Академический Документы

Профессиональный Документы

Культура Документы

Gea - Cooling Towers

Загружено:

FREDIELABRADORИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gea - Cooling Towers

Загружено:

FREDIELABRADORАвторское право:

Доступные форматы

Po acel Product Range

Thermal Engineering / GEA Polacel Cooling Towers b.v.

CMOR cooling tower type 630

Shopping center in Oubai

Natural draft cooling tower in Germany

(Project of GEA Energietechnik GmbH)

CMOI cooling tower type1500

Paper mill in Sweden

[GEA Polacel - Backgroundl

GEA Group

The GEA Group, headquartered in Bochum, Germany, is a glo-

bally successful technology group with more than 250 compa-

nies in 50 countries.

The company now focuses on specialty mechanical engineering

- especially process engineering and equipment. GEA Group tech-

nologies are applied in the food, chemical and petrochemical in-

dustries, the energy sector, air treatment and shipbuilding as well

as the pharmaceutical and cosmetic industries.

The GEA Group is one of the world's market and technology lea-

ders in 90 per cent of its businesses.

GEA is a solid foundation for the Polacel activities and it provides

us with greater scope. Good contacts with affiliated organizations

that are leaders in our field provide an ongoing stimulus to our

own development. This is what makes Polacel a leader in the intro-

duction of technological improvements.

_ One contact person for all solutions

_ Globally active in more than 40 countries

_ Native speakers speak your language

_ Individual solutions

_ Maximum availability, security of operation

and system efficiency

(Know how and service range)

Polacel cooling towers

Polacel designs, manufactures and maintains cooling towers.

Our company is synonymous with quality and innovation in

this area.

We have been buildingcooling towers that are designed to prevent

corrosion and we are still in the lead when it comes to efficiency

and noise reduction. Polacel stands for a high quality backed up by

and a complete service organization. This is how we offer security

to our customers.

CMOI cooling tower type 840

Chemical industrial plant in Belgium

ILongevityl

Cooling towers save

Cooling towers for process and climate cooling are energy-

efficient and environmentally-friendly generators of cooling

water.

Polacel cooling towers achieve a up to 95% and above saving in

water, a thermal load on surface waters that stays well within

the legal limits and substantially lower climate cooling costs.

Our cooling towers have a particularly long lifetime and are

very low-maintenance. Polacel is the best choice for man and his

environment.

) Product range)

Standard customization

Polacel designs, manufactures and installs a complete range

of cooling towers based on crossflow and counterflow. Our

modular system enables us to supply capacity to order.

Our standard product range can provide solutions to practically

all requirements. As a manufacturer with our own engineering

department, we can address specific client wishes where

necessary.

]AII around support service]

The complete pathway

Polacel is involved in the cooling towers we supply from the

first introductory discussion, through the manufacturing stage

to maintenance and service after installation.

We know and understand the complete pathway, we have all the

data and specifications and we can accommodate all wishes and

requirements in our own field. This makes Polacel a permanent

source of support and partner for our customers throughout all the

years that our cooling towers are in service.

Cell cooling tower I

Georgia. USA

)Improvementl

Talking to sales engineers

Polacel is a manufacturer of cooling towers. A coo-

ling tower is a technical product that has to meet

precise specifications.

This is why our sales organization relies on our sales

engineers, who are qualified professionals with specific

know-how. They give advice, analyze your wishes and

take personal responsibility for delivery so that your

order is completely in line with your instructions.

)Modular system)

Manufacturing and

installation

Polacel manufactures modules to size on the basis

of the data we have compiled. We produce smaller

units that are delivered ready to install as well as

large cooling towers, which we assemble on site.

Customer-specific requirements can easily be accommo-

dated thanks to the modular system. Client wishes

also form the basis of the installation phase. We can

supply the installation ready to operate within a short

delivery period.

[Servicel

Polacel's service organization

Polacel's own service organization specializes in the

maintenance of all cooling towers and it knows all

the ins and outs of the whole technical area.

The scopeofthe services includes scheduled maintenance,

capacity measurement, overhauls and the upgrading of

cooling towers. The Polacel service organization takes

care of clients' cooling tower installations in order

to make the operation problem-free and perform

superbly.

[Communicationl

The Polacel approach

Polacel believes in direct contacts and short lines

of communication. The organization is transparent

and our customers always have a permanent focal

point.

Up to and including completion this is the sales

engineer, a specialist who also remains involved in the

cooling tower afterwards. Once your cooling tower is in

operation, there is a permanent internal contact person

for all practical matters, such as maintenance.

[Conditionsl

Purchase, hire, hire purchase

and lease

Customization is also our standard approach to sales

policy. Clients are free to choose the form of purchase,

hire or lease that suits them best.

[Optionsl

New, used, trade in and

buy-back

Polacel makes durable, quality cooling towers. When

growth makes the capacity of a cooling tower too small,

for example, you can trade it in. The used tower is then

sold, after a thorough overhaul (as good as new, but at

a second-hand price).

Cross flow cooling tower type XM

Telephone-/Communication center in the Netherlands

Companies of the Thermal Engineering Division

GEA Powor Cooing Inc. (GPC)

Lakewood. USA

www.geapowercoomg.com

GEA Rainey Corporation (GRC)

Catoosa. USA

www.gearainey.com

GEA Pola",1 UC (PCLUS)

Houston. USA

www.polacel.com

GEA Powor Cooing Inc. (GPC)

Clearwater. USA

www.geapowercooling.com

w

0..

o

0::

::;)

w

GEA Enorgietechnik Ltd. U.K.

Staffordshire. Great Britain

www.geaenergietKhnik.com

2H Aqua Ltd. UK (ZHKUK)

Huntingdon. Great Britain

www.2hk:unststoft.de

Bittignolles TKhnofogies

ThermiqufS SA-So (8m

Nantes, France

www.bnnantes.com

GEA AIrflow S.rvic.s SAR.L.

(AFS) NantM. France

www.btt-nantes.com

GEA SA (GIB)

Igone, Spain

www.geaibericasa.es

GEA Scarnbiatori di alene

S.r.I. (GSC). Monv.... ltaly

www.gea-sc.com

EGI

Co. Ltd. (EG!)

BudapesL Hungary

www.egi.hu

GEA Polacel Cooling

Towe.. b_v. (PCL)

Doetinchem, Netherlands

www.polacel.nl

2H Kunststoff GmbH (ZHK)

Wettnngen. GerrT\illny

www.2hk:unststoff.de

GEA LuftkOhler GmbH (GLK)

HBnt. Germany

www.gea-Iuftkuehler.de

GEA Enorgietechnik GmbH (GEn

Herne. Germany

www.gea-energietechnik.com

GEA Industrial Services Ltd.

Wdienhall. Great Britain

www.geaindustrialservices.com

HEAD OFACE E-DIVISION

GEA En.rgy T.chnology GmbH

(GEM). 8o<hum. Gormany

www.geaeoergy.com

....J GEA Sistemas de

Vi Resfriamento Ltda. (GSR)

Alphavine. Brasil

a:l

000 GEA Enorgieted1nik M"'kau

Moskau. Russia =>

\WIW.gea-energietechnik.com a::

GEA Cooling Tower

Technology (India) M. Ltd.

(GCD

o Teynampet Chlnai. India

GEA PoIocel Middle East FleO

Oubai. U.A.E.

www.polacel.com

o

V

X

..,

::E

GEA Power Cooling de MexK:o

S. de R.L. de C.V. (GPM)

San his Potosi. MexKo

www.geapowercooing.com

GEA Power Cooling de Mexico

S. de R.L. de C.V. (GPM)

Mexico Gty. Mexico

www.geapowercooling.com

GEA Nlen,a Ltd. (GNL)

Germ;ston. South Africa

www.geanilenca.co.za

GEA Aircooled Systems <

(Ply.) Ltd. (GAS)

Germiston. South Africa u..

www.gea.co.za

Batignoll.. Technologies

ThorlTiques Qatar L.L.C. (BTTQ) I-

Doha. Qatar

www.btt-nantes.com LU

w

...J

o

o

Beijing GEA Energietechnik

Co. Ltd. (GBl)

Beijing. China

www.gea-enl!fgieted1nik.com

EGI Cooing Systems Trading

(Beijing) Co. Ltd. (EGIC)

Bei;ng. Ch.,.

www.f9I.hu

GEA Power Cooling Technology

Co. Ltd. (GPCD

langfang. China

www.geaenergretechnilt.com

Bat'9"oIles Thormal Technologies

(Changshu) Co. Ltd. (BITC) Z

Changshu. China :i:

U

Thermal Engineering

GEA Polacel Cooling Towers b.v.

Vlijstraat 25 - NL-7000 AG Doetinchem . The Netherlands

Telephone +31 314371414 . Telefax +31 314344884

www.polacel.nlsales@polacel.nl

(

E

CT I

II

y

v..

Q.

C"'w''''

oJ:

""m

A....'_u ""[Ill

CMC counterflow cooling towers

Thermal Engineering / GEA Polacel Cooling Towers B.V.

_ One contact person for all solutions

_ Globally active in more than 40 countries

_ Nalive speakers speak your language

_ Individual solutions

_ Maximum availability, security of operation

and systr.m efficienry

(Background]

GEA Polacel

GEA Polacel is a company of the GEA Group AG. The GEA

Group. headquartered ill Bochum. Germany. is a globally suc-

cessful technology group with more than 250 companies in

50 countries.

The company now focuses on specialty mechanical engineering

- especially process engineering and equipment. GEA Grollp tech-

nologies are applied in the food, chemical and pelrochemical in

t1ustries, the energy sector, air treatment and shiphuilding as well

as the pharmaceutical and industries. The GEA Group is

one of the work!"s market antitechnology leatlers in 90 per cent

of its businesses.

GEA is a solid foundatiotl for the GEA Polacel activities and it pro-

vides us with brreater scope. Goocl contacts with affiliated organiz,;r

tions that are leaders in 01lT field provide an ongoing stimulus to

our own dcvelnpmcnt. This is what makes GEA Polacel a leader in

the introduction of technological improvements.

ISyltt'm's functions]

The effect of counterflow

CMC cooling towe.. work on the principle of counterflow.

This means lhat lhe waler flows down while lhe air is pulled

upwards by a fan.

As the water nows further through the system, the air it enconn-

leTS is fresher, in other wonls cooler and less saturated with moi-

sture. Counternow cooling towers can approach the wet hulb tem-

perature better compared to cro5sflow cooling towers.

{Knowhow]

Polacel CMC cooling towers

GEA Polacel designs. manufactures and maintains cooling to-

wers for process and climate cooling. Our energy efficient and

environmentally-friendly cooling water generators stand out

because of the (omplete quality policy we employ.

The GEA Po(acel CMC systems combine a high cooling capacity

with low energy consumption. The modules arc supplied reatly

10 usc and they arc easy to adjust to cooling requirements and the

available space, whether they arc used singly or in series. The coo-

ling performance of these cooling towers Is optimal and operation

is problem free. With a 95%+ saving in water, the efficient CMC

systems are the best choice for man and his environment.

J IGEArol",,' CooUng T""".

Cooling lower Iypc e;MC 2.?

Chelllical Planl III ftance

Co,,,lruClltU' all,l slartup

of JI eMe; Cooling low,.,

IMllxlmum offidencyl

Cooling performance measured:

the wet bulb

The wet bulb temperature is in fact the lowest temperature

that can be achieved by air cooling in any particular set of

circumstances.

This temperature can be measured by wrapping a glass therm(r

mcter in a piece of cotton that has been drenched in water and

placing it In a streanl of air. The will evaporate lose

heat (swealiug while takiug exercise has the same funcHon and

makes a 'cooling tower' out of our skin). The wet bulb temperature

is therefore lower than the ambient temperature.

Cooling towcrs try to approach this achievable minimum tern

perature usillg as little ellcrgy and as efficieutly as possible. Thc

GEA rolacel CMC range succeeds ill doing this alld combines

maximum efficiency with low power consumption, anu therefore

minimal costs.

IModular systeml

Modules to size

The cooling water temperatures (inlet and outlet), the wet

bulb temperature, noise and the water load are the four most

important factors in the selection of a cooling tower.

GEA Palacel makes an inventory of the requirements together

with thr. client and IISCS this inventory as the basis of the design

for a suitable solution. The CMC system can be extended.

and there .Ire standard solutions available for different capacity

needs. GEA Palacel engineers make customized changes to meet

special requirements.

ISllentnessl

Noise reduction

As a rule cooling towers are outdoors, and usually on a roof

or at the edge of the site, The noise produced by the cooling

tower caused by, among other things, the fan, falling water,

the electrical motor or geared motor. can therefore present a

problem.

GEA Polacel has put a number of into practice that

rr.duce the noise nuisance. larger fans (lower speed. less noise

and higher efficiency). floating silcncers to reduce the noise of

splashing and other noise reducing measures combolt the different

sources of noise.

GEA Palacel provides a detailed picture of the nature and level of

the noise produced by means of detailed calculations. GEA Polacel

can also make calculations for all cooling towers beforehand in

relation to the requirements laid down ill euvirollmental permits.

I

GEA PoIK44 mod"lu eMC IYJll'm

fled!>le for InaJi",ldu.1 JOIUlluHS.

Structural feat lies

The advanced design engineering ha$ also resulted in

a number of special structural advantagC"s:

_ Only a nlininlUm number of support points

are necessary as a result of Ihe selfsupporling

fuundations and the high internal stiffness

_ Completely transportable, re"dy to be installed

_ The GEA Polacel water tank can

subzero temperatllres

_ The GI!A Polacd CMC system can also be

installed on existing water basins

_ The extendable modular system has virtually no

IIndtalions in terms of form anu capacity

_ All structural design premises are analyzed and

tested by means of dynamic calculations and

computer studies heforC"hand

51

GEA PoIacel Con1inXTowers

ulOlinSlowcr Iype C..IC ,6

Fooll

GE/\ Polncel cngillC'cring

The CMC design has a number of 01her special and

exclusivc features:

_ The design of the fan section alld the large

r.ms ensure lower energy consumption and a

sub.!itantial reduction in noise

_ The GEi\ Polacel CMC morlules are supplierl with

a dircctdrivc or indircct-drivc fan

_ The willcr uistribution system, lhc spray nozzlcs

audthe cooling modules can be geared to lhe

water used and guarantee maximum contact with

the air being drawn in

_ The air inlet louvres optimize the air inflow and

minimi7.c watcr losses through splashing

_ Floating silcncers minimizc noisc causcd by

falling waler

_ The designs lake into account the desired

variations In capacity, appropriate measures

during maintenance and other user wishes

IHigh standardsl

The security of quality

GEA Polacel designs and manufacturers cooling towers with

long lifetimes and minimal maintenance needs_

This is achicved through the materials used - stainJess stccl com

oillcd wilh glass fiurc alld plastic -lhe sound desigJl alld the CJCpc-

rience or our engineers. 'Cheap and cheerful' solutions, such as a

fan with a V-belt drive or painted panels, are avoided.

The result is a cooling tower that is low maintenance, energy effi

cient and able to supply constant excellent problem-free perfor

mancc.

IAII around support servicel

Advice and service

GEA Polacel builds cooling modules that meet precise specifi-

<ations. Our sales engineers give advice, analyze your wishes

and take personal responsibility for delivery so that your order

is completely in line with your instructions.

GEA Polaccl's own service organization specializcs in cooling

wer maintenance. Irrespective of brOlnt.l or version, the mainte-

nance specialists know all the ins and outs of the whole technical

area and are involved in the latest developments. GEA Poluce! has

broad experience in cooling lower maintenance. We work in accor

dance wilh the requirements described by ISO, VCA, VDMA, CTI

and Eurovent. The technicians can carry out the maintenance nee-

ded in virtually every location nnd in practically any time frame.

Companies of the Thermal Engineering Division

<{ GEA Power Cooling Inc. (GPC) w GEA ltd. U.K. GEA SA (GIB) GEA 2H Water Technologies HEAD OFFICE E-DIVISION

VI

Lakewood, USA

"-

Staffordshire. Great Britain Igorre, Spain GmbH (ZHK) GEA Energy Technology GmbH

:::> 0

www.geapowercooling.com a: www.geaenergieted'lnik..com Wettringen, Germany (GEM), Bochum, Genmany

:::>

www.gea-2h.com www.geaenefgy.com

w

GEA Rainey Corporation (GRC) 2H Aqua ltd, UK (ZHKUK) GEA Stambiatori Q calore

Catoosa, USA Hunti1gdon. Grut Britain S,rJ. (GSC), Manvalle, Italy GEA luftlcOhl... GmbH (GlK)

www.gearainey.com www.gu-2h.com www.gea-sc.com Heme. Germany

www.g..-Iuftkuehl....de

GEA Polacel Cooling GEA Batignoll.. Technologi.. GEA EGI Contraclin9'

Tow... LLC (PClUS) Thermiques S.A.S. (BTT) Engineering Co. ltd. (EGI) GEA En...gietechnilc GmbH (GEn

Houston, USA Nantes, Budapest, Hungary Herne. Germany

www.polaceJ.com www.bttnantes.com www.egi.hu www.guoenergieteehnik.com

GEA Power Co06ng Inc. (GPC) GEA Airflow Sennees S.A.R.L GEA Polacel Cooling GEA Industrial Services ltd.

Clearwater, USA (AFS) Nantes. Franu Towe" B.V. (PCl) Willenhall. Great Britain

www.geapowercooling.com www.bttnantes.com Doetinehem, Netherlands www.geaindustrialservices.com

www.polaeel.nl

GEA Sistemas de

Resfriamento Ltda. (GSR)

Alphavifle. Brasil

www.geasr.com.br

<{

000 GEA Energietechnik Moskau i:ii

Moskau. RUSSIa

www.gea-energietecMlk.com 0::

GEA Cooling Tower

Technology Ondia) Pvt. ltd.

:;!; (GCT)

Q Teynampet Chennai. India

W'w\IW.gea-energietechnik.com

GEA PoI.eel Cooling Towers FleO

Dubai, U.A.E.

www.polacel.eom

o

u

X

w

GEA Power Cooing de Mexico

S. de R.l. de C.V. (GPM)

san Luis Potosi. MeXICO

www.geapowercooling.com.mx

GEA NiI."ca ltd. (GNL)

Germiston. South Afro

www.geanienca.co.za

GEA Aireooled Systems <{

(Ply.) ltd. (GAS) U

Germlston. South Africa ff

www.gea.co.za <X:

GEA Batignole< Technologies

Th...miquos Qatar l.LC. (BITQ) ti;

Doha, Qatar <{

'NWW.bn.nantes.com \.&J

w

-'

o

o

Beijing GEA Energietechnik

Co., ltd. (GBl)

Beijing, China

www.geaenergietechn.com

GEA EGI Cooling Systems Trading

(Beijing) Co.. ltd. (EGIC)

Beijing. China

www.egl.hu

GEA Power Cooing Technology

Co., ltd. (GPCT)

Langfang. China

www.gea-energietechnik.com

GEA Batignolles Thermal <{

Technologi.. (Changsllu) Co., ltd. Z

(BITC) Changshu, China J:

www.btt-nantes.com U

Q

"",. IIltl11

Thermal Engineering

GEA Polacel Cooling Towers B.V.

Vlijstraat 25 . NL-7000 AG Doetinchem . The Netherlands

Telephone +31 314371414 Telefax +31 314344884

www.polacel.nlsales@polacel.nl

iP

Annexure I

2. _

2H Structured Media PP vs. PVC

At present about 25% of 2H structured media is made from polyvinyl chloride (PVC)

and 75% from polyp.ropylene (PP). We claim to have gained considerable experience

of both products over the past 15 years.

2H :find PP media has the following advantages:

~ It is more consistent in properties than PVC

Stronger than PVC

Has better operational properties such as wetting

Is less expensive to produce and sell

lIealthier for the work force

Has a lower cost of ultimate disposal

Some of these findings are apparently contrary to published polymer property data

and so require clarification and expansion. As is often the case, it is "not what you do

but how you do it" which provides the explanation.

Consistent properties

All PVC media is made from reground scrap. It is calendared to a flat sheet, usually

by a specialist manufacturer. Then the media producer theono or vacuum forms the

sheet to a corrugated or profiled surface which is then trimmed to size. The sheets are

coated with- solvent based -adhesives, stacked into a jig and left to dry. Sometimes,

aqueous based adhesives are used but these produce weaker bonds and they also

contain some solvent.

PP media is made from virgin polymer compounded with inert additives and passed

through a standard plastic sheet extruder. The molten extruded sheet is fed directly

into a revolving forming tool, cut to length and welded into blocks in one continuous

process. The automatic welding device controls temperature, pressure, time and

cooling cycle to close tolerances.

pp blocks produced by this method have fewer steps in their production and,

importantly, the polymer is subjected to leastlwo less melting cycles than glued PVC.

Every time a polymer undergoes amelting cycle, some degradation occurs.

With PP the handwork element of gluing is removed. Overall, the human factor is

much reduced.

2. _

IE--- L--""'!

31

30

34 /

1-----I.. J; A

32

PP is stronger than PVC

To welding plant

Not according to published data: this indicates that the ultimate tensile strength of

typical PVC is about 160% that of typical PP. Yet 2H PP blocks can be produced

whkh sustain the weight offully loaded articulated trucks. Similarly, it is possible to

build heavily loaded high rate tilters t.o 8m depth or more from PP media.

Following extensive independent evaluations by the TUV in Germany, 2H are able to

wan"antee their PP dynamic loading solutions for 30year+ lifetimes. So far this has

not been done for glued PVc.

2H PP media achieve their exceptional mechanical performance for the foUowing

reasons:

The density difference between PVC and Polypropylene polymers is about

40%. This allows thicker foils to be made from PP fOJ" equivalent weight to

PVC offsetting the strength difference.

The 21-1 process allows strengthening of the media block where the loads are

heaviest

The compounded fillers significantly improve the long-term strength

properties of the PP block

2

2._r__

2HFoil-thic1mess variation

0::.<?, 26.0.".,IlI J 40 1\1111 t. 2.6.0.m.II1

PP and some PVC media contain UV additives to improve weatherability. Ev.aluation

is ongoing. S:o far, long terJn tests (10 indicate similar results for PVC and PP

media i.e. good resistance. It is predicted, however, thaUhe greater [oil thickness of

PP media could give it the edge over tlie long teon. In Western Europe projected life

for both PVC and PP media is in of 30 years.

PP media bas better operational p"operfies such as wetting

Studies by CAMRE at Potion Down, originally into the growth of LegionelJa in

pipework, show that the growth of biomass on PP is more rapid than on PVC. This

I.eads to faster filter start-ups from PP. Meeting outlet consents withjn two weeks is

not ullusual.

The compounding of PP with fillers has the effect of roughening the surface and

reducing the surface energy ofPP media. Inpractice, this allows enhanced wetting

and biomass retention. Independent studies show the perfOlmance of cooling tower

fill fi'om 2H media is virtually identical to PVC. Thi.s would not be the case for

unmodified PP.

PP has generally better chemical resistance than PVC and its contit1U"ous operating

temperature is at least 8ddegC compared to PVC's 55degC. This is of considerable

importance for cooling tower operation.

In the field, 2H PP media ios significantly more robust than PVC. This allows faster

initial installation, safer- conditions and easy removability of blocks for

routine biomass inspections.

pp media is less expensive than PVC to produce-and to seU

Generally speaking PVC polytner is less expensive tha.!'l PP polymer but PP med.ia is

often less expensive than PVC media

The weight per specific volume of PP is less than PVC (0.91: J.42) - Thls is

only p&rtly negated by the greatel' thickness of2HPP media foils

Precise control of sheet thickness by the 2H manufacturing process

Fewer manufacturing steps

Automated process (lower labour costs)

No glue

No solvent recovery plant -investment and operation costs

3

2. _

PP is healthier for the workforce than PVC

Matters of health are always contentious as most materials can be hazardous if

mishandled. 2Hstrongly recommend that all users of p l a s t i ~ s materials strictly follow

manufacturer's safety requirements.

PVC is halogenated and is built into blocks by using solvent based adhesives. Such

products call- be toxic even in small amounts and especially, when ingested or inhaled

over prolonged periods.

Balogem and solvents are absent from PP media and from its construction processes.

So Tisks associated with them are also absent. ft is also worth noting that, in the

instance of those hazards mentioned luwe, when PP media is used, the possibility of an

afflicted person bringing legal action against a user who persists in purchasing PVC

media when a safer alternative is available is also eliminated.

PP has a lower cost of ultimate disposal than PVC

PVC is a halogenated product. Already in certain parts of Europe disposal by landfill

except under very special circumstances and at great cost is proillbited for this class of

chemical. Similarly, incineration is very expensive.

It can be expected that the trend towards greater harmonisation of regulations

throughout Europe will create a situation where the inevitable disposal of PVC media

may prove more expensive than the initial installation.

At present P-P can be disposed by landfill without additional cost penalties. Being

non-halogenated it can also be incinerated at less cost than PVC.

4

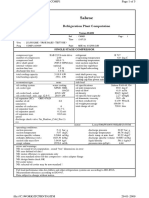

441.00 m/sec 340.00 Pa Required Volume Required Static Pressure

Pressure recovery 0.0 Pa Fan static pressure 340.00 Pa

57.35 Pa 397.35 Pa Velocity pressure Total pressure

nlet Air Humidity (%) 98.0

Site Elevation 431.0 m

24.0 ft

1.058 kg/m

Fan diameter

nlet Air Density

Blade Airfoil 40F FRP

Fan ring diameter 7344 mm

142.0 RPM

G2.0

Speed

Rotor hub type

N blades 10

Blade Tip Speed 54.40 m/sec

67.9 %

858 cpm

Static efficiency

Blade frequency +/-5%

Blade pitch angle 14.7 ()

Total efficiency 79.4 %

CHARACTERISTICS

Air Temperature 38.9 C

Rotor shaft power 220.9 kW

% 45 % Volume margin 11 Pressure margin

Tip Clearance/D 0.002 nlet CircuIar R/D=0.15

Diffuser:Length/D Diffuser angle ()

nlet Obstacle a/A 0.05 nlet Obstacle x/D 0.2

Outlet Obstacle x/D Outlet Obstacle a/A

nstallation Type Induced Aerod axial force 16691 N

Rotor total weight

Rotor inertia PD

Max residual unbalance

Blade Failure Load

2 Blades Failure Load

1795 kg

19524 kg x m

175.9 N

44249 N

84167 N

NOISE CHARACTERISTICS

dB(A) 105.0 PWL ( 2)

m 1.0 SPL @ dB(A) 85.7

nlet / outlet ( 2)

dB(A) 77.6

Side ( 2)

Tolerance on sound values +/- 2 dB(A)

Min. Ambient Temperature Rotor shaft power @ 0.0 C 0.0 258.3 C kW

Rotor shaft power @ AP point 301.5 kW

m/sec

Pa

Pa

C

ft

FRP

RPM

Octave [Hz] 31.5 63 125 250 500 1000 2000 4000 8000

PWL [dB] 108.0 110.0 110.0 106.0 103.0 100.0 92.0 88.0 84.0

nlet/Outlet SPL [dB] 88.7 90.7 90.7 86.7 83.7 80.7 72.7 68.7 64.7

Side SPL [dB] 80.6 82.6 82.6 78.6 75.6 72.6 64.6 60.6 56.6

Tolerance +/- 5.0 5.0 3.0 2.0 2.0 2.0 2.0 2.0 2.0

Via A. Gramsci, 62 - 28050 Pombia (NO) taly - Phone +39-0321-968311 - Fax +39-0321-958992

Customer Name Yussf Bin Ahmed Kanoo

Job Name JabaI Omar Devt

Job Reference

tem Number

200.224_E

CMDI19 1200-DH-150 (30)

9660 Grunwald Road - Beasley Texas 77417 - Phone +1 -281-275 8390 - Fax +1 -281-275 8388

Kai Xuan Hua Yuan, 111 Zhong Cao Road, Shanghai 200030, P.R.China - Phone +86-2164-686460 - Fax +86-2164-686460

1/13/2010 Date

ROTOR MODEL 7315-10-40F/G2.0T CT

All data must be approved by Cofimco Fantastic.NET 2008.1.3

Date : 13

th

January 2010

Our project number : OFF_200.224_E1

Your reference : Jabal Omar Development Project

Page : 1 / 2

GEA Polacel Cooling Towers FZCO

Thermal Engineering

TECHNICAL SPECIFICATION PER COOLING TOWER

Type : CMDI19 1200-DHS-150-PS10/2 (Non- STD, 8 nos)

Manufacturer : GEA Polacel Cooling Towers B.V.

Cooling principle : Counter flow

Number of cells : 1

Colour : Grey

Design conditions

Cooling capacity : 30,273 kW

Water flow : 3337.2 m3/h (927 L/sec)

Hot water temperature : 42.8 C

Cold water temperature : 35.0 C

Wet bulb temperature : 30.0 C

Max. water temperature : 80.0 C

Higher temperatures are possible, please contact supplier.

Technical Specification

Height of fill : 1500.0 mm.

Required sprayer pressure : 33.0 kPa, max. 49 kPa

Air volume per fan : 441.0 m3/s

External static pressure : 0.0 Pa

Number of fans : 1

Number of motors : 1

Motor power installed : 250.0 kW

Motor power consumption : 243.0 kW

Motor speed : 1800 rpm

Fan speed : 142 rpm

Type of drive : Indirect by rectangle gearbox

Electrical supply : 380V-3Ph-60Hz

Class of motor : IP 55 F

Dimensions and weights

Length : 11280 mm.

Width : 11280 mm.

Height : 10190 mm.

Shipping weight : 31160 kg (Approx)

Operating weight : 42050 kg (Approx)

Water consumption

Average evaporated loss : 34.0 m3/h

Date : 13

th

January 2010

Our project number : OFF_200.224_E1

Your reference : Jabal Omar Development Project

Page : 2 / 2

GEA Polacel Cooling Towers FZCO

Thermal Engineering

The maximum evaporation, which determines the design for the make up and drain, can be 25% higher.

Drain loss : Depends on the water quality

Sound power cooling tower

The total sound power (PWL) of the cooling tower is determined by the logarithmic summation of the partial

sources: fan outlet and air inlet. The noise at the air inlet is caused by the falling of the water in the water pan.

This noise can be attenuated using floating noise attenuators, a special Polacel development. The values are

calculated according to DIN 45635 Sub 46, class 3. The sound pressure at a certain distance can be calculated

using the table conversion from sound power to sound pressure for counter flow cooling towers.

PWL fan outlet : 105.0 dB(A)

PWL air inlet without attenuators : 107.5 dB(A)

PWL cooling tower total (excl. att) : 108.3 dB(A)

Material specification

Fan blades/ type : GRP / 24 Ft.

Fan support : Stainless steel 304

Fill/ type : PP / 19 mm

Fill support : Stainless steel 304

Eliminator : PP

Eliminator support : Stainless steel 304

Framework : Stainless steel 304

Casing : Fiberglass reinforced polyester

Air inlet louvers : Fiberglass reinforced polyester

Water distribution/ sprayer : PP

Cooling tower complete with:

Warm water connection (F1) DN400

GEA Heat Exchangers | GEA Polacel Cooling Towers

General Cooling towers Service PolaSelections Dutch Logged in as: 110808pol <<

Noise analysis for CMDI19 1200-DH-150 Back to specification

Project identification:

Date: 13 January 2010

User: Erwin Bautista

File number: 200224

Polacel file number: 808-100476

Project reference: Jabal Omar

Customer name: Yusuf Bin Ahmed Kanoo

Customer place: Jeddah SAUDI ARABIA

Number of towers: 8

Number of cells per tower: 1

Drive type: Indirect, by gearbox and separate motor

Clarification:

This noise calculation is based on field noise measurements results of the sound pressure level (Lp) close to the noise

emitting source by means of an omnidirectional sound pressure measurement device. The sound power level (Lw) is

calculated from the sound pressure measurement results with the formula below:

Lw = Lp + 10 log(S) + Lf

S = Surface of the measurement surface enveloping the noise source (e.g. hemispherical or cilindrical surface)

Lf = correction for the geometrical nearby field which is dependend on surface ratio Q

For the calculations we refer to emitting method C4 from IL-HR-13-01 'Handleiding meten en rekenen industrielawaai', page

2C-18 to 20. The enveloping measurement surfaces are based on method B4 and C4 and DIN 45635.

The sound pressure level data given below are based on selection programs, field measurements and data received from our

vendors.

The total sound power level of the cooling tower is calculated using the sound power data of the different noise emitting

sources. This method is described in DIN 45635 and is a value that can be used to compare different cooling towers.

The reference sound pressure level is 2 x 10^-5 Pa.

The reference sound power level is 10^-12 Watt.

Spectrum data:

Lineair noise spectrum in dB

Frequency: 63 125 250 500 1000 2000 4000 8000 dB(A)

A weighting values: -26,2 -16,1 -8,6 -3,2 0,0 1,2 1,0 -1,1

Fan - Sound power level:

Type: Cofimco 24-10-40F/G2.0T

Manufacturer: Cofimco

Quantity: 8 pcs

Sound power level fan: Lw 110,1 110,1 106,1 103,1 100,1 92,1 88,1 84,1 105,0

Correction for multiple fans: 10 x Log(n) 9,0 9,0 9,0 9,0 9,0 9,0 9,0 9,0

Total sound power level fans: Lw 119,1 119,1 115,1 112,1 109,1 101,1 97,1 93,1 114,0

Page 1 of 4 GEA PolaSelections

1/13/2010 http://www.polacel.nl/PolaSelections/NoiseAnalyzer.asp

Annexure V

Gearbox - Sound power level:

Type: Amarillo gear Co. Type 1713A - 1770 / 144 < 260 kW

Manufacturer: Amarillo gear Co.

Rated power (AGMA = 2): 520,0 kW

Quantity: 8 pcs

Sound power level gearbox: Lw 87,2 93,2 89,9 95,5 92,2 90,0 81,2 68,5 97,0

Correction for multiple gearboxes: 10 x Log(n) 9,0 9,0 9,0 9,0 9,0 9,0 9,0 9,0

Total sound power level gearboxes: Lw 96,2 102,2 98,9 104,5 101,2 99,0 90,2 77,5 106,0

Lw value of the diffuser is the sum of the fan and gearbox values.

Total sound power level diffusers: Lw 119,2 119,2 115,2 112,8 109,8 103,2 97,9 93,2 114,7

Diffuser - Sound pressure level:

Noise source: 1 diffuser, incl. contribution of falling water noise through fill.

Diffuser diameter: 26,3 ft

8,004 m

Measurement position: m beside 1,0

m above 1,0

Measurement surface: Half-hemisphere

Radius (R): 5,1 m

Surface (S): 163 m

Surface ratio (Q): 0,62 (estimated)

Sound power level per diffuser: Lw 110,1 110,2 106,2 103,8 100,9 95,1 91,9 89,7 106,0

Surface correction: 10 x Log(S) -22,1 -22,1 -22,1 -22,1 -22,1 -22,1 -22,1 -22,1

Geometrical nearby field correction: Lf 1,1 1,1 1,1 1,1 1,1 1,1 1,1 1,1

Sound pressure level at measurement pos.: Lp 89,1 89,1 85,1 82,8 79,9 74,1 70,9 68,7 84,9

Motor - Sound power level:

Type: ABB 250Kw 1500 M3BP 355 SMA

Manufacturer: ABB

Quantity: 8 pcs

Sound power level motor: Lw 93,0 95,0 94,0 94,0 96,0 92,0 81,0 71,0 99,0

Noise reduction hood: none 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Sound power level incl. noise hood: Lw 93,0 95,0 94,0 94,0 96,0 92,0 81,0 71,0 99,0

Correction for multiple motors: 10 x Log(n) 9,0 9,0 9,0 9,0 9,0 9,0 9,0 9,0

Total sound power level motors: Lw 102,1 104,1 103,1 103,1 105,1 101,1 90,1 80,1 108,0

Motor - Sound pressure level:

Model: M2BA 355 S

Length: 1400 mm

Frame size: 355 mm

Measurement surface: Half circle-cylinder + quarter bulb

Distance (R): m 1,0

Surface (S): 14,2 m

Surface ratio (Q): 0,3 (estimated)

Page 2 of 4 GEA PolaSelections

1/13/2010 http://www.polacel.nl/PolaSelections/NoiseAnalyzer.asp

Sound power level per Motor: Lw 93,0 95,0 94,0 94,0 96,0 92,0 81,0 71,0 99,0

Surface correction: 10 x Log(S) -11,5 -11,5 -11,5 -11,5 -11,5 -11,5 -11,5 -11,5

Geometrical nearby field correction: Lf 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Sound pressure level at measurement pos.: Lp 81,5 83,5 82,5 82,5 84,5 80,5 69,5 59,5 87,5

Falling water - Sound power level:

Wet surface per cell: 124,01 m

Length per cell: 11,28 m

Width per cell: 11,28 m

Noise emitting surface height: m 2,50

Configuration: 8 cells long, 1 cells wide

Total length: 90,24 m Open

Total width: 11,28 m Open

Cooling tower wet surface: 992,09 m

Total surface air inlet: 507,60 m

Water flow cooling tower: 26698,00 m/h

Water load cooling tower: 26,91 m/mh

Sound power level falling water: Lw 99,1 97,6 98,3 104,6 109,3 110,1 110,9 110,3 116,7

Floating sound attenuators: none 0,0 0,0 0,0 0,0 0,0 0,0 0,0 0,0

Sound power level with attenuators: Lw 99,1 97,6 98,3 104,6 109,3 110,1 110,9 110,3 116,7

Air inlet - Sound pressure level:

Noise source:

Noise of the falling water of the whole cooling tower, incl. fan and gearbox noise through

fill

Measurement surface: Enveloping with rounded corners

Distance to air inlet: m 1,0

Height measurement position: 1,5 m

Surface enveloping air inlet (S): 849 m

Surface Ratio (Q): 0,60 (estimated)

Sound power level air inlet: Lw 106,9 106,8 103,7 105,8 109,5 110,1 110,9 110,3 116,9

Surface correction: 10 x Log(S) -29,3 -29,3 -29,3 -29,3 -29,3 -29,3 -29,3 -29,3

Geometrical nearby field correction: Lf 1,0 1,0 1,0 1,0 1,0 1,0 1,0 1,0

Sound pressure level at measurement pos.: Lp 78,6 78,5 75,4 77,5 81,2 81,8 82,6 82,0 88,6

Total sound power level Cooling Tower:

Total sound power level diffusers: Lw 119,2 119,2 115,2 112,9 110,0 104,2 100,9 98,7 115,0

Total sound power level air inlet: Lw 106,9 106,8 103,7 105,8 109,5 110,1 110,9 110,3 116,9

Total sound power level motors: Lw 102,1 104,1 103,1 103,1 105,1 101,1 90,1 80,1 108,0

Total sound power level cooling tower: Lw 119,5 119,6 115,8 114,0 113,5 111,5 111,4 110,6 119,4

Tolerances:

Fan noise: Lw 5,0 3,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0

Gearbox noise: Lw 5,0 4,0 3,0 3,0 2,0 2,0 2,0 2,0 2,0

Motor noise: Lw 5,0 3,0 2,0 2,0 2,0 2,0 2,0 2,0 2,0

Water noise: Lw 5,0 4,0 3,0 2,0 2,0 2,0 2,0 2,0 2,0

Page 3 of 4 GEA PolaSelections

1/13/2010 http://www.polacel.nl/PolaSelections/NoiseAnalyzer.asp

Total cooling tower noise: Lw 5,0 4,0 3,0 3,0 2,0 2,0 2,0 2,0 2,0

Page 4 of 4 GEA PolaSelections

1/13/2010 http://www.polacel.nl/PolaSelections/NoiseAnalyzer.asp

1

2

0

0

m

i

n

Вам также может понравиться

- Air-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AОт EverandAir-Cooled Condenser Fundamentals: Design, Operations, Troubleshooting, Maintenance, and Q&AРейтинг: 5 из 5 звезд5/5 (1)

- SMST-Tubes Product Range en 2010 WebДокумент16 страницSMST-Tubes Product Range en 2010 Webalbejo_r9Оценок пока нет

- SPX Cooling TowerДокумент2 страницыSPX Cooling Towertanveer ansariОценок пока нет

- Design of Air IДокумент5 страницDesign of Air IInvedeОценок пока нет

- Prof Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmДокумент21 страницаProf Ir Dr. Ab Saman B. Abd Kader, Peng, Miem, Mcit Faculty of Mechanical Engineering, UtmakusuperОценок пока нет

- Positioning of Air Cooled CondensersДокумент9 страницPositioning of Air Cooled CondensersAlexОценок пока нет

- Aspen Plate Fin Exchanger - Getting Started Guide: Tutorial High Level OutlineДокумент17 страницAspen Plate Fin Exchanger - Getting Started Guide: Tutorial High Level Outlineingbarragan87Оценок пока нет

- Troubleshooting A Plate Heat Exchanger - CPE Systems IncДокумент7 страницTroubleshooting A Plate Heat Exchanger - CPE Systems Incrajmohan_kОценок пока нет

- Condensers: Report By-Ashna Anamika Mugdha PratishthaДокумент17 страницCondensers: Report By-Ashna Anamika Mugdha PratishtharashmiОценок пока нет

- Brochure - Wheel and Desiccant OptionsДокумент8 страницBrochure - Wheel and Desiccant OptionsSelvaraji MuthuОценок пока нет

- Fan Blades: Pro/ENGINEER Wildfire 3.0Документ35 страницFan Blades: Pro/ENGINEER Wildfire 3.0Pratik MakwanaОценок пока нет

- Catalogue CF For CTI 2.00 15dec2015Документ104 страницыCatalogue CF For CTI 2.00 15dec2015X-flies0% (1)

- Ceramic Heat Pipe For High Temperature Heat RecoveryДокумент11 страницCeramic Heat Pipe For High Temperature Heat RecoveryChander Prakash KamraОценок пока нет

- 9KF Assembly Manual 944X (2014.07)Документ45 страниц9KF Assembly Manual 944X (2014.07)Nancy MoncadaОценок пока нет

- Air Cooled CondensersДокумент6 страницAir Cooled CondensersruchiajmerОценок пока нет

- Regenerative Heat ExchangerДокумент4 страницыRegenerative Heat ExchangerSalehAfadlehОценок пока нет

- Types of Evaporator in Air ConditioningДокумент20 страницTypes of Evaporator in Air ConditioningEhsan DanishОценок пока нет

- Condenser 69-83Документ15 страницCondenser 69-83DIPAK VINAYAK SHIRBHATEОценок пока нет

- Ngineering ATA: Temperature & Altitude Effects On FansДокумент3 страницыNgineering ATA: Temperature & Altitude Effects On FansMohamed TahounОценок пока нет

- COFIMCO B - SeriesДокумент1 страницаCOFIMCO B - Serieszeids100% (2)

- Cooling TowerДокумент18 страницCooling TowerSalehAfadlehОценок пока нет

- Pur-15-02 - Air Purger Type PurДокумент4 страницыPur-15-02 - Air Purger Type PurAnderson Giovanny Herrera DelgadoОценок пока нет

- Twi CrossflowДокумент8 страницTwi CrossflowDota NgОценок пока нет

- Moore Fan 02Документ7 страницMoore Fan 02vikramОценок пока нет

- Nitrile Rubber InsulationДокумент2 страницыNitrile Rubber Insulationavid_ankurОценок пока нет

- NPTELДокумент31 страницаNPTELRashminda Attanayake100% (1)

- Performance Analysis of Refrigerator Using Water Cooled CondenserДокумент21 страницаPerformance Analysis of Refrigerator Using Water Cooled Condenserjaiminspatel127100% (1)

- Basic Refinery Equipment - Heat Exchanger (E003/1)Документ27 страницBasic Refinery Equipment - Heat Exchanger (E003/1)ebsmsart100% (1)

- 3000 Brochure PDFДокумент24 страницы3000 Brochure PDFFarooque ShaikhОценок пока нет

- SHARKДокумент4 страницыSHARKUnilabОценок пока нет

- Controlling Heat ExchangersДокумент11 страницControlling Heat ExchangersgermanaponteОценок пока нет

- WAДокумент28 страницWADota NgОценок пока нет

- Internal Heat ExchangerДокумент39 страницInternal Heat ExchangerNeal Christian ParatoОценок пока нет

- Kettle Reboilers Chemical Engineering Design Ray SinnoyДокумент6 страницKettle Reboilers Chemical Engineering Design Ray SinnoyFederico BogettiОценок пока нет

- Approved Catalogs - Centrifugal Fans For Air Handling Units November 2013 - 2013!12!16Документ142 страницыApproved Catalogs - Centrifugal Fans For Air Handling Units November 2013 - 2013!12!16ardyОценок пока нет

- FFE VolumeДокумент2 страницыFFE VolumeHemant K PatilОценок пока нет

- DST SSCR Rotor PresentationДокумент7 страницDST SSCR Rotor PresentationDanny DurhamОценок пока нет

- G Temperature Glide MF EN PDFДокумент14 страницG Temperature Glide MF EN PDFKanaga RajОценок пока нет

- Heat Exchangers Designing For Super-Critical Fluid ServiceДокумент6 страницHeat Exchangers Designing For Super-Critical Fluid ServiceHsein WangОценок пока нет

- Jet Pump Technical DataДокумент11 страницJet Pump Technical DataIdelia Cutipa Yauri100% (1)

- Hitachi S-4700 InstructionsДокумент19 страницHitachi S-4700 InstructionssuperheoОценок пока нет

- P&ID Process Cooling Symbols and Their Usage PDFДокумент4 страницыP&ID Process Cooling Symbols and Their Usage PDFHV UioОценок пока нет

- Steam Condensation ReportДокумент17 страницSteam Condensation ReportKingsley EdemidiongОценок пока нет

- Selection of A Suction Line Accumulator - Carly - The International Expert in Refrigeration ComponentsДокумент3 страницыSelection of A Suction Line Accumulator - Carly - The International Expert in Refrigeration ComponentsHoàngViệtAnhОценок пока нет

- 04 - How Does Altitude Affect HVAC UnitsДокумент2 страницы04 - How Does Altitude Affect HVAC UnitsMaiccoll OlmОценок пока нет

- Non Return Damper PDFДокумент7 страницNon Return Damper PDFMUHAMMED SHAFEEQОценок пока нет

- Tube Wire Vs Wall Condenser PDFДокумент15 страницTube Wire Vs Wall Condenser PDFHimanshu100% (1)

- STC (Buffer Tank 25KL) - Calc PDFДокумент4 страницыSTC (Buffer Tank 25KL) - Calc PDFAvril Rindra T PОценок пока нет

- Cooling & Dehumidification Coil PDFДокумент30 страницCooling & Dehumidification Coil PDFonkarratheeОценок пока нет

- Cooling Tower PowerPointДокумент12 страницCooling Tower PowerPointHaerОценок пока нет

- Effect of Fin SpacingДокумент12 страницEffect of Fin SpacingAnkit LonareОценок пока нет

- Process Duty Specification For 01-Pk-051 Vacuum System: Ejectors CapacityДокумент5 страницProcess Duty Specification For 01-Pk-051 Vacuum System: Ejectors CapacityvasudhaОценок пока нет

- NHsoft VPДокумент5 страницNHsoft VPBASEM NOMAN ALI MOHAMMEDОценок пока нет

- H Vs V CondensersДокумент1 страницаH Vs V CondensersParth PurohitОценок пока нет

- Heller System PPT 3 Cooling SystemsДокумент34 страницыHeller System PPT 3 Cooling SystemsShrey DattaОценок пока нет

- Pipe Thickness For BoilerДокумент3 страницыPipe Thickness For BoilersdrtfgОценок пока нет

- ASHRAE Psychrometric ChartДокумент1 страницаASHRAE Psychrometric ChartKenneth Dale San JuanОценок пока нет

- Mechanical Steam TrapsДокумент6 страницMechanical Steam TrapspramodtryОценок пока нет

- All Models Are Wrong PreiewДокумент12 страницAll Models Are Wrong PreiewJoão VictorОценок пока нет

- Subsonic Ejector RamjetДокумент99 страницSubsonic Ejector Ramjetmarco20874Оценок пока нет

- Fluor Design GuideДокумент61 страницаFluor Design GuideFREDIELABRADOR80% (5)

- Aws C5.5-80 Gtaw PDFДокумент45 страницAws C5.5-80 Gtaw PDFFREDIELABRADOR100% (1)

- Fuel Field ManualДокумент26 страницFuel Field ManualFREDIELABRADORОценок пока нет

- Fuel Field ManualДокумент18 страницFuel Field ManualFREDIELABRADORОценок пока нет

- Fuel Field ManualДокумент48 страницFuel Field ManualFREDIELABRADORОценок пока нет

- Combined Heating, Cooling & Power HandbookДокумент18 страницCombined Heating, Cooling & Power HandbookFREDIELABRADORОценок пока нет

- Combined Heating, Cooling & Power HandbookДокумент8 страницCombined Heating, Cooling & Power HandbookFREDIELABRADORОценок пока нет

- Es 200 Easy - Pintu Geser OtomatisДокумент8 страницEs 200 Easy - Pintu Geser OtomatisLivian TeddyОценок пока нет

- A Project Review Seminar On Designe and Implimentation of Application Specific Low Power MultipliersДокумент16 страницA Project Review Seminar On Designe and Implimentation of Application Specific Low Power MultipliersSaiKishoreОценок пока нет

- Brick WorkДокумент2 страницыBrick WorkvinitbardeОценок пока нет

- 3 PilesДокумент37 страниц3 PilesAnonymous nwByj9LОценок пока нет

- Blackmer Corporate Brochure PDFДокумент20 страницBlackmer Corporate Brochure PDFJonathanОценок пока нет

- Retaining Wall Analysis & Design (ACI318Документ13 страницRetaining Wall Analysis & Design (ACI318Aziz ul HakeemОценок пока нет

- Design and Analysis of Tank Ring Wall Fo PDFДокумент3 страницыDesign and Analysis of Tank Ring Wall Fo PDFsatyakamОценок пока нет

- Standard Truss Garage PlanДокумент12 страницStandard Truss Garage PlanCJ10aОценок пока нет

- CONT.9654353111//9654451541: Hind Book Center & PhotostateДокумент10 страницCONT.9654353111//9654451541: Hind Book Center & PhotostateQuestion paperОценок пока нет

- Construction Schedule With S-CurveДокумент23 страницыConstruction Schedule With S-CurveJp Gallardo100% (2)

- Western University: Undergraduate Viewbook 2021Документ21 страницаWestern University: Undergraduate Viewbook 2021Juan Carlos Alas Sr.Оценок пока нет

- Wbcs ExaminationДокумент19 страницWbcs ExaminationMUMPI RAHAMANОценок пока нет

- Structural Excavation and Back FillДокумент14 страницStructural Excavation and Back FillphilipyapОценок пока нет

- ISO 2768-2 PreviewДокумент2 страницыISO 2768-2 Previewcheng_cheng1234Оценок пока нет

- John Ngaya Mukabi, PHD Full CV 23NOV09Документ104 страницыJohn Ngaya Mukabi, PHD Full CV 23NOV09John Ngaya MukabiОценок пока нет

- Autodesk Product Keys PDFДокумент1 страницаAutodesk Product Keys PDFnahidОценок пока нет

- Clerk of WorksДокумент2 страницыClerk of WorksSylvia Francois100% (1)

- Transmission Line Inspection RobotДокумент1 страницаTransmission Line Inspection Robotbalu2258Оценок пока нет

- Road BOQДокумент129 страницRoad BOQSunil Kumar GeraОценок пока нет

- Tuning of A PID Controller Using Ziegler-Nichols MethodДокумент7 страницTuning of A PID Controller Using Ziegler-Nichols MethodTomKish100% (1)

- B.E. Civil Engineering Project ProposalДокумент10 страницB.E. Civil Engineering Project Proposalmahipal287Оценок пока нет

- AGH English Course ListДокумент22 страницыAGH English Course ListAzharuddin Ehtesham Farooqui100% (1)

- Benefits of Value EngineeringДокумент13 страницBenefits of Value EngineeringrubydelacruzОценок пока нет

- Impact FactorДокумент13 страницImpact FactorNindy SabrinaОценок пока нет

- Insights Into Sustainable EngineeringДокумент24 страницыInsights Into Sustainable Engineeringcmanning17Оценок пока нет

- IS 16172 2014 Coupler Splice BarДокумент16 страницIS 16172 2014 Coupler Splice BarMayank KumarОценок пока нет

- AI in Production A Game Changer For Manufacturers With Heavy AssetsДокумент7 страницAI in Production A Game Changer For Manufacturers With Heavy AssetsJohn GiannakopoulosОценок пока нет

- Volume 2 Building Works Ss R 2012Документ262 страницыVolume 2 Building Works Ss R 2012bbaplОценок пока нет

- Software System Safety HandbookДокумент247 страницSoftware System Safety HandbookbtjajadiОценок пока нет

- Engineering Specification For Reinfoced Concrete StuctureДокумент12 страницEngineering Specification For Reinfoced Concrete StuctureTri SuhartantoОценок пока нет

- Electric Motor Control: DC, AC, and BLDC MotorsОт EverandElectric Motor Control: DC, AC, and BLDC MotorsРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesОт EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesРейтинг: 4.5 из 5 звезд4.5/5 (21)

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceОт EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceОценок пока нет

- Electric Motors and Drives: Fundamentals, Types and ApplicationsОт EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsРейтинг: 4.5 из 5 звезд4.5/5 (12)

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AОт EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AОценок пока нет

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОт EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialОценок пока нет

- Shorting the Grid: The Hidden Fragility of Our Electric GridОт EverandShorting the Grid: The Hidden Fragility of Our Electric GridРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentОт EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingОт EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingОценок пока нет

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningОт EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningРейтинг: 5 из 5 звезд5/5 (4)

- Introduction to Power System ProtectionОт EverandIntroduction to Power System ProtectionРейтинг: 5 из 5 звезд5/5 (1)

- Handbook on Battery Energy Storage SystemОт EverandHandbook on Battery Energy Storage SystemРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsОт EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОт EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsОценок пока нет

- Global Landscape of Renewable Energy FinanceОт EverandGlobal Landscape of Renewable Energy FinanceОценок пока нет

- The Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadОт EverandThe Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsОт EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsОценок пока нет

- Asset Integrity Management for Offshore and Onshore StructuresОт EverandAsset Integrity Management for Offshore and Onshore StructuresОценок пока нет