Академический Документы

Профессиональный Документы

Культура Документы

Cooling Water Treatment

Загружено:

kichasИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cooling Water Treatment

Загружено:

kichasАвторское право:

Доступные форматы

Cooling Water Treatment Cooling tower may require these facilities.

Corrosion and Scale Control

Chemical formulation is dosed continuously in the sump from dosing tank by dedicated metering dosing pumps. Transfer system for transferring formulation into the dosing tank is provided. GTPL offers corrosion and scale inhibition based on efficient chemical treatment. Treatment with chemical formulations containing corrosion inhibitor, scale inhibitor and polymeric dispersant is done. a) Dosing rate of formulation will be based on blow down rate. Dispersant may be dosed separately or can be combined with the inhibitor into a single formulation with the help of a stabilizer.

Microbiological Control

GTPL offers microbiological control in the cooling water by chlorination and biocide dosing. Chlorination is done by chlorination system i.e. V-notch vacuum eductor type chlorinators to maintain free residual chlorine in the cooling tower return header. Alternately, ClO2 dosing with in-situ non hypochlorite based ClO2 generator is also offered. Shock dosing of biocides is offered.

pH Control

GTPL offers acid dosing system for maintaining pH of the circulating water by dosing Sulphuric Acid at regulated rate. Following facilities are generally provided for dosing system: Storage tank Dosing vessel Unloading/transfer pump for unloading and dosing pumps for transferring from tank to dosing vessels. Dosing Pumps Acid is taken from acid storage tank by unloading transfer pump to dosing drum to dose sulphuric acid by motorized dosing pumps into the cooling water sump. Transfer Pump offered is horizontal centrifugal driven by electric motor. Adequate facilities are provided to take care of spillage and accidental overflow of acid.

Control of Suspended Solids

GTPL offers side stream filtration system to control suspended solids within the stipulated limits in the recirculating water.

Oil Ingress Abatement

To nullify the effect of oil ingress in process cooling water system as and when it takes places, oil dispersant which can be dosed. Special oil skimming arrangement is provided to remove oil sludge from water.

Monitoring The treatment system is offered along with a sound and balanced monitoring scheme.

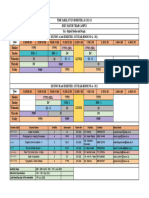

In a typical water treatment system, monitoring may be done for following parameters:

S. No 1. 2.

Parameters pH

Philosophy once in 4 hrs

TDS, turbidity, Oil, Alkalinity, CaH, TH, once in a day. Cl, SiO2, Fe, KMnO4 value, HEDP, Inorganic Polyphosphate Zinc Bacterial count Corrosion rate Heat transfer coefficient of some heat exchangers Oil ingress Bio fouling once a week once a week standard solid plug CS test coupons in coupon testing rigs Every two days As required Every week

3. 4. 5. 6 7 8

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- OPEC April Report 2016Документ96 страницOPEC April Report 2016Amos DesmondОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- DOT Pipeline SpecificationsДокумент20 страницDOT Pipeline Specificationssect349Оценок пока нет

- OPEC Annual Statistical Bulletin - 50th Edition - 2015Документ120 страницOPEC Annual Statistical Bulletin - 50th Edition - 2015studyendlessОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Guía de Ingeniería EclipseДокумент121 страницаGuía de Ingeniería Eclipsegiovanny1136Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Casing & Drill Pipe DataДокумент1 страницаCasing & Drill Pipe DatakichasОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Instrumentation BasicsДокумент85 страницInstrumentation BasicskichasОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- 300 Excel TipsДокумент5 страниц300 Excel TipsGlenn96% (23)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Generator & Exciter BasicДокумент8 страницGenerator & Exciter Basictowfiqeee100% (1)

- Mechanical - Pumps KSB Centrifugal Pump DesignДокумент44 страницыMechanical - Pumps KSB Centrifugal Pump DesignkichasОценок пока нет

- Calculate N.P.S.H.AДокумент9 страницCalculate N.P.S.H.AkichasОценок пока нет

- Calculate N.P.S.H.AДокумент9 страницCalculate N.P.S.H.AkichasОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Understanding The Basics of Packaged Steam GeneratorsДокумент5 страницUnderstanding The Basics of Packaged Steam Generatorskichas100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- TM 5-805-7 - Welding Technical Manual (US Army 1985)Документ96 страницTM 5-805-7 - Welding Technical Manual (US Army 1985)Ahmed FarazОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Air Receiver SizingДокумент2 страницыAir Receiver SizingkichasОценок пока нет

- AMECO Catalog For Stacker Reclaimer and ScrapperДокумент33 страницыAMECO Catalog For Stacker Reclaimer and Scrapperkichas100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- BC CEMA Power ConsumptionДокумент2 страницыBC CEMA Power ConsumptionkichasОценок пока нет

- CT Fill SelectionДокумент4 страницыCT Fill SelectionkichasОценок пока нет

- Dry Screw Vs Oil Flooded ScrewДокумент2 страницыDry Screw Vs Oil Flooded Screwkichas100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Comparision Between NDCT and IDCT PDFДокумент2 страницыComparision Between NDCT and IDCT PDFkichasОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- BFBC or StrokerДокумент6 страницBFBC or StrokerkichasОценок пока нет

- Materials For Steam SuperheatersДокумент9 страницMaterials For Steam Superheatersjyoti swaroop repaka50% (2)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- A Practical Approach To Predicting Ash DepositionДокумент13 страницA Practical Approach To Predicting Ash DepositionkichasОценок пока нет

- 16 20Документ5 страниц16 20kichasОценок пока нет

- 16 20Документ5 страниц16 20kichasОценок пока нет

- HFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanДокумент97 страницHFY3-3690-00-ELE-ITP-0001 - 0 ITP For Electrical Inspection and Test PlanAmmar AlkindyОценок пока нет

- Investigatory ProjectДокумент65 страницInvestigatory Projectnica pidlaoanОценок пока нет

- PSY563Документ1 страницаPSY563Za-c Pelangi Senja100% (1)

- EMCO WinNC GE Series Fanuc 21Документ98 страницEMCO WinNC GE Series Fanuc 21PHONG2790% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- FBXCVSDZX H AIATS For Olympiads 2024 - Class IXДокумент22 страницыFBXCVSDZX H AIATS For Olympiads 2024 - Class IXAtul KunduОценок пока нет

- Sample Test NTS NAT IE PDFДокумент11 страницSample Test NTS NAT IE PDFAwais SahabОценок пока нет

- Ko 2015Документ22 страницыKo 2015Mudavath Babu RamОценок пока нет

- Topic15 8p2 GalvinДокумент28 страницTopic15 8p2 GalvinSiddharth GuptaОценок пока нет

- Methodology For BA Political Science - 0Документ5 страницMethodology For BA Political Science - 0faizОценок пока нет

- Patterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsДокумент7 страницPatterns and Correlates of New Psychoactive Substance Use in A Sample of Australian High School StudentsFirli FarhatunnisaОценок пока нет

- ENGL201 Exercise 1Документ5 страницENGL201 Exercise 1Krupali RasiklalОценок пока нет

- Tugas 3 Siti Nur Afifah - MK Bahasa InggrisДокумент3 страницыTugas 3 Siti Nur Afifah - MK Bahasa InggrisDuda KerenОценок пока нет

- How To Use A Multimeter The Quick Guide To Accurately Measure Electrical Quantities and Make The Most of Your MultimeterДокумент23 страницыHow To Use A Multimeter The Quick Guide To Accurately Measure Electrical Quantities and Make The Most of Your MultimeterMohamad Hakimi Bin MakhtarОценок пока нет

- Ba-Dmd Sem 2 (S)Документ1 страницаBa-Dmd Sem 2 (S)dadagiri222002Оценок пока нет

- CAD Designer - Job at Vattenfall in Hamburg, KoldingДокумент4 страницыCAD Designer - Job at Vattenfall in Hamburg, KoldingKevin DungОценок пока нет

- Gyanpath 15-04-2024 Daily Current AffairsДокумент9 страницGyanpath 15-04-2024 Daily Current AffairsABHIDEV J KОценок пока нет

- CBSE-Class-4-Maths-Worksheet SubtractДокумент6 страницCBSE-Class-4-Maths-Worksheet Subtractkomaltagra0% (1)

- An Introduction To A Neurofeedback-Based Self-Rewarding Framework On Mobile Devices Using Modern HcisДокумент8 страницAn Introduction To A Neurofeedback-Based Self-Rewarding Framework On Mobile Devices Using Modern HcisakisОценок пока нет

- Gap AnalysisДокумент9 страницGap AnalysisNgân KhổngОценок пока нет

- Assignment-M3 1 GEDДокумент2 страницыAssignment-M3 1 GEDdeamon1 santosОценок пока нет

- 3RW50736AB14 Datasheet enДокумент8 страниц3RW50736AB14 Datasheet enRafael LucenaОценок пока нет

- Delhi Public School Bangalore North ACADEMIC SESSION 2022-2023 Class - ViiiДокумент28 страницDelhi Public School Bangalore North ACADEMIC SESSION 2022-2023 Class - Viiiharahej45Оценок пока нет

- ILC-single Line Volumetric SystemДокумент74 страницыILC-single Line Volumetric Systemfahmi derbel100% (1)

- Elitmus Elitmus Admit Card 05feb2023Документ1 страницаElitmus Elitmus Admit Card 05feb2023Dileep RajoriyaОценок пока нет

- iFIX Automation Reference Section2Документ587 страницiFIX Automation Reference Section2megamoto02 motosОценок пока нет

- Graphic Design Thesis TopicsДокумент8 страницGraphic Design Thesis Topicsafkololop100% (1)

- Toy Car Lab - 2Документ3 страницыToy Car Lab - 2api-260771184Оценок пока нет

- Deepwater Horizon Oil SpillДокумент5 страницDeepwater Horizon Oil SpillKartik GuptaОценок пока нет

- Desert Magazine 1984 NovemberДокумент44 страницыDesert Magazine 1984 Novemberdm1937100% (2)

- HPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Документ9 страницHPLC Method For The Analysis of Paracetamol Caffeine and Dipyron-1Đoàn Lê Thuý HiềnОценок пока нет