Академический Документы

Профессиональный Документы

Культура Документы

Effect of Fruit Storage Conditions On Olive Oil Quality

Загружено:

csrajmohan2924Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Effect of Fruit Storage Conditions On Olive Oil Quality

Загружено:

csrajmohan2924Авторское право:

Доступные форматы

Effect of Fruit Storage Conditions on Olive Oil Quality

A. Kiritsakisa,*, G.D. Nanosb, Z. Polymenopoulosa, T. Thomaib, and E.M. Sfakiotakisb

a

Laboratory of Lipids and Oils, Technological Educational Institution of Thessaloniki, Sindos, 54101 Thessaloniki, and bLaboratory of Pomology, Aristotelean University of Thessaloniki, 54006 Thessaloniki, Greece

ABSTRACT: Koroneiki olive fruit from trees grown in Crete were stored under five different conditions (0C, air; 5C, air; 5C, 2% O2 + 5% CO2; 7.5C, air; 7.5C, 2% O2 + 5% CO2). Oil was obtained from fruit immediately after harvest and after fruit storage for 30 and 60 d. Olive oil quality was evaluated by determining acidity, peroxide value, absorption coefficients (K232, K270), phenol and chlorophyll content, fatty acid composition, and the resistance to oxidation by oven test. Olives stored at 7.5C, even for 30 d, deteriorated from fungus development, and the obtained oil was of inferior quality with high acidity, peroxide value, and absorption coefficients. The same oil had high chlorophyll and phenol content, resulting in good oil resistance to oxidation. Olive oil from fruit stored at 0 or 5C for 30 d had acceptable acidity, peroxide value, and absorption coefficients, but showed low resistance to oxidation, which was attributed to low chlorophyll and phenol content. This condition is further attributed to chilling injury caused by low storage temperatures. During storage, all treatments resulted in an increase of oleic acid, partly as a result of linoleic acid oxidation. JAOCS 75, 721724 (1998). KEY WORDS: Acidity, chilling injury, fatty acids, hydroperoxides, oil stability, Olea europaea.

chilling causes an increase in unsaturated fatty acid content of the membranes (11,12). Olives grown at higher elevations (cooler temperatures) also contain a higher percentage of unsaturated fatty acids (1315). Reduced ambient O2 and/or increased CO2 concentration plus lower temperatures during storage have been shown to reduce the deterioration rate of various fruits and vegetables (16). These conditions especially are important for chilling sensitive crops. Ripening of Manzanillo olives grown in California is delayed by 2% O2 alone or in combination with 5% CO2 at 5C (7). Previous reports showed that CO2 above 5% or O2 below 2% were detrimental to the quality of olive fruit or oil (3,710). The objective of this study was to evaluate the effect of various storage temperatures and atmospheres on Koroneiki olives and on the quality characteristics of their oil. EXPERIMENTAL PROCEDURES Olives (Olea europaea cv. Koroneiki) were harvested from mature trees in the area of Chania, Crete, Greece. During the first season, mature olives were harvested on January 22, 1995, transported to the Department of Pomology, Aristotelean University of Thessaloniki, where on January 24, they were sorted, packed in 2-kg replicates, and stored at 5 and 7.5C. At each temperature, fruit were kept in air, 2% O2, 5% CO2, or 2% O2 + 5% CO2. Each replicated treatment was conducted in a 400-L sealed metal chamber with 90 to 95% relative humidity. All chambers were connected with a CO2 infrared gas analyzer and an O2 paramagnetic gas analyzer. Atmospheric conditions were regulated by computer with the addition of N2, air, or CO2. A 0.5% CO2 level was maintained by ushing the chamber air through a bath that contained 2 N KOH. Ethylene produced by the olives was removed by KMnO4 pellets present in each chamber. Three replicates for each treatment were removed after 20 and 40 d of storage. During the second season, olives were harvested on December 12, 1995, transported, sorted, packed in replicates as described above, and then stored at 0, 5, or 7.5C. Fruit stored at 0C were kept in air, while at the other two temperatures, fruit were kept in air or 2% O2 + 5% CO2, where controlled atmospheres were reached and regulated as described above. Three replicates for each treatment were removed after 30 and 60 d of storage.

JAOCS, Vol. 75, no. 6 (1998)

The major Greek olive cultivar is Koroneiki. Very often, Koroneiki fruit grown in southern Greece is harvested and stored in nets or sacks at ambient temperatures, which may exceed 10C. These olives are mechanically damaged and deteriorate easily due to fungus growth (1,2). Rotten olives produce high acidity, low stability during heating, and generally low-quality olive oil (35). To minimize olive deterioration before processing, either as oil olives or as table olives, storage of olive fruit at low temperatures has been studied in California (6,7) and in Spain (4,8). Other investigations (9,10) concluded that olives are sensitive to chilling at temperatures below 5C. Variation in chilling sensitivity between cultivars also was found during storage, even at 10C. The main chilling injury symptoms are internal browning around the pit, which progressively leads to external pitting and browning. It is known that these changes negatively affect table olive quality. However, the effect of olive fruit injury by low temperatures on the quality characteristics of the oil has not been studied. In other fruits,

*To whom correspondence should be addressed at P. Sindika 86, 54248 Thessaloniki, Greece. E-mail: kiritsak@athena.compulink.gr Copyright 1998 by AOCS Press

721

722

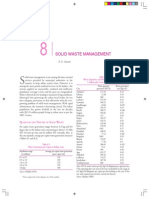

A. KIRITSAKIS ET AL. TABLE 1 Effect of Storage Conditions on Fruit Weight and Fungal Damage of Koroneiki Olivesa Weight loss (%) After 30 d 0/Air 5/Air 5/2 + 5c 7.5/Air 7.5/2 + 5c

a b

Fruit weight losses were followed by weighing certain replicates initially and at every fruit exit. Fungus growth on olives at each exit was graded on scale of: 0 (no fungus development) to 5 (samples were 100% rotting and sporulating). The oil of each 2-kg replicate was obtained as follows: fruit were rst crushed in a laboratory blender, and the resulting paste was mixed for 30 min in the presence of warm (30C) distilled water (about 30% of the paste w/w) to facilitate oil separation. Olive oil was obtained after centrifugation of the paste at 3000 rpm for 10 min and stored in bottles at 2C until it was analyzed. Total titratable acidity, peroxide value, and chlorophyll content were determined by AOCS (17) methods. Phenols were determined according to the colorimetric method described by Gutfinger (18) and expressed as ppm of caffeic acid. The specific absorbance values K232 and K270 were determined according to the method proposed by the International Olive Oil Council and described elsewhere (19). Oil (1 g) plus cyclohexane was mixed vigorously in a 100-mL volumetric flask. The absorbance at 232 and 270 nm was recorded against a blank (pure cyclohexane). Oil resistance to oxidation was determined by heating the oil samples at 63C (oven test) and periodically measuring the peroxide value of each sample. The fatty acids of each oil sample were methylated according to the method described by the Official Journal of European Communities (20) by mixing 0.5 g of oil sample with 0.3 g (approximately 0.4 mL) of sodium methylate (95%) in a glass vial. This vial was closed and immersed in a water bath at 85 to 90C for 2 h with periodic shaking to facilitate the reaction. The esterification process was completed when the contents of the vial were clear after sedimentation of the glycerine and reagent residues. Fatty acid analysis followed with the injection of 1 L of cooled fatty acid methyl ester in a Varian 3700 gas chromatograph (Varian, Sunnyvale, CA), equipped with chromosorb (80/100 mesh, DGS 10%, 1% H3PO4) and ame ionization detector. The chromatograph operated with N2 as carrier gas with a flow rate of 20 mL/min and column temperature 190C, injection temperature 220C, and detector temperature 250C. Each lipid present in the sample was quantitated with the DAPA software package (DAPA Scientic Pty, Ltd., Kalamunda, West Australia). The ratio (C18:1 + C18:2 + C18:3)/(C16:0 + C18:0) was used to further compare treatments. Analysis of variance was carried out for all data. A 5% level of least signicant difference (LSD) and Duncans multiple range test were used to establish differences between the means. All means were calculated from three replicates, and each quality parameter was measured twice for each replicate. RESULTS AND DISCUSSION Koroneiki olives did not show chilling injury symptoms at 5C in air, 2% O2, or 2% O2 + 5% CO2 and at 7.5C in 2% O2 or 2% O2 + 5% CO2, even after 40 d of storage (rst seasons results, not shown). Storing Koroneiki olives in 5% CO2

JAOCS, Vol. 75, no. 6 (1998)

Rot indexb (rating) After 30 d 0 1 0 4 4 After 60 d 1 2 1 5 5

After 60 d 2.9 5.3 1.5 7.4 5.6

1.1 1.5 1.1 3.1 1.6

Temperature values are in units of C. Index: 0, no rot; 1, few rotting olives without sporulation; 2, 30% rotting but few sporulating; 3, 50% rotting and sporulating; 4, 75% rotting and sporulating; 5,100% rotting and sporulating. c 2% O2 plus 5% CO2.

atmospheres resulted in poor-quality oil. It also became obvious that respiration of ripe Koroneiki olives increased the CO2 content of the storage room. Fruit weight losses increased with time in storage. Highest losses occurred at 7.5C in air (Table 1). Weight losses decreased with lower storage temperatures and controlled atmospheres. Fungus development (rot index) also was highest at 7.5C in air or controlled atmospheres. Olives stored at 5C in air after 60 d of storage had some fungus development, but olives stored at 0C in air or 5C in 2% O2 + 5% CO2 were almost unaffected by fungi, even after 60 d of storage. Oil acidity from freshly harvested olives was below 1%, a value that classifies olive oil as extra virgin. Oil acidity increased during storage of olives (Fig. 1). It was highest when olives were stored at 7.5C and decreased with lower storage temperature. For each temperature, oil obtained from olives stored in controlled atmospheres had lower acidity than oil from air-stored olives. The increase in acidity was probably the result of fungal lipase activity (1). Peroxide value of oils obtained from olives stored at various temperatures and controlled atmospheres increased during storage, compared to oil from freshly harvested olives

FIG. 1. Changes in acidity of oil during storage of olives at various conditions. Temperature values are in units of C. FFA, free fatty acid; LSD, least signicant difference.

OLIVE STORAGE CONDITIONS ON OIL QUALITY

723

FIG. 2. Changes in peroxide value (PV) of oil during storage of olives at various conditions. For other abbreviation see Figure 1.

FIG. 4. Changes in phenol content of oil during storage of olives at various conditions. For abbreviation see Figure 1.

(Fig. 2). The increase was signicant only for olives stored at 7.5C. The ultraviolet absorption coefficient K232 did not change in oil from olives stored at 0 or 5C but increased at 7.5C (Fig. 3), which indicates the formation of conjugated hydroperoxides (4). The same pattern was found for the K270 absorption coefficient, probably due to conjugated diene secondary products. Chlorophyll content was low in oil obtained from 0Cstored olives, even after 30 d of storage, probably due to chilling. Oil from 5C-stored olives had slightly less chlorophyll content than oil from freshly harvested olives, while oil from 7.5C-stored olives had similar chlorophyll content as oil from freshly harvested olives (data not shown). Phenol content was low in the oil obtained from 0Cstored olives, probably due to chilling, after 30 d of storage, and in the oil from olives stored for 60 d at 5C in 2% O2 + 5% CO2. All other treatments did not affect oil phenol content (Fig. 4).

Resistance to oxidation of oil from olives stored 30 d at 0C was lost after 14 d of oven heating (Fig. 5) and from olives stored for 60 d at 0C from the rst day of heating (data not shown). This was attributed to the decrease of natural antioxidants (phenols) and chlorophyll. The latter acts as an antioxidant in the dark (21). Oil oxidation of olives stored for 30 d at 5C in 2% O2 + 5% CO2 was increased after 35 d of heating. Oil from olives stored for 60 d at the same storage conditions was oxidized after 28 d of heating (data not shown). The resistance of oil to oxidation did not change, even after 57 d of heating, when it was obtained from olives stored at 5C in air or 7.5C in air or 2% O2 + 5% CO2 (Fig. 5). The main fatty acids determined in olive oil from freshly harvested olives were oleic acid (83%), palmitic acid (11.5%), and linoleic acid (3.2%). When olives were stored at low temperatures and controlled atmospheres for 30 and 60 d, palmitic acid content decreased slightly to around and below 10%, and linoleic acid content decreased to below 3%. Oleic

FIG. 3. Changes in the ultraviolet absorption coefficient K232 of oil obtained from olives stored at various conditions for 30 and 60 d. For abbreviation see Figure 1.

FIG. 5. Resistance to oxidation of oil (change in PV) obtained from olives stored for 30 d at various conditions. For abbreviation see Figure 2.

JAOCS, Vol. 75, no. 6 (1998)

724

A. KIRITSAKIS ET AL.

acid content increased 1 to 2% with storage regardless of storage temperature, atmospheric composition, and duration in storage, except when olives were completely deteriorated after 60 d of storage at 7.5C. Also, the unsaturated/saturated fatty acid ratio increased in oil from stored olives from 6.5 to 7.7, regardless of treatment. Oil obtained from olives stored at 7.5C for 30 d was of inferior quality due to increased oil oxidation. Therefore, this temperature is not recommended for storage of this oil-producing cultivar. However, oil obtained from olives stored at these storage conditions had high phenol and chlorophyll content, which resulted in good stability during heating. Shorter storage time of fruit at 7.5C or control of fungus development during fruit storage could result in a better overall oil quality. Storage of olives at 7.5C in controlled atmospheres had similar fungus development, but the oil quality, although still unacceptable, was better than that of oil from olives stored at 7.5C in air. Olives stored at 0C had no fungus development, and the oil had low acidity, low peroxide value, and low absorbance coefficients (K232, K270). Based on these results, the oil was rated of good quality (virgin oil) when fruit was stored for 30 d. However, olives stored at this temperature were severely injured due to chilling and showed almost complete external discoloration after 30 d of storage. Due to chilling, chlorophyll and phenol content were substantially reduced, resulting in low oil resistance to oxidation. These changes due to chilling of oil-producing olive cultivars are detrimental to oil quality. Therefore, oil cultivars that are chilling-sensitive should not be stored at chilling temperatures for long periods of time. Olives stored at 5C in air had low fungus development and produced relatively good oil quality after 30 d of storage, although oil acidity slightly increased. Prolonged storage at these conditions caused further deterioration in oil quality due to high oil acidity. Storage of olives at 5C in controlled atmospheres accelerated chilling and caused deterioration of oil quality. Results were similar but to a lesser degree than those obtained from olives stored at 0C. These negative changes also can be attributed to high percentage of CO2 in storage (3,8). In conclusion, storage of olives at 7.5C resulted in high fungus development and low oil quality. This temperature could be used for olive fruit storage if fungus development could be suppressed. Storage of olives at 0C was detrimental to oil quality due to chilling injury, because the natural antioxidants present in the olive fruit were destroyed and oil resistance to oxidation was diminished. The best storage condition for Koroneiki olives was at 5C in air because, even after 30 d of storage, oil obtained from these olives was of good quality. ACKNOWLEDGMENTS

This work was supported by research grants from the Technological Educational Institution of Thessaloniki and the Aristotelean University of Thessaloniki, Greece. Dr. I. Metzidakis supplied the olive fruit, and Mr. N. Efremidis and Mrs. D. Nikolaou provided lab assistance.

REFERENCES

1. Kiritsakis, A., and P. Markakis, Effect of Olive Collection Regime on Olive Oil Quality, J. Sci. Food Agric. 35:677680 (1984). 2. Metzidakis, I., D. Gerasopoulos, and A. Kiritsakis, Length of Time That Olive Fruit Remains on Collection Nets: Effect on Quality Characteristics of Olive Oil, Olivae 56:4046 (1995). 3. Gutierrez, F., S. Perdiguero, J.M. Garcia, and J.M. Castellano, Quality of Oils from Olives Stored Under Controlled Atmosphere, J. Am. Oil Chem. Soc. 69:12151218 (1992). 4. Kiritsakis, A., Olive Oil, 2nd edn., Food and Nutrition Press Inc., Trumbull, CT, 1998. 5. Psyllakis, N., L. Mikros, and A. Kiritsakis, Caracteristiques Qualitatives de lHuile d Olive et les Facteurs qui Influencent sur ces Caracteristiques, Proceedings of the 3rd International Congress on the Biological Value of Olive Oil, Institution of Subtropical and Olive Trees, Chanea, Greece, 1980, pp. 553565. 6. Kader, A.A., G.D. Nanos, and E.L. Kerbel, Storage Potential of Fresh Manzanillo Olives, Calif. Agric. 44:2324 (1990). 7. Kader, A.A., G.D. Nanos, and E.L. Kerbel, Responses of Manzanillo Olives to Controlled Atmospheres Storage, Proceedings of the 5th International Controlled Atmosphere Research Conference, Wenatchee, WA, Vol. 2, 1990, pp. 119125. 8. Garcia, J.M., and J. Streif, The Effect of Controlled Atmosphere Storage on Fruit and Oil Quality of Gordal Olives, Gartenbauwissenschaft 56:233238 (1991). 9. Maxie, E.C., Storing Olives Under Controlled Temperature and Atmosphere, Calif. Olive Assoc. Ann. Tech. Rpt. 42:3440 (1963). 10. Maxie, E.C., Experiments on Cold Storage and Controlled Atmospheres, Ibid. 43:1215 (1964). 11. Parkin , K.L., A. Marangoni, R.L. Jackman, R.Y. Yada, and D.W. Stanley, Chilling Injury: A Review of Possible Mechanisms, J. Food Biochem. 13:127153 (1989). 12. Wang, C.Y., Physiological and Biochemical Responses of Plants to Chilling Stress, Hortscience 17:173186 (1982). 13. Kiritsakis, A.K., and P. Markakis, Olive Oil, A Review, Adv. Food Res. 31:453 (1987). 14. Osman, M., I. Metzidakis, D. Gerasopoulos, and A. Kiritsakis, Qualitative Changes in Olive Oil of Fruits Collected from Trees Grown at Two Altitudes, Riv. Ital. delle Sost. Grasse 71:187190 (1994). 15. Mousa, Y.M., D. Gerasopoulos, I. Metzidakis, and A. Kiritsakis, Effect of Altitude on Fruit and Oil Quality Characteristics of Mastoides Olives, J. Sci. Food Agric. 71:345350 (1996). 16. Kader, A.A., Biochemical and Physiological Basis for Effects of Controlled and Modified Atmospheres of Fruits and Vegetables, Food Technol. 40:99104 (1986). 17. Official Methods and Recommended Practices of the American Oil Chemists Society, 4th edn., American Oil Chemists Society, Champaign, 1989. 18. Gutfinger, J., Polyphenols in Olive Oils, J. Am. Oil Chem. Soc. 58:966968 (1981). 19. Kiritsakis, A., and P. Markakis, Olive Oil Analysis, in Essential Oils and Waxes, edited by H.F. Linskens and J.F. Jackson, Springer-Verlag, Heidelberg, New York, 1991, pp. 120. 20. Official Journal of the European Communities, Commission Regulation (EEC) No. 2568/91, Analysis by Gas Chromatography of Methyl Esters of Fatty Acids, European Union, Brussels, 1991, No. L248, pp. 3647. 21. Kiritsakis, A., and L.R. Dugan, Studies in Photooxidation of Olive Oil, J. Am. Oil Chem. Soc. 62:892896 (1985). [Received July 7, 1997; accepted December 11, 1997]

JAOCS, Vol. 75, no. 6 (1998)

Вам также может понравиться

- Azeitona 2Документ7 страницAzeitona 2Andréia Dalla RosaОценок пока нет

- 234 151 PDFДокумент12 страниц234 151 PDFTülin ŞahinОценок пока нет

- Comparative Study of Virgin Olive Oil BehaviorДокумент6 страницComparative Study of Virgin Olive Oil BehaviorMaria Celina Machado de MedeirosОценок пока нет

- Volatile Profile of Heated Soybean Oil Treated With Quercetin and Chlorogenic AcidДокумент4 страницыVolatile Profile of Heated Soybean Oil Treated With Quercetin and Chlorogenic AcidGabriel DantasОценок пока нет

- 3 ArtДокумент12 страниц3 ArtADRIANA ALEJANDRA HUAMANI FLORESОценок пока нет

- Kadda Et Al. 2021Документ16 страницKadda Et Al. 2021khadijaОценок пока нет

- Atmosfera Modificada en BananaДокумент8 страницAtmosfera Modificada en BananaLizОценок пока нет

- 4 Ijasraug20174Документ8 страниц4 Ijasraug20174TJPRC PublicationsОценок пока нет

- Re-Cycling of Cooking Oils and The Effect On The Quality and StabilityДокумент4 страницыRe-Cycling of Cooking Oils and The Effect On The Quality and StabilitySyntiya Inanda KhoidirОценок пока нет

- El-Anany, A. 2009. Effects of Edible Coatings On The Shelf Life and Quality of Anna Apple Malus Domestica Boriili During Cold StorageДокумент7 страницEl-Anany, A. 2009. Effects of Edible Coatings On The Shelf Life and Quality of Anna Apple Malus Domestica Boriili During Cold StoragechikilinaОценок пока нет

- Articulo de Microbiologia 2Документ8 страницArticulo de Microbiologia 2manoloОценок пока нет

- Manuscript AguacateДокумент27 страницManuscript AguacateLoredana Veronica ZalischiОценок пока нет

- 110897-Article Text-305988-1-10-20141215Документ8 страниц110897-Article Text-305988-1-10-20141215Victini PikachuОценок пока нет

- Virgin Coconut Oil PDFДокумент10 страницVirgin Coconut Oil PDFnolaОценок пока нет

- Improving The Fatty Acid Composition of Chemlali' Virgin Olive Oil Through Clonal SelectionДокумент6 страницImproving The Fatty Acid Composition of Chemlali' Virgin Olive Oil Through Clonal SelectionaminehaddadaОценок пока нет

- Physicochemical Properties and Fatty Acids Profile of Seed Oil of Telfairia Hook, FДокумент6 страницPhysicochemical Properties and Fatty Acids Profile of Seed Oil of Telfairia Hook, FGarudaOzoОценок пока нет

- Queso Mantecoso PDFДокумент9 страницQueso Mantecoso PDFHannibal JPОценок пока нет

- Effect of CaCl 2 Sprays, Heat, and Combined CaCl 2-Heat Treatments On The Quality of Apples (Malus Domestica Borkh.)Документ5 страницEffect of CaCl 2 Sprays, Heat, and Combined CaCl 2-Heat Treatments On The Quality of Apples (Malus Domestica Borkh.)Shailendra RajanОценок пока нет

- Mehanni Et Al-2016-Journal of Food BiochemistryДокумент6 страницMehanni Et Al-2016-Journal of Food BiochemistryAdriana Fernandez HerreroОценок пока нет

- Characterization and Control of Chilling Injury of Some Horticultural CommoditiesДокумент9 страницCharacterization and Control of Chilling Injury of Some Horticultural CommoditiesafitantriОценок пока нет

- 1 s2.0 S0956713509001959 Main PDFДокумент7 страниц1 s2.0 S0956713509001959 Main PDFTülin ŞahinОценок пока нет

- Food Chemistry: Olusola Samuel Jolayemi, Figen Tokatli, Banu OzenДокумент8 страницFood Chemistry: Olusola Samuel Jolayemi, Figen Tokatli, Banu OzenMarly Flores MorenoОценок пока нет

- Single Cell ProductionДокумент5 страницSingle Cell Productioncha lieОценок пока нет

- Preservation of Fresh Meat With Active and Modified Atmosphere Packaging ConditionsДокумент11 страницPreservation of Fresh Meat With Active and Modified Atmosphere Packaging ConditionsPiroinnovationОценок пока нет

- Synergistic Effect of Tannic Acid and Modified Atmospheric Packaging On The Prevention of Lipid Oxidation and Quality Losses of Refrigerated Striped Catfish SlicesДокумент10 страницSynergistic Effect of Tannic Acid and Modified Atmospheric Packaging On The Prevention of Lipid Oxidation and Quality Losses of Refrigerated Striped Catfish SlicesSajid DijasОценок пока нет

- CHARACTERIZATION AND COMPARISON OF THE THREE CULTIVARS SEED OIL OF OPUNTIA FICUS-INDICA IN TUNISIA S. El Adib, S. Slim, E. HamdeniДокумент7 страницCHARACTERIZATION AND COMPARISON OF THE THREE CULTIVARS SEED OIL OF OPUNTIA FICUS-INDICA IN TUNISIA S. El Adib, S. Slim, E. HamdeniiajpsОценок пока нет

- 1984 Variables Affecting The Yield Fatty Ester From Transesterified Vegetable OilsДокумент6 страниц1984 Variables Affecting The Yield Fatty Ester From Transesterified Vegetable OilsAlberto Hernández CruzОценок пока нет

- WinterizationДокумент11 страницWinterizationmsarriatorresОценок пока нет

- Admin,+journal+manager,+34 AJPCR 18786 RA PDFДокумент4 страницыAdmin,+journal+manager,+34 AJPCR 18786 RA PDFIsaac GutierrezОценок пока нет

- 2019 Hura CrepitansДокумент8 страниц2019 Hura CrepitansNONVIHO GuévaraОценок пока нет

- 116 Total Fatty Acid AnalysisДокумент5 страниц116 Total Fatty Acid AnalysisEvantono Balin ChristiantoОценок пока нет

- Makhzangy Darkening of Brined Olives by Rapid AlkaДокумент14 страницMakhzangy Darkening of Brined Olives by Rapid AlkaRabia Azami HassaniОценок пока нет

- The Physicochemical and Thermal Properties of Malaysian High Free Fatty Acid Crude Palm OilДокумент8 страницThe Physicochemical and Thermal Properties of Malaysian High Free Fatty Acid Crude Palm OilTomTomОценок пока нет

- 11-Douglas Seijum Kohatsu1Документ3 страницы11-Douglas Seijum Kohatsu1Douglas KohatsuОценок пока нет

- Dos Santos2013. Profile of Bioactive Compounds in Avocado Pulp Oil Influence of Drying Processes and Extraction MethodsДокумент9 страницDos Santos2013. Profile of Bioactive Compounds in Avocado Pulp Oil Influence of Drying Processes and Extraction MethodsAntonio MedinaОценок пока нет

- Biolatto2005 PDFДокумент10 страницBiolatto2005 PDFRasha SryoОценок пока нет

- Prafulla Patil, Shuguang Deng, J. Isaac Rhodes, Peter J. LammersДокумент5 страницPrafulla Patil, Shuguang Deng, J. Isaac Rhodes, Peter J. LammersDinhtai NguyenОценок пока нет

- Passion Fruit Seed Oil As Alternative Feedstock For Biodiesel Production Via TransesterificationДокумент4 страницыPassion Fruit Seed Oil As Alternative Feedstock For Biodiesel Production Via TransesterificationSEP-PublisherОценок пока нет

- Production of Mayonnaise From Date Pit Oil: Amany Mohamed Mohamed Basuny, Maliha Ali Al-MarzooqДокумент6 страницProduction of Mayonnaise From Date Pit Oil: Amany Mohamed Mohamed Basuny, Maliha Ali Al-MarzooqAlphaRaj MekapoguОценок пока нет

- Steam Deacidification of Palm Oil: Food and Bioproducts ProcessingДокумент8 страницSteam Deacidification of Palm Oil: Food and Bioproducts ProcessingIlyas FaizОценок пока нет

- Possible Alternative Utilization of Cynara Spp. II. Chemical Characterization of Their Grain OilДокумент9 страницPossible Alternative Utilization of Cynara Spp. II. Chemical Characterization of Their Grain OilyemresimsekОценок пока нет

- Foods 09 00749Документ13 страницFoods 09 00749Prakash GanjalliОценок пока нет

- 8-The Optimization of Vacuum Frying To Dehydrate Carrot ChipsДокумент9 страниц8-The Optimization of Vacuum Frying To Dehydrate Carrot ChipsMiguel H. Mazzeo Meneses100% (1)

- Effect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventДокумент8 страницEffect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventMega MustikaningrumОценок пока нет

- A 2012 028 Original Paper pp23 29Документ7 страницA 2012 028 Original Paper pp23 29Sahil KumarОценок пока нет

- Fotooxidacion en Helados de CremaДокумент11 страницFotooxidacion en Helados de CremaYonar Shmit Gallo QuispeОценок пока нет

- Biolubricant Synthesis From Waste Cooking Oil Via Enzymatic Hydrolysis Followed by Chemical EsterificationДокумент6 страницBiolubricant Synthesis From Waste Cooking Oil Via Enzymatic Hydrolysis Followed by Chemical EsterificationLeonardo IndraОценок пока нет

- 0006 8705 Brag 1678 4499189 PDFДокумент10 страниц0006 8705 Brag 1678 4499189 PDFArinaAdilaОценок пока нет

- Food Chemistry: Shi-Ping Tian, Ai-Li Jiang, Yong Xu, You-Sheng WangДокумент7 страницFood Chemistry: Shi-Ping Tian, Ai-Li Jiang, Yong Xu, You-Sheng WangpascapanenipbОценок пока нет

- Mndez2007 PDFДокумент9 страницMndez2007 PDFKhaled Saif AldinОценок пока нет

- Castor OilДокумент6 страницCastor OilÖzlem YılmazОценок пока нет

- Characterizacion of Quinoa LipidsДокумент6 страницCharacterizacion of Quinoa LipidsLaura RondánОценок пока нет

- Aceite de FrituraДокумент8 страницAceite de FrituraNestor Andres Urbina SuarezОценок пока нет

- Food Control: G. Pristouri, A. Badeka, M.G. KontominasДокумент7 страницFood Control: G. Pristouri, A. Badeka, M.G. KontominasKhaled Saif AldinОценок пока нет

- Deterioration Fo Cane Juice - Sources and IndicatorsДокумент9 страницDeterioration Fo Cane Juice - Sources and IndicatorsDavid Fernando Tirado ArizaОценок пока нет

- Synthesis and Characterization of Luffa Cylindrica Fatty Acids-Based Alkyd ResinsДокумент13 страницSynthesis and Characterization of Luffa Cylindrica Fatty Acids-Based Alkyd Resinskavya shahОценок пока нет

- Salmonella Egg YolkДокумент8 страницSalmonella Egg YolkDeavid PrietoОценок пока нет

- Extraction of Avocado Peel Oil Using A Soxhlet Extractor and Investigation of Its Physicochemical PropertiesДокумент17 страницExtraction of Avocado Peel Oil Using A Soxhlet Extractor and Investigation of Its Physicochemical PropertiesNaHuynJungОценок пока нет

- Formation and Characterization of Paint Based On Alkyd Resin Derivative of Ximenia Americana (Wild Olive) Seed OilДокумент11 страницFormation and Characterization of Paint Based On Alkyd Resin Derivative of Ximenia Americana (Wild Olive) Seed OilUlfahanny RachsetyaОценок пока нет

- Olive Oil: Chemistry and TechnologyОт EverandOlive Oil: Chemistry and TechnologyDimitrios BoskouРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Man - Machine Chart PDFДокумент1 страницаMan - Machine Chart PDFMakarandd KolekarОценок пока нет

- InTech-Supply Chain Management SCM Theory and EvolutionДокумент13 страницInTech-Supply Chain Management SCM Theory and EvolutionRahat KhanОценок пока нет

- "Response Surface Methodology:An Overview": Ashwin Pathak, Dr. Vijaya Kumar K.NДокумент5 страниц"Response Surface Methodology:An Overview": Ashwin Pathak, Dr. Vijaya Kumar K.Ncsrajmohan2924Оценок пока нет

- Icaiea 2018Документ174 страницыIcaiea 2018csrajmohan2924Оценок пока нет

- 1508 6365 1 PBДокумент13 страниц1508 6365 1 PBcsrajmohan2924Оценок пока нет

- AgribusinessДокумент165 страницAgribusinesscsrajmohan2924Оценок пока нет

- Productions & Operations Management PDFДокумент164 страницыProductions & Operations Management PDFDuma DumaiОценок пока нет

- Omega Review PaperДокумент33 страницыOmega Review Papercsrajmohan2924Оценок пока нет

- Operations ManagementДокумент290 страницOperations Managementrockon60594% (104)

- A 1369 e 00Документ71 страницаA 1369 e 00Waseem A. AlkhateebОценок пока нет

- Solid WasteДокумент30 страницSolid WasteSanjay TiwariОценок пока нет

- Health CareДокумент233 страницыHealth Carecsrajmohan2924100% (2)

- Value EngineeringДокумент12 страницValue Engineeringcsrajmohan2924Оценок пока нет

- Operations ManagementДокумент68 страницOperations ManagementVijina ViswanadhОценок пока нет

- Construction SCMДокумент40 страницConstruction SCMcsrajmohan2924Оценок пока нет

- Solid Waste LandfillsДокумент7 страницSolid Waste Landfillscsrajmohan2924Оценок пока нет

- Application of 7 Quality Control (7 QC) Tools For Continuous Improvement of Manufacturing ProcessesДокумент8 страницApplication of 7 Quality Control (7 QC) Tools For Continuous Improvement of Manufacturing Processescsrajmohan2924Оценок пока нет

- AUTVS Green Belt BrochureДокумент2 страницыAUTVS Green Belt Brochurecsrajmohan2924Оценок пока нет

- Minitab DOE Tutorial PDFДокумент32 страницыMinitab DOE Tutorial PDFnmukherjee20100% (3)

- Green Supply-Chain Management.a State-Ofthe-Art Literaturereview.2007.Srivastava.Документ28 страницGreen Supply-Chain Management.a State-Ofthe-Art Literaturereview.2007.Srivastava.sankofakanianОценок пока нет

- A Multicriteria Decision Support System For Landfill SelectionДокумент8 страницA Multicriteria Decision Support System For Landfill SelectionGEORGIOS LOLOSОценок пока нет

- VRPДокумент20 страницVRPcsrajmohan2924Оценок пока нет

- VRPДокумент20 страницVRPcsrajmohan2924Оценок пока нет

- Anna University Report FormatДокумент7 страницAnna University Report Formatdilip_66690% (10)

- A 0-1 Model For Fire and Emergency Service Facility Location Selection:A Case Study in NigeriaДокумент10 страницA 0-1 Model For Fire and Emergency Service Facility Location Selection:A Case Study in Nigeriacsrajmohan2924Оценок пока нет

- AntДокумент20 страницAntcsrajmohan2924Оценок пока нет

- A 0-1 Model For Fire and Emergency Service Facility Location Selection:A Case Study in NigeriaДокумент10 страницA 0-1 Model For Fire and Emergency Service Facility Location Selection:A Case Study in Nigeriacsrajmohan2924Оценок пока нет

- A 0-1 Model For Fire and Emergency Service Facility Location Selection:A Case Study in NigeriaДокумент10 страницA 0-1 Model For Fire and Emergency Service Facility Location Selection:A Case Study in Nigeriacsrajmohan2924Оценок пока нет

- Plant Layout Design With Simulation: XdxdyДокумент6 страницPlant Layout Design With Simulation: Xdxdycsrajmohan2924Оценок пока нет

- Anaerobic Digestion BasicsДокумент6 страницAnaerobic Digestion BasicsMohamed HammamОценок пока нет

- Fatty Acid Composition and Quality Characteristic of Some Vegetable OilsДокумент5 страницFatty Acid Composition and Quality Characteristic of Some Vegetable OilsLuki Wahyuning TiyasОценок пока нет

- SESSION - 2021-22 Revision Booklet Term - I Science Grade - 6Документ17 страницSESSION - 2021-22 Revision Booklet Term - I Science Grade - 6hasneekОценок пока нет

- Growth of Eggplant Using Animal Manure, Garbage Soil, Organic FertilizerДокумент9 страницGrowth of Eggplant Using Animal Manure, Garbage Soil, Organic FertilizerJaypee BrionesОценок пока нет

- Combine Enzyme To Increase Loaf VolumeДокумент11 страницCombine Enzyme To Increase Loaf VolumeTrinh LamОценок пока нет

- Current Research in BiotechnologyДокумент16 страницCurrent Research in BiotechnologyDevita AmeliaОценок пока нет

- Preserving JaggeryДокумент6 страницPreserving JaggerySureshОценок пока нет

- A Brief Study On Neem (Azarrdirachta Indica A.) and Its Application-A ReviewДокумент4 страницыA Brief Study On Neem (Azarrdirachta Indica A.) and Its Application-A ReviewUdhaya KumarОценок пока нет

- Pullulanase Role in Starch Hydrolysis and Potentia PDFДокумент15 страницPullulanase Role in Starch Hydrolysis and Potentia PDFumunera2997Оценок пока нет

- Chemistry Investigatory Project: Pratyush Sharma XII - C' Roll No. - 35Документ12 страницChemistry Investigatory Project: Pratyush Sharma XII - C' Roll No. - 35Ruchi jaiswalОценок пока нет

- SG Rebong Medical Clinic: Update Product Cost and RevenueДокумент4 страницыSG Rebong Medical Clinic: Update Product Cost and RevenueSai BomОценок пока нет

- Carbon Black - PAH and RegulationsДокумент6 страницCarbon Black - PAH and RegulationsHeru SetiawanОценок пока нет

- Citric Acid-Production, Technology, Applications, Patent, Consultants, Company Profiles, Reports, MarketДокумент7 страницCitric Acid-Production, Technology, Applications, Patent, Consultants, Company Profiles, Reports, MarketGuillermo PARÉОценок пока нет

- FST 4822Документ54 страницыFST 4822Faatimah ShameemahОценок пока нет

- Activity and Purity Tests of Starter CultureДокумент12 страницActivity and Purity Tests of Starter CultureRohit PandeyОценок пока нет

- Natural Rubber: RSC Green Chemistry November 2009Документ33 страницыNatural Rubber: RSC Green Chemistry November 2009Çakıl ŞenolОценок пока нет

- Flax SeedДокумент12 страницFlax SeedabhilashОценок пока нет

- Sansthanam Abhay Daanam - 2020Документ28 страницSansthanam Abhay Daanam - 2020nikhil bajajОценок пока нет

- 2021 ADF Media kit-DIAA MagazineДокумент4 страницы2021 ADF Media kit-DIAA MagazineMuhammad RehmanОценок пока нет

- FMD Food List Phase 1 PDFДокумент2 страницыFMD Food List Phase 1 PDFLaraLencinaОценок пока нет

- Project Report On Extra Neutral Alcohol With Maize As Raw MaterialДокумент6 страницProject Report On Extra Neutral Alcohol With Maize As Raw MaterialEIRI Board of Consultants and PublishersОценок пока нет

- Gen Science P3 by Akshay VratДокумент6 страницGen Science P3 by Akshay VratAditya KumarОценок пока нет

- 8cosmetics Formulation LIQUID HAND SOAPДокумент57 страниц8cosmetics Formulation LIQUID HAND SOAPFADZAI DUBEОценок пока нет

- Thermosonication - Its Influence On Various Quality Properties in Fruit JuciesДокумент40 страницThermosonication - Its Influence On Various Quality Properties in Fruit JuciesprasannaОценок пока нет

- Minyakjarakmakalah Bernatal SaragihДокумент10 страницMinyakjarakmakalah Bernatal SaragihDiyah Ayu PermatasariОценок пока нет

- MATTHEW CORREIA Acids Bases and Salts WORKSHEETДокумент4 страницыMATTHEW CORREIA Acids Bases and Salts WORKSHEETFrank MassiahОценок пока нет

- Ysi 2700 SelectДокумент4 страницыYsi 2700 SelectTomaž StrmčnikОценок пока нет

- Tawi Tawi School of Arts and Trade: A Research ProposalДокумент19 страницTawi Tawi School of Arts and Trade: A Research Proposalmohammad arapa SipinОценок пока нет

- Lesson Plan in TVL 12 Topic 2Документ8 страницLesson Plan in TVL 12 Topic 2msalino.tcОценок пока нет

- Lecture 2 - Categories of Microbes - 2022Документ54 страницыLecture 2 - Categories of Microbes - 2022SREERUPAОценок пока нет