Академический Документы

Профессиональный Документы

Культура Документы

TRI-CORE Insulation Catalog2010

Загружено:

esagcojrИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TRI-CORE Insulation Catalog2010

Загружено:

esagcojrАвторское право:

Доступные форматы

TRI*CORE

SINGLE INTERNAL/EXTERNAL OR

DOUBLE-WALLED COMPOSITE INSULATION

"PATENT PENDING"

AAA TECHNOLOGY & SPECIALTIES CO., INC

Celerating 39 Years of Service to Industry

Since 1971

ION

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

Introduction to TRI*CORE

TRI*CORE is another premier Composite Insulation Shield exclusive from AAA TECHNOLGY & SPECIALTIES CO., INC. This

product designed as a composite reinforced material can be up to 40 times stiffer and at least 10 times stronger than

Polyurethane Insulation alone, depending on thickness and selected densities. It is used for areas that will be exposed to

rubbing, vibration or small impact loadings while dramatically increasing strength. It replaces the need for a vapor barriers ,

internal shieldings and the use of mastics.

TRI*CORE acts as a second skin protection, reinforcing the contact surface. The Fiberglass reinforced materials bonded to

the Polyurethane Foam core acts as a continuous multi-directional "I-Beam", which is proportionally stronger and stiffer

depending on the thickness and density of the insulation.

Made from molded Fiberglass reinforced Vinyl Ester and Epoxy resins bonded to Polyurethane Foam, TRI*CORE

Insulation provides a non-conductive surface that enhances the compressive strength of the Polyurethane. It further can

be glued directly to the pipe using epoxy adhesives. Being non-metallic this product not only insulates but also prevents

surface induced corrosion by keeping out moisture while also isolating from electrical continuity and has a superior

chemical resistance.

Our TRI*CORE Pipe Supports insulates from induced electrical currents that may filter from the ground acting as a barrier

that can cause localized corrosion to your pipeline while also inhibiting electrical shock. It further is lighter and more

transportable, speeding up installations and reducing transportation costs. These combined materials provide greater

bearing strengths while at the same time acting as a corrosion, electrical and insulation barrier.

TRI*CORE is available as an Internal/External or Double-Walled Composite Polyurethane sandwiched material.

When used as a single composite over/under the Polyurethane Insulation the contact surface acts as a wear pad, capable

of handling some friction and protecting the foam component internally or externally, while adding additional strength as a

"T-Beam". The double-walled version protects the insulation both internally and externally and acts as a continuous "IBeam", for enhanced strength and rigidity.

Light Duty TRI*CORE composites insulation is typically used with a single composite internal or external pad bonded to

the Polyurethane which is made of 2 lb/in to 6 lb/in density insulation. UV mastic coating can be added to any exposed

surfaces.

Medium Duty TRI*CORE composites is used with a medium density foam of 8 lb/in to 12 lb/in with either an internal or external

composite surface. In medium duty applications, double-walled surfaces can be added for internal and external support where

enhanced strength characteristics where needed.

Heavy Duty TRI*CORE composites is used with 12 lb/in to 20 lb/in density foam with either an internal or external

composite surface. The composite component can also be thicker to increase strength and is used preferably for heavy load

applications as double-walled high density Polyurethane foam core.

TRI*CORE Pipe supports can be used with our standard galvanized or painted steel pipe supports or our exclusive

TRI*COMPOSITE Pipe Supports, please refer to our Composite Catalog for additional details. Our Pipe Supports are

optionally available with our TRI*SLIDE Low Friction Slide Bearings that allow axial movement that can be guided or

directionally constrained. Please refer to our TRI*SLIDE catalog for types, capacities and sizing for your slide bearing

needs. These are stainless over stainless or Teflon over stainless and even Graphite over stainless as described in our TRI*SLIDE

guides.

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TABLE OF CONTENTS

Polyurethane Properties...

3, 4, 5

Testing and Scope of Work.....

....6

Shipping & Handling...

....7

Correspondence....

....8

Model Numbers and Description..

....9

Single Outer Reinforced Insulation.....

..10

Double-Walled Reinforced Insualtion.....

..11

Shoe Support Type....

..12

Graphical Selection Guide ....

13, 14

SWP - 180...

..15

DWP - 180..

..16

SWP - 360..

..17

DWP - 360...

..18

SWP - 180MS........19

DWP - 180MS..

..20

SWP - 360BC...

..21

DWP - 360BC..

..22

SWP - 180MS - FB...

..23

DWP - 180MS - FB...

..24

SWP - 360BC - FB..

..25

DWP - 360BC- FB..

..26

SWP - 360BC - DW.....

..27

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TABLE OF CONTENTS

DWP - 360BC - DW...

28

SWP - 360BC - DW - GC

29

DWP - 360BC - DW - GC...

30

SWP - 360BC - DW - BG.....

31

DWP - 360BC - DW - BG.

32

SWP - 360BC - DW - AG...

33

DWP - 360BC - DW - AG.

34

SWP - 360BC - DW - ST ..

35

DWP - 360BC - DW - ST....

36

SWP - 360BC - DW - ST & AG.....

37

DWP - 360BC - DW - ST & AG..

38

SWP -180 - HCV...

39

DWP - 180 - HCV...

40

SWP - 360 - HC.

41

DWP - 360 - HC..

42

SWP - 90 - FS....

43

DWP - 90 - FS..

44

SWP - 180 - FS..45

DWP - 180 - FS...46

SWP - 360 - FS..... 47

DWP - 360 - FS.... 48

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TRI*CORE High Density Polyurethane Pipe Supports

For Low Temperature Applications

This specification has been prepared to set forth the requirements for the design, the manufacturing, the

proper selection and the use of low temperature, load bearing, insulated pipe supports. This specification

covers low temperature, load bearing, insulated pipe supports for use with piping systems operating at

temperatures between -425 F (-254 C) to 275 F (135 C).

General Requirements

1. All low temperature, insulated piping shall be supported using insulated pipe supports.

2. All insulated pipe supports shall comply with the latest editions of the following piping codes and

Manufacturer'sStandards:

a. ANSI/ASME B31.1 Power Piping Code

b. ANSI/ASME B31.3 Refinery and Chemical Plant Piping Code

c. ANSI/ASME B31.4 Liquid Petroleum Piping Code

d. ANSI/ASME B31.5 Refrigeration Piping Code

e. ANSI/ASME B31.8 Gas Transmission and Distribution Piping Code

f. Manufacturer's Standardization Society MSS SP-58

g. Manufacturer's Standardization Society MSS SP-69

h. Manufacturer's Standardization Society MSS SP-89

i. Federal Specification WW-H-171D

3. The selection of all low temperature, load bearing, insulated pipe supports shall be based upon the

following considerations:

a. Maximum design loads that will be applied to the pipe support along the vertical, axial and lateral

axes from the primary and secondary loadings.

b. Maximum test loads that will be applied to the pipe support along the vertical, axial, lateral axes.

c. Maximum design load that may be applied to the pipe support along the vertical, axial and lateral

axes from occasional loading such as water hammer, seismic or impact type loads.

d. Maximum deflection and rotations along the vertical, axial and lateral axes that are expected to

occur and in what condition normal operating, testing, upset, seismic, water hammer, etc.

e. Lowest possible temperature expected to occur in the piping system.

f. Highest possible temperature expected to occur in the piping system.

g. Highest and lowest possible ambient temperature expected to be experienced.

h. Any dimensional clearances that may require during installation, testing or operating piping system.

i. Any localized welds or lug that is to be covered properly by low temperature, load bearing.

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TRI*CORE High Density Polyurethane Pipe Supports

For Low Temperature Applications

4. At the request of the Owner, design calculations and supporting data shall be made available.

5. At the request of the Owner, piping stress analysis calculations shall be made available as well as

Calculations indicating the stresses in the pipe wall at any attachment/lug juncture.

6. At the request of the Owner, material test reports or certified mill test reports may be requested.

TRI*FOAM High Density Polyurethane Properties

1. High density polyurethane shall have the following properties:

a. 6lb/ft foam

i. Thermal Conductivity = .16 BTU-in/ft - hr deg F (Imperial), 0.024 W/meter*K (SI)

ii. Thermal Resistance = 6.3 hr deg F - ft / BTU (Imperial), 1.11 m - K/W (SI)

iii. Density = 6 lbs/ft (Imperial), 96.111 Kg/M (SI) (+/- 15%)

iv. Ninety-five percent of the cells are closed

v. Water absorption = .05 lbs/ft (Imperial), 4.8055 Kg/m

b. 10lb/ft foam

i. Thermal Conductivity = .17 BTU-in/ft - hr deg F (Imperial), 0.024 W/meter*K (SI)

ii. Thermal Resistance = 5.9 hr deg F - ft / BTU (Imperial), 1.04 m - K/W (SI)

iii. Density = 10 lbs/ft (Imperial), 160.185 Kg/M (SI) (+/- 15%)

iv. Ninety-five percent of the cells are closed

v. Water absorption = .05 lbs/ft (Imperial), 4.8055 Kg/m

c. 15lb/ft foam

i. Thermal Conductivity = .19 BTU-in/ft - hr deg F (Imperial), 0.027 W/meter*K (SI)

ii. Thermal Resistance = 5.3 hr deg F - ft / BTU (Imperial), 0.901 m - K/W (SI)

iii. Density = 15 lbs/ft (Imperial), 240.277 Kg/M (SI) (+/- 15%)

iv. Ninety-five percent of the cells are closed

v. Water absorption = .05 lbs/ft (Imperial), 4.8055 Kg/m

d. 20lb/ft foam

i. Thermal Conductivity = .25 BTU-in/ft - hr deg F (Imperial), 0.035 W/meter*K (SI)

ii. Thermal Resistance = 4.2 hr deg F - ft / BTU (Imperial), 0.714 m - K/W (SI)

iii. Density = 20 lbs/ft (Imperial), 320.369 Kg/M (SI) (+/- 15%)

iv. Ninety-five percent of the cells are closed

v. Water absorption = .05 lbs/ft (Imperial), 4.8055 Kg/m

2. No CFC's shall be used in the fabrication process and no CFC's shall be contained in the high density

polyurethane pipe supports to be supplied.

4

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TRI*CORE High Density Polyurethane Pipe Supports

For Low Temperature Applications

TRI*FOAM High Density Polyurethane Saddle Properties

1. The high density polyurethane saddle shall have the following properties:

a. The insulation I.D. and the O.D. dimensions shall be manufactured in accordance with the ASTM

Specification C 585 unless otherwise specified.

b. The saddle shall be provided fully assembled with sufficient high density polyurethane insulation

extending beyond the support outer metal jacket in order to enable the insulator to make standard

butt joints.

c. The exposed polyurethane surfaces shall be coated with mastic to protect the foam from ultraviolet

light degradation and moisture. Mastic used shall have a minimum perm rating of.02 in accordance

with ASTM E-96.

d. A vapor barrier shall be provided between the jacket and the high density polyurethane insulation

with amaximum perm rating of .02.

e. The high density polyurethane pipe support assembly shall be designed to provide for a sufficient

clamping force on the pipe to assure that the pipe support assembly will move axially with the pipe.

The axial loading conditions shall not exceed the design loads for which the pipe support assembly

has been designed.

TRI*FOAM Saddle Properties- Others

1. The saddle shall have the following properties for components other than the Polyurethane Saddle:

a. All structural shapes and plate shall be of ASTM A-36, unless otherwise specified.

b. All bolts/studs greater than " in diameter shall be of ASTM A-193, Grade B7, unless otherwise specified.

c. All bolts and nuts less or equal to " in diameter shall be ASTM A-307, unless otherwise specified.

d. All Nuts greater than " in diameter shall be ASTM A-194, Grade B7, unless otherwise specified.

e. All high density polyurethane pipe support assemblies selected with a low friction slide plate assembly

shall have two slide plate surfaces at each support point. Each slide plate assembly shall consist of a

mating slide plates as follows:

i. Top - 3/32" thick glass filled reinforced Teflon bonded to a 10 ga. Carbon steel backing plate;

Bottom - 3/32" thick glass filled reinforced Teflon bonded to a 10 ga. Carbon steel backing plate.

ii. Top - 1/16" thick stainless steel plate welded to 10 ga. Carbon steel backing plate;

Bottom - 3/32" thick glass filled reinforced Teflon bonded to a 10 ga. Carbon steel backing plate.

iii. Top - 1/16" thick stainless steel plate welded to 10 ga. Carbon steel backing plate;

Bottom - " thick polyurethane slide bearing box restrained on a 10 ga. Carbon steel backing plate.

iv. For slide bearing assembly details, see the TRI*SLIDE literature published by AAA Technology and

Specialties Co., Inc.

5

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TRI*CORE High Density Polyurethane Pipe Supports

For Low Temperature Applications

Testing Standards for TRI*FOAM High Density Polyurethane Saddle

1. At the request of the owner, supplier shall provide compressive strength and thermal testing results of high

densitypolyurethane saddles conducted by an independent testing laboratory in accordance to MSS SP-89.

Testing of high density polyurethane samples shall take place at a temperature of -250 F (-156 C).

2. All tests performed to determine the load bearing capabilities of high density polyurethane saddles shall be

conducted in accordance with ASTM D16221, Standard Test Method for Compressive Properties of Rigid

Cellular Plastics.

3. A safety factor of 5.0 shall be used in determining maximum loads to be resisted by the high density

polyurethane pipe supports at the design temperature.

4. All tests performed to determine the thermal conductivity of high density polyurethane saddles shall be

conducted in accordance with ASTM C 177-85, Steady State Heat Flux Measurements and Thermal

Transmission Properties by means of the Guarded Hot Plate Apparatus.

Scope of Work

1. All high density polyurethane pipe support assemblies shall include:

a. The high density polyurethane saddle(s),

b. The vapor barrier,

c. The metal jacket,

d. The fabricated steel casing,

e. The low friction slide bearings, if specified by owner,

f. The guide and line stops, if specified by owner,

g. Tagging, and

h. Any associated pipe hanger hardware or structural members, if specified by owner.

2. All pipes are the responsibility of the purchaser.

3. All non-load bearing insulation is not the responsibility of the purchaser.

4. All items not clearly identified as being required from the pipe support manufacturer shall be the

responsibility of the purchaser.

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TRI*CORE High Density Polyurethane Pipe Supports

For Low Temperature Applications

Shipping and Handling

1. Each high density polyurethane pipe support assembly shall be clearly and permanently marked with the

support Identification number as specified by the owner. The marking shall be permanent in nature and

shall withstand water and fading when exposed to sunlight for a minimum period of five (5) years.

2. The mark shall be placed on the high density polyurethane pipe support assembly in a location that is visible

and readable to an observer from ten (10) feet away from the pipe support assembly.

3. Each high density polyurethane pipe support shall be shipped on a pallet with reinforced cardboard

protection for all exposed polyurethane surfaces or in a reinforced cardboard box strong enough to prevent

damage while assembly is in transit. Care shall be taken when packaging the high density polyurethane pipe

support assemblies so that damage shall not occur when individual pipe support assemblies shift during

shipment. All high density polyurethane pipes support assemblies shall be individually wrapped in plastic.

4. Each container shall be clearly marked with a unique number and each container shall have an individual

packing list in the container as well as attached to the outside of the container.

5. Prior to installation in the Owner's plant, the high density polyurethane pipe support assemblies shall be

stored in a dry covered area to avoid exposure to rain, moisture and sunlight.

6. At the time of the shipment, the supplier shall furnish installation instructions necessary for the proper

installation of each style of high density polyurethane pipe support assemblies being provided.

Quotations

1. All quotations for the pipe supports defined herein shall be submitted to __________________.

2. All quotations for the pipe supports defined herein shall be for all components defined herein. In the event

that you wish to submit a quotation for an alternate item, you must first define your price for the item and

then define your alternate, its costs and the advantage of your alternate offers.

3. The manufacturer of all pipe supports defined herein shall be AAA Technology and Specialties Co., Inc., 6219

Brittmoore Road, Houston, Texas 77041-5114 or an approved equal. AAA Technology may be contacted by

E-mail at info@aaatech.com or by telephone at (713) 849-3366 or by Fax at (713) 849-3654.

4. All quotations must include unit and extended pricing for each pipe support assembly. In addition, a total

price for all items proposed are to be supplied.

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

TRI*CORE High Density Polyurethane Pipe Supports

For Low Temperature Applications

Correspondence

1. All correspondence, drawings and other data must have the inquiry number or the order number marked

on it prominently.

2. All correspondence relating to the design or any engineering data for the pipe supports covered under this

inquiry shall be sent to: _______________________________.

3. All correspondence relating to any shipping information including weights and dimensions, and changes

orders or specification not covered by formal Change Order to the Purchase Order shall be sent

to: __________________________________.

Delivery

1. All pipe supports are to be delivered to the job site by _____________________.

2. The job site is located at: _______________________________.

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

Model Numbers and Description

TRI*CORE Reinforced Polyurethane Pipe Supports

Cold Shoe are Code with Type , Size, Dimension and Material as Follow:

Example:

3" - SWP360BC - 4"x 12" - DW/S1/GP - 6"Ins. - AG/HD

Pipe Size

Support and Duty TYPE

Mean Single Wear Pad

360 and Type Saddle

BOP and Length

Insulation Thick

Pipe Shoe Type

Slot Option and Gusset Plate

Model Numbers and Description of Code

Type

S1

Description of Slot Option

Type

Expansion Slot

FB

Description of Supprot

Flat Bottom

S2

Insulation Band Slot

BG

Beam Guide

S3

Expanison Slot & Insulation Band Slot

CG

Clip Guide

GP

Gusset Plate

AG

Angle Guide

RIB

Rib Plate

ST

Line Stop

AG& ST

Type

HDC

HC

HCV

Description of Saddle

FS

Angle Guide & Line Stop

Foam Support

Hold Down CLamp

Hanger Clamp

Hanger Clevis

BC

Body Clamp

MS

Metal Saddle

Type

T

DW

Description of Pipe Shoe

Tee

Double Web

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

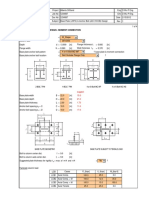

Detail of 180 deg. and 360 deg.

TRI*CORE Reinforced Polyurethane Pipe Supports

SINGLE WEAR PAD

180 degree one layer

If Insulation is thicker

than 3", two layers shall

be used.

180 degree double layer

180 degree one layer

180 degree double layer

WEAR PAD.

INSULATION

INSULATION

INSULATION

WEAR PAD

1" TYP.

2" TYP.

Detail of one layer with saddle

Detail of two layer with Saddle

10

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

Detail of 180 deg. and 360 deg.

TRI*CORE Reinforced Polyurethane Pipe Supports

DOUBLE WEAR PAD

180 degree one layer

If Insulation is thicker

than 3", two layers

shall be used.

180 degree double layer

180 degree one layer

180 degree double layer

WEAR PAD.

INSULATION

WEAR PAD

INSULATION

INSULATION

WEAR PAD.

WEAR PAD.

1" TYP.

2" TYP.

Detail of one layer with saddle

Detail of two layer with Saddle

11

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

Slot Option Detail

TRI*CORE High Density Pipe Shoe Support

TYPE S1

TYPE S2

Expansion Slot

Insulation Band Slot

TYPE S3

TYPE GP

Insulation Band & Expansion Slot

Gusset Plate

12

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

SWP -180

PAGE 15

DWP - 180

PAGE 16

SWP - 360

PAGE 17

DWP - 360

PAGE 18

SWP - 180MS

PAGE 10

DWP - 180MS

PAGE 20

SWP - 360BC

PAGE 21

DWP - 360BC

PAGE 22

SWP - 180MS - FB

PAGE 23

DWP - 180MS - FB

PAGE 24

SWP - 360BC - FB

PAGE 25

DWP - 360BC - FB

PAGE 26

SWP - 360BC - DW

PAGE 27

DWP - 360BC - DW

PAGE 28

SWP - 360BC - DW - GC

PAGE 29

DWP - 360BC- DW- GC

PAGE 30

SWP - 360BC - DW - BG

PAGE 31

DWP - 360BC - DW - BG

PAGE 32

SWP - 360BC - DW - AG

PAGE 33

DWP - 360BC- DW- AG

PAGE 34

13

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

SWP - 360BC - DW - ST

PAGE 35

DWP - 360BC - DW - ST

PAGE 36

SWP - 360BC - DW - ST & AG

PAGE 37

DWP - 360BC - DW - ST & AG

PAGE 38

SWP - 180 - HCV

PAGE 39

DWP - 180 - HCV

PAGE 40

SWP - 360 - HC

PAGE 41

DWP - 360 - HC

PAGE 42

SWP - 90 - FS

PAGE 43

DWP - 90 - FS

PAGE 44

SWP - 180 - FS

PAGE 45

DWP - 180 - FS

PAGE 46

SWP - 360 - FS

PAGE 47

DWP - 360 - FS

PAGE 48

14

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

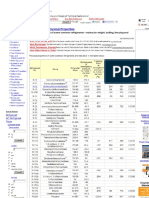

SWP - 180

O.D.

INS. THK.

SINGLE WEAR PAD.

INSULATION

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Light or Medium Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

1 "

2"

3"

4"

1/2"

3/4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

121"

120

155

1/4"

12

278"

12

321"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

12 1034"

12 1034"

18

958"

1034"

1034"

1134"

1134"

1234"

18

14"

18

14"

18

15"

16"

24

17"

PIPE

SIZE

2"

LIGHT MEDIUM

DUTY DUTY

155

185

PAD

THK.

12

321"

5169 "

5"

12

12

521"

12

5169 "

12

658"

12

658"

12

658"

12

18

758"

18

18

858"

18

4"

4"

12

421"

12

12

421"

12

5"

1/4"

12

5"

12

415

1/4"

12

5169 "

12

530

1/4"

185

225

1/4"

12

3"

215

275

1/4"

321"

275

345

4"

335

5"

435

421"

12

12

1/4"

221"

12

12

658"

12

24

758"

758"

858"

858"

958"

1034"

1234"

12

758"

12

18

858"

858"

958"

958"

1034"

1134"

12

858"

12

12

12

18

958"

958"

1034"

1034"

1134"

1234"

24

14"

24

15"

24

6"

495

610

1/4"

8"

555

690

1/4"

24

658"

658"

758"

758"

858"

958"

1134"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

15

12

12

12

18

18

12

12

12

18

12

12

12

18

12

12

12

12 1134"

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

DWP - 180

O.D.

INS. THK.

DOUBLE WEAR PAD

INSULATION

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Light or Medium Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

1 "

2"

3"

4"

1/2"

3/4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

121"

120

155

1/4"

12

278"

12

321"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

12 1034"

12 1034"

18

958"

1034"

1034"

1134"

1134"

1234"

18

14"

18

14"

18

15"

16"

24

17"

PIPE

SIZE

2"

LIGHT MEDIUM

DUTY DUTY

155

185

PAD

THK.

12

321"

5169 "

5"

12

12

521"

12

5169 "

12

658"

12

658"

12

658"

12

18

758"

18

18

858"

18

4"

4"

12

421"

12

12

421"

12

5"

1/4"

12

5"

12

415

1/4"

12

5169 "

12

530

1/4"

185

225

1/4"

12

3"

215

275

1/4"

321"

275

345

4"

335

5"

435

421"

12

12

1/4"

221"

12

12

658"

12

24

758"

758"

858"

858"

958"

1034"

1234"

12

758"

12

18

858"

858"

958"

958"

1034"

1134"

12

858"

12

12

12

18

958"

958"

1034"

1034"

1134"

1234"

24

14"

24

15"

24

6"

495

610

1/4"

8"

555

690

1/4"

24

658"

658"

758"

758"

858"

958"

1134"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

16

12

12

12

18

18

12

12

12

18

12

12

12

18

12

12

12

12 1134"

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

SWP - 360

O.D.

INS. THK.

SINGLE WEAR PAD.

INSULATION

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Light or Medium Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

1 "

2"

3"

4"

1/2"

3/4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

121"

120

155

1/4"

12

278"

12

321"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

12 1034"

12

4"

12

421"

12

12

12

12

12

12 1034"

18

18

14"

18

858"

958"

958"

1034"

1034"

1134"

1234"

958"

1034"

1034"

1134"

1134"

1234"

18

758"

858"

858"

958"

958"

1034"

1134"

18

14"

18

15"

PIPE

SIZE

LIGHT MEDIUM

DUTY DUTY

PAD

THK.

2"

155

185

1/4"

12

321"

221"

185

225

1/4"

12

4"

12

421"

12

5"

12

3"

215

275

1/4"

12

421"

12

5"

12

521"

12

321"

275

345

1/4"

12

5"

12

5169 "

12

658"

12

12

5169 "

12

658"

12

658"

758"

858"

12

8"

555

690

1/4"

24

5169 "

658"

658"

758"

758"

858"

958"

1134"

24

658"

758"

758"

858"

858"

958"

1034"

1234"

24

14"

24

15"

24

16"

24

17"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

4"

335

415

1/4"

5"

435

530

1/4"

18

6"

495

610

1/4"

18

18

18

17

12

12

12

12

18

18

12

12

12

12

18

12

12

12

12

18

12

12

12

12

12 1134"

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

DWP - 360

O.D.

INS. THK.

DOUBLE WEAR PAD

INSULATION

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Light or Medium Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

PIPE

SIZE

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

2"

3"

4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

2

238"

238"

278"

321"

LIGHT MEDIUM

DUTY DUTY

PAD

THK.

1/2"

1"

65

85

1/4"

12

141"

85

105

1/4"

12

121"

120

155

1/4"

12

2"

155

185

1/4"

12

1 "

3/4"

12

278"

12

278"

12

4"

12

5"

12

12

12

421"

12

12

321"

321"

12

5"

12

12

278"

321"

321"

12

4"

12

5"

12

12

4"

12

421"

12

5169 "

12

12

5"

12

12

24

5169 "

5169 "

658"

658"

758"

758"

858"

858"

958"

1034"

1234"

12

221"

185

225

1/4"

12

4"

12

421"

3"

215

275

1/4"

12

421"

12

5"

12

521"

12

321"

275

345

1/4"

12

5"

12

5169 "

12

658"

12

4"

335

415

1/4"

12

5169 "

12

658"

12

658"

12

5"

435

530

1/4"

18

758"

18

18

858"

18

12

658"

12

18

658"

658"

758"

758"

858"

858"

958"

958"

1034"

1134"

24

12

12

12

12

858"

12

958"

12

12

958"

12

958"

18

858"

858"

958"

958"

1034"

1034"

1134"

1134"

1234"

18

14"

18

14"

18

15"

15"

24

16"

24

17"

12

758"

12

18

758"

758"

858"

858"

958"

958"

1034"

1034"

1134"

1234"

14"

24

12

12

12

12

12

12

12 1034"

12 1034"

6"

495

610

1/4"

8"

555

690

1/4"

24

658"

658"

758"

758"

858"

958"

1134"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

12

12

12

18

18

12

12

12

12

18

12

12

12

12

18

12

12

12

12

12 1134"

12 1134"

12 1234"

12 1234"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

18

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

SWP - 180MS

O.D.

INS. THK.

SINGLE WEAR PAD

BOP

1

2"

INSULATION

TYP.

"F"

1" TYP.

METAL SHIELD

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Medium or Heavy Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

* Steel Component are constructed of A - 36 Steel

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

1 "

2"

3"

4"

1/2"

3/4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

12

321"

12

4"

12

5"

12

12

12

12

421"

12

5169 "

12

12

421"

12

5"

12

658"

12

521"

658"

658"

758"

858"

12

12

18

958"

958"

1034"

1034"

1134"

1134"

1234"

12 1034"

4"

18

14"

18

18

858"

858"

958"

958"

1034"

1034"

1134"

1234"

12

12

758"

758"

858"

858"

958"

958"

1034"

1134"

18

14"

18

15"

PIPE MEDIUM HEAVY

DUTY

SIZE DUTY

PAD

THK.

121"

120

155

1/4"

12

2"

155

185

1/4"

12

278"

321"

221"

185

225

1/4"

12

4"

12

5"

12

12

8"

555

690

1/4"

24

658"

758"

758"

858"

958"

1134"

24

658"

658"

758"

758"

858"

858"

958"

1034"

1234"

24

14"

24

15"

24

16"

24

17"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

3"

215

275

1/4"

12

421"

321"

275

345

1/4"

12

5"

12

5169 "

4"

335

415

1/4"

12

9

516

"

12

658"

5"

435

530

1/4"

18

6"

495

610

1/4"

18

12

12

12

18

18

19

12

12

18

18

12

12

12

12

12

18

12

12

12

12

12

18

12

12

12

12

12

12 1034"

12 1134"

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

DWP - 180MS

O.D.

INS. THK.

DOUBLE WEAR PAD

BOP

1

2"

INSULATION

TYP.

METAL SHIELD

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Medium or Heavy Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

* Steel Component are constructed of A - 36 Steel

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

2"

3"

4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

9

516

"

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

9

516

"

12

658"

12

758"

12

858"

12

958"

121"

120

155

1/4"

12

278"

12

321"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

12 1034"

12

4"

12

421"

12

12

12

12

12

12 1034"

18

18

14"

18

858"

958"

958"

1034"

1034"

1134"

1234"

958"

1034"

1034"

1134"

1134"

1234"

18

758"

858"

858"

958"

958"

1034"

1134"

18

14"

18

15"

24

658"

758"

758"

858"

858"

958"

1034"

1234"

24

14"

24

15"

24

16"

24

17"

PIPE MEDIUM HEAVY

DUTY

SIZE DUTY

PAD

THK.

1/2"

1 "

3/4"

2"

155

185

1/4"

12

321"

221"

185

225

1/4"

12

4"

12

421"

12

5"

12

3"

215

275

1/4"

12

421"

12

5"

12

521"

12

5169 "

658"

12

658"

658"

758"

858"

12

5"

435

530

1/4"

18

6"

495

610

1/4"

18

8"

555

690

1/4"

24

5169 "

658"

658"

758"

758"

858"

958"

1134"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

321"

275

345

1/4"

12

5"

12

4"

335

415

1/4"

12

9

516

"

12

12

12

18

18

20

12

12

12

12

18

18

12

12

12

12

18

12

12

12

12

18

12

12

12

12

12 1134"

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

SWP - 360BC

O.D.

A-307 OR B7

BOLT/ STUDS

INS. THK.

SINGLE WEAR PAD

BOP

1

2"

INSULATION

TYP.

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Medium or Heavy Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

* Steel Component are constructed of A - 36 Steel

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

2"

3"

4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

12

12

321"

12

12 1034"

18

958"

958"

1034"

1034"

1134"

1134"

1234"

18

14"

18

18

858"

858"

958"

958"

1034"

1034"

1134"

1234"

12

12

758"

758"

858"

858"

958"

958"

1034"

1134"

12

12

658"

658"

758"

758"

858"

858"

958"

1034"

1234"

18

14"

18

15"

24

14"

24

15"

24

16"

24

17"

19"

PIPE MEDIUM HEAVY

DUTY

SIZE DUTY

121"

PAD

THK.

1/2"

1 "

3/4"

2"

155

185

1/4"

12

278"

321"

221"

185

225

1/4"

12

4"

12

5"

12

12

120

155

1/4"

12

4"

12

5"

12

4"

12

421"

12

12

421"

12

5"

12

521"

658"

658"

758"

858"

12

5169 "

658"

658"

758"

758"

858"

958"

1134"

24

12

12

12

12

12

12

12

12 1034"

12 1134"

3"

215

275

1/4"

12

421"

321"

275

345

1/4"

12

5"

12

5169 "

4"

335

415

1/4"

12

9

516

"

12

658"

5"

435

530

1/4"

18

6"

495

610

1/4"

18

8"

555

690

1/4"

24

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

12

12

12

18

18

21

12

12

12

18

18

12

12

12

18

12

12

12

18

12

12

12

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

DWP - 360BC

O.D.

A-307 OR B7

BOLT/ STUDS

INS. THK.

DOUBLE WEAR PAD

BOP

1

2"

INSULATION

TYP.

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Medium or Heavy Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

* Steel Component are constructed of A - 36 Steel

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

2"

3"

4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

12

12

321"

12

12 1034"

18

958"

958"

1034"

1034"

1134"

1134"

1234"

18

14"

18

18

858"

858"

958"

958"

1034"

1034"

1134"

1234"

12

12

758"

758"

858"

858"

958"

958"

1034"

1134"

12

12

658"

658"

758"

758"

858"

858"

958"

1034"

1234"

18

14"

18

15"

24

14"

24

15"

24

16"

24

17"

19"

PIPE MEDIUM HEAVY

DUTY

SIZE DUTY

121"

PAD

THK.

1/2"

1 "

3/4"

2"

155

185

1/4"

12

278"

321"

221"

185

225

1/4"

12

4"

12

5"

12

12

120

155

1/4"

12

4"

12

5"

12

4"

12

421"

12

12

421"

12

5"

12

521"

658"

658"

758"

858"

12

5169 "

658"

658"

758"

758"

858"

958"

1134"

24

12

12

12

12

12

12

12

12 1034"

12 1134"

3"

215

275

1/4"

12

421"

321"

275

345

1/4"

12

5"

12

5169 "

4"

335

415

1/4"

12

9

516

"

12

658"

5"

435

530

1/4"

18

6"

495

610

1/4"

18

8"

555

690

1/4"

24

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

12

12

12

18

18

22

12

12

12

18

18

12

12

12

18

12

12

12

18

12

12

12

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

SWP - 180MS - FB

O.D.

INS. THK.

SINGLE WEAR PAD

1

2"

INSULATION

TYP.

"F"

1" TYP.

METAL SHIELD

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Medium or Heavy Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

* Steel Component are constructed of A - 36 Steel

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

1 "

2"

3"

4"

1/2"

3/4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

12

321"

12

4"

12

5"

12

12

12

12

421"

12

5169 "

12

12

421"

12

5"

12

658"

12

521"

658"

658"

758"

858"

12

12

18

958"

958"

1034"

1034"

1134"

1134"

1234"

12 1034"

4"

18

14"

18

18

858"

858"

958"

958"

1034"

1034"

1134"

1234"

12

12

758"

758"

858"

858"

958"

958"

1034"

1134"

18

14"

18

15"

PIPE MEDIUM HEAVY

DUTY

SIZE DUTY

PAD

THK.

121"

120

155

1/4"

12

2"

155

185

1/4"

12

278"

321"

221"

185

225

1/4"

12

4"

12

5"

12

12

8"

555

690

1/4"

24

658"

758"

758"

858"

958"

1134"

24

658"

658"

758"

758"

858"

858"

958"

1034"

1234"

24

14"

24

15"

24

16"

24

17"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

3"

215

275

1/4"

12

421"

321"

275

345

1/4"

12

5"

12

5169 "

4"

335

415

1/4"

12

9

516

"

12

658"

5"

435

530

1/4"

18

6"

495

610

1/4"

18

12

12

12

18

18

23

12

12

18

18

12

12

12

12

12

18

12

12

12

12

12

18

12

12

12

12

12

12 1034"

12 1134"

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

DWP - 180MS - FB

O.D.

A-307 OR B7

BOLT/ STUDS

INS. THK.

SINGLE WEAR PAD

BOP

1

2"

INSULATION

TYP.

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Medium or Heavy Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

* Steel Component are constructed of A - 36 Steel

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

1 "

2"

3"

4"

1/2"

3/4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

12

321"

12

4"

12

5"

12

12

12

12

421"

12

5169 "

12

12

421"

12

5"

12

658"

12

521"

658"

658"

758"

858"

12

12

18

958"

958"

1034"

1034"

1134"

1134"

1234"

12 1034"

4"

18

14"

18

18

858"

858"

958"

958"

1034"

1034"

1134"

1234"

12

12

758"

758"

858"

858"

958"

958"

1034"

1134"

18

14"

18

15"

PIPE MEDIUM HEAVY

DUTY

SIZE DUTY

PAD

THK.

121"

120

155

1/4"

12

2"

155

185

1/4"

12

278"

321"

221"

185

225

1/4"

12

4"

12

5"

12

12

8"

555

690

1/4"

24

658"

758"

758"

858"

958"

1134"

24

658"

658"

758"

758"

858"

858"

958"

1034"

1234"

24

14"

24

15"

24

16"

24

17"

10"

615

775

1/4"

24

14"

24

15"

24

16"

24

17"

24

18"

24

19"

12"

675

845

1/4"

24

16"

24

17"

24

18"

24

19"

24

20"

24

21"

14"

700

885

1/4"

24

17"

24

18"

24

19"

24

20"

24

21"

24

22"

16"

750

925

1/4"

24

19"

24

20"

24

21"

24

22"

24

23"

24

24"

18"

775

975

1/4"

24

21"

24

22"

24

23"

24

24"

24

25"

24

26"

20"

835

1040

3/8"

24

23"

24

24"

24

25"

24

26"

24

27"

24

28"

24"

925

1160

3/8"

24

27"

24

28"

24

29"

24

30"

24

31"

24

32"

3"

215

275

1/4"

12

421"

321"

275

345

1/4"

12

5"

12

5169 "

4"

335

415

1/4"

12

9

516

"

12

658"

5"

435

530

1/4"

18

6"

495

610

1/4"

18

12

12

12

18

18

24

12

12

18

18

12

12

12

12

12

18

12

12

12

12

12

18

12

12

12

12

12

12 1034"

12 1134"

12 1134"

12 1234"

12 1234"

AAA TECHNOLOGY AND SPECIALTIES CO., INC.

SWP - 360BC - FB

O.D.

A-307 OR B7

BOLT/ STUDS

INS. THK.

SINGLE WEAR PAD

BOP

1

2"

INSULATION

TYP.

"F"

1" TYP.

Features:

* Temperature Range : -425 Degree

* (-254 Degrees C ) to 275 Degrees F (135 Degrees C)

* Medium or Heavy Load Capacity

* Design Load are Based on a Safety Factor of 5

* Steel Surface Finish : Hot Dip Galvanized or painted

* Support Saddle are constructed on High Density

Polyurethane with Fiberglass Reinforced Composite.

* Support Saddle restrains - Y movement.

* Exposted Polyurethane Surface are coated with

Monolar Mastic.

* Support Saddles are constructed in accordance

with the MSS - SP58 and the ASME B31 Piping

Code Requirements.

* Technical Specification: AAAT - CS - 2010

* For Unique Applications, Contact AAA Tech.

* Steel Component are constructed of A - 36 Steel

INSULATION THICKNESS

VERTICAL LOAD ( lbs)

1

2"

3

4"

35

45

1/4"

2-1 / 2 "

2"

3"

4"

1-1 / 2 "

3-1 / 2 "

F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D. F O.D.

12

2

12 238" 12 278" 12 4"

12 5"

12 658" 12 758" 12 858" 12 958"

45

55

1/4"

12

12

278"

12

278"

12

4"

12

5"

12

658"

12

758"

12

858"

12

958"

1"

65

85

1/4"

12

238"

12

278"

12

321"

12

421"

12

5169 "

12

658"

12

758"

12

858"

12

958"

141"

85

105

1/4"

12

238"

12

321"

12

321"

12

5"

12

5169 "

12

658"

12

758"

12

858"

12

958"

12

12

321"

12

12 1034"

18

958"

958"

1034"

1034"

1134"

1134"

1234"

18

14"

18

18

858"

858"

958"

958"

1034"

1034"

1134"