Академический Документы

Профессиональный Документы

Культура Документы

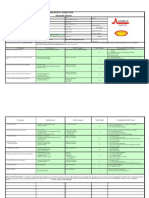

Job Hazard Analysis

Загружено:

uchechris05_23872118Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Job Hazard Analysis

Загружено:

uchechris05_23872118Авторское право:

Доступные форматы

S/N 1-A

WORK DESCRIPTION HOT WORK (INSIDE GAS&OIL FACILITY)

THREATS 1. Presence of Flammable Gas. 2. Presence of Oil /Sludge. 3. Incompetent welder/fitter, or mate. 4. Uncertified / Malfunctioning welding. equipment and power tools. 5. Poor site housekeeping. 6. Slippery site surfaces. 7. Poor site supervision and work procedure. 8. Absence of competent safety and supervisory personnel. 9. Unapproved work procedures. 10. Exposure to site hazards in horse playing.

WHO MIGHT BE HARMED OR EXPOSED Welder /Fitter crew, Facility, Work equipment, other personnel.

CONSEQUENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. Fire outbreak. Explosion. Body Injury / Accidents. Equipment /Tools damage. Falls due to tripping. Waste of man-hours and other resources. Doing unapproved work. Work interfacing dangerously with other activities. Grinding disk flying out to cause injury & harm to personnel. Grinding sparks / particles entering personnel eyes to cause harm. Stress. Fire/Heat burns.

CONTROL OF HAZARDS 1. Ensure P.T.W and relevant hot work certificate are valid and on site. 2. Conduct J.H.A before work commencement. 3. Gas test area for safety. 4. Carry out continuous gas monitoring. 5. Wash off area of all oil and sludge droppings. 6. Certify all welding equipment and tools. 7. Wear relevant P.P.E. 8. Discuss task with other crew/contractor. 9. Provide dedicated safety/supervisory team. 10. Provide & use safety fire blankets. 11. Flush all pipes & isolate properly. 12. Use inflatable balloons & mudding system. 13. Review task and update strategies continuously.

RECOVERY 1. Provide adequate First Aid resources and ensure ease to reach approved clinic. 2. Ensure effective communication.

11. 12.

S/N 2-A

WORK DESCRIPTION HOT WORK (OUTSIDE GAS & OIL FACILITY)

THREATS 1. Presence of flammable. 2. Incompetent welder/ fitter. 3. Uncertain malfunctioning equipment / power tools. 4. Site Housekeeping. 5. Level and competency of supervision. 6. Absence of safety supervision. 7. Unapproved work procedures. 8. Exposure to site hazard.

WHO MIGHT BE HARMED OR EXPOSED Welder / fitter crew, work equipment and other personnel.

CONSEQUENCES 1. Fire outbreak. 2. Body injury / accidents. 3. Equipment / tools damage. 4. Falls due to tripping. 5. Waste of resources /manhours. 6. Grinding disk flying out to cause injury or body harm. 7. Grinding particles/sparks entering personnel eyes to cause harm. 8. Stress. 9. Fall of pipe /steel due to improper positioning, support and guard. 10. Wrong work procedure.

CONTROL OF HAZARDS 1. Ensure P.T.W and relevant hot work certificates are on site. 2. Conduct J.H.A before work commencement. 3. Inspect and Free area of any flammable. 4. Certify all welding equipment and tools. 5. Provide dedicate supervisory and safety personnel. 6. Screw off area to prevent sparks particles and arcs from harming crewmembers and other workers. 7. Use relevant personnel and other protective equipment. 8. Ensure workers take adequate rest after work. 9. Ensure continuous supervision. 10. Review tasks regularly and update strategies continuously.

RECOVERY 1. Provide adequate first aid resources and ensure effective communication and means to reach approved clinic.

S/N 3-A

WORK DESCRIPTION EQUIPMENT SERVICING (PUMPS/UNITS)

THREATS 1. Poor work planning. 2. Wrong and defective tools. 3. Wrong work method and procedure. 4. Exposure to hazardous parts of the equipment. 5. Absence of competent safety and supervisory personnel. 6. Poor housekeeping. 7. Uncertified and malfunctioning work tools / aids. 8. Horseplaying.

WHO MIGHT BE HARMED OR EXPOSED 1. Equipment servicing crew, Environment, equipment damage, other personnel

CONSEQUENCES 1. Fire outbreak. 2. Body injury / accidents. 3. Equipment / parts damage. 4. Tools damage. 5. Fall of equipment due to faulty supports / guarding and lifting aids. 6. Waste of resources due to poor supervision and work procedures. 7. Fall of personnel due to slippery surfaces & untidy surfaces. 8. Absence of competent safety / supervisory personnel leading to waste and accident. 9. Stress/sickness. 10. Fire outbreak.

CONTROL OF HAZARDS 1. Carry out approved work. 2. Conduct J.H.A before work commencement. 3. Wash & free equipment of all oil and gas residues. 4. Isolate properly. 5. Provide dedicated supervisory and safety personnel. 6. Certify all work tools and personnel. 7. Wear relevant P.P.E 8. Use approved lifting aids /supports & guards. 9. Discuss tasks before execution. 10. Use safe tools to avoid fire outbreak. 11. Control start/switch off mechanism. 12. Monitor test running.

RECOVERY Provide adequate First aid resources and ensure effective means of communication and medical to approved clinic.

S/N 4-A

WORK DESCRIPTION RADIOGRAPHY

THREATS 1. Uncertified radiation equipment. 2. Obsolete radiation equipment. 3. Incompetent radiographers. 4. Excessive exposure to gamma radiation. 5. Unapproved work.

WHO MIGHT BE HARMED OR EXPOSED RADIOGRAPHERS, OTHER PERSONNEL AND THIRD PARTY

CONSEQUENCES 1. Accidents: Source jam/equipment failure. 2. Radiation sickness due to excess consumption.

CONTROL OF HAZARDS 1. Use approved P.T.W. 2. Conduct JHA, and use safe work procedure. 3. Post strong & visible warning signs. 4. Use dosimeter/ survey meter to monitor radiation level. 5. Use certified equipment / working tools. 6. Condone off work area & against trespass. 7. Use audible signs when energising source. 8. Provide rescue aids & team. 9. Engage competent safety & supervisory personnel.

RECOVERY Provide adequate First aid resources and ensure effective means of communication and medivac to approved clinic, and to base office.

S/N 5-A

WORK DESCRIPTION HYDRO TESTING

1.

THREATS

Uncertified testing equipment / accessories. 2. Incompetent personnel (testing crew). 3. Inadequate test bay / area. 4. Workers without P.P.E. 5. Presence of other workers in test area. 6. Poor housekeeping. 7. Unguarded test area & absence of strong warning signs. 8. Improper connection of test equipment to target vessel or pipe. 9. Commencing testing without J.H.A. 10. Carrying out testing without approval and following safe procedure. 11. Carrying out test without competent safety & supervisory personnel.

WHO MIGHT BE HARMED OR EXPOSED THREATS crew, environment, other workers.

CONSEQUENCES 1. Equipment failure. 2. Explosion of pipe/vessel on test. 3. Collapse of pipe/vessel on test due to unstable bay/area. 4. Harm to workers due to pressure should there be (explosion/burst of vessel on test.) failure. 5. Injury to personnel. 6. Damage to equipment. 7. Fire outbreak. 8. Pollution of environment. 9. Stress. 10. Fall by crew due to untidy work site. 11. Communication break downmisunderstanding .

CONTROL OF HAZARDS 1. Certify equipment/accessories to be used. 2. Conduct J.H.A before work commencement. 3. Obtain approval before work commencement. 4. Provide fire extinguishers. 5. Rope-off work area and post relevant caution signs. 6. Keep off workers from bay area. 7. Dedicate competent safety & supervisory personnel. 8. Keep work site clean & tidy. 9. Advise crew t have adequate rest. 10. Provide relevant P.P.E. 11. Brief & Debrief crew when necessary. 12. Follow other QA & QC and safety rules 13. Communicate effectively.

RECOVERY Provide First aid resources and effective means of communication and medivac to approved clinic, and base office.

S/N 6-A

WORK DESCRIPTION PIPE PREHEATING

1. 2. 3. 4. 5. 6. 7. 8.

THREATS

Uncertified preheating equipment / accessories. Incompetent team. Inadequate preparation of preheating area. Presence of other workers in work area. Poor housekeeping. Improper connection of test equipment to target pipe joints. Commencement of work without authorization. Absence of competent safety and supervisory personnel. Commencement of work without conducting J.H.A. Commencement of work without dedicated fire protection. Commencement of work without necessary personnel, safety and environmental protection preparation. Fire outbreak. Horseplaying.

WHO MIGHT BE HARMED OR EXPOSED Pre-heating crew, other workers, equipment / facility and environment.

CONSEQUENCES 1. Accident equipment failure. 2. Collapse of preheating equipment and target items. 3. Heat-burns / body injury. 4. Sickness due to heat consumption. 5. Damage to equipment. 6. Fire out-break. 7. Stress. 8. Fall by crew members due to untidy work site. 9. Communication break down. 10. Damage to pipe under heat. 11. Accident due to horseplaying.

CONTROL OF HAZARDS 1. Conduct J.H.A before work commencement. 2. Obtain approval (P.T.W) before work commencement 3. Certify all pre-heating equipment / accessories. 4. Provide dedicated fire extinguishers. 5. Dedicate competent safety and supervisory personnel. 6. Keep work site clean and tidy. 7. Provide relevant caution signs and barricade work area. 8. Provide relevant P.P.E. 9. Give crew adequate rest, and milk as required. 10. Dedicate signal man to control personnel traffic. 11. Follow other QA & QC and safety rules. 12. Review progress regularly. 13. Screen off pre-heating zone.

RECOVERY Provide First aid resources and effective means of communication and medivac to approved clinic, and base office.

9. 10.

11.

12. 13.

S/N 7-A

WORK DESCRIPTION PAINTING (SURFACE PREPARATION)

THREATS 1. Uncertified personnel. 2. Carrying out work without authorization. 3. Horseplaying. 4. Use defective tools. 5. Working without appropriate P.P.Es. 6. Flying Particles. 7. Poor housekeeping. 8. Uncertified work tools/ equipment.

WHO MIGHT BE HARMED OR EXPOSED Painting crew, others, environment tools.

CONSEQUENCES 1. Accident injury to personnel. 2. Damage to hand tools. 3. Flying particles entering personnel eyes. 4. Fall due to untidy work site. 5. Re-doing work due to low quality and failure to follow procedures. 6. Stress. 7. Sickness due to consumption of particles.

CONTROL OF HAZARDS 1. Conduct J.H.A before work commencement. 2. Dedicate competent safety and supervisory personnel. 3. Keep environment clean and tidy. 4. Obtain approval before work commencement. 5. Post relevant caution signs. 6. Provide P.P.E. 7. Use certified tools. 8. Keep off unauthorized personnel.

RECOVERY Provide First aid resources.

S/N 8-A

WORK DESCRIPTION PAINTING (PAINT APPLICATION)

THREATS 1. Uncertified personnel. 2. Working without authorization. 3. Horse-playing. 4. Working without appropriate P.P.Es. 5. Poor housekeeping. 6. Uncertified work tools / equipment. 7. Presence of other workers in painting area. 8. Flying paint fumes / atmospheric discharge.

WHO MIGHT BE HARMED OR EXPOSED Painting crew, other workers, environment, tools.

CONSEQUENCES 1. Sickness due to paint / chemicals inhaled. 2. Stains to personnel /other workers. 3. Damage to painted surfaces. 4. Fall due to untidy work area. 5. Stress. 6. Damage to hand tools.

CONTROL OF HAZARDS 1. Conduct J.H.A before work commencement. 2. Get approval before working. 3. Dedicate competent safety & supervisory staff. 4. Provide relevant P.P.E and caution signs. 5. Barricade wet paint zone. 6. Use approved work tools / equipment. 7. Keep off unauthorized personnel. 8. Keep environment clean & tidy.

RECOVERY Provide First aid resources and debrief workers after work.

10

S/N

WORK DESCRIPTION BREAKING OF FLANGES / FLUSHING ACTIVITIES 1. 2. 3. 4. 5. 6. 7.

THREATS Use of improper tools. Use of wrong work procedures & methods. Poor Housekeeping. Slippery work site. Discharge of gases into the atmosphere. Horse playing. Discharge of oil, sludge, water and sand into the environment. Use of incompetent personnel for task execution. Use of defective tools. Use of defective hoses/ absence of hoses. Absence / Inadequate water source. Carrying out activity without proper planning and authorization. Execution of tasks without competent safety and supervisory personnel. Absence of vacuum equipment.

9-A

WHO MIGHT BE HARMED OR EXPOSED Personnel involved in task execution, other workers on site, environment and facility.

CONSEQUENCES 1. 2. 3. 4. 5. 6. 7. 8. Injury to personnel Damage to hand tools / hoses. Damage to flanges. Pollution/spillage. Fire outbreak. Fall due to untidy work site or spilled oil. Delays / man-hours. Stress. 1.

CONTROL OF HAZARDS Obtain valid P.T.W before work commencement. 2. Conduct J.H.A first. 3. Engage competent safety and supervisory personnel. 4. Gas test work area continuously. 5. Use correct / safe hand tools. 6. Engage competent personnel for task execution. 7. Monitor discharge of oil / gas & other effluent. 8. Provide required vacuum and flushing equipment. 9. Isolate properly & monitor isolated points . Secure points properly. 10. Monitor workers behaviour. 11. Ensure good house keeping.

RECOVERY Provide First aid resources, effective communication, fire cover, vacuum equipment and medivac resources.

8. 9. 10. 11. 12.

13.

14.

11

S/N 10-A

WORK DESCRIPTION HOT TAPPING

THREATS 1. Activity on pressure pipe. 2. Commencement of task without (PTW) approval. 3. Commencement of task without J.H.A. 4. Commencement of task without adequate fire cover / protection. 5. Incompetent welders /fitters. 6. Uncertified/ malfunctioning equipment & tools. 7. Poor work supervision & planning. 8. Poor housekeeping. 9. Absence of competent safety & supervisory personnel. 10. Horse playing. 11. Inadequate / absence of emergency environmental rescue aids. 12. Congested work site. 13. Pipe not adequately supported/guarded.

WHO MIGHT BE HARMED OR EXPOSED Hot tapping team, other workers, environment & facility.

CONSEQUENCES 1. Collapses of pipe explosion. 2. Fire outbreak. 3. Damage to facility. 4. Environmental Pollution. 5. Damage to tools/equipment. 6. Injury to personnel LTI or Death possible. 7. Stress. 8. Failure of tools / equipment. 9. Fall due to untidy work area. 10. Dangerous interfacing of tasks.

CONTROL OF HAZARDS 1. Ensure P.T.W & relevant hot work certificates are valid and on site. 2. Conduct J.H.A before work commencement. 3. Test area for gas & continuously gas test. 4. Wash off area of all oil and sludge droppings. 5. Wear relevant PPE. 6. Discuss task with other crew or contractor. 7. Provide adequate support for piping. 8. Provide competent task execution team, supervisor and cashes team. 9. Relevant client & company representatives must be on site during hot tapping. 10. Provide adequate fire fighting / rescue equipment. 11. Provide relevant environmental pollution response resources. 12. Review tasks & update strategies. 13. Certify all hot tapping equipment / tools before task execution.

RECOVERY Provide adequate environmental response resources, first aid resources, effective means of communication and medivac. All key personnel to be at alert.

12

S/N 11-A

WORK DESCRIPTION COLD CUTTING

THREATS 1. Commencement of work without (PTW) approval. 2. Commencement of task without J.H.A. 3. Commencement of task without fire protection. 4. Incompetent crew. 5. Uncertified / malfunctioning equipment accessories. 6. Poor work supervision and planning. 7. Poor housekeeping. 8. Absence of competent safety & supervisory personnel. 9. Breach of safe work procedure. 10. Horse playing. 11. Pipe not adequately supported/ guarded.

WHO MIGHT BE HARMED OR EXPOSED Fitter & crew Facility and environment.

CONSEQUENCES 1. 2. 3. 4. 5. 6. 7. 8. Collapse of pipe. Fire outbreak. Damage to facility. Environmental pollution. Damage to tools / equipment. Stress. Failure of equipment. Fall due to untidy work area.

CONTROL OF HAZARDS 1. Ensure P.T.W is valid. 2. Conduct J.H.A before task execution. 3. Monitor gas continuously. 4. Wear relevant P.P.E. 5. Provide adequate support. 6. Provide competent task execution team, supervisor & safety advisor. 7. Provide Fire first aid. 8. Provide relevant environmental pollution response resources. 9. Review tasks & update strategies. 10. Certify all equipment / tools.

RECOVERY Provide adequate environmental response resources, First aid and effective means of communication and medivac.

13

S/N

WORK DESCRIPTION PLANT TEST RUNNING 1. 2. 3. 4. 5. 6. 7. 8.

THREATS Running pumps/system. Noise. Explosion. Fire outbreak. Trip / fall. Hydrocarbon. Working in hazardous (pressure). Non adherence to plan & procedure.

12-A

WHO MIGHT BE HARMED OR EXPOSED Test running crew, third party & equipment

CONSEQUENCES Injury and damage to pumps and equipment 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14.

CONTROL OF HAZARDS Deploy competent personnel to test running zones. De-isolate positively. Purge systems correctly before starting. Ensure strict adherence to manufacturers instructions. Obtain necessary permits before working in hazardous area. Watch out for open drains and surface piping / instrument items on the pumps. Employ the right hand tools. Follow strictly isolation procedure. Observe all depressurization procedures. Carry out oxygen analysis. Use proper respiratory equipment. Dedicate competent supervision / watchman. Use appropriate cleaning equipment. Carry out J.H.A before commencement of job. 1.

RECOVERY Provide communication link with main office and test running site. Provide first aid equipment. Provide fire extinguishers. Provide Medevac plans.

2. 3. 4.

12-B

VESSEL CLEANING

9. 10. 11. 12. 13. 14. 15.

Non compliance with isolation procedure. Non compliance with depressurization procedure. Non certification of oxygen level in the vessel. Use of improper respiratory masks Absence of dedicated supervision / watchman. Use of improper material resources Commencement of task without conducting J.H.A.

Vessel cleaning crew. Other personnel on site environment.

1. 2. 3. 4.

Suffocation. Injury to personnel. Explosion / fire. Pollution/spillage.

5.

6. 7. 8.

Observe all relevant procedure and supervision. Provide all necessary rescue aids. Provide all and standard working equipment. Provide standard safety items.

14

S/N

WORK DESCRIPTION ROAD TRANSPORTATION 1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

THREATS Uncertified operator. Uncertified equipment, truck or car. Overloading Improper stacking / securing of materials. Absence of good journey management / plan. Night driving / driving during bad weather. Truck operating without mate. Truck / car operating without relevant documents. Bad roads, potholes, bumps, sharp bends e.t.c. Road nuisances: other drivers, animals, cyclists, pedestrians, accidented vehicles etc. Attacks by highway robbers, revenue touts & other agencies. Fire outbreak. Vehicle without appropriate accessories. Driving off unfamiliar vehicles & without checking routine items. Driving off vehicle without pre-takeoff checks & confirmation

13-A

WHO MIGHT BE HARMED OR EXPOSED Driver, passenger, vehicle, materials on board, road, and other road users.

CONSEQUENCES 1. Accident minor injury, L.T.I or death. 2. Damage to equipment vehicle. 3. Damage or loss of materials on transit. 4. Arrest / detention by police or revenue touts. 5. Breakdown leading to man-hours loss. 6. Damage due to fire outbreak. 7. Damage to third party property. 8. Theft of vehicle or materials on transit. 9. Overloading leading to breakdown. 10. Fire outbreak. 1. 2. 3. 4. 5. 6. 7. 8.

CONTROL OF HAZARDS Ensure effective journey management. Engage qualified driver only Use approved vehicle for the journey. Ensure S.W.L not exceeded Observe no night driving rule . Dedicate escort for certain trips. Provide mechanical assistance for certain trips. Vehicles accessories / routine checks must be carried out, and fitness certified before journey commences. Watch out for highway robbers and revenue touts, and apply skills in each situation. Post relevant warning signs when carrying wide loads. All relevant statutory documents / waybills to be current and on board. Provide functional fire first aid. Observe relevant safety and operational rules.

RECOVERY Provide relevant first aid resources, ensure effective communication with office / police, and use available vehicle for medivac

9.

10. 11. 12. 13.

11. 12. 13. 14. 15.

15

S/N 14-A

WORK DESCRIPTION LIFTING (MECHANICAL)

THREATS 1. Uncertified Operator. 2. Absence / incompetent signal man or many signal men. 3. Uncertified crane / accessories. 4. Unsafe crane position 5. Wrong telescoping or swinging method. 6. Use crane not properly checked and confirmed fit. 7. Operating crane at night. 8. Road travelling. 9. Presence of man y personnel in crane operating area. 10. Presence of many equipment/materials in operation area. 11. Working during rains /without authorization 12. Operating crane without all safety signs / load charts in place. 13. Fire outbreak 14. Wrong lifting / shackling.

WHO MIGHT BE HARMED OR EXPOSED Crane operator, Helpers, other workers, crane, other equipment facilities and environment.

CONSEQUENCES 1. Fall of suspended load (near miss). 2. Fall of crane or part(s). 3. Damage to crane, equipment, facility or load due to equipment or accessories failure. 4. Fire outbreak causing losses. 5. Injury to crew ( operator / signal man). 6. Injury to other workers. 7. Equipment breakdown. 8. Stress. 9. Overload.

CONTROL OF HAZARDS 1. Engage qualified operator & mate. 2. Use certified crane. 3. Check & confirm. equipment fitness before use. 4. Conduct J.H.A before work commencement. 5. Keep-off unauthorized personnel. 6. Dedicate only one signal man throughout operation. 7. No night operation. 8. Only specified crane should travel by road. 9. Observe crane S.W.L before lifting any load. 10. Provide dedicated & functional fire extinguishers. 11. Competent crew to be engaged in lifting. 12. Plan and dedicate competent safety personnel during every lifting task. 13. Confirm safety of work environment before commencement of task. 14. Follow relevant safety and operational rules.

RECOVERY

16

S/N 15-A

WORK DESCRIPTION MANUAL LIFTING

THREATS 1. Improper task planning. 2. Commencement of task without conducting J.H.A. 3. Absence of competent safety and supervisory personnel. 4. Executing tasks with excess or lesser number of personnel. 5. Poor housekeeping. 6. Horseplaying.

WHO MIGHT BE HARMED OR EXPOSED Personnel involved in task execution, loadmaterial, environment, other personnel and other items around work area.

CONSEQUENCES 1. Damage to material-load. 2. Damage to environment / other items. 3. Injury to personnel involved in lifting operation or other workers. 4. Stress. 5. Fall by personnel. 6. Sickness.

CONTROL OF HAZARDS 1. Conduct J.H.A before task execution. 2. Plan task in advance of execution. 3. Ensure good housekeeping. 4. Engage right number of personnel for defined tasks. 5. Get rid of all obstructions. 6. Inspect and confirm takeoff and drop points. 7. Engage only healthy personnel. 8. Provide relevant P.P.E. 9. Ensure proper stacking of loads. 10. Label or separate loads clearly. 11. Ensure loads are secured against fall. 12. Observe relevant safety & operational rules.

RECOVERY Provide adequate first aid resources, effective means of communication and medivac.

17

S/N 16-A

WORK DESCRIPTION WORK AT HEIGHT

THREATS 1. Poor platform/ladder. 2. Commencement of work without conducting J.H.A. 3. Absence of competent safety & supervisory personnel. 4. Excess human load on platform/ladders. 5. Poor housekeeping. 6. Absence or wrong posting of directional caution signs. 7. Use of unapproved platform / ladder. 8. Working without safety harness/ belt. 9. Working without relevant P.P.E. 10. Personnel under platform /ladder. 11. Overload of platform / form with materials. 12. Other safety lapses.

WHO MIGHT BE HARMED OR EXPOSED Personnel involved in task execution, work materials, other personnel on site and facility / environment.

CONSEQUENCES 1. Injury to personnel. 2. Damage to materials /equipment. 3. Injury to workers leading to L.T.I or death. 4. Fall by personnel due to tripping hazards or collapse of platform / ladder. 5. Damage to environment & installations. 6. Stress.

CONTROL OF HAZARDS 1. Conduct J.H.A before task execution. 2. Plan task in advance of execution. 3. Ensure good housekeeping. 4. Competent personnel to erect platform. 5. Use approved platform / ladder. 6. Dedicate competent safety and supervisory personnel during task execution. 7. Post appropriate directional caution signs. 8. Dismantle/remove platform or ladder soon after task execution. 9. Personnel to use relevant harness/PPE. 10. Observe platform / ladder S.W.L and other safety rules. 11. Restrict traffic under platform.

RECOVERY Provide First aid resources, effective means of communication and medivac.

18

S/N 17-A

WORK DESCRIPTION INSTALLATION OF ELECTRICAL EQUIPMENT : 1. Air conditioner 2. Motor 3. Transformer 4. Fans 5. Detectors 6. Other devices

THREATS 1. Commencement of task without P.T.W. 2. Executing tasks without conducting J.H.A. 3. Poor housekeeping. 4. Poor work organization. 5. Absence of competent safety & supervisory personnel. 6. Horse playing. 7. Use of wrong & defective tools. 8. Executing task without isolation of relevant points. 9. Absence of relevant caution signs.

WHO MIGHT BE HARMED OR EXPOSED Electrical crew, other workers & facility.

CONSEQUENCES 1. 2. 3. 4. 5. 6. 7. 8. Electrocution. Shock. Fire outbreak. Damage to equipment. Stress. Fall due to untidy work area. Damage to work tools. Injury to personnel.

CONTROL OF HAZARDS 1. Obtain approval before task execution. 2. Conduct J.H.A first. 3. Provide dedicated safety & supervisory team. 4. Engage only competent team. 5. Isolate relevant points. 6. Wear proper P.P.E (e.g. P.V.C items). 7. Post relevant caution signs. 8. Provide Fire extinguishers. 9. Use right and safe tools. 10. Observe relevant rules. 11. Keep environment clean & tidy.

RECOVERY Provide First aid resources, adequate means of communication & medivac.

19

S/N 18-A

WORK DESCRIPTION CONSTRUCTION OF INSTRUMENT TRAYS, PANELS & TUBINGS

THREATS 1. Starting work without approval. 2. Commenceme nt of work without conducting J.H.A. 3. Poor housekeeping. 4. Poor work organization 5. Absence of competent safety & supervisory team. 6. Working without P.P.E. 7. Use of wrong & defective tools. 8. Horse playing.

WHO MIGHT BE HARMED OR EXPOSED Instrument team, equipment, and hand tools.

CONSEQUENCES 1. Damage to hand tools. 2. Damage to equipment. 3. Injury to personnel. 4. Fall due to untidy work area. 5. Stress.

CONTROL OF HAZARDS 1. Conduct J.H.A before task execution. 2. Obtain approval before work commencement. 3. Provide dedicated work team 4. Use right & safe tools. 5. Keep work area clean. 6. Post relevant caution signs. 7. Wear relevant P.P.E. 8. Provide fire extinguishers. 9. Observe relevant quality & safety rules. 10. Review strategies as work progresses.

RECOVERY Provide First aid resources, Effective means of communication and medivac.

20

S/N 19-A

WORK DESCRIPTION INSTALLATION OF INSTRUMENT ITEMS /EQUIPMENT

THREATS 1. Starting task without approval. 2. Commencement of task without conducting J.H.A. 3. Executing tasks without dedicated / competent supervisory team. 4. Working without relevant P.P.E. 5. Poor housekeeping. 6. Poor work organization. 7. Use of wrong & unsafe tools. 8. Executing tasks without relevant isolation. 9. Absence of relevant caution signs.

WHO MIGHT BE HARMED OR EXPOSED Instrument crew, other crew, facility and hand tools.

CONSEQUENCES 1. Fire outbreak. 2. Damage to equipment. 3. Damage to tools. 4. Fall due to untidy environment. 5. Injury to workers. 6. Overloading. 7. Stress.

CONTROL OF HAZARDS 1. Obtain P.T.W before task execution. 2. Use safe and right tools. 3. Conduct J.H.A before work commencement. 4. Check & confirm equipment fitness before use. 5. Engage only qualified crew 6. Provide P.P.E. 7. Keep environment clean & tidy. 8. Keep off unauthorized personnel. 9. Plan work well. 10. Follow relevant safety & operational rules. 11. Use correct lifting aids.

RECOVERY Provide Fire protection equipment. First aid resources, effective means of communication & medivac.

21

S/N 20-A

WORK DESCRIPTION FUNCTIONAL TESTING (MOTORS/ PANELS ETC)

THREATS 1. Commencement of work without approval. 2. Starting task without conducting J.H.A. 3. Damage to hand tools. 4. Fall due to untidy environment 5. Stress. 6. Explosion. 7. Horse playing. 8. Failure to isolate safely.

WHO MIGHT BE HARMED OR EXPOSED Testing crew, other workers, facility & work tools.

CONSEQUENCES 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Explosion. Fire outbreak. Equipment damage Facility damage. Injury to personnel. Work tools damage. Fall due to untidy environment or hurriness. Stress Equipment failure. Third party injury. Environmental pollution.

CONTROL OF HAZARDS 1. De-isolate positively. 2. Purge system correctly. 3. Watch out for open drains/ surface pipings & instrument items. 4. Use right and safe tools. 5. Provide competent team & supervisors. 6. Keep off non-critical personnel. 7. Provide temporary demarcation. 8. Plan work safely. 9. Use follow safe procedure. 10. Review strategies at intervals.

RECOVERY Provide First aid resources, effective communication and medivac.

22

S/N 21-A

WORK DESCRIPTION DISMANTLING OF CONTROL/ DISTRIBUTION SYSTEM OF ELECTRICAL PANEL.

THREATS 1. Starting work Without approval. 2. Commencement of task without conducting J.H.A. 3. Executing task without dedicated competent/ supervisory team. 4. Dismantling without relevant isolation. 5. Dismantling without relevant caution signs. 6. Working without protective Devices. 7. Use of wrong tools 8. Absence of lifting facility. 9. Failure to isolate.

WHO MIGHT BE HARMED OR EXPOSED Electrical crew, other crew, facility and work tools.

CONSEQUENCES 1. Fire out break 2. Damage to work tools. 3. Damage to facility/equipment. 4. Injury to personnel. 5. Object falling.

CONTROL OF HAZARDS 1. Obtain PTW before task exception. 2. Conduct JHA before commencement of job. 3. Use safe and right tools. 4. Safe check tools before use. 5. Engage only competent personnel. 6. Keep environment clean and tidy. 7. keep off unauthorised personnel. 8. Provide safe and approved lifting device. 9. Use relevant PPE 10. Observe dismantling procedures.

RECOVERY Provide protection equipment, first aid kits, communication system and medivac.

23

S/N

WORK DESCRIPTION SERVICE/REPAIRS OFCONTROL/ DISTRIBUTION SYSTEM OF ELECTRICAL PANEL.

THREATS

22-A

22-B

INSTALLATION OF CONTROL/DISTRIBU TION SYSTEM OF ELECTRICAL PANEL.

Starting task without approval. 2. Commencement of task without conducting J.H.A. 3. Executing task without dedicated, competent/ supervisory personnel. 4. Carrying out repairs without appropriate warning signs. 5. Working without P.P.Es. 6. Use of wrong tools. 7. Poor work organisation. 8. Non-observance of service procedures. 1. Starting task without approval. 2. Commencement of task without conducting J.H.A. 3. Executing task without dedicated/competent supervisory team. 4. Working without relevant P.P.E. 5. Use of wrong and unsafe tools. 6. Absence of relevant caution signs. 7. Absence of lifting facility.

1.

WHO MIGHT BE HARMED OR EXPOSED Electrical crew, other crew, equipment and facility.

CONSEQUENCES

CONTROL OF HARDS

RECOVERY Provide fire protection equipment. First and resources, effective communication and medivac.

1. 2. 3. 4. 5.

Injury to personnel Damage to work tools, equipment and facility. Electrocution Use of wrong tools Not isolating from power source.

1. 2. 3. 4. 5. 6. 7.

Obtain PTW before task execution. Conduct J.H.A before commencement of task. Use safe and right tools. Engage the services of only qualified and competent personnel. Use relevant PPEs Display relevant caution signs. Follow repairs procedures.

Electrical Crew, other crew, facility and hand tools

1. Falling object. 2. Use of wrong tools. 3. Damage to tools. 4. Over crowded work area. 5Injury to personnel.

1. Obtain P.T.W. before task execution. 2. Use safe and right tools. 3. Conduct J.H.A before work commencement. 4. Provide competent personnel for task execution. 5. Provide lifting facility. 6. Provide relevant caution signs. 7. Follow relevant installation procedures 8. Keep environment clean and tidy. 9. Use relevant P.P.E. 10. Keep unauthorised personnel.

Provide first aid resources, fire protection equipment, effective communication and medivac.

24

S/N 23-A

WORK DESCRIPTION CARPENTRY WORKS

THREATS Starting task without approval/PTW. 2. Commencement of task without conducting J.H.A. 3. Executing task without competent supervisor on site. 1. 4. 5. 6. 7. 8. Doing without appropriate warning signs posted. Personnel working without appropriate P.P.Es. Working with wrong tools and defective tools . Absence of a safe working environment. Horse playing on site.

WHO MIGHT BE HARMED OR EXPOSED Personnel, passersby and the environment

CONSEQUENCES 1. 2. 3. 4. 5. Injury to personnel Injury to passerby. Damage to tools and other resources. Low quality production. Wrong procedure may be followed.

CONTROL OF HARDS Obtain PTW before task commencement. 2. Use safe and right tools. 3. Brief personnel on hazards conduct J.H.A. 4. Provide dedicated/compete nt site supervisor. 5. Provide appropriate caution signs. 6. Keep work environment clean always. 7. Provide/use relevant P.P.Es. 8. Keep off unauthorized personnel. 9. Ban horse playing. 10. Closing supervise work. 1.

RECOVERY Provide effective communication and medical rescue/emergency aids.

WOOD PLANNING WOOD CUTTING NAILING NAIL REMOVAL GENERAL CONSTRUC TION ROOFING

25

S/N 24-A

WORK DESCRIPTION GRIT(SAND) BLASTING

1.

THREATS Starting activity without approval/P.T.W. 2. Commencement of activity without conducting J.H.A. 3. Commencement of activity without screening/shielding off blasting area. 4. Execution of work without competent supervisor on site. 5. Commencement of activity without preactivity inspection of equipment. 6. Using wrong and unsafe equipment. 7. Using wrong and unsafe equipment. 8. Horse playing on site. 9. Unauthorized personnel on site. 10. Personnel without appropriate P.P.E. 11. Absence of appropriate emergency aids. 12. Absence of appropriate warning signs.

WHO MIGHT BE HARMED OR EXPOSED Blasting crew, other workers environment and equipment and equipment.

CONSEQUENCES Injury to personnel. Access of blasting waste into sensitive and other parts of human body. Noise level may deafen. Damage to equipment Environmental impact in a negative manner. Sickness/death may result.

CONTROL OF HARDS Obtain approval P. T.W. before job commencement. Use safe/right tools. Brief crew on health hazards of the job/necessary precautions. Conduct J.H.A. and inspect equipment before work. Use certified equipment only. Screen/shield off work area. Post appropriate warning signs Provide appropriate P.P.E.s and medical emergency aids. Ban horse playing. Prohibit unauthorized on site. Maintain records of site visitors. Report defects promptly.

RECOVERY Provide communication facility/life aids and emergency aids.

1. 2.

1.

2. 3.

3. 4. 5.

4.

5. 6. 7. 8.

6.

9. 10. 11. 12.

26

S/N 25-A

WORK DESCRIPTION CONSTRUCTION OF WOODEN PERTITION PLAINING OF WOOD/WOOD CUTTING,NAIL DRIVING AND REMOVAL

THREATS 1. Starting task without approval/ relevant P.T.W. 2. Commencement of job without conducting J.H.A. 3. Poor work supervision. 4. Personnel working without appropriate P.P.E.S. 5. Working with wrong and defective tools.. 6. Absence of a safe working environment. 7. Protruding nails. 8. Improper guarding.

WHO MIGHT BE HARMED OR EXPOSED Personnel/passers -bye.

CONSEQUENCES 1. Temporary stoppage of work. 2. Personnel working without knowledge of associated hazard. 3. Deliverance of poor quality work. 4. Personnel suffers direct impact in case of an accident. 5. Personnel suffers injury from defective tools. 6. Task completed behind schedule due to defective tools. 7. Hazardous work environment as a result of the absence of good house-keeping. 8. Falls of materials/tools.

CONTROL OF HARDS 1. Obtain approval /relevant P. T.W. before work commencement. Conduct J.H.A. Acquaint crew with safety procedures. Provide competent supervisor. Provide crew with appropriate P.P.Es and ensure that provided gadgets are worn. Safe check tools before use. Report defective tools/rectify immediately. Embark on regular house keeping exercise. Observe relevant safety rules/ procedures.

RECOVERY Provide effective communication /medical rescue /emergency aids.

2. 3. 4.

5.

6. 7.

27

S/N 25-B

WORK DESCRIPTION POSITIONING/IN STALLATION OF PERTITION.

THREATS 1. Starting activity without approval/ relevant P.T.W. 2. Commencement of task without conducting J.H.A. 3. Poor work supervision. 4. Personnel working without appropriate P.P.E.S. 5. Working with wrong and defective tools. 6. Improper/unsafe arrangement of tools. 7. Improper guarding. 8. Horse-playing.

WHO MIGHT BE HARMED OR EXPOSED Personnel/ Passers-bye.

CONSEQUENCES 1. Temporary stoppage of work. 2. Personnel working without knowledge of associated hazard. 3. Deliverance of poor quality work. 4. Personnel suffer direct impact in case of an injury. 5. Injury to personnel from defective tools. 6. Tasks complete behind schedule because of defective tools. 7. Hazardous work environment as a result of the absence of good housekeeping. 8. Falls of materials and tools.

CONTROL OF HARDS 1. Obtain necessary document and approval before work commencement. Conduct job hazards analysis. Acquaint crew with safety procedures. Provide competent supervisor. Provide crew with appropriate P.P.Es. Safe-check tools before use. Report defective tools. And rectify immediately. Embark on regular house-keeping exercise. Observe relevant safety rules/ procedures. Avoid horse-playing. Keep unauthorised personnel off..

RECOVERY Provide first resource and effective means of communication.

2.

3. 4. 5.

6. 7. 8. 9.

28

S/N 25-C

WORK DESCRIPTION CONSTRUCTION AND INSTALLATION OF FALSE CEILING.

THREATS 1. Starting task without approval/ relevant P.T.W. 2. Commencement of job without conducting J.H.A. 3. Executing task without competent supervisor. 4. Personnel working without appropriate Safety wears. 5. Using wrong and defective tools. 6. Unsafe work environment. 7. Personnel not following procedures. 8. Absence of safe access ladder/work platform. 9. Fall of personnel/materials /tools. 9. No display of warning signs.

WHO MIGHT BE HARMED OR EXPOSED Personnel/passers -bye.

CONSEQUENCES

1. Temporary stoppage of work. 2. Personnel unaware of associated hazards. 3. Deliverance of poor quality job. 4. Personnel working without PPEs 5. Personnel sustains injury from defective tools. 6. Not achieving target because of defective tool. 7. Hazardous work environment. 8. Personnel not following procedures. 9. Injury as a result of falling from height. 10. Personnel not aware of restricted work area. 11. Damage to tools/materials. 12. Injury from protruding nails.

CONTROL OF HARDS

1. Obtain relevant documents/approval before commencing task. 2. Conduct J.H.A. with the view of acquainting crew with associated hazards. 3. Provide competent work/safety supervisors. 4. Provide necessary P.P.E.s and ensure that personnel use provided safety wears. 5. Safe-check tools/report defective tools for rectification. 6. Regularly carry-out housekeeping exercise on site with the view to eliminating existing hazards. 7. Observe safety rules and follow construction/ installation procedures. 8. Provide access ladder/platform for work at height. 9. Conspicuously display warning signs around work site. 10. Properly arranged serviceable materials from junks/ unserviceable ones. 11. Keep nails safely and carefully.

RECOVERY

29

S/N 25-D

WORK DESCRIPTION CONSTRUCTION AND INSTALLATION OF WOODEN TRUNCKINGS.

THREATS 1. Starting task without relevant document and approval. 2. Commencement of Job without conducting J.H.A. 3. Poor work supervision. 4. Personnel working without appropriate PPE's. 5. Working with wrong and defective tools. 6. Absence of a safe working environment. 7. Off-cuts littered around work site. 8. Off-cut with protruding nails. 10. Improper guarding. 11. Horse-paying. 12. Absence of safety signs. 13. Unauthorized personnel

WHO MIGHT BE HARMED OR EXPOSED Personnel/passers -bye.

CONSEQUENCES

1. 2. Temporary stoppage of task Personnel working without having knowledge of associated hazards. Deliverance of poor quality work. Personnel suffers direct impact/effects of accident in the absence of P.P.E.s . Injury to personnel from defective tools. Targets not reached due to defective tools. Hazardous work site. Nails piercing/injuring personnel. Tools/materials falling. Distraction/running. Personnel not aware of restricted work area. Damage to tools/materials. Injury from protruding nail.

CONTROL OF HARDS

1. Obtain relevant documents/approval before commencing task. 2. Carry out job hazards analysis with the aim of acquainting crew with associated hazards/procedures. 3. Provide dedicated and competent work/safety supervisors. 4. Provide appropriate safety wears. 5. Safe-check tool prior to work commencement with the aim to identifying defects. 6. Work, observing all safety rules in place. 7. Keep nails safely and remove all protruding nail from off-cuts. 8. Guard materials properly. Avoid horse playing. 9. Report nearmisses. 10. Avoid short cuts to safety. 11. Keep unauthorisd persons off.

RECOVERY Provide first aid resource/kits and effective means of communication.

3. 4.

5. 6. 7. 8. 9. 10. 13. 14. 15.

30

S/N 26-A

WORK DESCRIPTION CUTTING, GRINDING AND TACKING INSIDE VESSEL.

THREATS -Presence of toxic gases. - Lack of sufficient oxygen. - Presence of flammable substances. - Excessive heat. - Explosive atmosphere. - Lifting job around vessel (concurrent). - Presence of combustible material beneath vessel. - Presence of flammable gas and hydrocarbon. - Accidental gas leak round vessel. - Lack of WHIS/JHA.

WHO MIGHT BE HARMED OR EXPOSED Fitter/Welder and other personnel working round the vessel.

CONSEQUENCES

-Heart diseases due to inhalation of toxic gas. Suffocation. Death. Fire outbreak. Explosion. Excessive exhaustion.

CONTROL OF HARDS

-Wear approved nose mask such as light fume mask and other PPE, Eye goggle and face shield. Check and ensure that the oxygen level inside vessel is okay. Do not work inside vessel if oxygen level is less than 19.5%. Use gas detector to check for the presence of flammable gas. Shield adjacent area. Remove all combustible material inside and around vessel. Provide fire extinguishers. Suspend lifting job round vessel. Adhere to timing, dont over stay inside vessel. Suspend hot work outside vessel during hot work inside vessel. Continuously pour water on top of vessel. Check for leaking valves round vessel. Use extractor fan. Ensure that appropriate permit is in place.

RECOVERY

Standby man with live line standby nurse. First aid, Provide positive breathing apparatus.

31

S/N 26-B

WORK DESCRIPTION WELDING INSIDE VESSEL

THREATS Presence of toxic gases. - Lack of sufficient oxygen. - Presence of flammable substances. - Excessive heat. - Explosive atmosphere. - Lifting job around vessel (concurrent). - Presence of combustible material beneath vessel. - Presence of flammable gas and hydrocarbon. - Accidental gas leak round vessel. Lack of WHIS/JHA

WHO MIGHT BE HARMED OR EXPOSED Fitter/Welder and other personnel working round the vessel.

CONSEQUENCES

-Heart diseases due to inhalation of toxic gas. Suffocation. Death. Fire outbreak. Explosion. Excessive exhaustion.

CONTROL OF HARDS

RECOVERY

Standby man with live line standby nurse. First aid, Provide positive breathing apparatus.

Wear approved nose mask such as light fume mask and other PPE, EYE goggle and face shield. Check and ensure that the oxygen level inside vessel is okay. Do not work inside vessel if oxygen level is less than 19.5%. Use gas detector to check for the presence of flammable gas. Shield adjacent area. Remove all combustible material inside and around vessel. Provide fire extinguishers. Suspend lifting job round vessel. Adhere to timing, dont over stay inside vessel. Suspend hot work outside vessel during hot work inside vessel. Continuously pour water on top of vessel. Check for leaking valves round vessel. Use extractor fan. Ensure that appropriate permit is in place. -

32

S/N 27-A

WORK DESCRIPTION REPLACEMENT OF VESSEL -

THREATS Use of wrong tools Wrong work procedure Trapped pressure. Use of defective tool. Wrong position of personnel and crane. Lack of JSA poor job planning. Slippery hand tools. Tripping hazard. Poor house-keeping. Awkward valve. Wrong signal from signal man to operator. Wrong method of lifting manually and mechanically. Equipment failure. Poor house-keeping.

WHO MIGHT BE HARMED OR EXPOSED Fitter and other crew members round work place.

CONSEQUENCES

Sparks Explosion Fire outbreak , injury from trapped pressure. Death. Injury from defective tool. Injury due to wrong way of lifting valve. Damage to valve. Equipment and facility. Tripping and falling.

CONTROL OF HARDS

Use non-sparking tools, copper/bronze hammer. Ensure that line is completely depressurized and isolated. Carry out JSA. Plan your job to ensure safe execution. Use leather hand glove, hard hat, Safety boot. Liaise with client, supervisor. Consider your position and that of other personnel working with or round you. Carry out regular housekeeping. Ensure that valid permit to work (PTW) is in place.

RECOVERY

First aid. Refer to clinic if need be.

33

S/N 28-A

WORK DESCRIPTION SPRAY PAINTING

THREATS -Paint fumes. -Soil contamination. - Poor erection of scaffold. - Defective scaffold members. - Stray paint. - Scaffold failure. - Equipment failure. - Dangling air hose Hot surfaces Poor housekeeping. Absence of valid PTW. Absence of WHIS/JHA.

WHO MIGHT BE HARMED OR EXPOSED Painter/Passerby.

CONSEQUENCES

Heart diseases as a result of inhalation of paint. Dermal (skin) infection due to exposed skin. To skin to paint. Fall from height and body injury. Trip and fall and body injury. Injury from sharp objects. Damage to equipment. Fire outbreak Environmental pollution/violation of EMAS Environment standard. Poor work delivery. Temporary stoppage of work.

CONTROL OF HARDS

Appropriate nose mask and other PPEs Scaffold members should be inspected before erection. Scaffold to be erected by approved scaffolder and inspected before use. Scaffold should be erected on a firm level ground. Air hose should be kept to minimum length and coiled up after use. Provide waste bin for used cellophane and masking tape. Cellophane paper should be used to screen or cover nearby materials, equipment and ground where need be to avoid soil contamination. Dont spray on hot surfaces. Carry out WHIS/JHA. Display warning sign.

RECOVERY

Immediate First aid. Refer serious cases to clinic.

34

S/N 29-A

WORK DESCRIPTION BOLTING AND INSTALLATION OF NEW PIPINGS -

THREATS Defective tool. Use of wrong tool. No WHIS/JHA. Wrong position of personnel while bolting. Equipment failure slipping hammer Wrong signal during mechanical lifting awkward pipings. Wrong way of lifting manually. Wrong work procedure. Absence WHIS/JHA. No valid PTW. Lack of job concentration.

WHO MIGHT BE HARMED OR EXPOSED Fitters and other personnel round work area.

CONSEQUENCES

Injury to personnel. Bumping of personnel with one another. Accident or injury as a result of no WHIS/JHA. Injury to nearby personnel from flying hammer. Injury from awkward piping, due to wrong signal to crane operator or too many signal. Poor work delivery. Temporary stoppage of work. Nearmiss/Accident as a result of lack job concentration.

CONTROL OF HARDS Carry out WHIS/JHA use approved tools. Take a safe position while flogging bolt. Carry out checks on tools and equipment before start of work. Have a firm grip on the hammer dedicate a competent hand as signal man. Dedicate a competent crane operator, be on alert while carrying out mechanical lifting. Check and ensure integrity of lifting devices such as slings, robes, belts, etc. Engage competent supervisor.

RECOVERY

First aid. Refer where necessary.

35

S/N 30-A

WORK DESCRIPTION PILLING WORK 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11.

THREATS Wrong position of crane. Unstable grounding. Improper coupling of hammer. Uncertified equipment. High noise. Working at height. Presence of underground utilities. Wrong work procedure. Working without authorization. Wrong signal. Incompetent personnel.

WHO MIGHT BE HARMED OR EXPOSED Pilling crew.

CONSEQUENCES

1.Timbering of crane. 2. Equipment and material damage. 3. Injury to personnel. 4. High noise deafens. 5. Accident which may result in LTI and death in serious cases. 6. Damage to underground utilities such as pipes and cables. 7. Down time as a result of equipment failure. 8. Stress.

CONTROL OF HARDS

1. 2. Perform WHIS/JHA. Position crane on a firm ground. 3. Probe the ground. 4. Consult drawings to ascertain the position of underground utilities. 5. Competent supervisory and crew personnel. 6. P.P.E such as earmuff, hard hat, safety boots mandatory to pilling crew. 7. Use safety belt/harness for all jobs 2m above. 8. Carry out pre-start inspection an equipment and tools before commencement of task. 9. Check and re-check all lifting devices to ensure their integrity. 10. Restrict influx of personnel to piling area. 11. Provide fire extinguishers.

RECOVERY

First aid. Refer serious cases to Base or retainer clinic.

36

S/N 31-A

WORK DESCRIPTION LOADING MATERIALS INTO BARGE (MANUAL)

THREATS 1. Uncertified swimmer. 2. Commencement of Task without J.H.A. 3. Poor lifting of loads. 4. Wrong stacking of loads. 5. Overloading of barge. 6. Poor housekeeping/horse playing. 7. Absence of first aid facility 8. Loading the barge without competent supervisory and safety personnel and safe work method. 9. Tripping and falling. 10. Body injury.

WHO MIGHT BE HARMED OR EXPOSED Marine crew, watercraft and materials.

CONSEQUENCES

1. 2. 3. Mishap due to overloading. Fall into water by personnel/loads. Body injury/burns

CONTROL OF HAZARDS

1. 2. 3. 4. 5. 6. 7. Conduct J.H.A. before work commenced. Check out for favourable water for sailing against sinking. Ensure load is not above (SWL) of the barge. Engage certified marine crew officers. Dedicated life saver/divers. Ensure materials are safely loaded and well secured from falling. Provide portable fire extinguisher.

RECOVERY Provide adequate first aid equipment. Initiate medievac to base clinic and effective means of communication

37

S/N 32-A

WORK DESCRIPTION LOADING MATERIALS INTO BARGE (CRANE)

THREATS 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. Equipment failure. Uncertified swimmer. Uncertified Operator. Wrong swinging method. Wrong lifting and wrong shackling. Absence of competent signal man. Fire out break. Collapse of load and collapse of crane, due to wrong positioning. Fall of personnel and materials into water. Sinking the barge due to over loading. Commencement of task without (J.H.A.). Lifting above the S.W.L. of crane. Poor housekeeping. Wrong stacking of loads. Body injury/bruises. Working without relevant PPEs.

WHO MIGHT BE HARMED OR EXPOSED Crane operator, signal man, crane and other water craft crew.

CONSEQUENCES

1. 2. 3. Fall of suspended load and near misses. Barge mishap due to over loading of barge. Drowning and lost of lives.

CONTROL OF HAZARDS

1. 2. 3. 4. 5. 6. 7. 8. 9. Conduct J.H.A. before commencement of work. Keep a dedicated competent signalman and dedicated safety personnel. Ensure load do not exceed S.W.L. of crane. Engage certified crane operator. Routine check of crane. A dedicated life saver/driver. Obey all relevant safety operational rules. Check out for favourable water tide for sailing against sinking. Provide a functional fire extinguisher.

RECOVERY Provide adequate first aid equipment, initiate medievac to base clinic and effective means of communication

38

S/N 33-A

WORK DESCRIPTION OFF LOADING OF MATERIALS OUT OF BARGE (MANUAL)

THREATS 1. Uncertified swimmer. 2. Wrong position and lifting of materials. 3. Commencement of task without J.H.A. 4. Horse playing. 5. Poor housekeeping. 6. Working without adequate PPEs. 7. Absences of first aid equipment. 8. Body injury/bruises. THREATS

WHO MIGHT BE HARMED OR EXPOSED Marine crew and other group of personnel.

CONSEQUENCE S

1. 2. 3. Fall into water by personnel and materials. Tripping and falling. Collapse of load and damage due to wrong stacking. Body injury and bruises. Drowning due to bathing in the river.

CONTROL OF HAZARDS

1. 2. 3. 4. 5. 6. Dedicated life saver and divers. Conduct J.H.A. before work commenced. Engage dedicated competent safety personnel. Load should be properly stacked and well identified. Dedicated and certified quartermaster and others. Wear adequate relevant PPEs.

RECOVERY Provide adequate first aid equipment, initiate medievac to base clinic and effective means of communication

4. 5.

S/N 34-A OFF LOADING OF MATERIALS OUT OF BARGE (CRANE)

1. Uncertified swimmer. 2. Equipment failure. 3. Wrong swinging method. 4. Absence of competent signal man. 5. Fire out break. 6. Collapse of load and crane due to wrong positioning. 7. Fall of personnel and material into water. 8. Lifting above the sling wire capacity.

WHO MIGHT BE HARMED OR EXPOSED Crane operator and signal man. Crane and other water craft crew.

CONSEQUENCE S

1. Fall of personnel and material into water. Fire out break leading to LTI or death. Fall of suspended load and nearmisses.

CONTROL OF HAZARDS

1. 2. 3. 4. 5. 6. Conduct J.H.A. before work commence. A dedicated lifesaver and diver. Engage a competent crane operator and signalman. Provide functional first aid equipment. Ensure load is not above S.W.L. of crane. Obey all relevant operational rules.

RECOVERY Provide adequate first aid equipment, initiate medievac to base clinic and effective means of communication

2. 3.

39

S/N 35-A

WORK DESCRIPTION FLAME CUTTING

THREATS 1. Defective power tools. 2. Improper supervision. 3. Lack of J.H.A. and job planing. 4. Wrong work procedure. 5. Availability of combustible gas/materials. 6. Leaking oxy-acetlene gas bottles/hose. 7. Flying particles and hot surfaces. 8. Incompetent fitter/mate. 9. Violation of safety instruction.

WHO MIGHT BE HARMED OR EXPOSED 1. Fitters and mates. 2. Nearby work party.

CONSEQUENCES

1. 2. Injury to personnel, and damage to equipment. Accident leading to LTI and other losses.

CONTROL OF HAZARDS

1. Pre-mob all equipment and carry out regular and routine checks on equipment/tools. 2. Engage competent hands as supervisors. 3. Carry out J.H.A. before any task. 4. Follow work procedure and avoid short cuts. 5. Remove all combustible materials and carry out gas checks. 6. Flush the area thoroughly before flame cutting. 7. Shield work area against sparks and flying particles. 8. Provide fire extinguishers. 9. Adhere to safety instructions. 10. Wear correct PPE. 11. Obtain relevant P.T.W.

RECOVERY Provide first aid. Evacuate victim to retainer clinic where necessary.

40

S/N 36-A

WORK DESCRIPTION LOADING HEAVY DUTY INTO FLAT TRAILLER

THREATS 1. Wrong position of heavy duty equipment on trailer. 2. Overloading of trailer. 3. Equipment failure. 4. Lack of trained and competent driver and signal man and operators. 5. Slippery and unstable ground.

WHO MIGHT BE HARMED OR EXPOSED Operators and crew members.

CONSEQUENCES 1. Injury to personnel. 2. Damage to equipment due to fall of heavy duty equipment from trailer.

CONTROL OF HAZARDS

1. 2. 3. 4. 5. 6. 7. 8. Carry out J.H,A. Engage competent supervisors. Engage competent operators and signal man. Ensure that equipment used are certified. Carry out regular checks to ensure the integrity of equipment. Adhere to safe working load S.W.L and avoid overloading. Probe the ground and ensure that equipment are on firm leveled ground. Ensure that personnel are properly kitted with appropriate PPE.

RECOVERY Provide first aid. Evacuate victims where necessary.

S/N 37-A

WORK DESCRIPTION INDUSTRIAL DRILLING OF HOLE ON PLATE AND PIPE

THREATS 1. Defective equipment and tool. 2. Improper coupling of drilling bit. 3. Wrong work procedure. 4. Absence of pre-start inspection on equipment. 5. Not being attentive. 6. Incompetent personnel. 7. Horse playing. 8. Distraction. 9. Poor house keeping.

WHO MIGHT BE HARMED OR EXPOSED Welders/fitters.

CONSEQUENCES

1. 2. 3. Equipment failure. Down time/LTI. Injury to personnel and damage to equipment.

CONTROL OF HAZARDS

1. Use only approved and certified equipment. 2. Carry out JHA before start of work. 3. Follow work procedure. 4. Engage a competent personnel to operate the machine at a time. 5. Job concentration. 6. Avoid horse playing and distraction. 7. Ensure that drilling bit is properly coupled. 8. Wear appropriate P.P.E. 9. Carry out pre-start inspection on equipment before use. 10. Maintain good house keeping

RECOVERY Provide first aid/medevac must be put in place.

41

S/N 38-A

WORK DESCRIPTION SEIVING OF SAND FOR SANDBLASTING

THREATS 1. Dust. 2. Sharp objects. 3. Wrong tool.

WHO MIGHT BE HARMED OR EXPOSED Sandblaster/mate

CONSEQUENCES

1. 2. 3. 4. 5. Lungs disease as a result of inhalation of dust. Death may result in severe cases. Injury from sharp objects. Blockage of air hose. Damage to equipment.

CONTROL OF HAZARDS

1. 2. 3. 4. Remove sharp objects. Wear nose mask. Use approved sifter. Wear hand glove.

RECOVERY First aid.

S/N 39-A

WORK DESCRIPTION SAND BLASTING

THREATS 1. Frying sand particles. 2. Dust/fumes. 3. High noise. 4. Sudden pull out of air hose due to high pressure. 5. Poor house keeping. 6. Dangling air hose. 7. Absence of competent supervisor. 8. Commencement of work without pre-start inspection on equipment. 9. Excessive pressure inside blasting pot.

WHO MIGHT BE HARMED OR EXPOSED Sandblasting crew.

CONSEQUENCES

1. Sickness/death as a result of inhalation of sandblasting waste. High noise deafens. Injury to personnel. Damage to equipment. Trips and falls.

CONTROL OF HAZARDS

1. Engage competent supervisor. 2. Conduct JHA. 3. Use certified equipment. 4. Inspect equipment before start of operation. 5. Screen off sandblasting area. 6. Restrict movement of personnel to sandblasting area. 7. Install warning signs. 8. Ensure that air hose is tightly fitted. 9. Full face cover ear muff, coverall, safety boot mandatory. 10. Maintain good housekeeping. 11. Obtain relevant P.T.W.

RECOVERY Provide first aid. Standby man in case of emergency.

2. 3. 4. 5.

42

S/N 40-A

WORK DESCRIPTION EQUIPMENT SERVICING

THREATS 1. Incompetent personnel. 2. Wrong work procedure. 3. Working without authorisation PTW. 4. Working on live equipment. 5. Oil Spills. 6. Improvised tools.

WHO MIGHT BE HARMED OR EXPOSED Mechanics/Technici ans.

CONSEQUENCES

1. 2. 3. 4. Equipment damage. Injury to Personnel. Electric shock/electrocution . Environmental pollution.

CONTROL OF HAZARDS

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Engage competent hands. Perform JHA/WHIS. Liase with client personnel to ensure that equipment is isolated. Install warning signs. Obtain relevant P.T.W. Follow work procedure. Clean up oil spills and dribs. Maintain good house keeping. Provide drib cains and absorbent paper. Avoid horse playing. Wear appropriate P.P.E. Use correct tools. Provide functional fire extinguisher.

RECOVERY Provide first aid facility/effective means of communication.

43

S/N 41-A

WORK DESCRIPTION CUTTING OF ANGLE IRONS, RODS AND PIPES WITH MECHANICAL EQUIPMENT

THREATS 1. Incompetent personnel. 2. Absence of prestart equipment inspection. 3. Non use of adequate Personal Protective Equipment (PPE). 4. Danger of two or more personnel operating equipment at the same time since equipment has multi functions. 5. Horseplay within work area. 6. Poor house keeping. 7. Absence of competent supervisory personnel. 8. Distractions from personnel not involved in work activity.

WHO MIGHT BE HARMED OR EXPOSED Operating personnel or others.

CONSEQUENCES

1. 2. Damage to equipment and/or materials. Severe body injuries, due to nonuse of adequate PPEs. Inconsistency in equipment operation if two or more personnel use equipment at the same time. This might lead to severe injuries. Work stoppage, loss of man-hours and low productivity.

CONTROL OF HAZARDS

1. 2. Use competent personnel to operate the equipment. Mechanic to conduct prestart inspection on equipment during resumption in the morning and after lunch to identify sudden faults. Faults should be reported to mechanic promptly and work on equipment must be stopped until mechanic certifies it ok for use. Personnel must wear adequate Personal Protective Equipment (PPE). One personnel should use the equipment for any specific work item at a time. Eg. Cutting of angle iron and rods should not be carried out simultaneously. No house play is allowed at work areas. Work areas must be clean. There must be proper material layout. Put competent supervisor in place to ensure work is carried out according to specification to avoid mistakes. Personnel not involve in work activity must keepoff the area.

RECOVERY Provide first aid /medevac must be in place

3.

3.

4.

4.

5.

6. 7. 8.

9.

44

S/N 42-A

WORK DESCRIPTION MOBILIZATION

THREATS 1. Poor coordination. 2. Wrong collation of project resources. 3. Inadequate and poor planning. 4. Wrong timing. 5. Using wrong and unpremobed equipment. 6. Abuse/Failure to use journey management procedures. 7. Violation of accepted safety standards. *Execute miscellaneous task

WHO MIGHT BE HARMED OR EXPOSED Personnel, Equipment, tools, Environment and third party.

CONSEQUENCES 1. Injury to personnel 2. Damage to equipment. 3. Negative impact on the environment. 4. Injury to third party 5. Delay in project take - off.

CONTROL OF HAZARDS 1. Plan mobilization. 2. Sort resources. 3. Assign jobs to competent personnel. 4. Ensure that all procedures are followed. 5. Plan and protect the environment. 6. Use appropriate P.P.E.

RECOVERY Provide first aid resource and ensure effective use of available means of communication.

43-A

MISCELLANEOUS WORK

-Body injury, damage, fire out-break, poor housekeeping, damage to equipment etc.

S/N

WORK DESCRIPTION

THREATS

WHO MIGHT BE HARMED OR EXPOSED 45

CONSEQUENCES

CONTROL OF HAZARDS

RECOVERY

44-A

DEMOBILIZATION

1. Poor coordination. 2. Inadequate and poor planning. 3. Failure to take inventory of site resources. 4. Abuse and failure to use approved journey management procedure. 5. Failure to clean up and rehabilitate the environment. 6. Violation of other safety rules.

Personnel, equipment, tool environment and third party.

1. Injury to personnel. 2. Negative impact on the environment. 3. Lose of material and tools. 4. Accident and damages to equipment. 5. Compensation to third party.

1. Conduct demobilization meeting. 2. Plan for demobilization and allocate resources for exercise. 3. Draw up checklist and follow systematic. 4. Brief all stake holder payoff community accordingly. 5. Arrange for escort if necessary. 6. Obey all P.P.E AND Safety rules.

1. Provide adequate surveillance. 2. Provide first aid kits. 3. Ensure effective commination 4. Ensure effective emergency evacuation.

45-A

OTHER ITEMS AS MAY ARISE

*As determined

-Hazard to be identified/Analyzed

46

Вам также может понравиться

- JHA Civil WorksДокумент2 страницыJHA Civil Worksethelchudi100% (11)

- Job Hazard Analysis Form (Shutdown Activites)Документ4 страницыJob Hazard Analysis Form (Shutdown Activites)MARK ARQUE LACANARIA100% (1)

- Job Hazard Analysis TemplateДокумент12 страницJob Hazard Analysis TemplateMarvin Arinuelo100% (3)

- JSA Fitting and Welding Work For Pipe Trench InstalationДокумент6 страницJSA Fitting and Welding Work For Pipe Trench InstalationAzmi Fauzi78% (9)

- Toolbox TalksДокумент23 страницыToolbox TalksWali ul Islam100% (1)

- Jha For Earth WorkДокумент6 страницJha For Earth Worknik100% (14)

- JOB HAZARD ANALYSIS - Cable TrayДокумент10 страницJOB HAZARD ANALYSIS - Cable TrayJayson Escamillan100% (1)

- Crane JSAДокумент5 страницCrane JSAKritsada Tiwutanon100% (1)

- Jsa Grinding Welding Gas CuttingДокумент4 страницыJsa Grinding Welding Gas CuttingMark Roger Huberit IIОценок пока нет

- Activity Hazard AnalysisДокумент4 страницыActivity Hazard AnalysisGerrard Singh100% (1)

- Job Safety AnalysisДокумент4 страницыJob Safety AnalysisDedi Apriadi71% (7)

- Jha New Format-Painting Revision)Документ8 страницJha New Format-Painting Revision)Kenny Hassan100% (1)

- Job HAzard Analysis Welding Operations MiftahДокумент3 страницыJob HAzard Analysis Welding Operations MiftahLukmanElekAe100% (2)

- JHA LiftingДокумент3 страницыJHA LiftingPuntanata Siagian100% (7)

- Activity Hazard AnalysisДокумент43 страницыActivity Hazard AnalysisShawn James100% (4)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Документ6 страницJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganОценок пока нет

- Trades Guidelines - Excavation and TrenchingДокумент6 страницTrades Guidelines - Excavation and TrenchingMohammed Atef100% (1)

- Job Hazard AnalysisДокумент35 страницJob Hazard AnalysisVrigin Kathleen de Castro100% (2)

- Risk Assessment in A Welding and Construction SiteДокумент3 страницыRisk Assessment in A Welding and Construction SiteFad Tobi75% (8)

- How Chin Engineering: Job Safety AnalysisДокумент5 страницHow Chin Engineering: Job Safety AnalysisHow Chin Engineering Sdn BhdОценок пока нет

- SWMS 001 Drilling Soil BoresДокумент3 страницыSWMS 001 Drilling Soil BoresEngr Faheem AkhtarОценок пока нет

- JHA - Handrails and GratingsДокумент10 страницJHA - Handrails and GratingsVidyesh Nair67% (3)

- Ehs PR 03.f01 Patos FormДокумент2 страницыEhs PR 03.f01 Patos FormClyde Villanueva100% (4)

- Hazard AnalysisДокумент4 страницыHazard AnalysisFrancis Mayowa Ezekiel100% (1)

- JHA Risk Assesment 1Документ6 страницJHA Risk Assesment 1leonardo GaraisОценок пока нет

- Permit To Work Policy ProcedureДокумент7 страницPermit To Work Policy ProcedureChristian Auditor RiveraОценок пока нет

- Jha of PaintingДокумент3 страницыJha of PaintingAllan Camacho Regalado100% (1)

- Job Hazard AnalysisДокумент10 страницJob Hazard AnalysisDave ImpresoОценок пока нет

- Jsa-Jha For Using of Hand ToolsДокумент2 страницыJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- Job Hazard Analysis Welding Operations: Job Title: Work Place LocationДокумент18 страницJob Hazard Analysis Welding Operations: Job Title: Work Place Locationmuhammad imtiaz100% (1)

- Job Hazard AnalysisДокумент32 страницыJob Hazard AnalysisDonaryn MercaderОценок пока нет

- JSA Finishing Temporary FacilitiesДокумент6 страницJSA Finishing Temporary Facilitiesjet Louis Magallones100% (1)

- Job Hazard Analysis ExampleДокумент1 страницаJob Hazard Analysis ExampleDavid Pepito100% (1)

- Jsa Welding and Sleeve InstallationДокумент5 страницJsa Welding and Sleeve Installationshinto Lawrence100% (2)

- Job Hazard Analysis (Drilling)Документ2 страницыJob Hazard Analysis (Drilling)jay RОценок пока нет

- Grinding Equipment Risk AssessmentДокумент3 страницыGrinding Equipment Risk Assessmentdroffilcz270% (1)

- JSA - Mechanical Excavation PDFДокумент4 страницыJSA - Mechanical Excavation PDFMohammed MinhajОценок пока нет

- RISK ASSES-82 - Installation of Condenser Unit 2Документ8 страницRISK ASSES-82 - Installation of Condenser Unit 2Rochdi BahiriОценок пока нет

- Site Specific Safety PlanДокумент37 страницSite Specific Safety Plansgrsaya711100% (4)

- Jha RoofingДокумент4 страницыJha Roofingahmadhatake100% (1)

- Pha ExcavationДокумент13 страницPha ExcavationirshadОценок пока нет

- RA - Electrical WorksДокумент9 страницRA - Electrical WorksShezi Bhatti0% (1)

- 28 Job Safety AnalysisДокумент7 страниц28 Job Safety Analysisashish_kamat100% (3)

- Crane JHA OKДокумент4 страницыCrane JHA OKAbu Maaz100% (1)

- JHA 15-Work at Height Using ScaffoldingДокумент3 страницыJHA 15-Work at Height Using ScaffoldingWte SB100% (7)

- F5B-BMJV-0001-AHA-HSE 00 AHA For RC Pipes InstallationДокумент15 страницF5B-BMJV-0001-AHA-HSE 00 AHA For RC Pipes InstallationTaiwo Oshin100% (1)

- JSA For Cutting, Grinding and WeldingДокумент4 страницыJSA For Cutting, Grinding and Weldingyc safety100% (3)

- Civil JSA Form Application of Protective Coating On Sump PitsДокумент1 страницаCivil JSA Form Application of Protective Coating On Sump PitsdrmuhsinОценок пока нет

- Safety Program SampleДокумент30 страницSafety Program Samplerael MijaresОценок пока нет

- GL 16 Confined Space EntryДокумент1 страницаGL 16 Confined Space Entrytp101267Оценок пока нет

- Job Hazard Analysis of Fabrication WorkДокумент7 страницJob Hazard Analysis of Fabrication WorkBALAL AKRAMОценок пока нет

- Jsa For Work at HeightsДокумент4 страницыJsa For Work at Heightsjithin shankar100% (1)

- Safety Induction TrainingДокумент62 страницыSafety Induction TrainingIGede Sumantra100% (2)

- JSA-010 Excavation Sampling PDFДокумент5 страницJSA-010 Excavation Sampling PDFArgaYurIstiawanОценок пока нет

- 1 - Scaffolding WorkДокумент16 страниц1 - Scaffolding WorkPerwez21100% (14)

- Jha RebarsДокумент7 страницJha RebarsJaycee QuinОценок пока нет

- Job Hazard AnalysisДокумент3 страницыJob Hazard AnalysisChristine YasaОценок пока нет

- Biogeochemical CyclesДокумент25 страницBiogeochemical CyclesAlokfriОценок пока нет

- University of Cambridge International Examinations International General Certificate of Secondary Education Biology Paper 1 Multiple Choice May/June 2005 45 MinutesДокумент16 страницUniversity of Cambridge International Examinations International General Certificate of Secondary Education Biology Paper 1 Multiple Choice May/June 2005 45 Minutesmath magicОценок пока нет

- IKMAN NURHAKIM XII IPS 3 - Explanation Text BDRДокумент2 страницыIKMAN NURHAKIM XII IPS 3 - Explanation Text BDRikman nibosОценок пока нет

- International - Standard ISO 14175Документ3 страницыInternational - Standard ISO 14175Geom_MengoliОценок пока нет

- Mothballing Guidelines For Plant EquipmentДокумент11 страницMothballing Guidelines For Plant EquipmentthawatchaiОценок пока нет

- Energy and Material BalanceДокумент158 страницEnergy and Material BalanceUmer FarooqОценок пока нет

- 305.076.000 01 EN Bellavista Manual G6 PDFДокумент162 страницы305.076.000 01 EN Bellavista Manual G6 PDFanh khoa duongОценок пока нет

- Class Ix EnglishДокумент87 страницClass Ix EnglishAhmedEEEОценок пока нет

- Product Name: Oxygen, Refrigerated LiquidДокумент7 страницProduct Name: Oxygen, Refrigerated LiquidHugo AlvarezОценок пока нет

- Science Focus 3Документ311 страницScience Focus 3wantsomejuce93% (15)

- The Element of OxygenДокумент3 страницыThe Element of OxygenNadzrin PuadОценок пока нет

- Report 1 - Feasibility Study For Formalin ProductionДокумент51 страницаReport 1 - Feasibility Study For Formalin ProductionGizem Arslan100% (2)

- Compiled 1ST Periodical TestДокумент69 страницCompiled 1ST Periodical TestErgen GarciaОценок пока нет

- Manual DSC204F1 eДокумент96 страницManual DSC204F1 eFrancisca Belen VillafrancaОценок пока нет

- Maghreb Oxygene Strategic PlanДокумент104 страницыMaghreb Oxygene Strategic PlanAngel TehОценок пока нет

- How To Make The Most Of: Carbon DioxideДокумент3 страницыHow To Make The Most Of: Carbon Dioxidetorta1Оценок пока нет

- A Method of Activating The Deadman Region in Blast Furnace During OperationДокумент8 страницA Method of Activating The Deadman Region in Blast Furnace During OperationAloísio Simões RibeiroОценок пока нет

- Test Bank Chemistry, An Atoms First Approach 3rd Edition by ZumdahlДокумент12 страницTest Bank Chemistry, An Atoms First Approach 3rd Edition by ZumdahlalvinbookfinderОценок пока нет

- Bom 807 4759 Finalstudymaterial2ndterm8science1Документ52 страницыBom 807 4759 Finalstudymaterial2ndterm8science1Mohamed AliОценок пока нет

- Coral CalciumДокумент5 страницCoral CalciumRama ShaktiОценок пока нет

- Osha 29 CFR 1910.134Документ50 страницOsha 29 CFR 1910.134Ellis HowardОценок пока нет

- Chemistry ProjectДокумент7 страницChemistry ProjectPragya jhalaОценок пока нет

- FORM 1 Science Mid Year ExaminationДокумент12 страницFORM 1 Science Mid Year ExaminationMr_superbОценок пока нет

- 2001 Usnco Exam Part IДокумент9 страниц2001 Usnco Exam Part IAnas Kasmui100% (1)

- AP Gases WorksheetДокумент4 страницыAP Gases Worksheetburcak gecОценок пока нет

- Taller MasaДокумент2 страницыTaller Masa__Caro26__Оценок пока нет

- Standard Procedures For Tank Cleaning, Purging and Gas Free Operation For OiДокумент5 страницStandard Procedures For Tank Cleaning, Purging and Gas Free Operation For Oiวิทยา บุญมี67% (3)

- Chapter 1Документ23 страницыChapter 1Raziah Ahmad ZaideiОценок пока нет

- Rigo 2012Документ11 страницRigo 2012saeedОценок пока нет

- 12 Do LabДокумент3 страницы12 Do LabRick MoraОценок пока нет