Академический Документы

Профессиональный Документы

Культура Документы

ENGINEERING - MILL - Construction Plans For Horizontal Bench Mill. - (Ebook Diy Building How To Machine Tools 178848 PDF

Загружено:

Glaucius BorbaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ENGINEERING - MILL - Construction Plans For Horizontal Bench Mill. - (Ebook Diy Building How To Machine Tools 178848 PDF

Загружено:

Glaucius BorbaАвторское право:

Доступные форматы

for the bolts are 3/8 in. deep, and tapped with a 1/4-in. bottoming tap.

The base is a piece of 1/2-in. cold-rolled steel, or concrete, simplifying the work of con- iron, and is fastened to the front slide struction, and providing a means of mak- by means of two 1/4-in. flat-head screws, ing very heavy machines with a minimum countersinking the slide for the heads, of large castings. This method can be so that they will be flush with the adapted to the use of the mechanic in the surface. The spindle and overarm pipes small shop, and by using a combination of are fastened to the front slide by means of cement and cold-rolled steel, small ma- flanges, the pipes being boredthe overchines can be constructed sufficiently arm pipe to a sliding fit for a piece of strong to stand a considerable amount of l 1/4-in. cold-rolled steel, the spindle pipe heavy work, while eliminating entirely a to fit the two bronze bushings which form body casting. the spindle bearings. These pipes must The bench miller described in this article be fitted absolutely square with the front is an example of this method; only one slide. A bolt and pipe, with a flat piece casting is employed, and the rest of the of steel, will be seen at the bottom of the machine is of such construction that but base; these form a brace for that part of few simple tools, and little machine work, the slide projecting below the bench top, are required in the building of it. the flat piece also forming a bearing for The steel, flat and round, which can be the elevating screw. When this brace, the obtained from any steel merchant, is first base, front slide, and pipes have been carefully checked for straightness and assembled, the next operation is the pourparallelism, using a good straightedge and ing of the cement. The anchor bolts are a micrometer calii n t e r w o u n d with per; if any bent soft-iron wire, as spots are discernishown, and the form ble, straighten careis placed in position, fully, and if thick and clamped rigidly. spots occur in the A mixture of 1 part slides, scrape them cement to 3 parts off until a level surclean, sharp sand face is obtained. has proved ideal for The holes in the this purpose; durfront slide and base ing the pouring, should then be laid the spaces between off and drilled, inthe screws, and all cluding the holes edges and corners, for the spindle and must be thoroughly overarm, and the 1/4poked with a knife, in. holes for the anor o t h e r s h a r p chor bolts. These pointed tool, to inanchor bolts are 1/4sure that the cement in. stove bolts of reaches every part. varying lengths, as After pouring, level shown in the smaller off the surface, and drawing, and are then lay the assemplaced so that the bly aside to season; heads will be stagthis is a very imgered, to distribute portant part of the the hold and strains construction, the ceMain-Body Casting is Poured in a Mold Made more evenly in the The ment being wetted of Soft Pine, the Top of the Front Slide being cement. The holes Shaped to Conform to the Contour of the Casting at least twice a day

3557

URING the late war, machines which D required massive castings in their design were built with beds of cement or

3558

POPULAR

MECHANICS

of cold-rolled steel, as shown in the detail drawing, the various pieces being held together with 1/4 in. flat-head screws. This job can best be done by using a few rivets to hold the assembly, while performing the drilling and tapping operations. The T-slot in the table permits the use of 3/8in. bolts, to hold a vise, or the various fixtures used on the machine. All screws used on the vertical, longitud i n a l , and crossfeeds, are turned out of coldrolled steel, and run in b r a s s or bronze n u t s , fastened to the slides with round-head screws. The equipment necessary, such as arbors, centers, and a small vise with a homemade swivel base, can be made up as required. A good chuck should form part of the equipment, and should be fitted with a flange threaded to fit the spindle nose. While foot power may be used with the machine, a small 1/4-hp. motor, driving through a countershaft and cone pulley mounted directly over the machine, is advised. The cone pulley should be of the same size as the one on the miller. The builder of this miller will have a splendid little tool, at small cost.

for a period of about a week. While the cement is thus seasoning, the screws, slides, spindle, knee, and various other component parts may be made up. The spindle s h o u l d be turned and b o r e d , using a No. 2 Morse taper in the nose, a n d cutting the thread for the chuck, which is 1/16in. pitch; b r o n z e bushings are used for the bearings, being t u r n e d to make a press fit in the spindle pipe. A three-step cone pulley is t u r n e d to the dimensions shown, and is fastened to the spindle by a safety setscrew. A s i m p l e pattern is built for the knee casting, which is made of soft gray iron, and machined as indicated. On the top of the knee is the main carriage slide; it is machined very carefully on the edges and faces, and must be perfectly square in all directions. On the vertical sides of this slide are screwed the angle members, two for the table slide and two for the carriage slide. These angle members are made of 3/16-in. angle iron, filed and fitted with great care, a cut being taken through the inside fillet, on the shaper, before fitting; 1/4,-in. round-head screws hold them to the carriage slide. The table is built up

Вам также может понравиться

- Metalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopОт EverandMetalworkers' Hints and Tips for Home Machinists: Practical & Useful Advice for the Small ShopVic SmeedОценок пока нет

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsОт EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsОценок пока нет

- How to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheОт EverandHow to Run a Lathe - Volume I (Edition 43) The Care and Operation of a Screw-Cutting LatheРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Plans For Radial Drill Press PDFДокумент4 страницыPlans For Radial Drill Press PDFhightecrebelОценок пока нет

- Building: LatheДокумент60 страницBuilding: LathePierre799es86% (7)

- DIY Plans - Model Steam Marine EngineДокумент5 страницDIY Plans - Model Steam Marine Enginemigss107483% (6)

- 6 in ShaperДокумент4 страницы6 in ShaperRed Warrant100% (1)

- WPS 39 Model Engineers Workshop Projects PDFДокумент55 страницWPS 39 Model Engineers Workshop Projects PDFabeeraj100% (3)

- Lewis MillДокумент9 страницLewis MillCelso Ari Schlichting100% (2)

- Caterpillar Service Welding GuideДокумент77 страницCaterpillar Service Welding GuideGaston Gingarelli100% (1)

- Bench MillДокумент2 страницыBench MillEdward Elric2Оценок пока нет

- Design and Fabrication of Screw JackДокумент18 страницDesign and Fabrication of Screw JackPawan Seethepalli100% (2)

- Popular Mechanics - Hobby Lathe#1Документ19 страницPopular Mechanics - Hobby Lathe#1sonofsilas100% (1)

- A Rotary Sine Bar For The LatheДокумент2 страницыA Rotary Sine Bar For The LatheTheodor EikeОценок пока нет

- 3 in Shaper PDFДокумент5 страниц3 in Shaper PDFRob NairОценок пока нет

- Miniature Machining TechniquesДокумент40 страницMiniature Machining Techniqueskriskee1376% (17)

- Lathe Tool Post Grinder PlansДокумент5 страницLathe Tool Post Grinder Plansozland9Оценок пока нет

- Building A Six-Inch Turret LatheДокумент5 страницBuilding A Six-Inch Turret LatheJan SteinmanОценок пока нет

- Lathe-Milling AttachmentДокумент4 страницыLathe-Milling AttachmentFrenchwolf420Оценок пока нет

- Lathe Milling Attachment GuideДокумент7 страницLathe Milling Attachment Guidedodgydonkey100% (1)

- Shaper Gear CuttingДокумент4 страницыShaper Gear Cuttingnevadablue100% (4)

- Ajax Model Engineer 1947Документ4 страницыAjax Model Engineer 1947Stewart RunnallsОценок пока нет

- Homemade Bandsaw From Pipe Fittings and Auto PartsДокумент4 страницыHomemade Bandsaw From Pipe Fittings and Auto PartsJan Steinman100% (2)

- Simple Boring BarДокумент3 страницыSimple Boring BarMike Nichlos100% (1)

- RC Airplane Engine PlansДокумент8 страницRC Airplane Engine PlansLacramioara Veronica Malael100% (1)

- Popular Mechanics Plans-Small Horizontal Steam EngineДокумент5 страницPopular Mechanics Plans-Small Horizontal Steam Enginebogtudor100% (2)

- Airbus Seal Installation ManualДокумент9 страницAirbus Seal Installation ManualJivendra KumarОценок пока нет

- Lathe Chuck Backplate FittingДокумент2 страницыLathe Chuck Backplate FittingAnonymous iYKTkmhpZ100% (3)

- Micro-Lathe Plans (Popular Mechanics)Документ4 страницыMicro-Lathe Plans (Popular Mechanics)sjdarkman1930100% (13)

- Turning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningОт EverandTurning Lathes - A Manual For Technical Schools And Apprentices - A Guide To Turning, Screw-Cutting Metal SpinningРейтинг: 2.5 из 5 звезд2.5/5 (2)

- 4in Bench SlotterДокумент4 страницы4in Bench SlotterTeresa Melanathy100% (1)

- 8454 PDFДокумент72 страницы8454 PDFjon@libertyintegrationcom100% (2)

- Home Workshop Milling Machine GuideДокумент31 страницаHome Workshop Milling Machine Guidetaiwest100% (1)

- Shop Made SlotterДокумент4 страницыShop Made Slotternevadablue100% (4)

- A Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesОт EverandA Practical Workshop Companion for Tin, Sheet Iron, and Copper Plate Workers: Containing Rules for Describing Various Kinds of Patterns used by Tin, Sheet Iron, and Copper Plate Workers, Practical Geometry, Mensuration of Surfaces and Solids, Tables of the Weights of Metals, Lead Pipe, Tables of Areas and CircumferencesОценок пока нет

- WpsДокумент2 страницыWpsnaseema1100% (1)

- Clayton Steam Truck-Ocr PDFДокумент76 страницClayton Steam Truck-Ocr PDFbackyardcnc100% (1)

- Parts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.AДокумент16 страницParts Price List Atlas Milli NG Machine: Atlas Press Company - Kalamazoo 13D Michigan - U.S.Ataxmac100% (2)

- Process Failure Mode Effects AnalysisДокумент20 страницProcess Failure Mode Effects Analysissriramachandira100% (1)

- Light Ball-Bearing Column GrinderДокумент2 страницыLight Ball-Bearing Column GrinderFernando Morocho100% (1)

- Quorn - Part 1-4Документ24 страницыQuorn - Part 1-4catalin9494100% (3)

- Lathe Cross-Sli Olders.: " DuplexДокумент3 страницыLathe Cross-Sli Olders.: " Duplexjohnboy183100% (1)

- SIMPLIFIED MODEL STEAM ENGINEДокумент2 страницыSIMPLIFIED MODEL STEAM ENGINESabolek100% (1)

- Small Shaping MachineДокумент4 страницыSmall Shaping Machineomikami73% (11)

- Grinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogДокумент11 страницGrinding Lathe Tools On A Belt Sander - Part 3 - MachinistBlogredneckrepairsОценок пока нет

- MANUFACTURING TECHNOLOGY CASTING MCQSДокумент74 страницыMANUFACTURING TECHNOLOGY CASTING MCQSjpbhimani100% (1)

- Diamond Tool Holder for Mini LatheДокумент12 страницDiamond Tool Holder for Mini Latheian_newОценок пока нет

- Motor Driven HacksawДокумент3 страницыMotor Driven HacksawJim100% (3)

- Kant Twist Clamp AssemblyДокумент6 страницKant Twist Clamp Assemblysuzycreamcheeze60% (5)

- Atlas Lathe AccessoriesДокумент8 страницAtlas Lathe Accessoriesfix100% (1)

- Summary of Cutting Data For Profile Surface - Ball Nose: Material DetailsДокумент5 страницSummary of Cutting Data For Profile Surface - Ball Nose: Material DetailsPalade LucianОценок пока нет

- Usman Liaqat (17MME-S1-313) Shot PeeningДокумент6 страницUsman Liaqat (17MME-S1-313) Shot PeeningUsman GujjarОценок пока нет

- Buehler Technotes - Indentation Testing MappingДокумент3 страницыBuehler Technotes - Indentation Testing Mappingdev-nullОценок пока нет

- Surface Finish - Typical ValuesДокумент1 страницаSurface Finish - Typical ValuesShrikrishna BirajdarОценок пока нет

- PART MANUAL PM-300/U-PT400Документ24 страницыPART MANUAL PM-300/U-PT400Дм СевОценок пока нет

- Asme B18.2.3.4M 1999Документ14 страницAsme B18.2.3.4M 1999Jesse ChenОценок пока нет

- Failure of Jigs & FixtureДокумент27 страницFailure of Jigs & FixtureTooling ganeshОценок пока нет

- Metal FormingДокумент20 страницMetal FormingPrashant ShreshthaОценок пока нет

- Problems For Allowances in CastingДокумент2 страницыProblems For Allowances in CastingMohit Passi100% (2)

- Grinding MachineДокумент4 страницыGrinding MachineSridhar BhagavatullaОценок пока нет

- Operation Management Objective QuestionsДокумент22 страницыOperation Management Objective QuestionsAnonymous LFgO4WbIDОценок пока нет

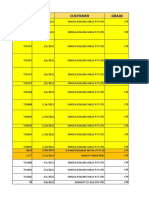

- City Vendor Type Ready To Onboard On OMS Email Address Vendor Type1Документ3 страницыCity Vendor Type Ready To Onboard On OMS Email Address Vendor Type1Biswajet RouthОценок пока нет

- Bibliography of Resistance Welding, Compiled For The PDFДокумент46 страницBibliography of Resistance Welding, Compiled For The PDFdhruvaОценок пока нет

- DTI Installation Instructions PDFДокумент3 страницыDTI Installation Instructions PDFBrad BorgesОценок пока нет

- Nail Making Business PlanДокумент11 страницNail Making Business PlanAbdul-Baaki KadriОценок пока нет

- Proposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsДокумент11 страницProposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsShipra MishraОценок пока нет

- TC Excel SheetДокумент16 страницTC Excel SheetVasudev DabholkarОценок пока нет

- TS 3 2022 MFP1Документ2 страницыTS 3 2022 MFP1Goloo yadavОценок пока нет

- Drilling Hole Opener WebДокумент2 страницыDrilling Hole Opener WebBehrangОценок пока нет

- Ball and Basket MillДокумент2 страницыBall and Basket Millusama juggОценок пока нет

- MappingДокумент13 страницMappingAzzah NazОценок пока нет

- PQMP-ITP-001 Rev 0Документ27 страницPQMP-ITP-001 Rev 0asexyguyОценок пока нет