Академический Документы

Профессиональный Документы

Культура Документы

CESCO-EnG-QPP.29-Underwater Inspection Criteria For Steel Structure

Загружено:

Sagun AlmarioИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CESCO-EnG-QPP.29-Underwater Inspection Criteria For Steel Structure

Загружено:

Sagun AlmarioАвторское право:

Доступные форматы

DOCUMENT NO.: CESCO-ENGQPP.

29 EFFECTIVE DATE:

REVISION NO.: 0 PAGE NO.: 1 of 5

DOCUMENT TITLE:

UNDERWATER INSPECTION CRITERIA for STEEL STRUCTURE

Revision History Originator B. Abecia Date

Rev. No. 0

Page No. 1-5 Initial Release

SIGNATURE PREPARED BY: ENGR. BONG R. ABECIA QA/QC HEAD ENGR. ARMAND C. FLORES QEHS HEAD ENGR. JOSE C. RIVERA JR. OPERATION MANAGER-PROJECT ENGR. FRUCTOSO N. MONTANO GENERAL MANAGER/PRESIDENT

DATE

REVIEWED BY:

APPROVED BY:

DOCUMENT NO.: CESCO-ENGQPP.29 EFFECTIVE DATE:

REVISION NO.: 0 PAGE NO.: 2 of 5

DOCUMENT TITLE:

UNDERWATER INSPECTION CRITERIA for STEEL STRUCTURE

1.0

OBJECTIVE The fundamental purpose of any inspection is to provide the information necessary to assess the condition (capacity, safety, and rate of deterioration) of a structure. This procedure encompasses the underwater examination of steel structures particularly pier piles.

2.0

SCOPE Underwater inspections are primarily visual observation of the facility being inspected. Quantitative measurements, such as underwater voltmeter readings on metal structures and thickness measurements on steel piling are often taken. Before making the observation, it is usually necessary to clean the structure of marine growth and fouling. Several techniques are used to accomplished this cleaning, ranging from hand cleaning with scrapers and wire brushes to the use of waterblasting and hydraulically powered mechanical abrasive tools.

3.0

GENERAL INSPECTION PROCEDURES The usefulness of an inspection depends on the suitability and recording of the data (observations) obtained for use in later engineering evaluation. An underwater inspection is a condition survey; therefore, the diver should make the report observations and measurements that can be used by an engineer to make engineering assessments. Ideally, the engineer making the engineering assessments is also a diver and dives on the facility for at least a portion of the inspection. A part of the engineering assessment will be to determine the cause of the failure or damage; therefore, detailing the inspection is important. For example, the diver should observe, measure, and report that a sheet pile wall has a hole measuring 2 feet by 3 feet, at depth of 2 feet below mean low water (MLW), and that behind the hole is a 6-foot deep cavity. These data may be supplemented by the divers opinion regarding the structural adequacy of the wall if the nature of its condition is obvious. A final conclusion, however, can only be reached after an analysis of the structures existing condition has been conducted. Since divers observations and measurements are often the only data available for the topside personnel to make an engineering assessment, the reliability of such data is critically important. Therefore, the quality control of measurements becomes an important issue. At least 10 percent of all measurements and observations must be rechecked by a second diver to ensure accuracy. If any discrepancy is discovered, all measurements and observations must be rechecked. An important part of any inspection operation is the recording of the divers observations. Observations, both qualitative and quantitative, can be recorded underwater on a Plexiglas slate with a grease pencil. However, direct hardwire communication between the diver and the topside is much more efficient. In addition, use a video recording system, a photographic camera, and a voice recorder whenever possible. The dive supervisor or inspection team leader should debrief the working diver as soon after the dive as possible. This valuable information should be recorded for later reference.

LEVELS OF INSPECTION Three basic types or levels of inspection are used for inspecting marine facilities. The resources and preparation needed to do the work distinguish the level of inspection. Also, the level of inspection determines the type of damage/defect that is detectable: 3.1.1.1 Level I General Visual Inspection. The Level I effort can confirm as-built structural plans and detect obvious major damage or deterioration due to overstress ( collision ), severe corrosion, or extensive biological growth attack. The Level I will provide initial input for an inspection strategy. Although this is an overview, close attention should be given to confirming or providing information to update available facility drawings and condition evaluations.

3.1 3.1.1

DOCUMENT NO.: CESCO-ENGQPP.29 EFFECTIVE DATE:

REVISION NO.: 0 PAGE NO.: 3 of 5

DOCUMENT TITLE:

UNDERWATER INSPECTION CRITERIA for STEEL STRUCTURE

This type of inspection does not involve cleaning of any structural elements and can therefore be conducted much more rapidly than the other types of inspections. The Level I effort is essentially a general inspection swim-by overview. It does not involve cleaning of structural elements, which allows the inspection to be conducted rapidly. The underwater inspector relies primarily on visual and/or tactile observation (depending on water clarity) to make condition assessments. These observations are made over the specified exterior surface area of the underwater structure, whether it is a quaywall, bulkhead, seawall, pile, or mooring. 3.1.1.2 Level II Close-Up Visual Inspection. Level II efforts are complete, detailed investigations of selected components or subcomponents, or critical areas of the structure, directed toward detecting and describing damaged or deteriorated areas that may be hidden by surface biofouling. Limited deterioration measurements are obtained. These data are sufficient for gross estimates of facility load capability. This type of inspection will generally involve prior or concurrent cleaning of part of the structural elements. Since cleaning is time consuming, it is generally restricted to areas that are critical or that may be typical of the entire structure. The amount and thoroughness of cleaning to be performed are governed by what is necessary to determine the general condition of the overall facility. Simple instruments such as calipers and measuring scales are commonly used to take physical measurements. 3.1.1.3 Level III Highly Detailed Inspection. This level of inspection is primarily designed to provide data that can be used to perform a structural assessment and will often require the use of Nondestructive Testing (NDT) techniques. The procedures are conducted to detect hidden or imminent damage, loss in cross-sectional area, and material homogeneity. The training, cleaning, and testing requirements will vary depending on the type of damage/defect that is to be investigated and the type of inspection equipment to be used. A Level III examination will normally require prior cleaning. The use of Level III inspection techniques is usually limited to key structural areas that may be suspect, or to structural areas that may be representative of the overall structure. Level III inspections will require considerably more experience and training than Level I or Level II inspections, and should be accomplished by qualified engineering or testing personnel. On steel H-piles, pipe piles, and sheet piles, metal thickness measurements are made with ultrasonic thickness equipment. In addition, electrical potential measurements, using a halfcell, are taken to verify the performance of the cathode protection system for steel structures. 4.0 EQUIPMENTS AND TOOLS REQUIRED To ensure a thorough inspection, the area must be cleared of all marine growth. This can be done by various means, depending on surface support. A high-pressure water jet is the most effective method for clearing marine growth sufficiently for visual inspection. Hand tools, such as wire brushes and scrapers are sufficient for smaller jobs. Sounding of the structure can be done with a small hammer or pickax. Inspection of the structure requires some type of underwater data recording device, such as a grease pencil/slate, or hardwire communications with topside personnel. Calipers and scales are used to determine thicknesses of steel flanges, webs, and plates. A portable reference electrode or an underwater voltmeter is used to determine the effectiveness of cathodic protection on steel structures. Table 4-1 gives voltages measured by the underwater voltmeter for steel structures. Visual documentation may be desirable for illustrating problem areas to others who did not physically make the inspection dive. Using an underwater camera or television system can do this.

DOCUMENT NO.: CESCO-ENGQPP.29 EFFECTIVE DATE:

REVISION NO.: 0 PAGE NO.: 4 of 5

DOCUMENT TITLE:

UNDERWATER INSPECTION CRITERIA for STEEL STRUCTURE

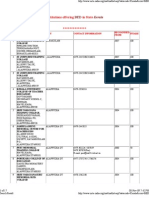

Table 4-1. Underwater Voltmeter Values for Steel Structures. Voltage Measured (V)

Description Steel is cathodically unprotected. The rate of corrosion depends on the effectiveness of paint or tar coatings, marine growth, and local water chemistry and water currents. On some structures, the hard layer of marine growth may provide some protection. The closer to 0 volts the more active is the corrosion potential. Note: -0.6 volt is the potential of bare, unprotected steel in seawater. The steel is partially protected. The steel is adequately protected. Cathodic protection systems are working effectively The steel is overprotected. Note: Under some circumstances, the metal surface can be made more brittle when overprotected. Surface coatings may be damaged or lifted off by the excess formation of hydrogen bubbles.

0.0 to -0.7

-0.7 to -0.82 -0.83 to -1.1 -1.1 or higher negative values

4.1 4.1.1

ULTRASONIC INSPECTION. Ultrasonic thickness measurement equipment is available for inspecting steel structures. Thickness measurements are obtained because certain types of ultrasonic waves travel at a constant speed through a material, because they travel in straight lines, and because a portion of the wave is reflected when it meets an interface. The difference in time between the detection of the front surface and back surface echoes is correlated to the thickness of the material. Ultrasonic thickness measurements require a thorough removal of marine growth and scale and can be unreliable if the surface on which the instrument is placed is heavily pitted. Adequate training and experience are required to obtain readings and to evaluate the measurements made with this equipment. DOCUMENTATION OF INSPECTION For the results of inspection to be useful, they must be documented in a clear and cincise manner and in accordance with generally understood terminology. Inspectors should maintain daily logs of inspection details including measurement data, locations of observation, and water depths, if relative. Inspection forms and reports should be completed as soon as possible after the inspection has been completed. Standard forms and report formats greatly facilitate the documentation procedure and are essential for comparing the results of the present inspection with past and future inspections. Steel pile inspection results are usually recorded in terms of remaining metal thickness. It should be noted, however, that the categorization of a defect, i.e., moderate, major, etc., will depend on the water depth. Piles in deeper water, with a long unsupported length, are susceptible to buckling, and loss in strength becomes more critical. When appropriate, damaged areas should be documented with still photography and closed circuit television. Still photography provides the necessary high definition required for detailed analysis, while video, though having a less sharp image, provides a continuous view of events that can be monitored by surface engineers and recorded for later study. All photographs should be numbered, dated, and labeled with a brief description of the subject. A slate or other designation indicating the subject should appear in the photograph. Video tapes should be provided with a title and lead-in, describing what is on the tape. The description should

5.0

DOCUMENT NO.: CESCO-ENGQPP.29 EFFECTIVE DATE:

REVISION NO.: 0 PAGE NO.: 5 of 5

DOCUMENT TITLE:

UNDERWATER INSPECTION CRITERIA for STEEL STRUCTURE

include the method of inspection used, the nature and size of the structure being inspected, and any other pertinent information.

Вам также может понравиться

- Under Water of BridgeДокумент9 страницUnder Water of Bridgejamjam75Оценок пока нет

- 259 QC and Assurance and Performance Cut Off Wall VerificationДокумент14 страниц259 QC and Assurance and Performance Cut Off Wall VerificationbimolaksoОценок пока нет

- Tank InspectionДокумент7 страницTank InspectionTina Miller100% (1)

- Manual Inspection of StructuresДокумент156 страницManual Inspection of Structuresramkumar121Оценок пока нет

- Underwater Inspection EvaluationДокумент115 страницUnderwater Inspection Evaluationnaoufel1706Оценок пока нет

- Repairs and Rehabilitation of Bridges PDFДокумент9 страницRepairs and Rehabilitation of Bridges PDFSourabh NegiОценок пока нет

- Instrumentation-Keystone of Dam MonitoringДокумент30 страницInstrumentation-Keystone of Dam MonitoringAnonymous ep7LE5ZdP5Оценок пока нет

- Engineering Encyclopedia: Underwater NDTДокумент9 страницEngineering Encyclopedia: Underwater NDTabyОценок пока нет

- Advanced Integrity Testing For Roofing and Water Proofing MembranesДокумент10 страницAdvanced Integrity Testing For Roofing and Water Proofing MembranesKasturi LetchumananОценок пока нет

- Advanced Integrity Testing For Roofing and Water ProofingДокумент10 страницAdvanced Integrity Testing For Roofing and Water ProofingHARSHALОценок пока нет

- Bridge Engineering: Maintenance: Bridge Maintenance TechniquesДокумент36 страницBridge Engineering: Maintenance: Bridge Maintenance TechniquesRam NepaliОценок пока нет

- NDT of Welded Steel Tanks1 PDFДокумент4 страницыNDT of Welded Steel Tanks1 PDFBulut Yildiz100% (1)

- Inspection Plan (Draft)Документ5 страницInspection Plan (Draft)pioneerinvincibleОценок пока нет

- 036 PEC ArticleДокумент7 страниц036 PEC Articlemahesh070100% (1)

- Fincher 1972Документ14 страницFincher 1972Jocilene Dantas Torres NascimentoОценок пока нет

- Detailed Visual Bridge Inspection Guidelines For Concrete and Steel Bridges Level 2 InspectionsДокумент313 страницDetailed Visual Bridge Inspection Guidelines For Concrete and Steel Bridges Level 2 Inspectionsjayryansantos2Оценок пока нет

- Module 2 1Документ15 страницModule 2 1Harshitha j gowdaОценок пока нет

- Offshore Surveys-Paper No. 729Документ11 страницOffshore Surveys-Paper No. 729Winger VelezОценок пока нет

- Pressure Vessel Inspection ProcedureДокумент16 страницPressure Vessel Inspection Procedurejabir ahmad anarwalaОценок пока нет

- Remr Technical Note Cs-Es-1.3 Ultrasonic System For Rapid Assessment of Soundness of Sheet Pile and Other Flat StructuresДокумент2 страницыRemr Technical Note Cs-Es-1.3 Ultrasonic System For Rapid Assessment of Soundness of Sheet Pile and Other Flat StructureskuyahmsОценок пока нет

- 01 Saip 06Документ7 страниц01 Saip 06malika_00Оценок пока нет

- Instrumentation in TunnelsДокумент14 страницInstrumentation in Tunnelssravan_ruby100% (2)

- The ABCs of Eddy Current Weld InspectionДокумент4 страницыThe ABCs of Eddy Current Weld Inspectionpadmgovi23Оценок пока нет

- A Critical Review of RDSO Guidelines BS 96 Underwater Inspection of BridgesДокумент12 страницA Critical Review of RDSO Guidelines BS 96 Underwater Inspection of Bridgesjamjam75Оценок пока нет

- l4 - Procedure of Civil Structure InspectionДокумент30 страницl4 - Procedure of Civil Structure InspectionWajira Sanjaya PereraОценок пока нет

- Subsea Pipeline InspectionДокумент17 страницSubsea Pipeline Inspectionianherzog86% (7)

- Destructive and Non-Destructive TestingДокумент17 страницDestructive and Non-Destructive TestingBhargav ChaitanyaОценок пока нет

- Handbook On Inspection of BridgesДокумент82 страницыHandbook On Inspection of BridgesBasha Sak100% (1)

- Ug 3Документ20 страницUg 3api-301328164Оценок пока нет

- Paper - Practical Considerations of Inspecting Post-Tensioned BridgesДокумент7 страницPaper - Practical Considerations of Inspecting Post-Tensioned Bridgessyndicate_mauliОценок пока нет

- Low Strain Pile Integrity TestingДокумент6 страницLow Strain Pile Integrity TestingWaqas SadiqОценок пока нет

- Internal & External Inspection GuidelinesДокумент5 страницInternal & External Inspection Guidelinesgeverett2765Оценок пока нет

- OSIM FieldGuide (Apr 2008)Документ50 страницOSIM FieldGuide (Apr 2008)mtor86Оценок пока нет

- Permanent Weldless Deepwater Repair Strategies: 1. AbstractДокумент14 страницPermanent Weldless Deepwater Repair Strategies: 1. AbstractSharkTech360 TVОценок пока нет

- Scope of WorkДокумент6 страницScope of WorkChukwuma Emmanuel OnwufujuОценок пока нет

- Underwater Inspection Reassessment of Italian Offshore PlatformsДокумент8 страницUnderwater Inspection Reassessment of Italian Offshore PlatformsRasheed YusufОценок пока нет

- Underground Piping TestingДокумент2 страницыUnderground Piping TestingDouglas HillОценок пока нет

- CorrosionДокумент14 страницCorrosionChalakAhmedОценок пока нет

- Instrumentation and Structural Monitoring of Dams 2018Документ16 страницInstrumentation and Structural Monitoring of Dams 2018Mohamed Ismail ShehabОценок пока нет

- Nde of Steel Bridges Fatigue Crack Detection and MonitoringДокумент8 страницNde of Steel Bridges Fatigue Crack Detection and MonitoringHyujeii MceОценок пока нет

- ECV5701 Notes For Concrete Inspection and Assessment-1Документ19 страницECV5701 Notes For Concrete Inspection and Assessment-1ahmed almhjani100% (1)

- MG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionДокумент11 страницMG-HSEQ-Q-P-0268 Rev A1 Corporate Procedure For Visual InspectionAbdelrahman Hosny100% (1)

- Inspection of Concrete StructuresДокумент56 страницInspection of Concrete StructuresAYOBAMI_OJUAWOОценок пока нет

- OTC-26560-MS Comprehensive Well Integrity Solutions in Challenging Environments Using Latest Technology InnovationsДокумент9 страницOTC-26560-MS Comprehensive Well Integrity Solutions in Challenging Environments Using Latest Technology InnovationsheydaripostОценок пока нет

- Condition Assessment of BoilerДокумент8 страницCondition Assessment of BoilerEzhil Vendhan PalanisamyОценок пока нет

- CIEM6000S - Lecture10Документ88 страницCIEM6000S - Lecture10K. Y. S LAUОценок пока нет

- Acoustic EmissionsДокумент12 страницAcoustic Emissionsharsha02.vardhanОценок пока нет

- 2ND ModuleДокумент33 страницы2ND ModuleGirish NaikОценок пока нет

- OPTIMIZATIONOFDAMMONITORINGFORLONGCONCRETEBUTTRESSDAMS Nordstrmetal Paper PDFДокумент17 страницOPTIMIZATIONOFDAMMONITORINGFORLONGCONCRETEBUTTRESSDAMS Nordstrmetal Paper PDFAlexander Felix PeniОценок пока нет

- Corrosion Under Insulation of Plant and Pipework v3Документ6 страницCorrosion Under Insulation of Plant and Pipework v3patrick6364Оценок пока нет

- Corrosion Under InsulationДокумент4 страницыCorrosion Under InsulationChem.EnggОценок пока нет

- spe 124932 ms光纤应变与缠绕角度关系Документ15 страницspe 124932 ms光纤应变与缠绕角度关系su feiyuОценок пока нет

- Part II Chapter 1 API RP 572Документ9 страницPart II Chapter 1 API RP 572Amr Mohamed SolimanОценок пока нет

- Inspection of Atmospheric Storage Tank BottomsДокумент23 страницыInspection of Atmospheric Storage Tank BottomsrajeshmohanaОценок пока нет

- I Introduction and ScopeДокумент3 страницыI Introduction and ScopeGetapo RaminОценок пока нет

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsОт Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsРейтинг: 4 из 5 звезд4/5 (1)

- Well Testing Project Management: Onshore and Offshore OperationsОт EverandWell Testing Project Management: Onshore and Offshore OperationsОценок пока нет

- Non-destructive Testing and Evaluation of Civil Engineering StructuresОт EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacОценок пока нет

- 1.2 CP S-04 Vol.1 Sec.4 20201027Документ63 страницы1.2 CP S-04 Vol.1 Sec.4 20201027Sagun AlmarioОценок пока нет

- Rev. Application Form For Evaluation Approval of Const. SafetyPДокумент3 страницыRev. Application Form For Evaluation Approval of Const. SafetyPSagun AlmarioОценок пока нет

- DOLE Construction Safety & Health Approval Checklist FormДокумент1 страницаDOLE Construction Safety & Health Approval Checklist FormSagun AlmarioОценок пока нет

- Critical Lift Plan FormДокумент2 страницыCritical Lift Plan FormSagun AlmarioОценок пока нет

- RIFC - EMERGENCY PLAN WДокумент6 страницRIFC - EMERGENCY PLAN WSagun Almario100% (1)

- Method Statement For Survey WorksДокумент13 страницMethod Statement For Survey WorksSagun Almario100% (1)

- METHOD STATEMENT For SCAFFOLDING WORKSДокумент11 страницMETHOD STATEMENT For SCAFFOLDING WORKSSagun AlmarioОценок пока нет

- Hardnes TestДокумент25 страницHardnes TestSagun AlmarioОценок пока нет

- Hedonic Calculus Essay - Year 9 EthicsДокумент3 страницыHedonic Calculus Essay - Year 9 EthicsEllie CarterОценок пока нет

- Sample Midterm ExamДокумент6 страницSample Midterm ExamRenel AluciljaОценок пока нет

- Strategic ManagementДокумент14 страницStrategic ManagementvishakhaОценок пока нет

- Djordje Bubalo BiografijaДокумент12 страницDjordje Bubalo BiografijaМилан КрстићОценок пока нет

- Chhabra, D., Healy, R., & Sills, E. (2003) - Staged Authenticity and Heritage Tourism. Annals of Tourism Research, 30 (3), 702-719 PDFДокумент18 страницChhabra, D., Healy, R., & Sills, E. (2003) - Staged Authenticity and Heritage Tourism. Annals of Tourism Research, 30 (3), 702-719 PDF余鸿潇Оценок пока нет

- SUBSET-026-7 v230 - 060224Документ62 страницыSUBSET-026-7 v230 - 060224David WoodhouseОценок пока нет

- ID2b8b72671-2013 Apush Exam Answer KeyДокумент2 страницыID2b8b72671-2013 Apush Exam Answer KeyAnonymous ajlhvocОценок пока нет

- Final PS-37 Election Duties 06-02-24 1125pm)Документ183 страницыFinal PS-37 Election Duties 06-02-24 1125pm)Muhammad InamОценок пока нет

- GN No. 444 24 June 2022 The Public Service Regulations, 2022Документ87 страницGN No. 444 24 June 2022 The Public Service Regulations, 2022Miriam B BennieОценок пока нет

- GearsДокумент14 страницGearsZulhilmi Chik TakОценок пока нет

- CEI and C4C Integration in 1602: Software Design DescriptionДокумент44 страницыCEI and C4C Integration in 1602: Software Design Descriptionpkumar2288Оценок пока нет

- A Guide To Relativity BooksДокумент17 страницA Guide To Relativity Bookscharles luisОценок пока нет

- UT & TE Planner - AY 2023-24 - Phase-01Документ1 страницаUT & TE Planner - AY 2023-24 - Phase-01Atharv KumarОценок пока нет

- Unified Power Quality Conditioner (Upqc) With Pi and Hysteresis Controller For Power Quality Improvement in Distribution SystemsДокумент7 страницUnified Power Quality Conditioner (Upqc) With Pi and Hysteresis Controller For Power Quality Improvement in Distribution SystemsKANNAN MANIОценок пока нет

- Basic Translation TerminologyДокумент7 страницBasic Translation TerminologyHeidy BarrientosОценок пока нет

- Sukhtankar Vaishnav Corruption IPF - Full PDFДокумент79 страницSukhtankar Vaishnav Corruption IPF - Full PDFNikita anandОценок пока нет

- Philosophy of Jnanadeva - As Gleaned From The Amrtanubhava (B.P. Bahirat - 296 PgsДокумент296 страницPhilosophy of Jnanadeva - As Gleaned From The Amrtanubhava (B.P. Bahirat - 296 PgsJoão Rocha de LimaОценок пока нет

- Analog Electronic CircuitsДокумент2 страницыAnalog Electronic CircuitsFaisal Shahzad KhattakОценок пока нет

- Why Do Firms Do Basic Research With Their Own Money - 1989 - StudentsДокумент10 страницWhy Do Firms Do Basic Research With Their Own Money - 1989 - StudentsAlvaro Rodríguez RojasОценок пока нет

- Long 1988Документ4 страницыLong 1988Ovirus OviОценок пока нет

- BedДокумент17 страницBedprasadum2321Оценок пока нет

- Cat4 Test Practice For Year 11 Level GДокумент6 страницCat4 Test Practice For Year 11 Level GJoel OkohОценок пока нет

- Activity Lesson PlanДокумент2 страницыActivity Lesson PlanPsiho LoguseОценок пока нет

- Case Study 1 (Pneumonia)Документ13 страницCase Study 1 (Pneumonia)Kate EscotonОценок пока нет

- Your Free Buyer Persona TemplateДокумент8 страницYour Free Buyer Persona Templateel_nakdjoОценок пока нет

- Research ProposalДокумент45 страницResearch ProposalAaliyah Marie AbaoОценок пока нет

- Playwriting Pedagogy and The Myth of IntrinsicДокумент17 страницPlaywriting Pedagogy and The Myth of IntrinsicCaetano BarsoteliОценок пока нет

- 38 Bayan Muna Vs MendozaДокумент3 страницы38 Bayan Muna Vs MendozaDavid Antonio A. EscuetaОценок пока нет

- Great Is Thy Faithfulness - Gibc Orch - 06 - Horn (F)Документ2 страницыGreat Is Thy Faithfulness - Gibc Orch - 06 - Horn (F)Luth ClariñoОценок пока нет

- The Berenstain Bears and Baby Makes FiveДокумент33 страницыThe Berenstain Bears and Baby Makes Fivezhuqiming87% (54)