Академический Документы

Профессиональный Документы

Культура Документы

200 W, Single Output Power Supply

Загружено:

Dragana VucinicАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

200 W, Single Output Power Supply

Загружено:

Dragana VucinicАвторское право:

Доступные форматы

DN06010/D

Design Note DN06010/D

200 W, Single Output Power Supply

Device

NCP1217

Application

Refrigerator

Input Voltage

90 to 270 Vac

Output Power

140 W / 200 W pk

Topology

CCM (Continuous Conduction Mode) Flyback

I/O Isolation

Yes

Other Specifications

Output 1 Output Voltage Ripple Nominal Current Max Current Min Current

14 V 200 mVp-p 10 A 14 A 0A

Output 2

N/A N/A N/A N/A N/A No 80% 0 to +70C

Output 3

N/A N/A N/A N/A N/A

Output 4

N/A N/A N/A N/A N/A

PFC (Yes/No) Minimum Efficiency Operating Temp Range

Circuit Description

This 14 Vout, off-line power supply was originally designed for refrigeration control applications but can be user tailored to accommodate most 12 to 15 volt applications requiring 140 watts output continuous with a 200 watt peak capability. The converter circuit is designed around a continuous conduction mode (CCM) flyback topology to minimize the inverters peak-toaverage current ratio. Slope compensation for D > 50% is achieved with the unique internal architecture of the NCP1217 controller and the value of resistor R9. The 100 kHz flyback transformer is designed with a compact PQ3230 ferrite core. Voltage feedback and regulation is implemented with a simple TL431 programmable reference and optocoupler.

Key Features

CCM operation for low peak to average current ratio. Output ripple reduction inductor (L3) Dual common mode EMI filter for low conducted EMI. Very low standby input current at no load (< 1 watt). Simple, low cost yet highly effective converter circuit. Overcurrent and overvoltage protection.

August 2006, Rev. 0

www.onsemi.com

DN06010/D

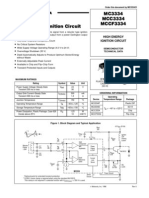

Schematic

10nf 500V C6 T1 12 D2 MBR20100 L3 4.7uH 10 C7 4,5,6 R4 0.15, 2W C8 C9 C10 2,200uf 16V

F1 5A

AC in

0.33uf "X2" C1

L1

L2

0.33uf "X2" C2 R1 1.0M 1/2W

BD1 6A 600V

R2 33K 5W C5 390uF 400Vdc

11 D1 MUR160

1,2,3

+

14 V, 10 A output

TH1

T

Q1 SPP20N60S5 (Infineon) R3 4.7

2,200uf 16V x 3

10 ohm 4A, NTC

C3 C4 2.2nf "Y2" x2

C11 0.1uf

Gnd

chassis ground

D3 R6 4.7K, 0.5W 1N5245B (15V) D4 C16 47uf 25V 10nf C17 R8 22K 1N4148A NCP1217 (100 kHz)

R5 10

R7 150

8 R9 2.4K R11 2K

8 6

U1

5 2 3 4

C15 0.1

SFH6156A-4 or H11A817A U2 C13 1nf U3

C14 100pf

R10 1K R12 1K C12 0.1uf

R13 15K

Opto

Notes: 1. Crossed schematic lines are not connected. 2. R4 sets current limit point; R9 sets slope compensation; R13 sets output voltage. 3. D4 sets OVP to 15V on Vcc rail (nominally 10 - 12Vdc) 4. Q1 and D2 will need heatsinks; Aavid #529802B02100 or similar 5 Small heatsink or plate recommended for BD1 6. L1 is Coilcraft CMT1-2.1-4L; L2 is Coilcraft F5593-A; L3 is Coilcraft PV-0-472-20L 7. TH1 is NTC thermistor for inrush limiting (Ametherm or equivalent). 8. Output caps C7, 8, 9, 10 should have low ESR with high ripple current rating.

TL431

R14 3.3K

August 2006, Rev. 0

www.onsemi.com

DN06010/D

MAGNETICS DESIGN DATA SHEET

Project / Customer: 14 Vout, 200 Wpk power supply Part Description: 100 kHz flyback transformer, 14 Vout Schematic ID: T1 Core Type: PQ3230 (Ae = 1.6) Core Gap: Gap center leg approximately 1 mm for L = 300 uH Inductance: 300 uH +/-10% (measured from pins 10 to 12) Bobbin Type: Vertical 12 pin pcb mount Windings (in order): Winding # / type "A" Primary (12 - 11) Vcc/Aux (8 - 7) 14 V Secondary (4,5,6 - 1,2,3)

Turns / Material / Gauge / Insulation Data 20 turns of 2 strands of #26HN over one layer; Self-leads to pins; insulate for 2.7 kV to next layer. 5 turns sprial wound over the center 12.5mm with 3mm end margins. Insulate for 2.7 kV to next layer. 6 turns of #17 equivalent Litz wire (or 8 strands of #26HN twisted) over the center 12.5mm with 3mm end margins. Insulate with tape for 2.7 kV to next winding. Same as "A" primary. Insulate with tape.

"B" Primary (11 - 10)

Hipot: 2.7 kV primary/aux to 14V secondary. Vacuum varnish. Schematic

12

Lead Breakout / Pinout Bottom (pin side) view

Pri A

11

1 2 3

Pri B

10

14V 4 Sec

5 6

Aux

7 8

12 11 10 9 8 7

1 2 3 4 5 6

1

2006 ON Semiconductor. Disclaimer: ON Semiconductor is providing this design note AS IS and does not assume any liability arising from its use; nor does ON Semiconductor convey any license to its or any third partys intellectual property rights. This document is provided only to assist customers in evaluation of the referenced circuit implementation and the recipient assumes all liability and risk associated with its use, including, but not limited to, compliance with all regulatory standards. ON Semiconductor may change any of its products at any time, without notice.

Design created by Frank Cathell, E-mail: f.cathell@onsemi.com

August 2006, Rev. 0 www.onsemi.com 3

Вам также может понравиться

- +/-18 V, Dual Output Power Supply: Design Note - DN06008/DДокумент3 страницы+/-18 V, Dual Output Power Supply: Design Note - DN06008/Dcornel_24Оценок пока нет

- Single Power Supply Synchronous PWM Controller: Description FeaturesДокумент17 страницSingle Power Supply Synchronous PWM Controller: Description FeaturesIonel CociasОценок пока нет

- UCC381ADДокумент33 страницыUCC381ADbenaya2012Оценок пока нет

- Isolated Flyback Switching Regulator W - 9V OutputДокумент16 страницIsolated Flyback Switching Regulator W - 9V OutputCasey DialОценок пока нет

- Tda 7375Документ15 страницTda 7375Angeles Santos MartinezОценок пока нет

- Voltage-Controlled Oscillator: ... The Analog Plus CompanyДокумент24 страницыVoltage-Controlled Oscillator: ... The Analog Plus CompanyMoltrevОценок пока нет

- Delta PLC DVP SS ModelДокумент4 страницыDelta PLC DVP SS ModelTarun SonwaneОценок пока нет

- LYNX Audio Amplifier 275W 4 OhmiДокумент11 страницLYNX Audio Amplifier 275W 4 OhmiDanut777750% (2)

- Switching IC for compact power supply STR-A6252Документ9 страницSwitching IC for compact power supply STR-A6252Fernando ChingaОценок пока нет

- Op To CouplerДокумент5 страницOp To CouplersamponОценок пока нет

- 300mA LDO REGULATOR RP114x SERIES DATA SHEETДокумент28 страниц300mA LDO REGULATOR RP114x SERIES DATA SHEETSol De GabrielОценок пока нет

- Trace Elliot Velocette 12r Schematic DiagramДокумент9 страницTrace Elliot Velocette 12r Schematic DiagramjonnycoolОценок пока нет

- Rp103X Series: Low Noise 150ma Ldo RegulatorДокумент29 страницRp103X Series: Low Noise 150ma Ldo RegulatorSol De GabrielОценок пока нет

- 20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness HeadquartersДокумент9 страниц20 W 2-Channel BTL AF Power Amplifier For Car Stereos: SANYO Electric Co.,Ltd. Semiconductor Bussiness Headquartersfernandes66Оценок пока нет

- AN-2061 LM3445 A19 Edison Retrofit Evaluation Board: User's GuideДокумент11 страницAN-2061 LM3445 A19 Edison Retrofit Evaluation Board: User's GuideVanessaDDMОценок пока нет

- Low-Cost HF Amplifier Board and Filter ModsДокумент14 страницLow-Cost HF Amplifier Board and Filter ModsaugustinetezОценок пока нет

- Delta DVP-SV Sv2 I Mul 20130722Документ19 страницDelta DVP-SV Sv2 I Mul 20130722nilyenmaОценок пока нет

- Panasonic Inverter ManualДокумент8 страницPanasonic Inverter Manualsamernet2100% (1)

- AZ3842 PWM Controller Data Sheet SummaryДокумент13 страницAZ3842 PWM Controller Data Sheet SummaryEngr Khalid IqbalОценок пока нет

- High Voltage Power Operational Amplifiers: Features DescriptionДокумент6 страницHigh Voltage Power Operational Amplifiers: Features DescriptionWaqas Ayub100% (1)

- Forward Design 300W STmicroelectronics App NoteДокумент10 страницForward Design 300W STmicroelectronics App Notecristi7521Оценок пока нет

- SS Instruction Sheet-English-20060505 PDFДокумент2 страницыSS Instruction Sheet-English-20060505 PDFstgpereiraОценок пока нет

- UCC35702Документ24 страницыUCC35702Malay K GhoshОценок пока нет

- TEA5101B Ds PDFДокумент6 страницTEA5101B Ds PDFMingo YontoОценок пока нет

- Ba3308 PDFДокумент9 страницBa3308 PDFAnghelescu CristinaОценок пока нет

- Application Note 2034 LM3445 - 120VAC, 8W Isolated Flyback LED DriverДокумент20 страницApplication Note 2034 LM3445 - 120VAC, 8W Isolated Flyback LED DriverEduardoОценок пока нет

- Data SheetДокумент8 страницData SheetRucelle Chiong GarcianoОценок пока нет

- DatasheetДокумент13 страницDatasheetkishore kumarОценок пока нет

- LA4278Документ7 страницLA4278aalex28Оценок пока нет

- NCP1216 DДокумент18 страницNCP1216 DDavid Isaias Jaimes Reyes100% (1)

- CPWRAN10Документ5 страницCPWRAN10Vasco RodriguesОценок пока нет

- Uc3842b 3843BДокумент10 страницUc3842b 3843Bbob75Оценок пока нет

- Data Sheet Ic fr9886Документ14 страницData Sheet Ic fr9886Setya Budi S100% (1)

- Description Features: Programmable Synchronous DC/DC Converter, Dual Low Dropout Regulator ControllerДокумент12 страницDescription Features: Programmable Synchronous DC/DC Converter, Dual Low Dropout Regulator ControllerthongleОценок пока нет

- Ca3306 (A, C)Документ17 страницCa3306 (A, C)notaden1849Оценок пока нет

- HV9910BDB7 HV9910B PFC 40W LED Driver Demoboard: Specifications General DescriptionДокумент5 страницHV9910BDB7 HV9910B PFC 40W LED Driver Demoboard: Specifications General DescriptionNT372Оценок пока нет

- 28V 2A Step-Down Switching Regulator: Power Management Features DescriptionДокумент19 страниц28V 2A Step-Down Switching Regulator: Power Management Features DescriptionLuis Espino PérezОценок пока нет

- SSR Rp1a23d6Документ3 страницыSSR Rp1a23d6BlAdE 12Оценок пока нет

- La 4278Документ6 страницLa 4278Carlos López Rivera0% (1)

- LM25005 42V, 2.5A Step-Down Switching Regulator: Literature Number: SNVS411BДокумент24 страницыLM25005 42V, 2.5A Step-Down Switching Regulator: Literature Number: SNVS411BPravin MevadaОценок пока нет

- AP2182Документ17 страницAP2182ابراهيم السعيديОценок пока нет

- CA3102Документ11 страницCA3102bonaparteCWBОценок пока нет

- MRC, QRC & IRC Relay GuideДокумент2 страницыMRC, QRC & IRC Relay GuidesimbugowriОценок пока нет

- LM 4755Документ18 страницLM 4755Ovidio RiosОценок пока нет

- Datasheet LTC1298 LTC1286 PDFДокумент24 страницыDatasheet LTC1298 LTC1286 PDFletterniОценок пока нет

- 10-Bit and 12-Bit Binary Multiplying DACs from National SemiconductorДокумент14 страниц10-Bit and 12-Bit Binary Multiplying DACs from National SemiconductormicochangoОценок пока нет

- CA3189EДокумент8 страницCA3189EelektrovodaОценок пока нет

- Diagnostic Data For The Aerial AnalyserДокумент4 страницыDiagnostic Data For The Aerial Analysergogu vasileОценок пока нет

- OP37Документ16 страницOP37Josef StevanusОценок пока нет

- Ulta Stepup DC To DC Conveter With Reduced Switch StressДокумент21 страницаUlta Stepup DC To DC Conveter With Reduced Switch StressDRISHYAОценок пока нет

- Report 20WRangdongДокумент11 страницReport 20WRangdongNguyễn ViệtОценок пока нет

- Datasheet MC3334Документ6 страницDatasheet MC3334odipasОценок пока нет

- 2SD10617Документ12 страниц2SD10617info5280Оценок пока нет

- 4 x 10W DUAL/QUAD POWER AMPLIFIER SPECIFICATIONSДокумент18 страниц4 x 10W DUAL/QUAD POWER AMPLIFIER SPECIFICATIONSjesadОценок пока нет

- LCT B85TDU22H Service ManualДокумент59 страницLCT B85TDU22H Service ManualCristina NistorОценок пока нет

- stk433 330 PDFДокумент11 страницstk433 330 PDFLesley HoodОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1От EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Display PDFДокумент6 страницDisplay PDFoneoceannetwork3Оценок пока нет

- ArДокумент26 страницArSegunda ManoОценок пока нет

- DOE Tank Safety Workshop Presentation on Hydrogen Tank TestingДокумент36 страницDOE Tank Safety Workshop Presentation on Hydrogen Tank TestingAlex AbakumovОценок пока нет

- IQ CommandДокумент6 страницIQ CommandkuoliusОценок пока нет

- Correlation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesiДокумент8 страницCorrelation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesimuqfiОценок пока нет

- Checklist of Requirements For OIC-EW Licensure ExamДокумент2 страницыChecklist of Requirements For OIC-EW Licensure Examjonesalvarezcastro60% (5)

- Unr Ece R046Документ74 страницыUnr Ece R046rianteri1125Оценок пока нет

- Pasadena Nursery Roses Inventory ReportДокумент2 страницыPasadena Nursery Roses Inventory ReportHeng SrunОценок пока нет

- Qad Quick StartДокумент534 страницыQad Quick StartMahadev Subramani100% (1)

- Mobile ApplicationДокумент2 страницыMobile Applicationdarebusi1Оценок пока нет

- Typical T Intersection On Rural Local Road With Left Turn LanesДокумент1 страницаTypical T Intersection On Rural Local Road With Left Turn Lanesahmed.almakawyОценок пока нет

- Training Customer CareДокумент6 страницTraining Customer Careyahya sabilОценок пока нет

- ITP Exam SuggetionДокумент252 страницыITP Exam SuggetionNurul AminОценок пока нет

- Easa Management System Assessment ToolДокумент40 страницEasa Management System Assessment ToolAdam Tudor-danielОценок пока нет

- Audio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionДокумент29 страницAudio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionLuc SchramОценок пока нет

- BIT 4107 Mobile Application DevelopmentДокумент136 страницBIT 4107 Mobile Application DevelopmentVictor NyanumbaОценок пока нет

- SolBridge Application 2012Документ14 страницSolBridge Application 2012Corissa WandmacherОценок пока нет

- BenchmarkДокумент4 страницыBenchmarkKiran KumarОценок пока нет

- New Hire WorkbookДокумент40 страницNew Hire WorkbookkОценок пока нет

- Build A Program Remote Control IR Transmitter Using HT6221Документ2 страницыBuild A Program Remote Control IR Transmitter Using HT6221rudraОценок пока нет

- Efaverenz p1Документ4 страницыEfaverenz p1Pragat KumarОценок пока нет

- Audi Q5: First Generation (Typ 8R 2008-2017)Документ19 страницAudi Q5: First Generation (Typ 8R 2008-2017)roberto100% (1)

- Breaking NewsДокумент149 страницBreaking NewstigerlightОценок пока нет

- Price List PPM TerbaruДокумент7 страницPrice List PPM TerbaruAvip HidayatОценок пока нет

- What Is A Problem?: Method + Answer SolutionДокумент17 страницWhat Is A Problem?: Method + Answer SolutionShailaMae VillegasОценок пока нет

- Baobab MenuДокумент4 страницыBaobab Menuperseverence mahlamvanaОценок пока нет

- NLP Business Practitioner Certification Course OutlineДокумент11 страницNLP Business Practitioner Certification Course OutlineabobeedoОценок пока нет

- Mosfet 101Документ15 страницMosfet 101Victor TolentinoОценок пока нет

- Consensus Building e Progettazione Partecipata - Marianella SclaviДокумент7 страницConsensus Building e Progettazione Partecipata - Marianella SclaviWilma MassuccoОценок пока нет