страницыLong Run Average Cost (LRAC) : Economies of ScaleA PОценок пока нет

- Jesus - The Creator Unleashes Our Creative PotentialДокумент1 страницаJesus - The Creator Unleashes Our Creative PotentialKear Kyii WongОценок пока нет

- Migration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Документ28 страницMigration (LIN 19/051: Specification of Occupations and Assessing Authorities) Instrument 2019Ajay palОценок пока нет

- Critique On A Film Director's Approach To Managing CreativityДокумент2 страницыCritique On A Film Director's Approach To Managing CreativityDax GaffudОценок пока нет

- The Invisible Hero Final TNДокумент8 страницThe Invisible Hero Final TNKatherine ShenОценок пока нет

- All MeterialsДокумент236 страницAll MeterialsTamzid AhmedОценок пока нет

- Research Paper Theory of Mind 2Документ15 страницResearch Paper Theory of Mind 2api-529331295Оценок пока нет

- Future Design of Accessibility in Games - A Design Vocabulary - ScienceDirectДокумент16 страницFuture Design of Accessibility in Games - A Design Vocabulary - ScienceDirectsulaОценок пока нет

- The Impact of Information Technology and Innovation To Improve Business Performance Through Marketing Capabilities in Online Businesses by Young GenerationsДокумент10 страницThe Impact of Information Technology and Innovation To Improve Business Performance Through Marketing Capabilities in Online Businesses by Young GenerationsLanta KhairunisaОценок пока нет

- Trove Research Carbon Credit Demand Supply and Prices 1 June 2021Документ51 страницаTrove Research Carbon Credit Demand Supply and Prices 1 June 2021Ceren ArkancanОценок пока нет

- Published Filer List 06072019 Sorted by CodeДокумент198 страницPublished Filer List 06072019 Sorted by Codeherveduprince1Оценок пока нет

- Aircraft ChecksДокумент10 страницAircraft ChecksAshirbad RathaОценок пока нет

- Chapter 1 - IntroductionДокумент42 страницыChapter 1 - IntroductionShola ayipОценок пока нет

- Medical filter performance specificationsДокумент1 страницаMedical filter performance specificationsPT.Intidaya Dinamika SejatiОценок пока нет

- RestrukturisasiДокумент17 страницRestrukturisasimuhammad hayel wallaОценок пока нет

- Rubric - Argumentative EssayДокумент2 страницыRubric - Argumentative EssayBobОценок пока нет

- Dell EMC VPLEX For All-FlashДокумент4 страницыDell EMC VPLEX For All-Flashghazal AshouriОценок пока нет

- CH - 3Документ3 страницыCH - 3Phantom GamingОценок пока нет

- Call SANROCCO 11 HappybirthdayBramanteДокумент8 страницCall SANROCCO 11 HappybirthdayBramanterod57Оценок пока нет

- Joyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Документ11 страницJoyful Living: (Based On Chapter 13: Advaitananda Prakaranam of Panchadashi of Sri Vidyaranya Swami)Raja Subramaniyan100% (1)

- Guidelines 2.0Документ4 страницыGuidelines 2.0Hansel TayongОценок пока нет

- Week 6Документ7 страницWeek 6Nguyễn HoàngОценок пока нет