Академический Документы

Профессиональный Документы

Культура Документы

Planer Slotter

Загружено:

Kishor PatilИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Planer Slotter

Загружено:

Kishor PatilАвторское право:

Доступные форматы

Valery Marinov, Manufacturing Technology

Planing, Shaping and Broaching

117

6.4

PLANING, SHAPING AND BROACHING

This section covers several machining operations that are used to machine straight and open external or internal surfaces: v v Planing and shaping: these operations are used to machine straight open mainly external surfaces with a single-point cutting tool; Broaching is used to machine straight and open basically internal surface of complex cross-section shapes by means of a special tool called a broach.

PLANING AND SHAPING

Planing and shaping are similar operations, which differ in the kinematics of the process. Planing is a machining operation in which the primary cutting motion is performed by the workpiece and feed motion is imparted to the cutting tool. In shaping, the primary motion is performed by the tool, and feed by the workpiece:

Kinematics of shaping and planing.

The cutting conditions in planing and shaping are illustrated in the figure. Only the shaping operation is portrayed but the cutting conditions are essentially the same and for planing:

Cutting conditions in orthogonal (Left) and oblique (Right) shaping.

118

Planing, Shaping and Broaching

Valery Marinov, Manufacturing Technology

Cutting velocity V in planing is linear and constant along the cutting path. In shaping, the picture is more complicated. The cutting tool is held in the tool post mounted in the ram, which reciprocates over the work with a forward stroke, cutting at velocity V and a quick return stroke at higher velocity. The cutting velocity is therefore not constant along the cutting path. It increases from zero to maximum in the beginning of the stroke and gradually decreases to zero at the end of the stroke. The cutting speed V is assumed to be twice the average forwarded ram velocity. Feed f in planing and shaping is in mm per stroke and is at right angles to the cutting direction. Depth of cut d is defined as usual as the distance between the work and machined surfaces.

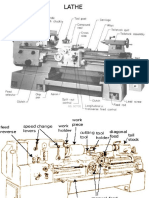

Machine tools for shaping and planing

Shapers Shaping is performed on a machine tool called a shaper. The major components of a shaper are the ram, which has the toolpost with cutting tool mounted on its face, and a worktable, which holds the part and accomplishes the feed motion.

Components of a shaper

Components of an open-side planer.

Planers The machine tool for planing is a planer. Cutting speed is achieved by a reciprocating worktable that moves the part past the single-point cutting tool. Construction and motion capability of a planer permit much larger parts to be machined than on a shaper. Planers can be classified as either open side planers or double-column planers. The open side planer, also known as a single-column planer has a single column supporting the crossrail on which a toolhead is mounted. The configuration of the open side planer permits very wide workparts to be machined. A double-column planer has two columns, one on either side of the bed and worktable. The columns support the crossrail on which one or more toolheads are mounted. The two columns provide a more rigid structure for the operation but limit the width of the work that can be handled.

Cutting tools for shaping and planing

Cutting tool for shaping or planing is essentially the same single-point cutting tool that is used in turning. The only difference is that the cutting tool for planing and shaping must be more rigid to withstand the higher impact cutting forces. The clearance angle must be bigger to avoid plunging of the cutting tool into the machined surface during the quick return of the ram over the workpiece.

Valery Marinov, Manufacturing Technology

Planing, Shaping and Broaching

119

BROACHING

Broaching is a machining operation that involves the use of a multiple-tooth cutting tool moved linearly relative to the workpiece in the direction of the tool axis:

The broaching operation.

The cutting tool is called a broach, and the machine tool is called a broaching machine. The shape of the machined surface is determined by the contour of the cutting edges on the broach, particularly the shape of final cutting teeth. Broaching is a highly productive method of machining. Advantages include good surface finish, close tolerances, and the variety of possible machined surface shapes, some of them can be produced only by broaching. Owing to the complicated geometry of the broach, tooling is expensive. Broaching is a typical mass production operation. Productivity improvement to ten times or even more is not uncommon, as the metal removal rate by broaching is vastly greater. Roughing, semi finishing and finishing of the component is done just in one pass by broaching, and this pass is generally accomplished in seconds. Broaching can be used for machining of various integrate shapes which can not be otherwise machined with other operations. Some of the typical examples of shapes produced by internal broaching are:

Various shapes produced by internal broaching operation.

Cutting conditions in broaching

The cutting speed motion is accomplished by the linear travel of the broach past the work surface. Feed in broaching is unique among machining operations, since is accomplished by the increased step between successive teeth on the broach. This step is actually the feed per tooth, fz. The feed per tooth is not a constant for all the teeth. The total material removed in a single pass of the broach or the total feed f is the cumulative result of all the steps in the tool. Since not all of the broach teeth are engaged simultaneously in cutting but only a part of them, the term active cumulative feed can be introduced, defined as the sum of all the steps only of the active teeth. Depth of cut in broaching is defined as the length of the active cutting edge. In internal broaching, which is the most common type of broaching, the entire length of a single broach tooth is engaged in cutting and the depth of cut is actually the tooth circumference. From the definitions of feed and depth of cut it follows that the total area of cut and respectively the cutting force in broaching will be substantial.

120

Planing, Shaping and Broaching

Valery Marinov, Manufacturing Technology

Cutting tools for broaching

The terminology of the broach is shown in the figure:

Typical broach for internal broaching.

Most broaches are made of high-speed steel, although broaches with carbide inserts either brazed or mechanically attached are also available.

Broaching machines

There is no relative feed motion that is carried out by either the tool or the work. It makes the kinematics of the broaching machine quite simple.

Major components of a broaching machine.

Horizontal (Left) and vertical (Right) broaching machine.

The basic function of a broaching machine is to provide a precise linear motion of the tool past a stationary work position. There are two principal modifications of the broaching machines, horizontal, and vertical. The former are suitable for broaching of relatively long and small diameter holes, while the later are used for short lengths and large diameters.

Вам также может понравиться

- Shaper Chapter From Manufacturing TechnologyДокумент8 страницShaper Chapter From Manufacturing Technologygaurav110790Оценок пока нет

- Press Dies TutorialДокумент13 страницPress Dies TutorialRaj SatoskerОценок пока нет

- Ryobi P271 Owners ManualДокумент36 страницRyobi P271 Owners ManualDavid Gaines100% (1)

- BME Lecture 5 ShaperДокумент6 страницBME Lecture 5 ShaperRoop LalОценок пока нет

- QcadCAM Tutorial enДокумент12 страницQcadCAM Tutorial enartisanicviewОценок пока нет

- Colibri SampleДокумент26 страницColibri SampleGergő Attila TóthОценок пока нет

- Scroll Saw 40-100 16 1246Документ8 страницScroll Saw 40-100 16 1246Theodor EikeОценок пока нет

- Aircraft PropplerДокумент25 страницAircraft PropplerSajjad ShamimОценок пока нет

- Sutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesДокумент3 страницыSutton Tools L343 Engineers Black Book - 3rd Edition 235 PagesPloop2000Оценок пока нет

- Woodworking MachineryДокумент511 страницWoodworking MachineryCristiano RochaОценок пока нет

- Layher Allround CatalogДокумент52 страницыLayher Allround CatalogOswaldo RomeroОценок пока нет

- BenchMark ShopCraftДокумент21 страницаBenchMark ShopCraftn9mct50% (2)

- Car Maintainer, Group B: Passbooks Study GuideОт EverandCar Maintainer, Group B: Passbooks Study GuideОценок пока нет

- Sunlu s2 ManualДокумент9 страницSunlu s2 ManualDan HendersonОценок пока нет

- Precision Drill Frame ConstructionДокумент7 страницPrecision Drill Frame ConstructionMahesa SanggadipaОценок пока нет

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureДокумент20 страницDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaОценок пока нет

- PowerTIG 250EX 2016Документ32 страницыPowerTIG 250EX 2016Bob john100% (1)

- Kinematics of PantographДокумент10 страницKinematics of PantographFa VelizОценок пока нет

- Riding Mower PartsДокумент17 страницRiding Mower PartsDwight MorrisonОценок пока нет

- Hand PlanesДокумент3 страницыHand PlanesDavid DonaldsonОценок пока нет

- Catalog CMT PDFДокумент396 страницCatalog CMT PDFmillenaОценок пока нет

- S.70349 David BrownДокумент92 страницыS.70349 David BrownRyan WshaОценок пока нет

- Portable WorkshopДокумент7 страницPortable WorkshopJose PichardoОценок пока нет

- Threading OptionsДокумент3 страницыThreading Optionsapi-522254901Оценок пока нет

- Milling CatalogueДокумент127 страницMilling CatalogueCristian FuentesОценок пока нет

- The "How-To-Do-It" Books 1Документ130 страницThe "How-To-Do-It" Books 1Gutenberg.org100% (2)

- Woodwork Joints: How They Are Set Out, How Made and Where UsedОт EverandWoodwork Joints: How They Are Set Out, How Made and Where UsedОценок пока нет

- Wood Tooling CatalogДокумент32 страницыWood Tooling CatalogLam NguyenОценок пока нет

- Lathe: GS, SctceДокумент48 страницLathe: GS, SctceGouthamPrasad100% (2)

- Nomenclature of Face and End Milling CutterДокумент4 страницыNomenclature of Face and End Milling CutterIsmael AibisОценок пока нет

- Wooden Scrub Plane From ScrapДокумент9 страницWooden Scrub Plane From ScrapRod HyattОценок пока нет

- Shaper Used As Surface GrinderДокумент1 страницаShaper Used As Surface Grinderradio-chaserОценок пока нет

- Workshop Manual Demo PurposeДокумент36 страницWorkshop Manual Demo PurposeAnindya Vikram SinghОценок пока нет

- Lathebeddesign00hornrich PDFДокумент56 страницLathebeddesign00hornrich PDFLatika KashyapОценок пока нет

- Sheet MetalДокумент5 страницSheet MetalAlapati PrasadОценок пока нет

- Dapra Biax Article Art of ScrapingДокумент2 страницыDapra Biax Article Art of ScrapingPedro Ernesto SilvaОценок пока нет

- Woodworking Plans - RabbetingДокумент3 страницыWoodworking Plans - RabbetingBob Kowalski100% (2)

- US CAT Niagara Cutter Catalog GT17-136Документ342 страницыUS CAT Niagara Cutter Catalog GT17-136MANUEL VICTORОценок пока нет

- Machinists Tools by Williams 1944Документ32 страницыMachinists Tools by Williams 1944OSEAS GOMEZОценок пока нет

- ArtofWoodworking WorkbenchДокумент4 страницыArtofWoodworking Workbenchsalulai100% (1)

- Sash PlanesДокумент5 страницSash PlanesBlakdawg15100% (1)

- Planer Quick Return MechanismДокумент21 страницаPlaner Quick Return Mechanismlalagandu100% (1)

- Machining Processes Used To Produce Various Shapes: MillingДокумент28 страницMachining Processes Used To Produce Various Shapes: MillingSuleiman SaidОценок пока нет

- Bandsaw ManualДокумент52 страницыBandsaw ManualPatty Ulrich0% (2)

- Wood Joint Work Part 4Документ2 страницыWood Joint Work Part 4Lo M'hОценок пока нет

- Popular Woodworking No 78 May 1994Документ100 страницPopular Woodworking No 78 May 1994aleksandar.omasystemsОценок пока нет

- A Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.От EverandA Little Book of Vintage Designs and Instructions for Making Dainty Gifts from Wood. Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box: Including a Fitted Workbox, a Small Fretwork Hand Mirror and a Lady's Brush and Comb Box.Оценок пока нет

- Four-Way ClampsДокумент4 страницыFour-Way ClampsPierre799esОценок пока нет

- End Mill and Cutting Tool Design Criteria and Technical FeaturesДокумент4 страницыEnd Mill and Cutting Tool Design Criteria and Technical FeaturesdkkОценок пока нет

- E-Book - Cutting Tools For CNC RouterДокумент11 страницE-Book - Cutting Tools For CNC RouterVictor ParvanОценок пока нет

- Veritas Steam Bending BookletДокумент16 страницVeritas Steam Bending BookletDelfina CamachoОценок пока нет

- 5 Router PlaneДокумент4 страницы5 Router PlaneAngel R Rodriguez100% (1)

- Name of The Experiment:: Study and Operation Bench Drilling MachineДокумент5 страницName of The Experiment:: Study and Operation Bench Drilling MachinemadОценок пока нет

- Anonymous Go-Kart: Specification ReportДокумент17 страницAnonymous Go-Kart: Specification ReportKishor PatilОценок пока нет

- Development of SurfacesДокумент6 страницDevelopment of SurfacesKishor PatilОценок пока нет

- Modernization and Removal of Obsolenscence (Modrobs)Документ3 страницыModernization and Removal of Obsolenscence (Modrobs)Kishor PatilОценок пока нет

- About NBA 2. Objective of NBA 3. Authorities of The NBAДокумент5 страницAbout NBA 2. Objective of NBA 3. Authorities of The NBAKishor PatilОценок пока нет

- Orthographic ProjectionДокумент10 страницOrthographic ProjectionKishor PatilОценок пока нет

- Maharashtra Institute of Technology, Aurangabad: "Padma Shri" Dr. Kiran Seth Speech and Student Chapter InaugurationДокумент1 страницаMaharashtra Institute of Technology, Aurangabad: "Padma Shri" Dr. Kiran Seth Speech and Student Chapter InaugurationKishor PatilОценок пока нет

- Schedule of WorkshopRW13Документ2 страницыSchedule of WorkshopRW13Kishor PatilОценок пока нет

- Angle Measurement: S.Y. B.Tech. (MQC) Part-IIДокумент1 страницаAngle Measurement: S.Y. B.Tech. (MQC) Part-IIKishor PatilОценок пока нет

- Seminar 2Документ20 страницSeminar 2Kishor PatilОценок пока нет

- Revised Ty MechДокумент37 страницRevised Ty MechKishor PatilОценок пока нет

- Assembly 4Документ6 страницAssembly 4Kishor PatilОценок пока нет

- Introduction To Aircraft IndustryДокумент94 страницыIntroduction To Aircraft IndustryKishor PatilОценок пока нет

- Cad Cam CaeДокумент60 страницCad Cam CaeKishor PatilОценок пока нет

- AerospaceДокумент63 страницыAerospaceKishor PatilОценок пока нет

- 2) I Have A Bath. 3) I Cut My Nails. 4) I Comb My Hair. 5) I Wear Clean ClothesДокумент8 страниц2) I Have A Bath. 3) I Cut My Nails. 4) I Comb My Hair. 5) I Wear Clean ClothesKishor PatilОценок пока нет

- Manufacturing OperationsДокумент31 страницаManufacturing OperationsAkash KharatОценок пока нет

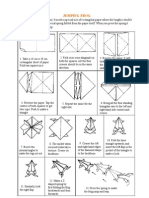

- FrogdoitДокумент1 страницаFrogdoitKishor PatilОценок пока нет

- Co-Simulation of Algebraically Coupled Dynamic Subsystems Without Disclosure of Proprietary Subsystem ModelsДокумент13 страницCo-Simulation of Algebraically Coupled Dynamic Subsystems Without Disclosure of Proprietary Subsystem ModelsKishor PatilОценок пока нет

- Tổng hợp các tiêu chuẩn hiện cóДокумент10 страницTổng hợp các tiêu chuẩn hiện cóĐường LâmОценок пока нет

- Quantum With Unity Pro: 140 ERT 854 10 Time Stamp Module User's ManualДокумент92 страницыQuantum With Unity Pro: 140 ERT 854 10 Time Stamp Module User's ManualarfeemОценок пока нет

- Ewo PDFДокумент2 страницыEwo PDFKellyОценок пока нет

- Career Objective: 60.20% MarksДокумент2 страницыCareer Objective: 60.20% MarksSumit JangraОценок пока нет

- CAKRA Presentation PDFДокумент16 страницCAKRA Presentation PDFAtozpay AtozpayОценок пока нет

- Power System Loss Analysis-EngДокумент5 страницPower System Loss Analysis-EngRatana KemОценок пока нет

- Hitachi CP RX94Документ3 страницыHitachi CP RX94Jose Faver Urbano AОценок пока нет

- Disclosure To Promote The Right To InformationДокумент6 страницDisclosure To Promote The Right To InformationAyoub BouguernОценок пока нет

- G3608 Spec SheetДокумент4 страницыG3608 Spec SheetTu Pham100% (1)

- Chemicals Zetag DATA Beads Zetag 7563 - 0410Документ2 страницыChemicals Zetag DATA Beads Zetag 7563 - 0410PromagEnviro.comОценок пока нет

- Surgelogic NQPanelboards PDFДокумент6 страницSurgelogic NQPanelboards PDFgramirezsalazar@yahoo.com.mxОценок пока нет

- Abp-2030 Tds-Iso-EngДокумент2 страницыAbp-2030 Tds-Iso-Engkatolokchok100% (2)

- ULC UL142 Comparison SpreadsheetДокумент43 страницыULC UL142 Comparison Spreadsheetgrincheu70Оценок пока нет

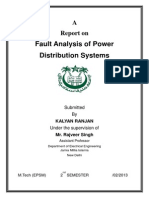

- A Report On Fault Analysis of Power Distribution SystemsДокумент19 страницA Report On Fault Analysis of Power Distribution SystemsKalyan Ranjan100% (3)

- T7-R18-P2-Principles-v9.1 - Study NotesДокумент12 страницT7-R18-P2-Principles-v9.1 - Study NotesRanjeev LabhОценок пока нет

- Lenovo Ideapad S145-15iil LCFC Nm-c711 Gs44d Gs54dДокумент60 страницLenovo Ideapad S145-15iil LCFC Nm-c711 Gs44d Gs54dJulián ToméОценок пока нет

- Iso 8502 - 9-2001Документ14 страницIso 8502 - 9-2001smupy_122-1Оценок пока нет

- Java Applications Developer Responsibilities and DutiesДокумент4 страницыJava Applications Developer Responsibilities and DutiessatishОценок пока нет

- HSDPA 7.2Mbps Bitrate RequirementsДокумент2 страницыHSDPA 7.2Mbps Bitrate RequirementsVikrant SinghОценок пока нет

- RISHABH Rish EINE Digital Panel Meter DatasheetДокумент6 страницRISHABH Rish EINE Digital Panel Meter Datasheetpriyanka236Оценок пока нет

- SelectPdf HTML To PDF Online APIДокумент7 страницSelectPdf HTML To PDF Online APISelectPdfОценок пока нет

- Sap ScriptДокумент15 страницSap ScriptamarpoonamОценок пока нет

- Stealth Cam Instruction Manual For Model STC g42ngДокумент60 страницStealth Cam Instruction Manual For Model STC g42ngBillОценок пока нет

- BSNL Training ReportДокумент47 страницBSNL Training Reportdivatitiksha33% (3)

- Mitsubishi Manuals 1004Документ487 страницMitsubishi Manuals 1004Rohmat Budi PrasetyaОценок пока нет

- Manual Tecnico de Reparacio Tele DisneyДокумент32 страницыManual Tecnico de Reparacio Tele Disneyyo mismoОценок пока нет

- Nexus Chassis LP8A EX4200Документ69 страницNexus Chassis LP8A EX4200servel123Оценок пока нет

- Inmarsat BGAN Terminal Comparison PDFДокумент2 страницыInmarsat BGAN Terminal Comparison PDFJoel BarbaraОценок пока нет

- 162gb 0Документ41 страница162gb 0JdhdkdidbdjdubdnjfbebeirhrbОценок пока нет

- VertualizationДокумент5 страницVertualizationPawan YadavОценок пока нет