Академический Документы

Профессиональный Документы

Культура Документы

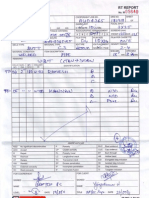

Receipt and Inspection of Materials

Загружено:

Maina MuhoroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Receipt and Inspection of Materials

Загружено:

Maina MuhoroАвторское право:

Доступные форматы

Prepared by muli.samuel.

com

RECEIPT AND INSPECTION OF MATERIALS Materials /inventory may be received from Suppliers Production department User department

Receiving procedure The supplier, on receipt of the purchase order, fills up the buyer's requirements and arranges for delivery of the materials in accordance with the instructions relating to the quantities, time, route, mode of transport etc. mentioned in the purchase order. The section or department that is entrusted the responsibility of receiving materials and getting them inspected is known as 'Receipt' or 'Receiving' department/section. In a small company, the function of receiving materials is generally looked after by the store department. The activities involved are as under: (i) Receipt or collection of materials

Materials to be delivered by the suppliers are received accompanied by the supplier's 'Delivery Challan', 'Delivery Note 'or' Delivery Advice which may either be in duplicate or triplicate. The original copy of the delivery challan is retained by the receipt department. The duplicate copy is stamped 'subject to physical count and inspection 'and is signed by the receipt clerk and is handed over to the supplier's representative. When materials are received with the supplier's delivery challan, the person

from the receiving department takes out the copy of the relevant purchase order and verifies to ensure; that the goods were actually ordered and have been received the supplies are in accordance with the delivery schedule (i.e. excess supply is not received) Purchase order number, part name, part number, broad purchase category and so on are mentioned clearly and correctly (ii) Unpacking and inspection of the goods

Once the store man is satisfied that the goods were actually ordered then unpacking of the goods immediately takes place. This is mostly done in the store receiving yard or it could be in the quarantine storage area. The goods are checked based on the purchase order and the suppliers delivery note thus the store-man checks on;

Prepared by muli.samuel.com

the quantity ordered and quantity delivered or as indicated in the delivery note weight if the goods were ordered based weight size of the goods were ordered on basis of size expiry date of the commodities pack lots check for damages

* Mostly in the private sector the store man usually notifies the user department immediately a delivery is made so that they aid in making sure that the right quality of goods has been received and ascertain that the goods conform to the technical specifications set in the purchase order. Inspection (in public sector) Inspection and acceptance is done by inspection and acceptance committee. This committee is composed of a chairman and at-least other two members appointed by the accounting officer or the head of procuring entity on the recommendation of the procurement unit. Immediately after delivery of the goods works or services the committee; inspects and where necessary test the goods received inspects and review the goods, works or services in order to ensure compliance with the terms or specifications of the contract accept or reject on behalf of the procuring entity the delivered goods works and services ensures that the correct quantity has been received ensure goods, works and services meet the technical standards defined in the contract ensure that the goods, works or services have been delivered or completed on time and any delay noted ensure that all required manuals or documentation have been received issue interim or completion certificates (iii) Storage and generation of goods received information

After inspection, the goods are segregated into accepted/rejected or rework categories and only the fully accepted quantity is forwarded to the stores. The quantity is physically verified and a goods received note is generated. This could be done manually or the system if any. The storekeeper then updates the stock control records or cards, kardex/ledger or bin cards. when updating the bin cards for goods received use a red biro pen

Prepared by muli.samuel.com

(iv)

Invoicing and Payment

Once the storekeeper has completed the goods received reports a copy of Goods Received Note (GRN), original invoice, delivery note, copy of Local Purchase order is attached together and forwarded to finance/ accounts department to facilitate the payments for the supplier. Issuing procedure 1. User department raises a requisition to get goods from the store or warehouse, alternatively the requisition may be send via the electronic systems to the store 2. Once the requisition has been received by the store man, he checks to ensure that its dully signed by the relevant authority 3. The store man confirms the availability of the goods and picks the required amount from the racks and raises an issue not indicating the quantity that has been issued, the requested number in which issues have been issued against and the person receiving the items signs in the issue note which a copy is kept by the store man 4. The quantity issued is updated in the bin cards/ stock control cards. Make sure the quantity issued is accurately subtracted in order to get actual stock balance. Use a blue or black biro pen to update the bin cards. Green colour is usually used by auditors in event of auditing the bin cards Issuing of tools The store man should have a tools register for issuing tools. It may have the following contents Date issue of Employee name PF Type tool of Serial number Date returned Comments (condition)

Preservation of materials/inventory Materials could be preserved in the following ways Painting especially for items prone to corrosion Coating Refrigerating Packaging Treating with chemicals

Prepared by muli.samuel.com

PURCHASING TECHNIQUES AND BASIS OF MATERIAL COSTING Special buying systems (i) Hand to Mouth Buying Hand to mouth buying also called "buying according to the requirements" refers to the frequent purchases of an item in small quantities. The important characteristics of hand to mouth buying are: Purchases are made only when the demand arises. Purchases are made to cover immediate requirements. Quantity purchased is generally small, though, at times, large quantity may be purchased. The terms of contract are negotiated. Competitive bids are generally not obtained, as there is no sufficient time. Suitability of the method These method apply to: Items required for prototypes and for products under development Items which are used infrequently and would not be required to be stocked, because of which they are purchased when they are needed for definite consumption. Machine tools, special building materials, office furniture etc. are some of the examples of this group the immediate requirements of a stock item caused either due to a delay in delivery from regular suppliers or due to an increase in consumption the immediate requirements of items, whose prices are expected to fall in the near future; the procurement of replacement spares ' items which have a limited shelf life and are not stocked for fear of perishability Items which are bulky (e.g. packing materials like wooden boxes and thermocole sheets, cotton waste etc.) and need a lot of storage space. 2. Scheduled Buying Scheduled buying is the process of procuring an item in staggered deliveries according to the delivery schedule furnished to the supplier by the buyer. The salient characteristics of scheduled buying are as follows:

Prepared by muli.samuel.com

A purchase order covering annual requirements (alternatively a purchase order without specifying the order quantity, called open order) is placed with the supplier. The supplier is given the estimate of the procurement needs covering a mutually agreed period of time. It is a common practice to give 2-3 months confirmed schedule and 2-3 months tentative schedule.

Fresh delivery schedules are given to the supplier prior to the completion of the previous schedule. Fresh schedule supersedes the previous schedule.

Suitability of the system Scheduled buying is best suited for Items of regular use such as cutting tools, castings, forgings, lubricants etc. Items produced to the buyer's design and requiring long lead time to manufacture. Proprietary items from suppliers who insist on long-term schedules. 3. Forward Buying Forward buying refers to the procurement of sufficient quantity of an item in advance of its need and at a time when the prices are low (and/or expected to rise). The important characteristics of forward buying are as follows: Purchases are made to cover production requirements for a considerable period Quantity purchased is generally large The atmosphere is usually favourable for negotiation Purchases are made when the prices are low. The buyer also gets a discount on large purchases. 4. Speculative Buying Speculative buying refers to the buying of large requirements of an item, when its price is low with the intention to sell a bulk of it at a higher price for speculative profits. Some important characteristics of speculative buying are: Purchases are in no way related to the company's production programme. An item which is not required for production may be purchased. Speculative buying does not base decisions on quantity. Its single aim is to make speculative profits. The quantity purchased is thus generally high and is as much as the company finance can permit to buy.

Prepared by muli.samuel.com

5. Contract Buying Usually, all purchases are by contract. The term contract buying is applied to those special contracts which call for deferred delivery over a period of time. According to Spriegal, "Contract buying is the purchasing made under contract, usually formal, of needed materials, the delivery of which is frequently spread over a period of time." Some important characteristics of contract buying are: Contracts are given to suppliers for a large amount of future requirements or for a certain period (say a year). Quantity received per occasion is generally small. The cycle time between two consecutive receipts may be a week, fortnight, a month or any period considering the value of requirements, distance and the mode of transport. The buying department usually finds sufficient time to secure competitive bids and negotiate terms of contract. 6. Blanket Orders Blanket orders refer to the purchase of a variety of items from a single source, usually a middleman. Some important characteristics of blanket orders are: A blanket order specifies the categories of items covered by the order The items covered by the order generally have low unit value More than one middleman may be selected to avoid hold-ups in case of non availability of an item with one 'Market-price' is generally specified on the order, which may include a specified method of determining price variations; The supplier is given requirements regarding who supplies and bills at the 'prevailing prices less agreed discount' on the phone. The records of the supplier are open to inspection on demand. Alternatively, the buyer may contact vendors on phone, enquire about price and buy from one who quotes the lowest the other terms of contract being common to all. 7 Seasonal Buying

Seasonal buying refers to 'buying of the annual requirements of an item during its season.' This method is used for items available in a particular season only

Вам также может понравиться

- Halachew Chapter 45 CZДокумент63 страницыHalachew Chapter 45 CZMekiya MuhamedОценок пока нет

- Industerial Managment and Engineering Economy by Chalachew Z (MSC)Документ64 страницыIndusterial Managment and Engineering Economy by Chalachew Z (MSC)Mekiya MuhamedОценок пока нет

- Pem M C07: Project Materials ManagementДокумент77 страницPem M C07: Project Materials ManagementKingSantoshОценок пока нет

- Sap PP CycleДокумент6 страницSap PP Cycleshashank sharmaОценок пока нет

- Module 2 Materia Costing, Planning and ControlДокумент18 страницModule 2 Materia Costing, Planning and Controlazra khanОценок пока нет

- Op MGT Module 3Документ13 страницOp MGT Module 3Emil E. AОценок пока нет

- Sap Notes InterviewДокумент15 страницSap Notes InterviewShane India RazaОценок пока нет

- Acm 602Документ202 страницыAcm 602Hritika SinghОценок пока нет

- PPM FinalДокумент49 страницPPM FinalTadele DandenaОценок пока нет

- Unit 2Документ27 страницUnit 2mbaintern2023Оценок пока нет

- Accounting For Material SolutionsДокумент36 страницAccounting For Material Solutionsdanish khan100% (1)

- Pur CostДокумент1 страницаPur CostravindranathОценок пока нет

- Purchasing ManagementДокумент21 страницаPurchasing ManagementJiju Justin100% (3)

- Procedure of Material Management SyestemДокумент25 страницProcedure of Material Management SyestemNitesh Bhura100% (1)

- Purchasing Management RegulationsДокумент4 страницыPurchasing Management Regulations2074073Оценок пока нет

- Procurement 06052019Документ14 страницProcurement 06052019VenkateshОценок пока нет

- Topic Four Issue and Dispatch: IssuingДокумент23 страницыTopic Four Issue and Dispatch: IssuingScott Tchaller100% (1)

- Purchasing Materials - Module On Cost AccountingДокумент5 страницPurchasing Materials - Module On Cost AccountingAdriel James RestarОценок пока нет

- Purchasing ManagementДокумент113 страницPurchasing ManagementHussain Ehtesham67% (3)

- Documents For OrderingДокумент5 страницDocuments For OrderingJohn LavalieОценок пока нет

- 1) Answer: 13 Important Function of Purchasing Department of An OrganisationДокумент21 страница1) Answer: 13 Important Function of Purchasing Department of An OrganisationBerihun EngdaОценок пока нет

- Note Procurement MidДокумент31 страницаNote Procurement MidRihana Nhat KhueОценок пока нет

- Working Capital Management 3Документ4 страницыWorking Capital Management 3Roshankumar S PimpalkarОценок пока нет

- Warehouse Operations and Activities Receiving and Issuing of SuppliesДокумент13 страницWarehouse Operations and Activities Receiving and Issuing of SuppliesJasmine KariukiОценок пока нет

- Purchase 1Документ20 страницPurchase 1N.Usha RaoОценок пока нет

- Purchase ManagementДокумент32 страницыPurchase ManagementManjula Ashok100% (1)

- Chapter IV Material ManagementДокумент22 страницыChapter IV Material ManagementFiraaОценок пока нет

- OM Lecture 13 Purchase PolicyДокумент13 страницOM Lecture 13 Purchase PolicyqamarulislamОценок пока нет

- MM ch5Документ8 страницMM ch5thebestofworld2014Оценок пока нет

- Parchase DPTMNTДокумент3 страницыParchase DPTMNTBini K NairОценок пока нет

- Store Keeping and Clearing and ForwardingДокумент10 страницStore Keeping and Clearing and ForwardingSooraj PurushothamanОценок пока нет

- ACCTSYS Unit 5Документ12 страницACCTSYS Unit 5Joielyn CabiltesОценок пока нет

- Material Cost and Its AccountingДокумент83 страницыMaterial Cost and Its Accountingramadhanamos620Оценок пока нет

- Purchasing MaterialsДокумент26 страницPurchasing MaterialsJV EstanislaoОценок пока нет

- POM LL GRP 3Документ13 страницPOM LL GRP 32143tohid tasildarОценок пока нет

- Purchasing Management: Taruna Banga Mba-Assistant ProfessorДокумент32 страницыPurchasing Management: Taruna Banga Mba-Assistant ProfessorGunjan BangaОценок пока нет

- Chapter 2 Accounting For Materials: Review SummaryДокумент15 страницChapter 2 Accounting For Materials: Review SummaryGileah ZuasolaОценок пока нет

- Unit-2 Material CostДокумент12 страницUnit-2 Material CostAishwarya NagrajОценок пока нет

- HRI 8 - 12 SOP PurchaseДокумент16 страницHRI 8 - 12 SOP Purchaserabi shadОценок пока нет

- Inventory ManagementДокумент8 страницInventory ManagementSimar ZuluОценок пока нет

- 1 Purchasing SystemsДокумент6 страниц1 Purchasing SystemsAbhishek ChowdhuryОценок пока нет

- Новый документ в форматеДокумент8 страницНовый документ в форматеКристи АбдушаОценок пока нет

- Inventory Control NotesДокумент11 страницInventory Control NotesBob34wОценок пока нет

- Procedure of Material Procurement and Use (Final)Документ29 страницProcedure of Material Procurement and Use (Final)asadfarooqi4102100% (6)

- Unit 10 Study Guide Procurement and Inventory ManagementДокумент13 страницUnit 10 Study Guide Procurement and Inventory ManagementBryan FrancisОценок пока нет

- MM CH 3Документ21 страницаMM CH 3YabsielОценок пока нет

- Material ControlДокумент14 страницMaterial ControlKavana DОценок пока нет

- Report ProcurementДокумент1 страницаReport Procurementabulnishu08Оценок пока нет

- PurchasingДокумент7 страницPurchasingyatindharna1024Оценок пока нет

- Scientific Procedure of Purchase: Presented by Intramantra Global Solution PVT LTD, IndoreДокумент7 страницScientific Procedure of Purchase: Presented by Intramantra Global Solution PVT LTD, IndoreDeepak Rathore100% (1)

- Materi Minggu 8Документ89 страницMateri Minggu 8Zihan AbdullahОценок пока нет

- Material & LogisticsДокумент10 страницMaterial & LogisticsSumit KumarОценок пока нет

- Chapter 2 Material PDFДокумент73 страницыChapter 2 Material PDFShwetaJainОценок пока нет

- Chapter Four: 2. Audit of Inventory, Cost of Sales and Related AccountsДокумент8 страницChapter Four: 2. Audit of Inventory, Cost of Sales and Related AccountsZelalem HassenОценок пока нет

- Types of Purchases in A Purchasing ProcessДокумент3 страницыTypes of Purchases in A Purchasing ProcessJonnah Fernandez Dalogdog100% (1)

- Ordering Procedure-1Документ7 страницOrdering Procedure-1vincentayodiОценок пока нет

- Functions of Production ManagementДокумент5 страницFunctions of Production ManagementSudhanshu BhattОценок пока нет

- Purchasing, Inventory, and Cash Disbursements: Common Frauds and Internal ControlsОт EverandPurchasing, Inventory, and Cash Disbursements: Common Frauds and Internal ControlsРейтинг: 5 из 5 звезд5/5 (1)

- Textbook of Urgent Care Management: Chapter 7, Exit Transactions: The Process of Selling an Urgent Care CenterОт EverandTextbook of Urgent Care Management: Chapter 7, Exit Transactions: The Process of Selling an Urgent Care CenterОценок пока нет

- Actuarial ValuationДокумент47 страницActuarial ValuationTutz Casurao100% (1)

- Career Developemt 2Документ6 страницCareer Developemt 2Maina MuhoroОценок пока нет

- Amclc SuppДокумент63 страницыAmclc SuppMaina MuhoroОценок пока нет

- Edu Exam FM Supple Notes PDFДокумент18 страницEdu Exam FM Supple Notes PDFJhosi RAОценок пока нет

- Actuaries in Insurance 201: Project ReportДокумент54 страницыActuaries in Insurance 201: Project ReportMaina MuhoroОценок пока нет

- The Theory of Interest (Stephen G. Kellison)Документ167 страницThe Theory of Interest (Stephen G. Kellison)Farhan89% (62)

- Medical Management and Legal Obligations To Members: Managed Health Care Handbook, 4Документ11 страницMedical Management and Legal Obligations To Members: Managed Health Care Handbook, 4Maina MuhoroОценок пока нет

- Subject CA1 Actuarial Risk Management Syllabus: For The 2013 ExaminationsДокумент11 страницSubject CA1 Actuarial Risk Management Syllabus: For The 2013 ExaminationsMaina MuhoroОценок пока нет

- Actuaries in Insurance 201: Project ReportДокумент54 страницыActuaries in Insurance 201: Project ReportMaina MuhoroОценок пока нет

- 06 SOA ExamMFallДокумент41 страница06 SOA ExamMFallMaina MuhoroОценок пока нет

- Kenya MDG Needs AssessmentДокумент253 страницыKenya MDG Needs AssessmentMaina MuhoroОценок пока нет

- Fundamental Concepts of Actuarial ScienceДокумент90 страницFundamental Concepts of Actuarial ScienceJim Walsh100% (13)

- GSK Hsa Sales & Stock ReportДокумент3 страницыGSK Hsa Sales & Stock ReportMaina MuhoroОценок пока нет

- GSK Hsa Sales & Stock ReportДокумент3 страницыGSK Hsa Sales & Stock ReportMaina MuhoroОценок пока нет

- Actuarial Standards of PracticeДокумент954 страницыActuarial Standards of PracticebmjantoОценок пока нет

- 06 SOA ExamMFallДокумент41 страница06 SOA ExamMFallMaina MuhoroОценок пока нет

- Ap 821208Документ24 страницыAp 821208Maina MuhoroОценок пока нет

- 2012 July Exam PДокумент3 страницы2012 July Exam PLetsogile BaloiОценок пока нет

- TSR 9510Документ28 страницTSR 9510Maina MuhoroОценок пока нет

- 0214 00 PDFДокумент12 страниц0214 00 PDFjunaid112Оценок пока нет

- Challenges Facing Urban TransportationДокумент8 страницChallenges Facing Urban TransportationcarolsaviapetersОценок пока нет

- Warehouse An Overview ProjectДокумент24 страницыWarehouse An Overview ProjectHuzaifa Jamnagarwala0% (1)

- Ji MMMMMMMMMMДокумент6 страницJi MMMMMMMMMMGeorgian GradeaОценок пока нет

- SSDR Information NoticeДокумент6 страницSSDR Information NoticeIvan Gonzo SaboОценок пока нет

- 97 Manufacturer of Medicine and DrugsДокумент17 страниц97 Manufacturer of Medicine and Drugshcbf138Оценок пока нет

- Inventory VelocityДокумент3 страницыInventory VelocityGuru SarafОценок пока нет

- Excipient Master File Guide: The IPEC-AmericasДокумент5 страницExcipient Master File Guide: The IPEC-Americasmailtorubal2573Оценок пока нет

- Airport SecurityДокумент63 страницыAirport SecurityPhilip Gommesen100% (2)

- WQT For CSДокумент5 страницWQT For CSkumar08686Оценок пока нет

- Tank Erection JackДокумент2 страницыTank Erection JackardaneОценок пока нет

- Sea ProtestДокумент5 страницSea ProtestenglisgoОценок пока нет

- NIOP Trading Rules Book V 2013Документ154 страницыNIOP Trading Rules Book V 2013Marito Morán CoelloОценок пока нет

- Logistics Management 1Документ70 страницLogistics Management 1Sachet AnandОценок пока нет

- Comparison of Pipe Flow EquationsДокумент6 страницComparison of Pipe Flow EquationsJohn HarkenОценок пока нет

- KMI All Share Index FileДокумент3 страницыKMI All Share Index FileSaadKhan247Оценок пока нет

- BDL Project Supply Range and Specification For Piping Materials PDFДокумент49 страницBDL Project Supply Range and Specification For Piping Materials PDFEngr Arfan Ali DhamrahoОценок пока нет

- LMS Week 2 Metal CastingДокумент56 страницLMS Week 2 Metal Castingabdulaziz100% (1)

- Introduction To Panel CavingДокумент52 страницыIntroduction To Panel CavingJorge Eduardo100% (3)

- Cu-Ni Pipes, Flanges & FittingsДокумент67 страницCu-Ni Pipes, Flanges & Fittingssdk1978Оценок пока нет

- Itp - HvacДокумент3 страницыItp - HvacAbdulah Asagi100% (1)

- Conveyor ChainsДокумент172 страницыConveyor Chainsmkpasha55mpОценок пока нет

- Liveable CityДокумент4 страницыLiveable CityaffansyahОценок пока нет

- Esol Child WorkbookДокумент19 страницEsol Child WorkbookAleksandra Kovachovska-PostolovskaОценок пока нет

- Traffic Diversion Proposal v3Документ19 страницTraffic Diversion Proposal v3shukriОценок пока нет

- Dry Docking NotesДокумент16 страницDry Docking NotesIshan Vyas100% (1)

- Balance SheetДокумент8 страницBalance Sheetmohammed Arshad100% (1)

- ASLI 03 Return Air Grilles SetДокумент23 страницыASLI 03 Return Air Grilles SetAminul HassanОценок пока нет

- Datasheet Cae 7000 SeriesДокумент2 страницыDatasheet Cae 7000 SeriesYuvraj KumarОценок пока нет

- Group 9 - Section E - HPДокумент12 страницGroup 9 - Section E - HPShubham ShuklaОценок пока нет