Академический Документы

Профессиональный Документы

Культура Документы

SPE 71749 Geological Sequestration of CO in Deep, Unmineable Coalbeds: An Integrated Research and Commerical-Scale Field Demonstration Project

Загружено:

tassili17Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SPE 71749 Geological Sequestration of CO in Deep, Unmineable Coalbeds: An Integrated Research and Commerical-Scale Field Demonstration Project

Загружено:

tassili17Авторское право:

Доступные форматы

SPE 71749 Geological Sequestration of CO2 in Deep, Unmineable Coalbeds: An Integrated Research and Commerical-Scale Field Demonstration Project

Scott R. Reeves, Advanced Resources International

Copyright 2001, Society of Petroleum Engineers Inc. This paper was prepared for presentation at the 2001 SPE Annual Technical Conference and Exhibition held in New Orleans, Louisiana, 30 September-3 October 2001. This paper was selected for presentation by an SPE Program Committee following review of information contained in an abstract submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material, as presented, does not necessarily reflect any position of the Society of Petroleum Engineers, its officers, or members. Papers presented at SPE meetings are subject to publication review by Editorial Committees of the Society of Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300 words; illustrations may not be copied. The abstract must contain conspicuous acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O. Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

presents the fundamental reservoir mechanisms of CO2 sequestration and enhanced recovery of methane from coalseams, and the field performances to date of the Tiffany and Allison Units.

Introduction and Background The concentration of carbon dioxide (CO2 ) in the atmosphere is rising and, due to growing concern about its effects, the U.S. and over 160 other countries ratified the Rio Mandate in 1992, which calls for stabilization of greenhouse gas concentrations in the atmosphere at a level that would prevent dangerous anthropogenic interference with the climate system. Since under virtually any stabilization or market scenario fossil fuels will remain the mainstay of energy production for the foreseeable future even modest stabilization will require enormous reductions in greenhouse gas (GHG) emissions resulting from fossil fuel use; energy-related CO2 emissions resulting from fossil-fuel combustion account for 82% of all U.S. GHG emissions1 . Further, in addition to emissions reductions via fuel-switching, conservation, and efficiency improvements, achieving atmospheric stabilization that is deemed acceptable will require large-scale, low-cost sequestration of carbon, a need for which no cost-effective technology exists today. As a result, the U.S. Department of Energy (DOE) developed its carbon sequestration R&D program, which addresses the entire carbon sequestration life cycle of capture, separation, transport, and storage or reuse. As a first priority, the sequestration pathways being pursued by the program are those that can impact large point-source CO2 emissions, offer large CO2 storage capacities, and can accomplish sequestration at comparatively lower costs. In terms of large CO2 point-sources, power plants represent the greatest opportunity due to their large-scale, stationary nature; the electric power industry accounts for 41% of all energyrelated CO2 emissions1 . Furthermore, coal-fired plants account for 81% of that, or one-third of total energy-related CO2 emissions. In terms of sequestration, geologic options for value-added sequestration with multiple benefits, such as using CO2 in enhanced oil recovery (EOR) operations and in methane production from deep, unmineable coal seams,

Abstract Coalseams represent an attractive opportunity for near-term sequestration of large volumes of anthropogenic CO2 at low net costs. There are several reasons for this: Coals have the ability to physically adsorb large volumes of CO2 in a highly concentrated state. Coals are frequently located near large point sources of CO2 emissions, specifically power generation plants. The injection of CO2 into coalseams actually enhances the commercial methane recovery process. The recovery of coalbed methane is enhanced when the injected gas contains nitrogen, a major constituent of power plant flue gas.

A joint U.S. Department of Energy and industry project to study the reservoir mechanisms and field performance of CO2 sequestration in coalseams has recently been initiated. The project involves laboratory and field-testing to define critical reservoir mechanisms, including multi-component (CO2 -CH4 N2 ternary) sorption behavior. Two existing fields in the San Juan Basin, the most prolific coalbed methane basin in the world, are currently under CO2 and/or N2 injection. These two fields, the Tiffany Unit (operated by BP) now under N2 injection (but with mixed CO2 /N2 injection being studied), and the Allison Unit (operated by Burlington Resources) under CO2 injection since 1995 will be thoroughly studied via reservoir simulation to understand CO2 sequestration and enhanced coalbed methane recovery performance, using both pure CO2 and N2 , as well as CO2 /N2 mixtures. This paper

SCOTT R. REEVES

SPE 71749

provide the greatest opportunity for near-term, low net-cost CO2 sequestration, and hence are of immediate interest. This paper addresses one of the options that meet these immediate program objectivesthe geologic sequestration of CO2 in deep, unmineable coalbeds. The concept and synergies of CO2 sequestration and enhanced coalbed methane (ECBM) recovery are illustrated in Figure 1. Here, a flue gas (presumably with some pre-treatment for contaminant and/or dilutant removal) from a power plant is injected into nearby coal seams, where the CO2 is sequestered and methane production from the coal is enhanced. The produced methane is sold to reduce the net cost of CO2 sequestration (and in some cases make it profitable), and increases the supply of a more environmentally friendly fossil fuel for use at the plant or elsewhere. The opportunities to actually achieve these synergies, in particular the coincidence of large power plants near deep, unminable coal deposits, are shown in Figure 21,2,3 . This map shows the locations of known coal deposits and large (>1,000 megawatt) coal-fired power plants. States with the greatest total CO2 emissions are also highlighted. Clearly there appear to be many opportunities where the proposed scheme might be implemented, particularly along the Texas Gulf Coast, Northern Appalachia, and Illinois/Indiana. Additional opportunities also exist in the Mid-Continent and Rocky Mountain regions. In response to these opportunities, in October 2000 the U.S. DOE awarded a 3-year R&D contract to Advanced Resources International (ARI) for the purpose of studying and understanding the reservoir mechanisms of CO2 sequestration and ECBM via a combination of laboratory studies and field demonstrations. The field sites are in the San Juan Basin, the premier coalbed methane (CBM) basin in the U.S., if not the world. A rigorous program of science and reservoir engineering will be performed, including extensive single-, binary-, and ternary-component isotherm testing, to provide a strong research foundation for understanding the performance of the field projects. This understanding will be used to assess the feasibility of CO2 sequestration in a broad set of coal and CO2 emissions environments across the U.S. (particularly those areas with synergistic opportunities as identified in Figure 2), and to develop screening models for project-specific technical and economic evaluations. This paper presents the fundamental reservoir mechanisms of CO2 sequestration in coalseams, some of the merits of pure versus mixed gas (CO2 and N2 ) injection on CO2 sequestration and ECBM performance, and the field performances to date of the Tiffany and Allison Units. Reservoir Mechanisms The mechanism by which CO2 (or N2 ) can enhance the coalbed methane recovery process, and CO2 is sequestered, is a complex mix of physical and chemical interactions that must achieve equilibrium simultaneously in the sorbed state and in the gaseous state. Coal has the capacity to hold considerably

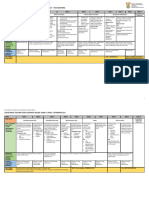

more CO2 than either methane (CH4 ) or N2 in the adsorbed state (in an approximate ratio of 4:2:1), as shown in Figure 3. As a result, in the presence of multiple gases (e.g., CO2 , CH4 and N2 ), the amount of each in the adsorbed state would be in approximately these proportions. However, since any injected gas for ECBM is unlikely to be of exactly that composition, a partial-pressure disequilibrium will be created in the gaseous phase (i.e., in the coal cleat system). Adsorption/desorption of individual components will therefore occur until the gases in both the sorbed and gaseous states are each in equilibrium, and are in equilibrium with each other. As an example, consider ECBM recovery via N 2 injection. Under certain conditions, the equilibrium ratio of CH4 to N2 in the adsorbed state is 2:1, but is 1:3 in the gaseous state (see point A in Figure 4a). As pure N 2 is injected however, it flushes the gaseous methane from the cleats, creating a near 100% N 2 saturation. The partial pressure of methane in the gaseous cleat-system phase is reduced to zero, a disequilibrium condition in a system containing both methane and nitrogen. As a result, methane desorbs and is drawn (or pulled) into the gaseous phase to achieve partial-pressure equilibrium. This is why the N2 -ECBM recovery process is referred to as methane stripping. On the other hand, as CO2 is injected, it becomes preferentially adsorbed onto the coal, displacing methane. There is no pull on the methane into the cleat system, rather it is pushed from the matrix by the highly adsorptive CO2 . Consider Point B in Figure 5a. The equilibrium ratio of CH4 to CO2 is 1:1 in the sorbed state, but is 3:1 in the gaseous state. As pure CO2 is injected it is quickly adsorbed into the coal matrix to achieve sorbed equilibrium, displacing sorbed CH4 in the process. Modeling work using ARIs COMET2 coalbed reservoir simulator demonstrates the advantages and disadvantages of N2 and CO2 on ECBM recovery. Figures 6, 7, and Table 1, provide the results of a series of three simulations one base case where no gas injection occurs, and one each for N2 and CO2 injection at a rate of 500 Mcfd. The simulation well pattern is a quarter 5-spot; reservoir parameters are described in reference 5, and are indicative of a San Juan Basin setting. The model results indicate a immediate and significant gas production enhancement with N2 injection. However, N2 breakthrough occurs fairly quickly and becomes a high percentage of total production. Hence any enhanced recovery benefit gained by N2 injection must be balanced against higher gas treatment costs. Injection of CO2 also results in an immediate gas production response, albeit less so than with N2 . In the case of CO2 , however, no significant breakthrough of CO2 is predicted over the 20-year simulation (the model assumes a homogeneous reservoir for all cases, absent of potential reservoir pathways for early breakthrough). These behaviors have an important impact on an integrated ECBM recovery and CO2 sequestration project; to achieve the desired

SPE 71749 GEOLOGICAL SEQUESTRATION OF CO2 IN DEEP, UNMINEABLE COALBEDS: AN INTEGRATED RESEARCH AND COMMERICAL-SCALE FIELD D EMONSTRATION PROJECT

low net-cost for CO2 sequestration, an injection gas consisting of both N2 (for rapid methane recovery) and CO2 (for sequestration), in optimised proportions, is the likely outcome. Obviously, this is attractive since power plant flue gas is comprised mostly of these two components. Water production increases with either N 2 or CO2 injection. The higher water response with N2 is surmised to be a result of its lesser compressibility and higher viscosity than methane. On the other hand, CO2 is quickly adsorbed by the coal matrix, which releases methane to the fracture system. Hence, it occupies a minimal portion of the in-situ pore space. Field Performance There are currently only two known field sites where CO2 and/or N2 injection is being performed on a multi-well scale for ECBM purposes. These sites, both in the San Juan Basin, are the Tiffany Unit operated by BP and the Allison Unit operated by Burlington Resources (Figure 8). They represent unique opportunities to gain insights into the nature of fullscale CO2 sequestration and ECBM recovery, and to verify and/or modify our understanding of the reservoir processes described above. Tiffany Unit. BP (formerly Amoco Production Company) began to investigate ECBM techniques in the late 1980s, primarily via laboratory experiments, which involved injecting a gas, or mixture of gases such as N 2 , CO2 , or flue gas, to improve CBM recovery. Building on the success of laboratory and pilot tests, and after acquiring numerous patents on the process, Amoco moved forward with the first and largest full scale N 2 -ECBM commercial pilot known as the Tiffany Unit. After nine years of primary production, nitrogen injection was commenced in January 1998; utilizing ten newly drilled directional nitrogen injection wells, and later into two additional converted production wells (in December, 1998), Figure 9. Note that a portion of this field was part of a CBM reservoir characterization R&D project in the early 1990s, also performed by ARI and funded by the Gas Technology Institute (formerly the Gas Research Institute). Care was taken to ensure both new and existing wellbores had proper seals and integrity to ensure that the gas was injected into and confined within the coal seam. Injection volumes have averaged 24-28 MMcfd into the 12 wells. Total Tiffany Unit production prior to injection of nitrogen averaged approximately 5 MMcfd from 34 wells. In March 1999, gas production peaked at 29 MMcfd, representing a 5-fold increase in methane production (Figure 10). Nitrogen levels in the produced gas reached 16%. These results seem to confirm the quick production response (and N2 breakthrough) predicted by reservoir modeling. The Tiffany Unit is being evaluated for the potential of injecting a mixture of waste CO2 and the already generated N2 . While many variables may exist, information from this already

active N2 -ECBM flood will enhance understanding the effects of CO2 injection. Allison Unit. The Allison Unit, is the worlds first experimental (pure) CO2 -ECBM recovery pilot, and is the second field demonstration site (Figure 8). The pilot comprises of four CO2 -injection wells and nine methane production wells (Figure 11). Formerly, these wells had been produced using conventional pressure-depletion methods for over five years. During 1995 Burlington drilled the four injection wells and began CO2 injection at an initial rate of 5 MMcfd; since then a loss of injectivity has reduced injection rates to about 3 MMcfd. Operations began with an initial 6-month period of CO2 injection, during which time five of the production wells were temporarily shut in to facilitate CO2 /CH4 exchange in the reservoir (Figure 12). A sharp increase in water production was observed immediately. After six months, CO2 injection was suspended to evaluate field performance, and the five shut-in wells were re-opened. Injection resumed about 8 months later. Breakthrough of CO2 has been minimal during the life of the project; following almost five years of injection, current CO2 concentrations at the production wells average 6%, which is only slightly above initial pre-injection levels of 4%. This suggests that the physical processes of CO2 sequestration and methane release are indeed taking place, again as predicted by reservoir modelling. Future Work This 3-year project, just now underway, will use the Tiffany and Allison Units as foundations for studying and understanding ECBM-recovery/CO2 -sequestration in coal seams. The reservoir studies will be supported by laboratory tests for single-, binary-, and ternary-component isotherm measurements, as well as studies into the potential impact of matrix shrinkage/swelling and geochemical reactions on CO2 injectivity. A benchtop core-flooding experiment may also be performed to understand some of these issues in a controlled environment. Based on the results from this work, economic optimization studies will be performed, and a project screening model developed. Conclusions While it is too early in the project to drive any concrete conclusions, the modeling and field results suggest that both N2 and CO2 can enhance CBM recovery, and that coals appear to effectively sequester CO2 . It also appears that there will be an economic optimum N2 /CO2 mix and rate for each potential project, and hence being able to determine these parameters will be important for integrated ECBM/sequestration projects to be undertaken by industry.

SCOTT R. REEVES

SPE 71749

Acknowledgements This work is being sponsored by The U.S. Department of Energy under contract DE-FC26-00NT40924, Geologic Sequestration of CO2 in Deep, Unmineable Coalbeds: An Integrated Research and Commercial-Scale Field Demonstration Project; DOEs Technical Manager is Mr. Charles Byrer.

References 1. 2. 3. 4. Emissions of Greenhouse Gases in the United States, 1999 (EIA/DOE-0573 (99)). Electric Power Annual, 2000 (DOE/EIA-0348(99)/2). Electric Power Industry Road Atlas for North America, UDI/McGraw-Hill, 1995. Arri, L.E., Yee, D., Morgan, W.D., Jeansonne, M.W., Modeling Coalbed Methane Production with Binary Gas Sorption, SPE paper 24363 presented at the SPE Rocky Mountain Regional Meeting, Casper, WY, May 18-21, 1992. Stevens, Scott H., Schoeling, Lanny, Pekot, Larry, CO2 Injection for Enhanced Coalbed Methane Recovery: Project Screening and Design, Paper 9934 presented at the International Coalbed Methane Symposium, Tuscaloosa, May 37, 1999.

5.

SPE 71749 GEOLOGICAL SEQUESTRATION OF CO2 IN DEEP, UNMINEABLE COALBEDS: AN INTEGRATED RESEARCH AND COMMERICAL-SCALE FIELD D EMONSTRATION PROJECT

Table 1 Incremental Methane Recoveries from N2/CO2 Injection (Quarter 5-Spot Pattern)

BASE CASE Total Recovery (MMcf) Incremental Recovery (MMcf) 1,171

NITROGEN 2,933

CARBON DIOXIDE 2,147

n/a

1,762

976

Figure 1: The Integrated Power Generation, ECBM & CO2 Sequestration Concept

SCOTT R. REEVES

SPE 71749

Figure 2: Coincidence of State CO2 Emissions, Large Coal-Fired Power Plants, and Coal Basins

Figure 3: Relative Adsorption Capacities of N 2 , CH4 and CO2 , San Juan Basin Coal (reproduced from reference 4)

SPE 71749 GEOLOGICAL SEQUESTRATION OF CO2 IN DEEP, UNMINEABLE COALBEDS: AN INTEGRATED RESEARCH AND COMMERICAL-SCALE FIELD D EMONSTRATION PROJECT

(a)

(b)

Figure 4: N2 - CH4 Binary Sorption Behavior, San Juan Basin Coal (reproduced from reference 4)

(a)

(b)

Figure 5: CH4 - CO2 Binary Sorption Behavior, San Juan Basin Coal (reproduced from reference 4)

SCOTT R. REEVES

SPE 71749

1000 N2 @ 500 Mcfd Net Methane CO2 @ 250 Mcfd

70.00%

60.00%

50.00%

Gas Rate, Mscfd

40.00% 100 30.00%

Base Case

20.00%

Nitrogen Content

10.00%

10 0 30 60 90 120 Month 150 180 210

0.00% 240

Figure 6: Gas Production Response to N2/CO2 Flooding

1000

CO2 @ 500 Mcfd N2 @ 500 Mcfd

100 Water Rate, Bpd

10

Base Case

1 0 30 60 90 120 Month 150 180 210 240

Figure 7: Water Production Response to N 2 /CO2 Flooding

Nitrogen Content

SPE 71749 GEOLOGICAL SEQUESTRATION OF CO2 IN DEEP, UNMINEABLE COALBEDS: AN INTEGRATED RESEARCH AND COMMERICAL-SCALE FIELD D EMONSTRATION PROJECT

LA PLATA CO. ARCHULETA CO.

Dur ango Pagosa Spr ing s

F l or i da R iv er P lan t

COAL Site F COLORADO NEW MEXICO A I

Tiff an y Un it

San Juan Basin Outline

Du lce

A llis o n U n it

Aztec

F arm i ngton Blo omfi el d KAO991 00.C DR

Figure 8: Location of N 2 /CO2 -ECBM Pilots, San Juan Basin

Figure 9: Tiffany Unit N 2 Flood Well Pattern

10

SCOTT R. REEVES

SPE 71749

Tiffany Unit Production

100000 Nitrogen Injection Suspended Gas Production Water Production Nitrogen Injection

10000

Rate, Mcfd or Bpd

1000

100

10

Water Measurement Discrepency

1 May-90

Sep-91

Jan-93

Jun-94

Oct-95

Mar-97

Jul-98

Dec-99

Apr-01

Sep-02

Figure 10: Tiffany Unit Production N 2 Flood Pilot Area

Figure 11: Allison Unit CO2 Flood Pilot Well Pattern

SPE 71749 GEOLOGICAL SEQUESTRATION OF CO2 IN DEEP, UNMINEABLE COALBEDS: AN INTEGRATED RESEARCH AND COMMERICAL-SCALE FIELD D EMONSTRATION PROJECT

11

Allison Unit Production

10000000 CO2 Injection Resumed (Jul, 1996)

CO2 Injection Suspended, Five Wells Re-Opened (Nov, 1995) 1000000 Monthly Gas, CO2 or Water, Mcf or Bbls Begin CO2 Injection, Five Wells Shut-In (May, 1995)

100000

Line Pressures Reduced

10000

Gas 1000 Water CO2 Injection Five Wells Reworked

100 Aug-87

Dec-88

May-90

Sep-91

Jan-93

Jun-94

Oct-95

Mar-97

Jul-98

Dec-99

Apr-01

Sep-02

Figure 12: Allison Unit Production, CO2 Flood Pilot Area

Вам также может понравиться

- Case AnalysisДокумент15 страницCase AnalysisCool2raОценок пока нет

- CE Module 22 - Open Channel and Weirs (Principle)Документ3 страницыCE Module 22 - Open Channel and Weirs (Principle)Angelice Alliah De la CruzОценок пока нет

- Toward An Urban Design ManifestoДокумент10 страницToward An Urban Design ManifestoLuis Sebastian Romero CorredorОценок пока нет

- E Allison Unit CO2-ECBM Pilot in The San Juan BasinДокумент6 страницE Allison Unit CO2-ECBM Pilot in The San Juan BasinPritam RajОценок пока нет

- Flue-Gas Carbon Capture On Carbonaceous Sorbents: Toward A Low-Cost Multifunctional Carbon Filter For "Green" Energy ProducersДокумент12 страницFlue-Gas Carbon Capture On Carbonaceous Sorbents: Toward A Low-Cost Multifunctional Carbon Filter For "Green" Energy ProducersKaspars KrutkramelisОценок пока нет

- CCSДокумент22 страницыCCSkingsley kaputoОценок пока нет

- Experiment 6Документ15 страницExperiment 6JAN JERICHO MENTOYОценок пока нет

- A Computational Model of Catalyzed Carbon Sequestration: Back To Exploration - 2008 CSPG CSEG CWLS ConventionДокумент4 страницыA Computational Model of Catalyzed Carbon Sequestration: Back To Exploration - 2008 CSPG CSEG CWLS ConventionsahanchemОценок пока нет

- CalcinationДокумент7 страницCalcinationVelu ManiОценок пока нет

- Carbonation-Calcination Cycle Using High Reactivity Calcium Oxide For Carbon Dioxide Separation From Flue GasДокумент8 страницCarbonation-Calcination Cycle Using High Reactivity Calcium Oxide For Carbon Dioxide Separation From Flue GasPola PoliОценок пока нет

- Economic Feasibility of Carbon Sequestration With Enhanced Gas Recovery (Csegr)Документ20 страницEconomic Feasibility of Carbon Sequestration With Enhanced Gas Recovery (Csegr)Anand aashishОценок пока нет

- Techno Analysis 9Документ16 страницTechno Analysis 9Thilagavathi RajaОценок пока нет

- Chemical Lopping CombustionДокумент19 страницChemical Lopping CombustionAstha YadavОценок пока нет

- Characterize The Trapped Carbon Dioxide in Impermeable Reservoir Rocks During SequestrationДокумент20 страницCharacterize The Trapped Carbon Dioxide in Impermeable Reservoir Rocks During Sequestrationmoscow01Оценок пока нет

- The Economics of Co Separation and CaptureДокумент18 страницThe Economics of Co Separation and CaptureJonah VaughnОценок пока нет

- Carbon Capture, Usage & Storage: AbstractДокумент16 страницCarbon Capture, Usage & Storage: AbstractPriyanshОценок пока нет

- Carbon Dioxide Capture and Storage: April 2008Документ5 страницCarbon Dioxide Capture and Storage: April 2008chirag sabhayaОценок пока нет

- IJETR042116Документ6 страницIJETR042116erpublicationОценок пока нет

- khảo sát phản ứng động học engДокумент8 страницkhảo sát phản ứng động học engKhánh TrangОценок пока нет

- Carbon Capture and StorageДокумент32 страницыCarbon Capture and StorageAyush BaliОценок пока нет

- GTL Conversion ProcessesДокумент4 страницыGTL Conversion Processesslidey1Оценок пока нет

- Vol45-4 PDFДокумент268 страницVol45-4 PDFGoh Aik WeiОценок пока нет

- Carbon Capture StorageДокумент9 страницCarbon Capture StorageTS WongОценок пока нет

- Molecular Insights Into Carbon Dioxide Enhanced Multi-Component ShaleДокумент17 страницMolecular Insights Into Carbon Dioxide Enhanced Multi-Component Shale荣健淇Оценок пока нет

- 10 1016@j Jphotochem 2019 111933Документ10 страниц10 1016@j Jphotochem 2019 111933zmaxprom5Оценок пока нет

- 1 s2.0 S0360319920304262 MainДокумент6 страниц1 s2.0 S0360319920304262 MainBharatSuryaОценок пока нет

- Carbon Dioxide Sequestration by Injection To Various Geological ReservoirsДокумент6 страницCarbon Dioxide Sequestration by Injection To Various Geological ReservoirsStanislaw NagyОценок пока нет

- Carbon Dioxide Recycling: Emerging Large-Scale Technologies With Industrial PotentialДокумент22 страницыCarbon Dioxide Recycling: Emerging Large-Scale Technologies With Industrial PotentialLoredana Veronica ZalischiОценок пока нет

- Co2 Capture & StorageДокумент14 страницCo2 Capture & StorageYagnesh ChainyОценок пока нет

- Analysis of A Waste-To-Energy Power Plant With CO SequestrationДокумент8 страницAnalysis of A Waste-To-Energy Power Plant With CO SequestrationFerdiansyah Iqbal RafandiОценок пока нет

- CO2 Injection in CBMДокумент14 страницCO2 Injection in CBMmhuf89Оценок пока нет

- Tplus en 4875Документ9 страницTplus en 4875mitramkh99Оценок пока нет

- Carbon Capture and Storage: UNFCCC Secretariat Financial and Technical Support ProgrammeДокумент18 страницCarbon Capture and Storage: UNFCCC Secretariat Financial and Technical Support ProgrammeSilva KurniawanОценок пока нет

- Assessment of CO Capture Options From Various Points in Steam Methane Reforming For Hydrogen ProductionДокумент10 страницAssessment of CO Capture Options From Various Points in Steam Methane Reforming For Hydrogen ProductionSaif EvonyОценок пока нет

- Vol45 4 PDFДокумент268 страницVol45 4 PDFShailesh LohareОценок пока нет

- Process Design and Energy Requirements For The Capture of CO2 From AirДокумент12 страницProcess Design and Energy Requirements For The Capture of CO2 From AirKeena Rahim100% (1)

- Carbon Capture and Storage From Fossil Fuel Use: NtroductionДокумент19 страницCarbon Capture and Storage From Fossil Fuel Use: NtroductionFaheem Ahmad ZafarОценок пока нет

- Carbon Dioxide Storage: Geological Security and Environmental Issues - Case Study On The Sleipner Gas Field in NorwayДокумент20 страницCarbon Dioxide Storage: Geological Security and Environmental Issues - Case Study On The Sleipner Gas Field in NorwayThay VaniaОценок пока нет

- Us Currsci PaperДокумент10 страницUs Currsci PaperJoão GabrielОценок пока нет

- Carbon CaptureДокумент28 страницCarbon Capturedebasish2000100% (1)

- Modeling CO2 Storage in Aquifers With A Fully-CoupДокумент17 страницModeling CO2 Storage in Aquifers With A Fully-CoupFatimah Az ZahraОценок пока нет

- Combustion Carbon Capture ViaДокумент17 страницCombustion Carbon Capture ViaJulian De BedoutОценок пока нет

- Project Descriptions 2012-13. Supplementary List 9.10.12Документ7 страницProject Descriptions 2012-13. Supplementary List 9.10.12Moao AomoОценок пока нет

- Applied Energy: Hao Liu, Yingjuan ShaoДокумент9 страницApplied Energy: Hao Liu, Yingjuan ShaoJayanath Nuwan SameeraОценок пока нет

- Optimal CO2 Capture and StorageДокумент34 страницыOptimal CO2 Capture and Storagemechanist100% (2)

- Generic Design of A NGCC Capture Ready PlantДокумент26 страницGeneric Design of A NGCC Capture Ready PlantDigant VishnuОценок пока нет

- Geo Ptoject 2Документ17 страницGeo Ptoject 2MUDIT DALMIA VIS GroupОценок пока нет

- 49 1 Anaheim 03-04 0837Документ2 страницы49 1 Anaheim 03-04 0837castelo_grandeОценок пока нет

- 2005 - Pressure - Swing - Adsorption - For - Carbon - Dioxide - SequeДокумент11 страниц2005 - Pressure - Swing - Adsorption - For - Carbon - Dioxide - SequeMarcela FragozoОценок пока нет

- Try Reforming of Co2Документ10 страницTry Reforming of Co2tabrejalamdps19Оценок пока нет

- A Century of Re-Exploring CO2 Capture SolventsДокумент5 страницA Century of Re-Exploring CO2 Capture SolventsQigang CenОценок пока нет

- Carbon Capture and Storage (CCS) : January 2015Документ13 страницCarbon Capture and Storage (CCS) : January 2015chirag sabhayaОценок пока нет

- ACS Energy Lett 2017 2 454Документ8 страницACS Energy Lett 2017 2 454preemeeОценок пока нет

- An Overview of CO2 Capture TechnologiesДокумент25 страницAn Overview of CO2 Capture Technologiesherschel5100% (1)

- Enhanced CBM/CMM Recovery: 1.0 Overview/Description of The TechnologyДокумент9 страницEnhanced CBM/CMM Recovery: 1.0 Overview/Description of The TechnologyNilesh SinghalОценок пока нет

- Coal GeologyДокумент24 страницыCoal GeologySonali SwagatikaОценок пока нет

- Carbon Dioxide Capture ThesisДокумент6 страницCarbon Dioxide Capture ThesisProfessionalPaperWritingServiceCanada100% (2)

- Gasification in Carbon-Constrained WorldДокумент5 страницGasification in Carbon-Constrained WorldLTE002Оценок пока нет

- Methodology For Estimation of CO Storage Capacity in ReservoirsДокумент5 страницMethodology For Estimation of CO Storage Capacity in ReservoirsKilaparthi SatyavammaОценок пока нет

- AZEP - Development of An Integrated Air Separation Membrane - Gas TurbineДокумент6 страницAZEP - Development of An Integrated Air Separation Membrane - Gas TurbineeddyОценок пока нет

- Post-Combustion CO2 CaptureДокумент26 страницPost-Combustion CO2 CaptureAbubakkar siddiqОценок пока нет

- Combustion Processes For Carbon Capture: Terry F. WallДокумент17 страницCombustion Processes For Carbon Capture: Terry F. WallEdgar SharapovaОценок пока нет

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsОт EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsОценок пока нет

- Tunisia Geology PDFДокумент33 страницыTunisia Geology PDFtassili17Оценок пока нет

- 3 Degasser Technology PDFДокумент8 страниц3 Degasser Technology PDFtassili17Оценок пока нет

- Tunisia Geology PDFДокумент33 страницыTunisia Geology PDFtassili17Оценок пока нет

- 2003 Barnett Shales y MPДокумент14 страниц2003 Barnett Shales y MPtassili17Оценок пока нет

- Rystad Energy - Forecast For Global Shale - ShortДокумент10 страницRystad Energy - Forecast For Global Shale - Shorttassili17Оценок пока нет

- Ian Palmer HTДокумент33 страницыIan Palmer HTtassili17Оценок пока нет

- Connell Australia Activity1Документ19 страницConnell Australia Activity1tassili17Оценок пока нет

- Revised Fuel Manuscript-Gasem 2Документ40 страницRevised Fuel Manuscript-Gasem 2tassili17Оценок пока нет

- Barnett Shale Fact SheetДокумент3 страницыBarnett Shale Fact Sheettassili17Оценок пока нет

- Advances in Carbon CaptureДокумент3 страницыAdvances in Carbon Capturetassili17Оценок пока нет

- Paleozoic and Triassic Petroleum Systems in North AfricaДокумент3 страницыPaleozoic and Triassic Petroleum Systems in North Africatassili17Оценок пока нет

- SECARB Phase III Early Test Receives Recognition For Furthering CCS Technology and Meeting G-8 Goals For DeploymentДокумент1 страницаSECARB Phase III Early Test Receives Recognition For Furthering CCS Technology and Meeting G-8 Goals For Deploymenttassili17Оценок пока нет

- New Carbon Capture AllianceДокумент1 страницаNew Carbon Capture Alliancetassili17Оценок пока нет

- 117 Dinmore Flora Popular SciДокумент11 страниц117 Dinmore Flora Popular Scitassili17Оценок пока нет

- AEL - Company ProfileДокумент13 страницAEL - Company Profileajeeit8Оценок пока нет

- Influence Des Attributs Forestiers Sur Le Stock de Carbone Des Unités de Végétation Sud-Soudaniennes Au Burkina Faso, Afrique de L'ouestДокумент16 страницInfluence Des Attributs Forestiers Sur Le Stock de Carbone Des Unités de Végétation Sud-Soudaniennes Au Burkina Faso, Afrique de L'ouestRomaric TiendrebeogoОценок пока нет

- Introduction To PlantsДокумент17 страницIntroduction To PlantsS'thembiso ThwalaОценок пока нет

- Wins ReportДокумент17 страницWins ReportArnel De QuirosОценок пока нет

- 1.390 ATP 2023-24 GR 11 Geo FinalДокумент4 страницы1.390 ATP 2023-24 GR 11 Geo FinalmongadilepholaОценок пока нет

- Book Review On UrbanizationДокумент7 страницBook Review On UrbanizationKalu UchennaОценок пока нет

- Bilge and Ballast System Layout - Procedure For Ship Service SystemsДокумент5 страницBilge and Ballast System Layout - Procedure For Ship Service SystemsharimecОценок пока нет

- Rivers of The World Reading ComprehensionДокумент5 страницRivers of The World Reading Comprehensioncarolain wallsОценок пока нет

- Researching The Hybrid Geographies of Climate (Popke, 2016)Документ5 страницResearching The Hybrid Geographies of Climate (Popke, 2016)Manuel SalasОценок пока нет

- Integrated Approach To Water/ Wastewater Treatment at Zero Liquid Discharge, Combined Cycle Power PlantsДокумент6 страницIntegrated Approach To Water/ Wastewater Treatment at Zero Liquid Discharge, Combined Cycle Power PlantsNoureddine MerahОценок пока нет

- Diversity of LifeДокумент6 страницDiversity of LifePriyanka VermaОценок пока нет

- Vertical GatesДокумент243 страницыVertical GatesSannyBombeoJomocОценок пока нет

- Rhar Final Prog 10octДокумент8 страницRhar Final Prog 10octanuragmishra.civilОценок пока нет

- Module 8 - SSP-1Документ8 страницModule 8 - SSP-1KenkОценок пока нет

- Environmental Challenges During DrillingДокумент46 страницEnvironmental Challenges During Drillingrishibarathi100% (1)

- Fiji Water and Corporate Social ResponsibilityДокумент24 страницыFiji Water and Corporate Social ResponsibilityAnimo TonibeОценок пока нет

- Unit 3 - Test 1 - KeyДокумент4 страницыUnit 3 - Test 1 - KeyPhạm MơОценок пока нет

- Airline OverbookingДокумент6 страницAirline OverbookingHania AsadОценок пока нет

- Module 1 Lesson 2Документ4 страницыModule 1 Lesson 2SOMERA Princess Nicole V.Оценок пока нет

- Garbage EnzymeДокумент6 страницGarbage Enzymefaiez100% (1)

- NCERT Solutions For Class 8 GeographyДокумент3 страницыNCERT Solutions For Class 8 GeographyYuki ShizukuОценок пока нет

- Concept of Gene PoolДокумент41 страницаConcept of Gene PoolBandook Gamers0% (1)

- MN It ConferenceДокумент5 страницMN It ConferenceEdison ChandraseelanОценок пока нет

- 3 TLEd205 Chapter1Документ19 страниц3 TLEd205 Chapter1charmen rogando50% (2)

- Biology Investigatory Project GGG 1 PDFДокумент20 страницBiology Investigatory Project GGG 1 PDFshadabdel007Оценок пока нет

- MCQ - Optimisation & WastageДокумент4 страницыMCQ - Optimisation & WastageASWIN KUMAR N SОценок пока нет

- Iqra's Vocabulary Register: Word Dictionary Meaning Synonyms Antonyms Sample SentenceДокумент4 страницыIqra's Vocabulary Register: Word Dictionary Meaning Synonyms Antonyms Sample SentenceiqraОценок пока нет