Академический Документы

Профессиональный Документы

Культура Документы

FlowLine Level Transmitter Contact DeltaSpan LD30 Quick Start

Загружено:

PromagEnviro.comАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

FlowLine Level Transmitter Contact DeltaSpan LD30 Quick Start

Загружено:

PromagEnviro.comАвторское право:

Доступные форматы

Technical Support

For complete product documentation, video training, and technical support, go to www.flowline.com. For phone support, call 562-598-3015 from 8am to 5pm PST, Mon - Fri. (Please make sure you have the Part and Serial number available.) Flowline Inc. 10500 Humbolt St, Los Alamitos, CA 90720

Warranty

Flowline warrants to the original purchaser of its products that such products will be free from defects in material and workmanship under normal use and service in accordance with instructions furnished by Flowline for a period, which is equal to the shorter of one year from the date of purchase of such products or two years from the date of manufacture of such products. Flowline's obligation under this warranty is solely and exclusively limited to the repair or replacement, at Flowline's option, of the products or components, which Flowline's examination determines to its satisfaction to be defective in material or workmanship within the warranty period. Flowline must be notified pursuant to the instructions below of any claim under this warranty within thirty (30) days of any claimed lack of conformity of the product. Any product repaired or replaced under this warranty will be warranted only for the remainder of the original warranty period.

Returns

Products cannot be returned to Flowline without Flowline's prior authorization. To return a product that is thought to be defective, go to www.flowline.com, and submit a customer return (MRA) request form and follow the instructions therein. All warranty and non-warranty product returns to Flowline must be shipped prepaid and insured. Flowline will not be responsible for any products lost or damaged in shipment.

Limitations

This warranty does not apply to products which: 1) are beyond the warranty period or are products for which the original purchaser does not follow the warranty procedures outlined above; 2) have been subjected to electrical, mechanical or chemical damage due to improper, accidental or negligent use; 3) have been modified or altered; 4) anyone other than service personnel authorized by Flowline have attempted to repair; 5) have been involved in accidents or natural disasters; or 6) are damaged during return shipment to Flowline. Flowline reserves the right to unilaterally waive this warranty and dispose of any product returned to Flowline where: 1) there is evidence of a potentially hazardous material present with the product; or 2) the product has remained unclaimed at Flowline for more than 30 days after Flowline has dutifully requested disposition. This warranty contains the sole express warranty made by Flowline in connection with its products. ALL IMPLIED WARRANTIES, INCLUDING WITHOUT LIMITATION, THE WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. The remedies of repair or replacement as stated above are the exclusive remedies for the breach of this warranty. IN NO EVENT SHALL FLOWLINE BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND INCLUDING PERSONAL OR REAL PROPERTY OR FOR INJURY TO ANY PERSON. THIS WARRANTY CONSTITUTES THE FINAL, COMPLETE AND EXCLUSIVE STATEMENT OF WARRANTY TERMS AND NO PERSON IS AUTHORIZED TO MAKE ANY OTHER WARRANTIES OR REPRESENTATIONS ON BEHALF OF FLOWLINE. This warranty will be interpreted pursuant to the laws of the State of California. If any portion of this warranty is held to be invalid or unenforceable for any reason, such finding will not invalidate any other provision of this warranty.

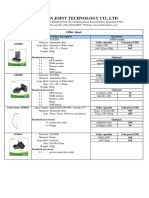

Model: LD30

DeltaSpan Industrial Pressure Transmitter

Quick Start

QS301030 Rev.B 2011 Flowline, Inc. All Rights Reserved Made in USA 10500 Humbolt Street, Los Alamitos, CA 90720 USA We do Your Level Best Tel: 562.598.3015 Fax: 562.431.8507 www.flowline.com

We do Your Level Best

Welcome to the DeltaSpan Quick Start

The DeltaSpan Quick Start is meant to show some of the more common setup solutions to getting the DeltaSpan up and running quickly. If you run into an issue that is not addressed here or wish to install or set up with a non-standard configuration, please address the DeltaSpan Manual or refer to the Flowline website at www.flowline.com.

Finally, check your Electrical Connections. The maximum length of wire connecting the transmitter and receiver is a function of wire size and receiver resistance. Wiring should not contribute more than 10% of the receiver resistance to total loop resistance. For runs exceeding 1000 feet, choose receivers with higher resistance to minimize the size and cost of connecting leads. Where wiring length is under 100 feet, wire as small as 22 AWG can be used. Electrical connections to the pressure transmitters are made to the terminal block located inside the housing. Remove the screws and lift off the cover. Wire as shown in the diagram below. When using cable version of General Purpose Housing with Cable, black wire is negative (-) and red wire is positive (+).

We Do Your Level Best

The LD30 Series Pressure Transmitters convert a single positive pressure into a standard 4-20 mA output signal. The LD30 Series can be used to accurately measure compatible gases and liquids; full scale accuracy is 0.25%. Designed for industrial environments with a NEMA 4X (IP66) housing, this transmitter resists most effects of shock and vibration. This Quick Start includes everything youll need to get the DeltaSpan up and running. For complete information, please refer to DeltaSpan documentation located at www.flowline.com.

CAUTION

Do not exceed specified supply voltage ratings. Permanent damage not covered by warranty will result. This device is not designed for 120 or 240 volt AC operation. Use only on 13 to 30 VDC.

Current Output

Current (4-20 mA) Output Operation

Pressure Ranges

Pressure Range (psig) Max. Distance Measured

Compensated Temperature Range 118 to 79 C 0 - 175 F

0-5

0-15 0-30

11.5 / 3.5M

34.6 / 10.1M 69.3 / 21.1m

An external power supply delivering 13-30 VDC with minimum current capability of 40 mA DC (per transmitter) is required to power the control loop. The Current Output diagram (above) shows the connection of the power supply, transmitter and receiver. The range of appropriate receiver load resistance (RL) for the DC power supply voltage available is expressed by the formula: RL Max = Vps-13 20 mA DC Shielded cable should always be used for control loop wiring. Maximum Loop Resistance is 1300ohms @ 30VDC.

Installation

First, select a location. The DeltaSpan should be located within a temperature range of 0 and 175F (-18 to 79C). Distance from the receiver is limited only by total loop resistance. While the tubing or piping supplying pressure to the unit can be practically any length, remember that long lengths will increase response time slightly. Next, position the DeltaSpan. Although the transmitter is not position sensitive, standard models are factory calibrated in a position with the pressure connection downward. The DeltaSpan functions at greatest accuracy in this position. Create a pressure connection. Use a small amount of plumbers tape or other suitable sealants to prevent leaks. Be sure the pressure passage inside the port is not blocked.

We do Your Level Best

Maintenance

After final installation of the pressure transmitter and its companion receiver, no routine maintenance is required. A periodic check of system calibration is suggested. The LD30 transmitters are not field repairable and should be returned if repair is needed.

Troubleshooting

If you face any issues not addressed in this Quick Start, please refer to the DeltaSpan Manual located on Flowline website at www.flowline.com. Where personal safety or significant property damage can occur due to a spill, the installation must have a redundant backup safety system installed.

We do Your Level Best

Вам также может понравиться

- Walchem Pump HRP Series BrochureДокумент2 страницыWalchem Pump HRP Series BrochurePromagEnviro.comОценок пока нет

- Walchem Pump Overview BrochureДокумент8 страницWalchem Pump Overview BrochurePromagEnviro.comОценок пока нет

- Walchem Pump LKN Series ManualДокумент38 страницWalchem Pump LKN Series ManualPromagEnviro.comОценок пока нет

- Walchem Pump Remote Cable Assembly InstructionsДокумент2 страницыWalchem Pump Remote Cable Assembly InstructionsPromagEnviro.comОценок пока нет

- Walchem Pump LKN Series BrochureДокумент2 страницыWalchem Pump LKN Series BrochurePromagEnviro.comОценок пока нет

- Walchem Pump High Pressure Spring InstallationДокумент1 страницаWalchem Pump High Pressure Spring InstallationPromagEnviro.comОценок пока нет

- Walchem Pump HRP Series ManualДокумент46 страницWalchem Pump HRP Series ManualPromagEnviro.comОценок пока нет

- Walchem Pump IX Series Manual, IXC060, IXC150Документ84 страницыWalchem Pump IX Series Manual, IXC060, IXC150PromagEnviro.comОценок пока нет

- Walchem Pump IX Series Brochure, IXC060, IXC150Документ4 страницыWalchem Pump IX Series Brochure, IXC060, IXC150PromagEnviro.comОценок пока нет

- Walchem Pump EW-F Series Manual, EWB, EWCДокумент35 страницWalchem Pump EW-F Series Manual, EWB, EWCPromagEnviro.comОценок пока нет

- Walchem Pump EZ Timer Module Instructions, EZB, EZCДокумент4 страницыWalchem Pump EZ Timer Module Instructions, EZB, EZCPromagEnviro.comОценок пока нет

- E00159 EZ11 ManualДокумент31 страницаE00159 EZ11 ManualRobert RojasОценок пока нет

- Walchem Pump EZ Series Brochure, EZB, EZCДокумент4 страницыWalchem Pump EZ Series Brochure, EZB, EZCPromagEnviro.comОценок пока нет

- Walchem Pump EW-Y Series ManualДокумент39 страницWalchem Pump EW-Y Series ManualPromagEnviro.comОценок пока нет

- Walchem Pump EWN-Y Series BrochureДокумент4 страницыWalchem Pump EWN-Y Series BrochurePromagEnviro.comОценок пока нет

- Walchem Pump EWN-Y Series ManualДокумент128 страницWalchem Pump EWN-Y Series ManualPromagEnviro.comОценок пока нет

- Walchem Pump EH-HV Series Manual, EWN, EHE35E1, EHE35E2Документ124 страницыWalchem Pump EH-HV Series Manual, EWN, EHE35E1, EHE35E2PromagEnviro.comОценок пока нет

- Stenner SVP1 Series Peristaltic Metering Pump Spec SheetДокумент2 страницыStenner SVP1 Series Peristaltic Metering Pump Spec SheetPromagEnviro.comОценок пока нет

- Walchem Pump EW Series Brochure, EWB, EWCДокумент4 страницыWalchem Pump EW Series Brochure, EWB, EWCPromagEnviro.comОценок пока нет

- Walchem Pump EH-HV Series Manual, EWN, EHE35E1, EHE35E2Документ124 страницыWalchem Pump EH-HV Series Manual, EWN, EHE35E1, EHE35E2PromagEnviro.comОценок пока нет

- Walchem Pump EK Series Brochure, EKB, EKCДокумент4 страницыWalchem Pump EK Series Brochure, EKB, EKCPromagEnviro.comОценок пока нет

- Walchem Pump EW-F Series Manual, EWB, EWCДокумент35 страницWalchem Pump EW-F Series Manual, EWB, EWCPromagEnviro.comОценок пока нет

- Walchem Pump EHE Series Brochure, EHE31, EHE36, EHE46, EHE56Документ4 страницыWalchem Pump EHE Series Brochure, EHE31, EHE36, EHE46, EHE56PromagEnviro.comОценок пока нет

- Walchem Pump EH-HV Series Brochure, EWN, EHE35E1, EHE35E2Документ2 страницыWalchem Pump EH-HV Series Brochure, EWN, EHE35E1, EHE35E2PromagEnviro.comОценок пока нет

- Stenner SVP1 Series Peristaltic Metering Pump Spec SheetДокумент2 страницыStenner SVP1 Series Peristaltic Metering Pump Spec SheetPromagEnviro.comОценок пока нет

- Stenner SVP Series Pump FAQ Frequently Asked QuestionsДокумент1 страницаStenner SVP Series Pump FAQ Frequently Asked QuestionsPromagEnviro.comОценок пока нет

- Walchem Pump EHE Series Manual, EHE31, EHE36, EHE46, EHE56Документ35 страницWalchem Pump EHE Series Manual, EHE31, EHE36, EHE46, EHE56PromagEnviro.comОценок пока нет

- Stenner SVP Series Peristaltic Metering Pump Manual QuickPro AddendumДокумент2 страницыStenner SVP Series Peristaltic Metering Pump Manual QuickPro AddendumPromagEnviro.comОценок пока нет

- Stenner SVP Series Peristaltic Metering Pump Manual (Without QuickPro Addendum)Документ80 страницStenner SVP Series Peristaltic Metering Pump Manual (Without QuickPro Addendum)PromagEnviro.comОценок пока нет

- Stenner SVP Series Peristaltic Metering Pump Manual QuickPro AddendumДокумент2 страницыStenner SVP Series Peristaltic Metering Pump Manual QuickPro AddendumPromagEnviro.comОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Check List of MossesДокумент319 страницCheck List of MossesAshen NirodyaОценок пока нет

- Toolbox Meeting Or, TBT (Toolbox TalkДокумент10 страницToolbox Meeting Or, TBT (Toolbox TalkHarold PonceОценок пока нет

- Example 02 - Moment Capacity of A Concrete Beam - Reinforced Concrete Design ReviewДокумент5 страницExample 02 - Moment Capacity of A Concrete Beam - Reinforced Concrete Design ReviewJohn Michael GeneralОценок пока нет

- Vehicle Tracker Offer SheetДокумент1 страницаVehicle Tracker Offer SheetBihun PandaОценок пока нет

- Ucc 900 Sor em Wpi 0001 - B01Документ73 страницыUcc 900 Sor em Wpi 0001 - B01JonesОценок пока нет

- 182 - GE8076, GE6075 Professional Ethics in Engineering - 2 MarksДокумент17 страниц182 - GE8076, GE6075 Professional Ethics in Engineering - 2 Markssharon sylvia .sОценок пока нет

- CDM 856 WheelloaderweichaiengineДокумент1 страницаCDM 856 WheelloaderweichaiengineRusmiyanto YantoОценок пока нет

- Proposal BP3IP FinalДокумент3 страницыProposal BP3IP FinalGiant SeptiantoОценок пока нет

- Efficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar ExtractionsДокумент10 страницEfficacy of Platelet-Rich Fibrin On Socket Healing After Mandibular Third Molar Extractionsxiaoxin zhangОценок пока нет

- Kerala University 2013 Admission ProspectusДокумент50 страницKerala University 2013 Admission ProspectusMuneer SainulabdeenОценок пока нет

- CP QB PT-3 Harish KumarДокумент3 страницыCP QB PT-3 Harish KumarVISHNU7 77Оценок пока нет

- A6V12050595 - Valve Actuator DIL-Switch Characteristic Overview - deДокумент42 страницыA6V12050595 - Valve Actuator DIL-Switch Characteristic Overview - depolo poloОценок пока нет

- Section V - Contract Adminstration Procedures Major BuildingsДокумент13 страницSection V - Contract Adminstration Procedures Major BuildingsAyodele Oluwaseyi DinaОценок пока нет

- CS 704 Socio-Emotional and Moral Development in Middle ChildhoodДокумент25 страницCS 704 Socio-Emotional and Moral Development in Middle ChildhoodPatricia PamintuanОценок пока нет

- Grupo Stoncor Description - Stonhard Carboline Fibergrate PDFДокумент22 страницыGrupo Stoncor Description - Stonhard Carboline Fibergrate PDFAndres OsorioОценок пока нет

- Eccsa Five Year (2014 15 - 2018 19) Strategic PlanДокумент95 страницEccsa Five Year (2014 15 - 2018 19) Strategic Planyayehyirad100% (1)

- Đề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnДокумент22 страницыĐề Minh Họa 2020 Số 23 - GV Trang Anh - Moon.vnLily LeeОценок пока нет

- Sculptures by The SeaДокумент1 страницаSculptures by The Seaapi-457802597Оценок пока нет

- Keynote Proficient End-Of-Course Test BДокумент7 страницKeynote Proficient End-Of-Course Test Bana maria csalinasОценок пока нет

- An Introduction To Pascal Programming MOD 2010Документ5 страницAn Introduction To Pascal Programming MOD 2010Johnas DalusongОценок пока нет

- Hemispherical Head Design ToolДокумент1 страницаHemispherical Head Design Toolnaveen_86Оценок пока нет

- Detect and Diagnose HVAC Equipment ErrorsДокумент1 страницаDetect and Diagnose HVAC Equipment ErrorsCatalin DragomirОценок пока нет

- Flap System RiginДокумент12 страницFlap System RiginHarold Reyes100% (1)

- Overview On Image Captioning TechniquesДокумент6 страницOverview On Image Captioning TechniquesWARSE JournalsОценок пока нет

- IIT BOMBAY RESUME by SathyamoorthyДокумент1 страницаIIT BOMBAY RESUME by SathyamoorthySathyamoorthy VenkateshОценок пока нет

- Development Drop - Number - Peformance - For - EstimateДокумент11 страницDevelopment Drop - Number - Peformance - For - Estimateanon_459056029Оценок пока нет

- Mini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler ModulesДокумент2 страницыMini-Com Cat6E - ®TX6 ™ PLUS UTP Coupler Moduleslejlas77Оценок пока нет

- Aw MD700 Manual G10 150706Документ73 страницыAw MD700 Manual G10 150706Heraldo Ulguim Luis OliveiraОценок пока нет

- Veiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inДокумент8 страницVeiga Et Al. 2015 - Composition, Structure and Floristic Diversity in Dense Rain Forest inYakov Mario QuinterosОценок пока нет

- An Overview On Recognition of State in International LawДокумент17 страницAn Overview On Recognition of State in International LawRamanah VОценок пока нет