Академический Документы

Профессиональный Документы

Культура Документы

Bond Characteristics High-Strength Steel Reinforcement

Загружено:

Umair Baig0 оценок0% нашли этот документ полезным (0 голосов)

103 просмотров6 страницCivil Enginering

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документCivil Enginering

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

103 просмотров6 страницBond Characteristics High-Strength Steel Reinforcement

Загружено:

Umair BaigCivil Enginering

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

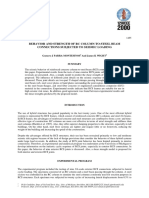

ACI STRUCTURAL JOURNAL TECHNICAL PAPER

Title no, 103-878

Bond Characteristics of High-Strength Steel Reinforcement

by Raafat EI-Hacha, Hossam EI-Agroudy, and Sami H, RizkalJa

This paper summarizes an investigation undertaken to study the

bond characteristics oj high-strength steel reinforcement bars

commercially known as microcomposite, multistructural, fonnable

steel (MMFX). The objective a/the investigation is to examine the

applicability of the ACI 318-02 equation and a current proposed

equation by Zuo and Danvin on bond behavior of steel reinforcement

10 the concrete member. The experimental program included two

phases. The jirsfphase of the experimental program consisted oj

testing four beam-end specimens reinforced with MMFX steel

bars, whereas the second phase included testing eight beam-splice

specimens reinforced with MMFX steel bars. The selectedfour factors

considered in this study were bar size, level of confinement,

bonded length, and bar cast pOSition. The bond behavior of the

MMFX steel bars was found to be similar to that of cOIwentional

Grade 420 MPa (60 ksi) steel up to the proportional limit of

550 MPa (80 ksi). The bond strength of the MMFX significantly

changes as the tensile stresses developed in the bar exceed the

proportional limit. The test results indicated that both the ACI 318-02

equation and the current proposed equation by ZliO and Darwin on

bond are adequate and resulted in conservative prediction at low

stress levels up to 550 MPa (80 ksi). At high stress levels, however, the

prediction using both equations is unconservative due to the

nonlinear behavior of the MMFX stress-strain relationship.

Based on the limited number of specimens considered in this

study, modification (0 both the ACI 318-02 equation and the

Zuo and Darwin equation is proposed to predict the bond forces

beyond the proporlionailimitfor MMFX steel bars.

Keywords: bond; confinement; flexure; splice; steel; strength.

INTRODUCTION

Bond behavior of reinforcing steel bars to concrete is one

of the most important mechanisms that should be properly

designed to ensure satisfactory performance of reinforced

concrete structures, The bond strength and mode of bond

failure are affected by many factors, The most important

factors are thickness of the clear concrete covers (bottom

and/or side), clear spacing between bars, nominal bar diameter,

embedment or development and splice length, amount of

transverse steel reinforcement, and concrete compressive

strength, The individual contributions of these factors are

difficult to separate or quantify, Another factor that influences

the bond strength of bars is the depth of fresh concrete below

the bar during casting.

In general, any increase in confinement of the bar by the

surrounding concrete, and/or by transverse reinforcement

increases the bond strength and minimizes splitting.

Confinement by the concrete is dependent on the clear

concrete covers (bottom andlor side) and the bar spacing,

Increasing the development/splice length of a reinforcing bar

increases its bond strength, The bond strength, for a given

length, mobilized by both concrete and transverse reinforcement,

increases as the bar diameter increases. Bond strength of bars

confined by transverse reinforcement increases with the

increase in the relative rib area. Top-cast bars have lower

bond strength than bottom-cast bars, Also, bond strength

ACI Structural Journal/November-December 2006

increases with increasing concrete compressive strength for

bars not confined by transverse reinforcement approximately

with the 1/4 power of the compressive strength (f; 1/4), The

additional bond strength, provided by transverse reinforcement,

increases approximately with the 3/4 of the compressive

strength 3/4), Note that the 14 has been shown to

provide a better representation of the effect of concrete

strength on bond than 112 This point is recognized by

ACI Committee 408 and within ACI 318, which sets an upper

limit on the value of 1/2 for use in design. An increase in the

aggregate quantity and strength results also in an increase in

bond strength, More details on the factors that affect the bond of

reinforcing steel to concrete can be found in ACI 408R-03

1

Bond characteristics of cooventional carbon steel reinforce-

ment and epoxy-coated reinforcement with concrete has

been thoroughly investigated by many researchers

2

-

12

and

addressed in terms of bond or development length, Their

experimental results contributed to the ACI Committee 408

database on "Bond and Development of Straight Reinforcing

Bars in Tension" and were used in formulating the current

equations in both ACI 318-02

13

and ACI 408R-03

1

to

predict the bond force,

The experimental investigation presented in this paper is

designed to study the bond behavior of the high-strength

steel (conunercially known as MMFX steel bar) and included

the effect of bar size, level of confinement with transverse

reinforcement, bonded length, and bar cast position, The

MMFX steel bars exhibit superior mechanical properties

when compared with conventional steel reinforcement,14

and the requirements covering deformation dimensions of

ribs (length, height, and frequency along bars) are the same

as conventional steel bars and confonn to ASTM A 1035-06

15

and ASTM A 615-04,16 The validity of such innovative

reinforcement and its ability to transfer stresses to the

concrete through bond must be considered, To

the best knowledge of the authors, very little information is

available about the bond strength of high-strength steel

reinforcement. Therefore, MMFX steel reinforcement was

considered to provide a database and kTIowledge of the bond

of high-strength steel to concrete and to compare the

behavior to conventional A61S Grade 420 MPa (60 ksi)

carbon steel reinforcement.

RESEARCH SIGNIFICANCE

Typical design code equations attempt to ' predict a

required bonded length that will result in yielding of the bar

before bond failure, The importance of conducting an

experimental investigation to identify the bond characteristics

ACI Structural Journal, V. 103, No.6, November-December 2006.

MS No. 03-378 received July 25. 2005, and reviewed under Institute publication policies.

Copyrighl 2006, American Concrete Institute. All rights reserved, including the making

of copies unless pennission is obtained from the copyright proprietors. Pertinent discussion

including author's closure, jf any, will be published in the September-October 2007

ACI Structural Journal if the discussion is received by May I, 2007.

771

Table 1-Test matrix of experimental Program 1: beam-end specimens

MMFXbar Concrete dimensions

location

Beam ID n during cast

lb, m.m

L,mm b,mm h.mm

Bl I No. I3 Bottom 356 2032 356 508

B2 I No. I3 Top 356 2032 356 508

B3 I No. 13 Bauam 356 2032 356 508

B4 I No. 2S Bottom 864 2032 356 508

>N""O"'''go' l' :"'\ ............

(211 6 Gnde 60) sea mm

(20 in)

4No.2S Oracle 420 . .

MM!'X b&r L .1

NOi l orNo2S {1'1- ) S6mm( 14in)fOrNo. 13 (II4) MMI'X

01118) ' (14 in) Sanded ungth L. e 864 mm (14 in) for No.2S (_8) MMFX

I 2032 mm -----I

(80 in)

Fig. 2-Details of beam-end specimens.

possible conical failure. the flrst 102 mm (4 in.) of the

MMFX steel bar from the concrete surface at the loaded end

were debonded using a plastic tube. as shown in Fig. 2. The

test matrix for the beam-end specimens program is shown in

Table 1. Details of the test setup are shown in Fig. 3.

The MMFX steel bar was tensioned using a hydraulic jack.

and the specimen was held in place using steel beams and

high-strength Dywidag steel bars anchored to the laboralory

floor. as shown in Fig. 3. The applied tension load was

measured using a load cell placed at the jacking side of the

beam-end specimen. Three 6 mm (0.25 in.) 120 ohm electrical

resistance strain gauges. installed on the bonded surface of

each MMFX steel bar. were used to measure the strain distribu-

tion along the bonded length of the bar. lb. at distances of Ib/6.

Ib12. and 5I

b

/6. A 50 mm (2 in.) extensometer was used to

measure the strain of the unbonded loaded Uacking) end of

the MMFX steel bar. Both the loaded and the unloaded

(dead) end slippage were measured using a linear variable

differential transformer (L VDT).

The bearn-end specimens were cast using normal-strength

concrete of 41.4 MPa (6000 psi) supplied by a local concrete

plant. Standard concrete cylinders 102 x 204 mm (4 x 8 in.)

were caSI according to ASTM C 31_00

23

for the purpose of

determining the compressive strength of the concrete. The

concrete cylinders were cured in the same manner as the test

specimens. The average concrete compressive strength for

each specimen, as measured on the day of testing using three

cylinders according to ASTM C 39-01,24 is given in Table 1.

Results of beam-end specimens

Failure mode-Beams BI. B2. and B3. each reinforced

with one No. 13 (No.4) MMFX steel bar. failed by rupture

of the MMFX bar. As the applied load increased. the number

and width of the flexural cracks developed along the bonded

length of the MMFX steel bar increased. The spacing

between these cracks was approximately equal to the spacing

between the stirrups. No signs of bond failure were observed

in these beams. It was concluded that the bonded lengths

were greater than the development lengths required to

develop the ultimate strength of the bar for the levels of

confinement provided in the three beams. For the beam

reinforced with one No. 25 (No.8) MMFX steel bar

(Beam B4). a longitudinal crack developed in the concrele

cover at the loaded end and propagated toward the unloaded

end of the specimen along the steel bar. indicating a typical

ACI Structural Journal/November-December 2006

Concrete cover Stirrup details

d. mm

db. mm C

so

mm Cb,mm MPa S, mm dst, mm i YI ,mm

464

464

464

457

12.7 172 38 36. 1 229 9.5 420

12.7 172 38 36 229 9.5 420

12.7 172 38 36.06 76 9.5 420

25.4 165 38 36.7 229 9.5 420

"

Fig. 3- Test setup of beam-end specimens.

Fig. 4--Splitting bondfailure mode for beam-end Specimen B4

(top view).

splitting mode of bond failure. as shown in Fig. 4. An

excessive increase in the width of the first flexural crack

near the loaded end was observed. Figure 5 shows the Iensile

stress and the average bond stress developed in the MMFX

steel bar in Beam B4 versus the measured slip at the loaded

and unloaded ends of the bar.

Bond distribution- Figure 6 shows the bond stress distri-

bution Ub; at distance x; from the loaded end along the

bonded length of the MMFX steel bar for Beam B I at

different stress levels based on the linear behavior of MMFX

within the elastic range to determine the stress /;. corresponding

to the measured strain. Figure 6 was developed as follows: at

a given bar stress level, the .corresponding strain readings

along the bonded length. as measured by the three strain

gauges, were determined. Using the stress-strain curve

oblained from the mechanical properties of the MMFX steel

bar. the corresponding stress levels were obtained for each

strain gauge reading along the bar. These stress values were

773

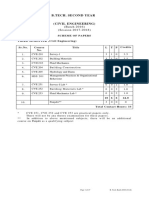

Table 3-Test matrix of Experimental Program 2: beam-splice specimens

Concrete di mensions

Group Specimen

no. lD

(,. mm

L. mrn

b

w

mm Bf , mm

h. mrn

I B-6-12 305 4877 305

-

311

11 B-6-24 610 4877 311

-

362

III B-6-36 914 4877 305 61 3 464

IV B-6-60 1524 6096 305 121 9 457

I B-8- 12 305 4877 305 - 305

11 B-8-24 610 4877 305 356

III B-8-48 1219 4877 311 616 470

IV B-8-n 1829 6096 305 1219 470

.

DimenSIOns of specimens were measured after castmg.

specimens allows only rotation of the section without deflection

of the beam at the location of bonded length. Deflection of

flexural beams simulated by the beam-splice specimens

allows for deflection of the beam, which reduces the bond

strength of the spli ced bars as the deflection forces the

spliced bar to exert additional outward pressure on the

bottom concrete cover, causing a premature failure of the

splice. TIris behavior is supported by Ferguson and Thompson.

27

Phase II: beam-splice specimens

A total of eight large-scale concrete beams reinforced with

MMFX steel bars splicea at the midspan were tested. Four

specimens were each reinforced with two No. 19 (No.6)

MMFX steel bars and the other four with one No. 25 (No.8)

MMFX steel bar. The beam-splice specimens were divided

into four groups, as shown in Table 3. Each group consisted

of two specimens with identical concrete dimensions but had

different amounts (one or two) and sizes (No. 19 or No. 25

[No.6 or No.8]) of the reinforcing MMFX steel bars. The

specimens in Groups I and II were rectangular in cross

section, whereas those in Groups III and IV had T-shaped

cross sections. The spliced lengths varied from one specimen

to another and ranged from 305 to 1829 mm (1.0 to 6.0 tt),

as shown in Table 3. To minimize the effect of the applied

loads on the spliced length, the distance between the end of

the splice length and the center of the applied load was

always more than 305 rum (1.0 tt) . For the specimens reinforced

with No. 25 (No.8) MMFX steel bars. double-legged closed

stirrups were evenly di stributed along the splice length to

provide the required level of confinement around the spliced

bars. To prevent possible premature shear failure, shear

reinforcement was provided using No. 10 (No.3) Grade 60

double-legged closed stirrups spaced at 127 rum (5 in.) along

the shear span for all tested beam specimens. Compression

reinforcement was provided by two No. 13 (two No.4)

Grade 420 MPa (60 ksi) steel bars as top reinforcement. The

variation in tbe beam's dimensions was selected to achieve

different stress levels in the MMFX steel bar length at failure.

The bottom and side concrete covers and the transverse spacing

between the spliced bars were kept constant for all the beams

reinforced with two No. 19 (two No.6) MMFX steel bars.

The selected values were 1. 8d

b

, 3d

b

, and 6d

b

where db is the

bar diameter. For beams reinforced with one No. 25 (No.8)

MMFX steel bar, the bottom and side concrete covers were

al so kept constant at values of 1.375d

b

and 5d

b

, respectively.

Table 3 shows the actual measured dimensions of the specimens

after casting.

The test matrix for the beam-splice test program is shown

in Table 3. The first letter of the beam designation "B" stands

for Beam; the middle number identifies the bar size- No. 19

ACI Structural Journal/November-December 2006

Cover and spacing Stirrup details along spli ce length

d. mrn Csa.mm Csi, mm Cb,mm

N S. mrn ds" mm fyl' MPa

264

314

419

143

254

305

422

410

~

J

~

0

m

~

0

~

~

~

~

E

~

60.3 54.0 38 0 - - -

54.0 70.0 38 0

- - -

54.0 60.3 35 0 - -

57.2 57.2 35 0 - -

-

123.8 - 38 I 305 9.53 420

123.8 38 2 305 9.53 420

114.3 - 35 5 245 9.53 420

120.7 - 35 7 260.4 9.53 420

0.9

m LImit confinment level I

IiiI Actual conflnrnent level

0.'

0.'

0.8

0.5

0.'

0.3

81, No. 13 (/II4) MMFX B2, No.13(/II4) MMFX 83, NQ.13 (II4) MMFX B<I .No.25(II8) w.t=X

Zuo and Darwin (2000) Equation

Fig. 7- Experimentallpredicted ratio for bonded length for

beam-end specimens using Zuo and Dmwin12 equation.

c

~

~

~

0

m

~

0

~

j

~

f

~

~

~

0.'

0. '

0.'

0.5

0.'

0.3

0.2

0.'

0

III Urnlt confinrnent level :

iii Actual confinment level

81 , No.13(#4)MMFX 82, No. 13 (AI4)MMFX 83. No.13 (#4) MMF"X 84, No.25 (/l8)MMFX

ACI318-02 Code Equation

Fig. 8-Experimentallpredicted ratio for bonded length f or

beam-end specimens using ACI 318-02

13

equatioll.

and No. 25 (No.6 and No. 8); whereas the last number represents

the spliced length of the bar, in inches. Standard concrete

cylinders, 102 x 204 rum (4 x 8 in.), were cast according to

ASTM C 31_00

23

for the purpose of determining the compres-

sive strength of the concrete. The concrete cylinders were

cured in the same manner as the test specimens. The average

concrete compressive strength, determined using three

cylinders according to ASTM C 39-01 ,24 at the age of 28 days

was 41.8 MPa (6071 psi). Table 4 shows the concrete

compressive strengths as measured on the day of testing.

All beams were simply supported loaded in four-point

bending. The load was applied using an MTS actuator operated

775

Fig. 12-Failure of beam-splice Specimen B-8-48.

just before failure, calculated using the moment curvature

analysis, are given in Table 4.

Evaluation of bond strength and splice length

The experimental results of the bond force of No. 19 and

No. 25 (No.6 and No. 8) MMFX steel bars were compared

with the rredictions from the proposed by Zuo and

Darwin 1 and the ACI 318-02 3 equation. The bond force

was calculated from the bar stress detennined using the

experimental stress-strain curve of the MMFX bar (Fig. I)

for the corresponding measured strain reading in the bar, as

measured by the strain gauges attached to the MMFX steel bars.

Zuo and Darwinl2 equarion-The bond capacity of the

No. 19 and No. 25 (No.6 and No.8) MMFX steel bars was

evaluated using the equation proposed by Zuo and Darwin,I2

as shown in Fig. 13 and 14, re';j'ectively. Test results indi-

cated that the Zuo and Darwin 1 equation provided conser-

vative prediction of the bond capacity of No. 19 (No.6)

MMFX steel bars at stress levels up to the proportional

strength of 579 MPa (84 ksi), and provided a very close

prediction to the bond capacity of No. 25 (No.8) MMFX

steel bars up to the proportional strength of 607 MPa (88

ksi). At higher stress levels; however, the equation resulted

in unconservative prediction for both No. 19 and No. 25

(No.6 and No.8) MMFX steel bars. Test results suggested

that there is a need to modify the Zuo and Darwinl 2 equation

to include a higher stress level. The stress limitation imposed

by ACI 318-02

13

for the maximum allowed design yielding

strength of 550 MPa (80 ksi) has been selected as an upper

boundary for using the equation by Zuo and Darwin12

Therefore, modification of the equation has been proposed

beyond the stress level of 550 MPa (80 ksi).

Bond equations generally relate bar stresses to bond

lengths. The equation proposed by Zuo and Darwinl2 for bond

strength of bars not confined with transverse reinforcement

(Tb = Tc and Ts = 0), in terms of bond force T

b

, as is the case

for Beams B6-12, B6-24, B6-36, and B6-60, is given by

SI units

Imperial units

ACI Structural Journal/November-December 2006

Splice Length (In)

"

20 30 40 50 60 70

::, ,,[1.43/,k_ +O.Sd.l+S6.ZA.(O.JC- +0.9) (Sf uMirs) 80000

J. c ...

"'0000

60000

L'wTent Luo and OllWln (WUU) cqva\1OII

TCSlRaults

No. 19 (N6)

MMFXBar

_ .

Modified ZUG . nd Dlrwin (2000) equl lion

;'" -[! I.(c_ .. O.ScI,)+ 120A, I 0.1:: +0.9) (Sf tlMIIJ)

o 250 51)0 750 1000 1250 1500 1750

Splice Length (mm)

""00

60000

g

' 0000

<

o

"""0

20000

"x,oo

Fig. 13-Bond force versus splice length for beams reillforced

with No. 19 (No.6) MMFX steel bars using Zuo and

Darwin

J2

equation.

_ '00000

Z

. """""

"

& """"'"

21 250000

o

200000

"'''00

,-

"""'"

o 10

Splice length (In)

20 30 ., 50 70

o 200 500 150 1000 1250 1500 1150

Splice length (mm)

10000

Fig. 14-Bolldforce versus splice length for beams reinforced

with No. 25 (No.8) MMFX steel bars using Zuo and

Darwin12 equation.

To limit the applicability of Eq. (2a) and (2b) to cases in

which a splitting failure governs

SI orimperial units

Equations (2a) or (2b) were modified by changing only

the numerical constants to ensure conservative predic-

tions at any stress level between 550 and 831 MPa (80 and

120.5 ksi). The proposed modification of the Zuo and

Darwin 12 equation for MMFX beyond the stress level of

550 MPa (80 ksi) is

SI units

(3a)

777

Imperial units

Equations (6a) and (6b) can be rewritten in terms of Id

as follows

SI units

Id

!ilL

I

=

db 10 J1[ (" ;";n + 0.5db)

db

(7a)

Imperial units

Id

llL

I

=

db 40 J1[ (C ;";n + O.5db)

db

(7b)

Equations (7a) and (7b) were written in terms of the yield

stress. To determine the development length of the bar in the

tested beams. however. this stress should be taken as the actual

measured stress in the MMFX steel bars.

Based on the tested results. Eg. (6a) or (6b) was modified by

changing the numerical constants and addition of a term func-

tion of d/. The proposed modification of the ACI 318_02

13

equation for MMFX beyond stress level of 550 MPa (80 ksi) is

SI units

Tb T, 1. 2

- = -= - ldn( e . + O.5d

b

) + 40d

b

9 min

Imperial units

(8a)

(8b)

Equations (8a) and (8b) can be rewritten in terms of I

d

as

follows

SI units

lL- sl

Id

=

Jj;

db

;";n + O.5db)

(9a)

9 db

Imperial units

lL - 637

Id

=

Jj;

(9b)

db 52(C ;";n + O.Sdb)

10 db

ACI Structural Journal/November-December 2006

Splice Length (in)

0

" "

30

" "

60

" 600000

T. 5 ( . ) ,

"0000

550000

,; IS '," '- +O.Sd, .. IS"' IOJ.4, ..

(SI

" 0000

500000

ACI JI8-02 Codecq\ll.Uon 1'0000

"0000 700000

_ 400000

Test Results No. 25 90000

(*8) MMFX Bar

80000

GI 350000 .

"

"'000

"

& 300000 Limiw"", IOttwSInM

&

2SOOOO

- . - . - - - (AClJis-:ii2i - . 60000

<

0

60000

0

= """

=

"'"

"0000

r, e' (' OSd) 4OJ'J - . A..I"

30000

700000

.1:- 9,trc ... + . + ," SOOOm

'DODO

50000

70000

0

0 250 500 750 7000 1250 1500 1150

Splice Length (mm)

Fig. 16-Bondforce versus splice length for beams reinforced

with No. 25 (No.8) MMFX steel bars using ACI 318-02

13

equation.

Using Eq. (8a) or (8b) to predict the bond capacity of No. 19

(No.6) MMFX steel bars for stress levels higher than 550 MPa

(80 ksi). the maximum test/predict ratio was approximately

1.19. as can be seen in Fig. 15.

The current ACI 318-02

13

equation. for bars confmed with

transverse reinforcement (Tb = T, + T,). in terms of bond force

T

b

as is the case for Beams B8-l2. B8-24. B8-48. and B8-72. is

given by

SI units

Tb = T, + T,= 2. l

dn

(c'. + 0 5d

b

) + 5 nldA"/,, (lOa)

/;112 18 ,",". 181O.34sn

Imperial units

(lOb)

Equations (lOa) and (lOb) can be rewritten in terms of Id as

follows

SI units

Imperial units

and k = A,,!,,

" ISOOsn

(lla)

779

, ."

900

..

l

100

!.

""

g

""

m

. 00

300

'"

'00

0

0

CIlo.2>.... '*2.9

__ __ ____ _

lim;la1ioft fur bu strtu l8Oksi)

-_._ . _._- -_._._- --- ---_ . _ -----

\0

(ACI 3I B_0l)

C"'-2SIHl

aZ

.

8

20

_ Experlmantal for No.19 (116) MMFX Steel Bin

_Experimentill for No.25 (118) MMFX Steel Bars

C : Level of Confinment

30 50 60 10 00

SptJce Length/Bar Diameter (L .ld b)

'"

130

120

'"

100 ';i

"-

90

j

00

10

60

m

"

"

30

20

"

90

Fig. 19-5teel bar stress versus splice length/bar diameter

for beams reinforced with No. 19 (No.6) and No. 25 (No. 8)

MMFX steel bars.

Midspan Deflection (in)

0 0.'

,.,

2

225

50

200 ' 6-&60 (p =0.45%)

45

'"

B-{J72 (p -0.40%)

40

35

'i:

"-

125

30

"

25 .9

1

100

'ii

20

75

'ii

<

"

<

50

,.

25 ,

0 0

0

,.

20 30 40 50 60

Midspan Deflection (mm)

Fig. 20-Load-midspan deflection for beams reinforced

with No. 19 (No.6) and No. 25 (No.8) MMFX steel bars.

is nearly linearly related, but not proportional, to the splice

length to the bar diameter ratio (L,ld

b

) up to the minimum

yield strength for No. 19 and No. 25 (No.6 and No.8)

MMFX steel bars. The relationship also suggests that a

splice length of 30d

b

can be safely used to achieve the

maximum yield strength of 550 MPa (80 ksi) limited by

ACI 318-02.

13

As shown in Fig. 19, a splice length of 45d

b

can be used to achieve the yield strength of758 MPa (110 ksi)

for MMFX steel bars. The linear, not proportional, relationships

extend to a stress of 831 MPa (120.5 ksi), which corresponds

to a splice length of 50d

b

. Beyond the yield strength, the

relationship becomes highly nonlinear and significant splice

length is required to achieve higher stress levels, which

could be impractical to use for typical applications.

Load-midspan deflection-The load-midspan deflection

behavior for the beam-splice specimens reinforced with two

No. 19 (No.6) MMFX bars and specimens reinforced with

one No. 25 (No.8) MMFX bar with different splice lengths

ranging from 305 to 1829 mm (12 to 72 in.) are shown in

Fig. 20. Two important points are worth noting. As can be

seen, for the beams reinforced with two No. 19 (No.6)

MMFX bars or with one No. 25 (No.8) MMFX bar, the

behavior is affected by the splice length in which increasing

the splice length increased the deflection at ultimate. By

comparing the beams with tbe same splice length (such as

ACI Structural Journal/November-December 2006

B-6-12 and B-8-12) throughout the post-cracked portion of

the load-midspan deflection, and at any given load level, the

deflection for the beams with a higher reinforcement ratio is

always less than that for beams with a lower reinforcement

ratio. This behavior is due to the higher stiffness as a result

of the higher reinforcement ratio. Throughout the post-

cracking behavior, the stiffnesses presented by the slopes of

the curves were also different. For beams with a lower

reinforcement ratio, the slope was less than for beams with a

higher reinforcement ratio. The difference was found to be

closely matching the difference in the reinforcement ratio

between the beams with higher reinforcement ratios and

the beams with lower reinforcement ratios. The ultimate

load-carrying capacity is bigher for beams with higher

reinforcement ratios than beams with lower reinforcement

ratios. Note that the results of Beams B-6-36 and B-8-48 are

not shown in Fig. 20 due to problems that occurred during

the test in measuring the deflection at midspan.

CONCLUSIONS

The following conclusions were made based on the limited

number of tested specimens:

1. Bond behavior of the MMFX steel bars is similar to that

of the conventional Grade 420 MPa (60 ksi) carbon steel up

to the stress level corresronding to the proportional limit,

imposed by ACI 318-02, 3 of 550 MPa (80 ksi). At higher

stress levels, bond failure changed from the typical sudden

and brittle failure, normally observed for conventional steel,

to a gradual and ductile failure due to the nonlinear behavior

of the MMFX steel bars in this range;

2. The nonlinear ductile response of the MMFX bars at

high stress levels beyond proportional limit strength bas a

strong influence in reducing the bond strength of the MMFX

bars compared with Grade 420 MPa (60 ksi) steel;

3. The current eguations proposed by Zuo and Darwin

l 2

and ACI 318_02

13

for bond force provided conservative

prediction of the bond capacity for No. 19 and No. 25 (No.6

and No.8) MMFX steel bars up to 550 MPa (80 ksi). For

stress levels exceeding 550 MPa (80 ksi) and up to a stress

level of 831 MPa (120.5 ksi) for No. 19 (No.6) MMFX bars,

and 955 MPa (138.5 ksi) for No. 25 (No. 8) MMFX bars,

respectively, both equations were modified to provide better

prediction of the bond force capacity; and

4. The splice length to bar diameter ratio is nearly linearly, but

not proportionally, related to the induced stress in the MMFX

steel bar up to yield strength. The relationship becomes highly

nonlinear beyond a stress level of758 MPa (llO ksi).

ACKNOWLEDGMENTS

The authors would like to thank the technical staff and graduate students

at the Constructed Facilities Laboratory at N.C. State Uni versity for their

help with the laboratory work. The authors are grateful to the support

provided by MMFX Tcchnologies Corp. for donating the steel materials.

NOTATION

A

ty

area of each stirrup or tie crossing potential plane of splitting

adjacent to reinforcemenl being developed or spliced

Bf width of flange of beam

b

w

width of web of beam

Cb thickness of clear bottom concrete cover

Cm/U = maximum of cb or C

s

minimum of concrete covers surrounding bar or half clear spacing

between bars, minimum of csi and (cb or cso)

cmill minimum of cb or C

s

C

s

minimum of e

so

or csi + 6.35 mm (Csi + 0.25 in.)

esi half clear spacing between spliced bars

C so thickness of clear side concrete cover

781

Вам также может понравиться

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОт EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyОценок пока нет

- Reinforced Concrete Buildings: Behavior and DesignОт EverandReinforced Concrete Buildings: Behavior and DesignРейтинг: 5 из 5 звезд5/5 (1)

- Proposed Modification Aci 318-02 Code Equation MMFX SteelДокумент10 страницProposed Modification Aci 318-02 Code Equation MMFX SteelbryantmckinnieОценок пока нет

- Shear Tests of FRP-Reinforced Concrete Beams Without StirrupsДокумент8 страницShear Tests of FRP-Reinforced Concrete Beams Without StirrupsMarcel SteoleaОценок пока нет

- Splice Length of Conventional Steel Bars To Pretentioned StrandsДокумент16 страницSplice Length of Conventional Steel Bars To Pretentioned StrandsKhoi Hung Nguyen CongОценок пока нет

- Numerical Study of R.C. Beams Strengthening by External Steel PlateДокумент9 страницNumerical Study of R.C. Beams Strengthening by External Steel PlateAJER JOURNALОценок пока нет

- The Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsДокумент7 страницThe Diagonal Tension Behavior of Fiber Reinforced Concrete BeamsChris LumyОценок пока нет

- Steel Capacity of Headed Studs Loaded in ShearДокумент10 страницSteel Capacity of Headed Studs Loaded in ShearMallesh NenkatОценок пока нет

- Short ColumnsДокумент15 страницShort ColumnssrividyaОценок пока нет

- Ijesit201301 55Документ10 страницIjesit201301 55mfhfhfОценок пока нет

- 7 Research Paper STRENGTH AND SERVICEABILITY OF FRP GRIDДокумент10 страниц7 Research Paper STRENGTH AND SERVICEABILITY OF FRP GRIDMuhammad DaniyalОценок пока нет

- Behavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic LoadingДокумент8 страницBehavior and Strength of RC Column-To-Steel Beam Connections Subjected To Seismic Loadingbravo deltafoxОценок пока нет

- F 97 S 65Документ12 страницF 97 S 65Tavio TavioTavioОценок пока нет

- Behaviour and Strength of Composite Slabs With Ribbed DeckingДокумент19 страницBehaviour and Strength of Composite Slabs With Ribbed DeckingRoberval PimentaОценок пока нет

- Experimental Behaviour of Concrete-Filled Stiffened Thin-Walled Steel Tubular ColumnsДокумент11 страницExperimental Behaviour of Concrete-Filled Stiffened Thin-Walled Steel Tubular ColumnshanlamphamОценок пока нет

- Seismic Upgrade of Beam-Column Joints With FRP ReinforcementДокумент17 страницSeismic Upgrade of Beam-Column Joints With FRP Reinforcementodhie79Оценок пока нет

- CFRP Bridge BeamsДокумент5 страницCFRP Bridge BeamsAnonymous nQ9RqmОценок пока нет

- ConcreteFilledSteelTubesSubjectedToAxialCompression Fam QieДокумент41 страницаConcreteFilledSteelTubesSubjectedToAxialCompression Fam QieTejaswini TejuОценок пока нет

- ADVSteelConstKOROGLU PDFДокумент16 страницADVSteelConstKOROGLU PDFAbdulkadir ÇevikОценок пока нет

- Use of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningsДокумент10 страницUse of Steel Fiber Reinforced Concrete For Enhanced Performance of Deep Beams With Large OpeningssuhagОценок пока нет

- Composite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemДокумент27 страницComposite Cold-Formed Steel-Concrete Structural System Composite Cold-Formed Steel-Concrete Structural SystemVladimirОценок пока нет

- Earls, 1999Документ24 страницыEarls, 1999carlosОценок пока нет

- Sand 4Документ17 страницSand 4Pavan MОценок пока нет

- Bond STRGДокумент8 страницBond STRGyuva_86Оценок пока нет

- Effect of Cyclic Loading On Flexural Behaviour of FRP Strengthened RC Beams: A Stability Point ApproachДокумент18 страницEffect of Cyclic Loading On Flexural Behaviour of FRP Strengthened RC Beams: A Stability Point ApproachTam LamОценок пока нет

- Performance of RC Beams With Embedded Steel TrusseДокумент9 страницPerformance of RC Beams With Embedded Steel TrussevignamОценок пока нет

- Mechanism of Shear TransferДокумент8 страницMechanism of Shear TransferSana'a AamirОценок пока нет

- Tests of Cold-Formed Channel ColumnsДокумент27 страницTests of Cold-Formed Channel ColumnsHadeer MohamedОценок пока нет

- Strengthen of Cold Formed Steel Column With Ferrocement Jacket Push Out TestsДокумент4 страницыStrengthen of Cold Formed Steel Column With Ferrocement Jacket Push Out TestsMahfuzur RahmanОценок пока нет

- Applsci 10 00822 v4 Good PaperДокумент20 страницApplsci 10 00822 v4 Good PaperAbdulkhaliq AbdulyimahОценок пока нет

- An Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFДокумент21 страницаAn Experimental Study On Steel Encased Buckling Restrained Brace Hysteretic Dampers PDFM. Murat ErginОценок пока нет

- Effect of Reinforcement StiffenersДокумент13 страницEffect of Reinforcement Stiffenersjust meОценок пока нет

- Behavior of External Column New Paper Fprma11tДокумент19 страницBehavior of External Column New Paper Fprma11tUpali KarunarathneОценок пока нет

- Copy First Phase Report MSДокумент39 страницCopy First Phase Report MSSREEKUMARA GANAPATHY V S stellamaryscoe.edu.inОценок пока нет

- Behaviour and Design of Structural Steel PinsДокумент28 страницBehaviour and Design of Structural Steel PinsJoão BarrigóОценок пока нет

- Ijciet 08 05 112Документ12 страницIjciet 08 05 112nagham tariqОценок пока нет

- Thesis On Steel Fibre Reinforced ConcreteДокумент8 страницThesis On Steel Fibre Reinforced Concretedenisemillerdesmoines100% (2)

- Innovative Technique For Seismic Upgrade of RC Square ColumnsДокумент15 страницInnovative Technique For Seismic Upgrade of RC Square Columns오상진Оценок пока нет

- Shear Behavior of Ultra-High-Strength Steel Fiber-Reinforced Self-Compacting Concrete BeamsДокумент8 страницShear Behavior of Ultra-High-Strength Steel Fiber-Reinforced Self-Compacting Concrete BeamsRawash OmarОценок пока нет

- Seismic Behavior of Steel Beam and Reinforced Concrete Column ConnectionsДокумент20 страницSeismic Behavior of Steel Beam and Reinforced Concrete Column Connectionsjuan carlosОценок пока нет

- Smeared Crack Models of RC Beams With Externally Bonded CFRP PlatesДокумент8 страницSmeared Crack Models of RC Beams With Externally Bonded CFRP Platessmadireddy1Оценок пока нет

- Reinforced HSC Beams Strengthened With CFRP Plates Under BendingДокумент33 страницыReinforced HSC Beams Strengthened With CFRP Plates Under BendingAafan ShahidОценок пока нет

- Shear Behaviour of Steel Fibre Reinforced Self-Compacting ConcreteДокумент8 страницShear Behaviour of Steel Fibre Reinforced Self-Compacting Concretejack21abОценок пока нет

- 10 18400-Tekderg 674889-1190133Документ26 страниц10 18400-Tekderg 674889-1190133natasha asnaОценок пока нет

- 86-S60confinement of Reinforced Concrete Columns With Welded Wire FabricДокумент9 страниц86-S60confinement of Reinforced Concrete Columns With Welded Wire Fabricshuangyaksa100% (1)

- Development of Cylindrical Shear Connector Inserted in Perforated Steel Plate and Apply To The Hybrid StructureДокумент12 страницDevelopment of Cylindrical Shear Connector Inserted in Perforated Steel Plate and Apply To The Hybrid Structureerky arkvathonejhОценок пока нет

- Articulo 1Документ16 страницArticulo 1Daniel Andres SanesОценок пока нет

- 1 s2.0 S1877705813003883 MainДокумент10 страниц1 s2.0 S1877705813003883 Mainfakher alaviОценок пока нет

- Elastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004Документ16 страницElastic Buckling Behavior of Steel Frames With Corrugated Steel Shear Wall 20-12-2004EliyaHeninОценок пока нет

- Strengthening of Two-Way Slabs Subjected To Moment and Cyclic LoadingДокумент10 страницStrengthening of Two-Way Slabs Subjected To Moment and Cyclic LoadingMarcel SteoleaОценок пока нет

- Analytical Performance of CFST Columns Under Axial CompressionДокумент10 страницAnalytical Performance of CFST Columns Under Axial CompressionIJRASETPublicationsОценок пока нет

- Research ReportДокумент31 страницаResearch ReportIshwarya SrikanthОценок пока нет

- PC Research PaperДокумент5 страницPC Research PaperghОценок пока нет

- 10 5923 J Cmaterials 20120203 02Документ10 страниц10 5923 J Cmaterials 20120203 02ashenafiОценок пока нет

- Design of Box CulvertДокумент11 страницDesign of Box Culvertjs kalyana ramaОценок пока нет

- Passive and Active Near Surface Mounted FRP Rods For Flexural Strengthening of RC BeamsДокумент12 страницPassive and Active Near Surface Mounted FRP Rods For Flexural Strengthening of RC BeamsmarkicivanОценок пока нет

- Seismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsДокумент10 страницSeismic Behavior of Short Coupling Beams With Different Reinforcement LayoutsleotramontinОценок пока нет

- Print Axial Capacity of Circular Concrete-Filled Tube ColumnsДокумент20 страницPrint Axial Capacity of Circular Concrete-Filled Tube ColumnsMona MahmoudОценок пока нет

- Encased ColumnsДокумент14 страницEncased ColumnsjimmyfontanaОценок пока нет

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesОт EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesОценок пока нет

- Rate - ErectionДокумент1 страницаRate - ErectionAnjum JauherОценок пока нет

- B.Tech (Civil Engineering) Part-II (Sem III & IV) Batch 2016 PDFДокумент27 страницB.Tech (Civil Engineering) Part-II (Sem III & IV) Batch 2016 PDFHoe BhajiОценок пока нет

- Constance Vertical Forced Convection Oven (FCH 9006 Series)Документ1 страницаConstance Vertical Forced Convection Oven (FCH 9006 Series)Uswatul HasanahОценок пока нет

- AN-P-CL 001 Recommendation For Civil Engineering and Construction of Chemical Plant Structures and InfrastructureДокумент33 страницыAN-P-CL 001 Recommendation For Civil Engineering and Construction of Chemical Plant Structures and InfrastructureRanjit Koshy AlexanderОценок пока нет

- Guidelines For Pipe Bursting: U.S. Army Corps of Engineers Engineering Research and Development Center (ERDC)Документ55 страницGuidelines For Pipe Bursting: U.S. Army Corps of Engineers Engineering Research and Development Center (ERDC)Pilar MartínezОценок пока нет

- Advanced Construction MaterialsДокумент16 страницAdvanced Construction MaterialsEsakki RajaОценок пока нет

- Ovm PrestressingДокумент68 страницOvm Prestressingnadeesha100% (1)

- Number:: Erico International Corporation 34600 Solon Road Solon, Ohio 44139 (800) 248-2677Документ11 страницNumber:: Erico International Corporation 34600 Solon Road Solon, Ohio 44139 (800) 248-2677Kevin ChanОценок пока нет

- GEOWEB Load Support Contruction PackageДокумент31 страницаGEOWEB Load Support Contruction PackageJohnEMERYОценок пока нет

- Part E2 Supplementary Trenchless SpecificationДокумент34 страницыPart E2 Supplementary Trenchless Specificationindra_sujatmikoОценок пока нет

- Final Exam Ce 1351 PDFДокумент1 страницаFinal Exam Ce 1351 PDFJustine Joy De LeonОценок пока нет

- Ice Breaker and Acceleration Record SelectionДокумент5 страницIce Breaker and Acceleration Record SelectionAdriansyah SiregarОценок пока нет

- Geotechnical Engineering ReportДокумент31 страницаGeotechnical Engineering ReportNadir Khattak Jr.Оценок пока нет

- Neptune Benson ANTI VORTEX PLATES Tech DataДокумент1 страницаNeptune Benson ANTI VORTEX PLATES Tech DatasyedahmedsabirОценок пока нет

- DWWQQWДокумент12 страницDWWQQWRanjanDsОценок пока нет

- Sewerage DesignДокумент21 страницаSewerage DesignJi Sian Lee100% (6)

- Tile Adhesive BrochureДокумент9 страницTile Adhesive BrochureOsama AbdulWahabОценок пока нет

- Two Way Slab Design Excel SheetДокумент11 страницTwo Way Slab Design Excel SheetZevanyaRolandTualakaОценок пока нет

- Commercial Brochure - Uponor Ecoflex Thermo and Varia - EN - 070813 - 55750Документ4 страницыCommercial Brochure - Uponor Ecoflex Thermo and Varia - EN - 070813 - 55750portocala12Оценок пока нет

- Element A - Frame Item Descriptions Unit QTY RateДокумент18 страницElement A - Frame Item Descriptions Unit QTY RateRubbyRdОценок пока нет

- CE3155-1-Introduction 2011Документ47 страницCE3155-1-Introduction 2011huiting loy100% (1)

- PUBL5510 CatalogДокумент368 страницPUBL5510 CataloghassОценок пока нет

- Design of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)Документ16 страницDesign of Shear Reinforcement in RCC Structures: Intended Learning Outcomes (ILO)anirbanpwd76Оценок пока нет

- Indeterminate Structures Flexibility MethodДокумент63 страницыIndeterminate Structures Flexibility MethodDebbySintaDeviОценок пока нет

- Final Assignment: Higher College of Technology Department of EngineeringДокумент4 страницыFinal Assignment: Higher College of Technology Department of EngineeringAdeel AhmedОценок пока нет

- Lec - 6Документ12 страницLec - 6Arif AhmedОценок пока нет

- Schedule C Attachment I For IFP Addendum No. 1 - REVIEWEDДокумент79 страницSchedule C Attachment I For IFP Addendum No. 1 - REVIEWEDJonald DagsaОценок пока нет

- Base Plate DesignДокумент8 страницBase Plate DesignHiep Truong Tuan100% (1)

- Guide For Installing RTR Pipe Courtesy Bondstrand For InfoДокумент4 страницыGuide For Installing RTR Pipe Courtesy Bondstrand For InfoHafiz Ali Alvi100% (1)

- Static MixerДокумент2 страницыStatic Mixerjemakl1568Оценок пока нет