Академический Документы

Профессиональный Документы

Культура Документы

7 de Abril Del 2013

Загружено:

Francisco BeltranИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

7 de Abril Del 2013

Загружено:

Francisco BeltranАвторское право:

Доступные форматы

Protection of Metals, Vol. 41, No. 1, 2005, pp. 7683. Translated from Zashchita Metallov, Vol. 41, No.

1, 2005, pp. 8290. Original Russian Text Copyright 2005 by Moiseeva.

REVIEW

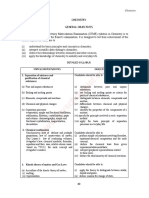

Carbon Dioxide Corrosion of Oil and Gas Field Equipment

L. S. Moiseeva

Scientic and Engineering Center, Oil Company LUKOIL, ul. Usacheva 11, Moscow, 119048 Russia e-mail: cselukoil@hotmail.com

Received August 6, 1999; in nal form, December 3, 2003

AbstractConditions for carbon dioxide corrosion in oil, gas, and gas-condensate elds are discussed. Corrosion mechanisms in oil, gas, and gas-condensate elds and gas and oil pipelines are compared. Various factors are shown to affect the CO2 corrosion rate of steel in oil and gas eld media.

Carbon dioxide corrosion was rst faced with at gas and gas-condensate elds of the USA in the 1940s [1]. In Russia, this problem dates from the 1950s (Krasnodar region) [2]. Intense corrosion of oil and gas pipelines in West Siberia and oil and gas-condensate elds of Ukraine and Belarus was rst reported in the late 1970s [24]. Carbon dioxide corrosion takes place in the operation of gasher, pumping, and gas-lift oil, gascondensate, and gas wells and in recovering oil under water drive with the use of fresh water containing 3 to 4% CO2 [215]. In [15, 16], we began to discuss the patterns of carbon dioxide attacks on oil and gas eld equipment and methods of their inhibition. The goal of this review is to further consider conditions for carbon dioxide corrosion in oil and gas elds and discuss its mechanisms with the aim of searching for the most promising lines of steel protection. PECULIAR CONDITIONS FOR CO2 CORROSION OF STEEL IN OIL, GAS, AND GAS-CONDENSATE FIELDS At present, types of carbon dioxide corrosion in oil, gas-condensate, and gas elds are distinguished. The distinctions arise from the nature of an electrolyte and the hydrocarbon phase, as well as from the possibility of self-inhibition [1, 2]. Specic corrosion patterns in oil and gas wells are determined by differences between them. The temperature in a common gas well (100 to 150C) is higher and extracted hydrocarbons are lighter than those in an oil well (30 to 60C). The oil well pressure is low, while the pressure in gas and gas-condensate wells reaches 30 to 35 MPa. Gas wells are usually deeper, their aqueous phase is less strongly mineralized, and the gas-liquid ow rate is higher [2, 17]. A considerable temperature difference between the upper and lower parts of a gas well causes a variety of corrosion attacks in the same well, which is not characteristic of oil wells [18]. The presence of two (electrolyte hydrocarbon) or more phases in oil and gas wells gives rise to the distribution of CO2 between them according to its solubility in the phases.

In oil wells, CO2 dissolves in 1 to 10% NaCl brine supplied with oil; equipment is most intensely attacked by general corrosion at a water content of 70 to 85% [2, 17]. Because of pressure and temperature gradients along the well bore from the bottom hole to the wellhead and discharge lines, gases (including CO2) evolve from the solution; for this reason, the pH value at the wellhead (6.8 to 7.6) is higher than in the depth (4.2 to 5.1) [2, 17]. Mineralized water in oil wells can contain aliphatic (formic and acetic) acids, but their concentrations are mostly much lower than that of CO2 and insufcient to produce a serious effect on corrosion [1719]. Gas-lift oil wells are more susceptible to general and localized corrosion than pumping wells because of the higher temperature t and the higher concentration of CO2 (provided that CO2 and H2S have not been removed from a working gas, so that the solution at the well bottom shows pH 2 to 3) and a lot of water and O2 is present in the injected gas [17, 19, 20]. In addition, low-molecular hydrocarbons of a gas condensate, in contrast to oil, exhibit no protective effect [2, 4]. In operated gas wells more than 6000 m deep at high total and partial CO2 pressures ( P CO2 ) and t > 200C their production contains no liquid hydrocarbons, while the CO2 content of the aqueous phase is 2 to 5% equipment is attacked by intense carbon dioxide corrosion promoted by low-molecular carboxylic acids [2123]. Carbon dioxide and carboxylic acids occupy separate corrosion zones. Organic acids attack metal tubing at a depth of 120 to 150 m and at 40 to 100C. In this range, the corrosion rate is 1 to 3 mm/yr (shallow and deep pitting) [22]. In gas-condensate wells, corrosion attacks are usually caused by CO2 and H2S dissolved in water droplets condensed on the tube walls. As a rule, tubing below the condensation zone does not corrode. The pressure in gas-condensate wells, which determines the solubility and corrosivity of carbon dioxide, usually exceeds 1 107 Pa [2, 17]. As noted in [11, 20], the corrosion rate decreases from 4 to 5 to 0.2 to 2 mm/yr during the

0033-1732/05/4101-0076 2005 Pleiades Publishing, Inc.

CARBON DIOXIDE CORROSION

77

development of gas-condensate elds because of decreasing P CO2 and temperature. The corrosion pattern becomes more uniform. However, when the initial P CO2 value is low, corrosion intensifies with time because of a growing moisture content [11, 19]. Carbon dioxide corrosion of the underground equipment of gas-condensate elds can be substantially intensied by formic, acetic, propionic, and butyric acids; their total concentration in condensation waters is 500 mg/l, they are characterized by close pH values (~ 4.6), and iron salts are nearly equally soluble in them [17]. Corrosion is favored by high temperature (80 to 90C) and low pH (3 to 5). Even at the acetic acid concentration of 15 to 20 mg/l, the corrosion rate by carbon dioxide increases 1.5 to 2 times [19] and the corrosion is initiated at lower P CO2 [2022]. At present, the role of acetate ions in corrosion is considered complexly. First of all, it is taken into account that in the presence of several acids, pH is determined by the strongest one (pK a CH3 CO2 H = 4.76 [23], pK a H2 CO3 = 3.88 [24]) and that the best buffering effect is exhibited by solutions with close pH and pKa values [23]. As a result of their interaction, hydrogen ions are transferred from one buffer to the other (relaxation reaction) [25]: H 2 CO 3 + Ac

(1)

Two viewpoints are involved when treating the cathodic process at carbon steels in oil and gas elds [315]. One viewpoint assumes that in the presence of CO2 , it is H3O+ cations generated near the cathode that are mainly reduced, while buffering carbonic acid serves as their source. According to the other, carbonic acid itself (or, at elevated temperatures, HC O 3 ions) serves as a proton carrier [1, 7, 9, 10, 1214, 16, 24, 25]. Homogeneous, heterogeneous, and mixed depolarization mechanisms are distinguished [1, 9, 10, 1216, 2634]: HCO 3sol + e

H ads + CO 3 ,

(2)

2

HCO 3near-el + H ads + e H 2 CO 3sol + e

+

H 2 + CO 3 ,

(2a) (3)

H ads + HCO 3ads ,

with the subsequent regeneration of carbonic acid [10]: HCO 3ads + H 3 O near-el H 2 CO 3ads + H 2 O. (4)

HAc + HCO 3 .

(1)

Actually, this means that carbonic acid combines the functions of a buffer and a carrier of discharging proton [9, 10, 3036]. Apparently, homogeneous and heterogeneous depolarization mechanisms may be applied to any of the possible depolarizers involved in the cathodic reaction, including hydroxonium ions. In neutral and weakly basic media, the equilibrium HCO 3 + OH H 2 O + CO 3

2

This makes carbonate solutions more acid, increasing the limiting diffusion current of hydrogen ions. It is not improbable that carboxylic acids affect metal directly; iron carboxylates were reported to inhibit, under certain conditions, carbon dioxide corrosion in gas wells [25]. MECHANISMS OF THE CARBON DIOXIDE CORROSION OF STEEL At different segments of the same unit (e.g., an oil well), CO2 corrosion can follow different mechanisms because of changing conditions. On the whole, the mechanisms of the carbon dioxide corrosion of steel in oil and gas elds are complex and many-sided, yet being characterized by some common features. Two peculiar effects of CO2 were reported in [1, 9, 1215, 2527]: (1) more intense cathodic evolution of hydrogen than that expected from the acidity of the solution and (2) the formation of carbonate lms at the anodic metal surface. The rst effect is associated with the buffering properties of carbonic acid [1, 13, 15, 25, 26], while the other, with the low solubility of iron carbonate [1, 9, 1214, 2527]. It was experimentally proved in [26] that carbonic acid solutions are more corrosive than solutions of the stronger acids (e.g., HCl) at the same pH value, which is quite natural since the latter exhibit no buffering effect.

PROTECTION OF METALS Vol. 41 No. 1 2005

(5)

is shifted to the right, which accounts for carbonate deposition in water lines. For reaction (3), De Waard and Milliams [10, 31] take the standard kinetic equation i c = k c [ H 2 CO 3 ] exp ( E / RT ) ,

n

(6)

where kc is the cathodic reaction rate constant, [H2CO3] is the concentration of carbonic acid in solution, E is the activation energy of the process, and n is the reaction order in H2CO3 . Taking the Henry law for the solubility of CO2 in mineralized water and the vant Hoff isobar G = G exp(H/RT) (where H is the change in the enthalpy during dissolution and G is the Henry constant), they derive the temperature dependence [3, 10] log i c = log k c ( E /2.3026 RT ) + n log P CO2 . In [3], its antilogarithmic version was reported: i c = k c P CO2 nG 0 ( exp ( n H / RT ) ( exp ( 2.3 E c / b c ) ) , (8) where kc is the cathodic reaction rate constant and Ec is the potential of the cathode through which a current ows. In a hydrogen atmosphere, the potentials of the electrode reactions under consideration [29] satisfy the

n

(7)

78

MOISEEVA

equation E r = 0.059pH 0.295 log P H2 . (9)

HCOOH + 2H 3 O + 2 e HCOH + 2H 3 O + 2 e

+ +

HCOH + 3H 2 O, (11) CH 3 OH + 2H 2 O, (12) (13)

The Tafel slope of the cathodic voltammogram of lowcarbon steel in two-phase carbon dioxide media is close to a classic value of 120 mV, being sometimes affected by diffusion control [5, 35]. For synthetic stratal water of the Samotlor oil eld ( P CO2 = 1 to 100 kPa, [Cl] = 17 g/l, pH 6.5), bc = 0.115 to 0.128 V [3]. For 3 in the mineralized waterkerosene two-phase system saturated with CO2 and acidied to pH 2, we obtained bc = 0.11 V [29]; this value correlates, for a heterogeneous metal surface, with the slow electrochemical desorption theory. However, the bc value alone is insufcient to specify the mechanism of cathodic hydrogen evolution during CO2 corrosion. According to [3], the kinetic parameters Ec/pH and log i c /pH (Ec is the cathode potential at a current ic) in the stratal water of oil elds at P CO2 = 1 to 100 kPa unambiguously t neither the slow discharge nor slow molization theory and different mechanisms are valid for different areas of the electrode surface. In the most general case covering the whole range of possible conditions in oil and gas elds in the presence of CO2 , the cathodic current can be written as ic = i H2 CO3 + i HCO + i H O+ + i H2 O + i O2 . Each term can vary

3 3

CH 3 OH + 2H 3 O + 2 e

CH 4 + 2H 2 O,

In [38], these reactions were believed to be responsible for an increased steel potential in a wet ground through which CO2 had been passed; however, this is questionable simply because the equilibrium potential of reaction (10) is more negative by about 0.2 V than the hydrogen potential at the same pH value. During cathodic polarization of pipe steels in carbonate electrolytes (0.5 M NaHCO3 + 0.5 M Na2CO3) starting from free corrosion potentials, an anomalous anodic loop was observed [45]. X-ray powder diffraction analysis revealed that the surface lm covering 171 steel at 22 and 42C consists of FeOOH, while the lm at 82C is formed by iron carbonates. The identied surface compounds are not primary corrosion products, yet their nature is obviously temperaturedependent. The formation of carbonateoxide lms is closely related to anodic metal dissolution. Earlier [15, 16], we described in detail the main groups of dissolution reactions in the media of oil and gas elds in the presence of CO2 . The most typical anodic reactions are: at pH < 7, Fe + 2H 2 O Fe ( OH ) 2s + 2H + 2 e , 2Fe ( OH ) 2s .

+

from 0 to the total (or part of the total) depending on pH, P CO2 , t, the chemical composition of the medium, and its ow rate [15, 16]. When comparing the proposed schemes for the cathodic process [1, 3, 7, 912, 15, 3038] with the data for ion equilibria in carbon dioxide media [3941], one can distinguish between the ranges in which one or another depolarizer is dominant. The most probable depolarizers are H2CO3 and H3O+ at pH < 5 ([H2CO3] 100%), HC O 3 and H2CO3 at 5 pH < 6.8 ([H2CO3] 30%, [HC O 3 ] 70%), HC O 3 at pH 6.8 ([HC O ] 100%), and H2O and HC O 3 at pH > 7. In deep and ultradeep gas wells, an intense CO2 attack occurs in the upper part of the well bore (water condensation zone) [10, 25]. Because pH is low and the concentration of carbonic acid is high, the cathodic process can roughly be represented as its direct reduction followed by regeneration in reaction (4). In special cases (e.g., in CO2-saturated aqueous calcium chloride; [CaCl2] up to 30%, pH 2 to 4, t = 20 to 107C), CO2 itself can be successively reduced to formic acid, formaldehyde, and further to methane [37, 38, 4144]: CO 2 + 2H 3 O + 2 e

+

(14) (15)

and at pH > 7, in the presence of oxygen, 2Fe + O 2 + 2H 2 O Most of researchers [912, 30] assign a signicant role to OH ions in the anodic process during CO2 corrosion. Heusler [46] and Bockris models [47] are often said to be classical. According to Heusler, the surface compound FeOHads acts autocatalytically. The limiting step is Fe (FeOH) ads + OH ads

FeOH ads + FeOH + 2 e . (16)

The kinetic equation has the form i a = k a a OH exp [ ( 1 + 2 ) FE / RT ] ,

2

(17)

where ka is the anodic reaction rate constant, is the transfer coefcient, and a OH is the activity of OH ions. According to Bockris [47], the limiting step is FeOH FeOH + 2 e ,

+

(18) (19)

2005

and the kinetic equation is written as ia = ka a OH exp[(1 + )FE/RT].

PROTECTION OF METALS Vol. 41 No. 1

HCOOH + 2H 2 O,

(10)

CARBON DIOXIDE CORROSION

79

In the former case, the reaction order m in hydroxyl ion is two and ba = 30 mV. In the latter case, the slope equals 40 mV. For 3 in a CO2-saturated two-phase system at pH 2 and 20C, we obtained ba 40 mV [28]. For a steel electrode in synthetic stratal water of the Samotlor oil eld ( P CO2 = 1 to 100 kPa, [Cl] = 17 g/l, pH 6.5, 50C), ba = 0.1 V and m 0.7 [3]; i.e., neither individual mechanism is valid. Lorenz et al. [48] assumed that the process includes a number of series ((20)(24)) and parallel chemical and electrochemical reactions ((24), (25)): (20) Fe + H 2 O FeOH ads + e , FeOH ads

+ +

and possibly water. May be, this is FeOOH formed in the reactions Fe + O 2 + 2H 2 O 4Fe ( OH ) 2 + O 2 4FeOOH m H 2 O + ( 2 m ) H 2 O. Fe ( OH ) 2s , (27) (28)

According to [9, 52], the corrosion mechanism changes at 40 to 60C: the corrosion rate is now determined by a siderite lm (FeCO3). At t < 60C, the anodic formation of FeHC O 3 and the cathodic discharge of H2CO3 (at pH < 5) are the limiting heterogeneous steps. The resulting porous lms exhibit no protective effect. At t 60C, corrosion products form a denser protective lm, thus changing the limiting step [9]. Now the corrosion rate is controlled by the deposit solubility and permeability and hence is pH-dependent: with a decrease in pH, the corrosion rate increases. However, this dependence is ambiguous. Iron carbonate can both form immediately at the metal surface and precipitate from solution. In the former case, its formation includes several steps, the number and sequence of which depend on the pH of the medium [1, 9, 12, 51]. These steps were described in detail in [15]. In real oil elds at t > 60C, crystalline forms of iron carbonate contain calcium and magnesium carbonates 2 [52]. The higher the concentrations of C O 3 , iron, and calcium in solution, the lower the dissolution rates of siderite and calcite [37, 38, 53, 54]. In neutral and weakly basic media over the temperature range from 20 to 100C, siderite dissolves more rapidly than iron(II) hydroxide so that the adsorption of carbonate ions stimulates the destruction of a passive hydroxide lm [37, 38]. At t > 100C, the fraction of iron carbonate in the layer of corrosion products is reduced, while the content of magnetite Fe3O4 grows [9]. This suggests an important role of a summary reaction [13, 14] 3Fe + 4H 2 O Fe 3 O 4 + 4H 2 . (29)

+

FeOH + e ,

2+

(21) (22)

+

FeOH + H Fe

+ H 2 O,

FeOH ads + H 2 O Fe ( OH ) 2ads + H + e , Fe ( OH ) 2ads + A Fe ( OH ) 2ads + H

(23) (24) (25)

Fe ( OH ) A + OH , FeOH + H 2 O + e .

+

Currents (20), (21), (23), and (25), which add up to give the net current, involve adsorbed species Fe(OH)2ads and FeOHads. According to the theory developed by Kolotyrkin and his school [49, 50], the electrochemical dissolution of metals includes adsorption-electrochemical and chemical steps. Electrolyte anions are directly involved in the anodic reaction to give unstable intermediate complexes, even though they are not components of the nal reaction product. With the participation of OH ions, the kinetic equation takes the form [10, 31]: i a = k a [ OH ] exp ( 2.3 E a / b a ) ,

m

(26)

where ka is the anodic reaction rate constant, Ea is the potential of the anode through which a current ia ows, and m is the reaction order in OH. Carbonateoxide lms play an important role in the carbon dioxide corrosion of iron. Ultimately, the corrosion rate depends on their composition and structure, while their protective properties are primarily determined by the t and the pH of the medium [1, 5, 814, 18, 29, 3032]. These lms exhibit a poor protective effect at pH < 7 and a good one at pH > 7; at pH 7, both nonprotective and protective lms can form. At pH < 7, the corrosion rate can vary stepwise with pH. For instance, the highest corrosion rates were found in 3% NaCl at pH ~ 6.6, 5.6, and 4.2 [8, 51]. In water lines for stratal and waste waters of oil elds, a shift in pH to basic values increases the risk of intense carbonate deposition because stratal water contains calcium ions. In [9, 11, 13, 14], lms formed during the carbon dioxide corrosion of ferrous metals at t < 20C were found to contain iron and oxygen in nearly 1 : 2 ratio

PROTECTION OF METALS Vol. 41 No. 1 2005

At t > 150C, siderite decomposes and undergoes surface hydrolysis to give Fe3O4 and Fe2O3 , thus significantly decreasing the corrosion rate to ~1 mm/yr. In [1, 29, 31, 49, 5260], this effect is believed to be responsible for easy steel passivation in carbon dioxide media. It should be noted that graphite inclusions (1 to 2%) were detected in corrosion products in a number of gas wells operated at t > 80C [25]. Apparently, graphite forms in a summary reaction 3Fe + 2CO 2 Fe 3 O 4 + 2C (30)

80

MOISEEVA

Carbon steel corrosion in water and NaCl solutions at P CO2 = 0.002 to 6 MPa yields several types of lms [8, 13, 14]: (1) transparent lms difcult to discern visually, which contain FeO H2O and FeOOH. These stable lms form at t < 20C even in the absence of Fe2+ ions from solution, though their presence substantially accelerates the lm formation; (2) predominantly siderite lms form in media saturated with Fe2+ at t > 40C (at pH 6 to 8, even at room temperature); (3) thin lms with cementite inclusions (Fe3C) form at 60 < t < 90C; (4) high-temperature (predominantly magnetite) lms form at t > 90C. The protective properties of transparent lms are enhanced with time. After a one-week exposure, the corrosion rate decreases ten times and the specimens are passive [13, 14, 33]; this is not the sole type of lowtemperature lms. After a prolonged (>7 days) exposure sufcient for the solution to be saturated with Fe2+ ions, an upper siderite layer can form to give two-layer lms at room and lower temperatures [7, 13]. The solubility of siderite increases with an increase in P CO2 and diminishes with an increase in the temperature; for this reason, an increase in both the temperature and pH of the medium enhances the protective properties of siderite lms, making them more adhesive and less permeable [13, 14]. In CO2-containing water, lms can either form or dissolve. The direction of the process is determined by the concentration of Fe2+ and the pH of solution. When [Fe2+] is lower than the limiting solubility (30 mg/l) in CO2-saturated NaCl solutions, the formation of FeCO3 stops and its lm begins to dissolve. At pH > 6, the effect of [Fe2+] is insignicant because of the very low solubility of FeCO3 . The critical concentrations of Fe2+ ions in simulated stratal water were reported in [8]. Later, the phase diagram of FeCO3 for Nizhnevartovsk oil elds was plotted from the calculated saturation indices of the aqueous phase [3]. At P CO2 = 60 kPa, [HC O 3 ] = 750 mg/l, and [Fe2+] = 10 mg/l, the protective siderite layer covers steel even at 20C. A temperature range from 20 to 50C was reported for carbon dioxide media in some other works [7, 11]. When passing from one temperature range to another, both the compositions and structures of surface layers change. The limiting step can be the dissolution of FeOOH, FeCO3 , or oxides. In the rst case, the dissolution rate depends on the concentrations of anions and hydrogen ions in solution and deposit pores; in the 2 second case, on the concentrations of C O 3 and Fe2+

ions; in the last case, on the concentrations of HC O 3 and FeOH+. ESTIMATION OF THE EFFECT OF VARIOUS FACTORS ON CARBON DIOXIDE CORROSION Oil eld media favoring carbon dioxide corrosion vary in pH from 2 to 8 and in temperature from 15 to 200C. Even in the same oil eld, the operating conditions do not remain constant. Contributions from many factors (temperature, pH, P CO2 , the chemical composition of mineralized water, etc.) were estimated by generalizing the literature data [1, 2, 9, 11, 1719, 5365]. For instance, under the real conditions of oil and gas extraction, an increase in the gas-liquid ow rate from 1 to (8 to 10) m/s accelerates the carbon dioxide corrosion 1.5 to 2 times but then inhibits it; however, at ow rates of 10 to 12 m/s, the corrosion rate increases again, especially in eddy ows [2]. With a decrease in P CO2 in wells, the maximum Vcor value and the erosive corrosion range are shifted to higher ow rates, which provide better supply of CO2 and, hence, acidication of the near-electrode layer to make corrosion more intense [14, 5359]. Carbon dioxide corrosion is mostly controlled by mixed kinetics and therefore is strongly temperaturedependent. At t < 20C, the restrictions are few and the corrosion rate is virtually independent of the ow rate; the limiting step is the heterogeneous discharge of adsorbed H2CO3 molecules or HC O 3 ions. At t > 60C, when the corrosion is controlled by siderite dissolution, the role of the ow rate becomes decisive [5355]. The corrosion rate is limited by the removal of the dissolved substance (the concentration gradients of Fe2+ and 2 C O 3 ions between the surface and the bulk of electrolyte) and described by an equation [54]: d ( FeCO 3 ) 2 1/2 2+ ----------------------- = kS ( SP [ Fe ] [ CO 3 ] ) , d (31)

where S is the surface area of a specimen, SP is the solubility product of siderite at 60C, and [Fe2+] and 2 [C O 3 ] are the concentrations of these ions in solution (mg/dm3). It was found [59] that the dependence of the corrosion rate on the ow rate of CO2-saturated mineralized water (<15 m/s) varies with time at 60 to 80C. The initial (0.5 h) pronounced dependence disappears within three hours and the corrosion rate decreases ve times. This is due to the formation of a protective surface lm, which prevents the ow hydrodynamics from controlling the process any longer. First dark spots of deposits (S = 0.1 to 0.5 cm2) at the carbon steel surface in a CO2-saturated mineralized water also appear within 0.5 to 1.5 h [8], while it takes

PROTECTION OF METALS Vol. 41 No. 1 2005

CARBON DIOXIDE CORROSION

81

an additional one to two hours for the surface to be completely covered with a gray or black deposit. The process (at 50C) is stabilized over less than 3.5 h and the nal corrosion rate Vcor (7 to 9 h) remains unchanged. An increase in pH favors deposition. At pH < 6.5 and high P CO2 values, no deposit forms [6, 60]. For real ows in an oil or gas well, the dependence is more complicated. With an increase in the partial pressure of CO2 to 0.3 MPa, the corrosion rate steeply increases but then its growth sharply decelerates to reach a level of 5.7 mm/yr at 1.2 MPa [2, 6]. Several equations relating P CO2 and temperature to the corrosion rate were proposed. Among them, the De WaardMilliams equation is best known [10]: log V cor = 6.467 1710/ ( 273.2 + t ) + 0.67 log P CO2 , (32) where Vcor is the corrosion rate (mm/yr) and P CO2 is the partial pressure of CO2 (MPa). The equation is valid at P CO2 < 1.0 MPa and t < 140C [3, 10]. In [3], it was extended to P CO2 > 1.0 MPa and modied by introducing a pH-dependent term. For stratal water of the Samotlor oil eld saturated with CO2 (1 to 100 kPa), the resulting equation log V cor = 3.996 + 1730/ ( 273.2 + t ) + 0.32pH + 0.3651 log P CO2 ,

under constant external conditions is characteristic of CO2 corrosion [9] and is due to nonuniform deposition. Crolet proposed an equation relating the initial and nal corrosion rates to the surface lm thickness [12]: 2l -, = ---------------------------------R ( V cor + V cor0 ) (36)

where Vcor0 and Vcor are the initial corrosion rate and the rate at a time , respectively (mm/yr); R is the ratio between the molar iron volumes in the metal and deposits, which depends on the deposit type (3 for FeCO3 below 60C and 4.3 for FeCO3 above 60C). In [30], the coefcient Fdep considering the effect of the deposit on the corrosion rate was introduced for more accurate prediction of the carbon dioxide corrosion rate under conditions of siderite deposition: V cor = V cor F dep ,

sider

(37)

where Vcor is calculated by Eq. (31) and Fdep depends on the temperature and P CO2 . Because FeCO3 is believed to form a protective deposit, Fdep ranges from 0 to 1. The effect of P CO2 on the Vcor of steel was explained differently [13, 14] depending on the temperature. At t < 60C, corrosion stimulation by growing P CO2 is due to an increase in the H2CO3 concentrations at the metal surface. For 60 < t < 150C, Vcor is determined by P CO2 , the rate success for carbon dioxide to the surface, and the removal of dissolution products. At a H+ a CO2 <

3

(33)

is valid for 10 < t < 60C, 5.4 < pH < 7.6, 0.001 < P CO2 < 0.1 MPa, and 85 < [HC O 3 ] < 600 mg/l [3]. For the condensation water in gas and gas-condensate wells, the following equations are true [7, 11]: log V cor = 0.7493 log P CO2 0.5060 ( at 25 C ) , (34) log V cor = 0.7493 log P CO2 ( at 80 C ) , (35)

SP HCO , an increase in

3 3

H+

and

2 C O3

intensifies steel

corrosion. For a H+ a CO2 > SP HCO , an increase in [Fe2+]

3

and inhibits corrosion and increases the potential and pH. The adsorption of CO2 and carbonate ions at steel depends on its electrode potential [31, 57, 61]. The iron surface covered with corrosion products can sorb CO2 at both the anodic and cathodic polarization from the free corrosion potential Ecor, while bare iron mainly adsorbs it at anodic potentials. In 1 M NaHCO3 + 0.5 M Na2CO3 at pH 9.5, carbon steel most intensely corrodes at ~0.53 V (NHE) [57]. In [61], cathodic polarization from Ecor was found to result in a gradual acceleration of carbon steel corrosion in 1 M Na2CO3 + 1 M NaHCO3; the corrosion rate shows a peak at E = 0.5 V for 3 and 1.0 V for 702 and then decreases to reach a plateau. The dependence of hydrogenation on E shows a diffuse minimum near Ecor (0.24 V (NHE)). When the potential is shifted to more negative values, the amount of absorbed hydrogen sharply grows to a saturation level at E = 1.0 V.

2 [C O 3 ]

where P CO2 is the partial pressure of carbon dioxide (bar; 1 bar 0.1 MPa). Equations (32), (34), and (35) were veried by us experimentally for a model system (3, 3% NaCl, P CO2 = 0.7 to 1.0 MPa) [29]. The calculated values proved to be lower by one order of magnitude than the experimental ones. Only at 80C, Eq. (32) ts well the experimental data. Obviously, these equations ignore the effect of corrosion products accumulated at the metal surface and in solution on prolonged exposure to the medium and with an increase in the temperature. As noted in [9], carbonate deposition makes it difcult to predict the carbon dioxide corrosion rate. A large scatter of the corrosion rates (over one order of magnitude and more) in nearly neutral mineralized media

PROTECTION OF METALS Vol. 41 No. 1 2005

82

MOISEEVA

CONCLUSION Carbon dioxide corrosion of steel in oil and gas elds is an electrochemical process involving, beside H3O+ ions, such depolarizers as HC O 3 and H2CO3 (CO2 H2O) generated in solution, in near-electrode layer, or at the metal surface. In neutral (with free access for oxygen) and weakly basic media, water and O2 can also serve as depolarizers. The role of one or another depolarizer in the cathodic process is determined by its concentration and the electrolyte pH. The cathodic process is controlled by the formation of carbonic acid and can follow three mechanisms, depending on the character of this formation (homogeneous, heterogeneous, or mixed). Here, these depolarization mechanisms are treated more widely than in [9, 10, 15]. The distinctive features of the corrosion of ferrous metals in CO2-containing oil-eld media are more intense hydrogen evolution at the cathode and the formation of carbonate and carbonateoxide lms at the metal surface. Carbonate ions are also involved in the anodic dissolution of steel. Corrosion products FeOOH, Fe3O4 , -Fe2O3 , Fe3C, (Fe(OH)2 , Fe(OH)CO3 , Fe2(OH)4CO3 , and FeCO3) form a thin lm, which grows thicker with a prolonged exposure of the metal to the corrosive medium. Carbonateoxide lms or deposits can exhibit a protective effect or not, depending on the temperature, pH, and the composition of the electrolyte. They determine the corrosion rate and affect the mechanism of carbon dioxide corrosion. The formation of a protective siderite layer at the steel surface (usually at 40 to 60C) changes the corrosion mechanism. The currently proposed equations make it possible to estimate the effects of P CO2 , pH, and t on the carbon dioxide corrosion rate of steel and calculate its value in gas and gas-condensate wells and lines for stratal and waste waters of oil elds. However, prediction of the localized and general corrosion rates in oil collectors in the presence of CO2 is still a challenge. REFERENCES

1. Crolet, J.-L., 10th Eur. Corros. Congr., Barcelona, 1993, Paper no. 270. 2. Saakiyan, L.S. and Efremov, A.P., Zashchita neftegazopromyslovogo oborudovaniya ot korrozii (Protection of Oil and Gas Field Equipment from Corrosion), Moscow: Nedra, 1982. 3. Markin, A.N., Zashch. Met., 1996, vol. 32, no. 5, p. 497. 4. Vorobev, A.G., Fedorov, Yu.V., Gnatyuk, A.M., et al., Nauchno-Tekh. Ref. Sb., Ser.: Korroz. Zashch. Neftegazov. Prom-sti, Moscow: VNIIOENG, 1982, no. 3, p. 10. 5. Gonik, A.A., Korroziya neftepromyslovogo oborudovaniya i mery ee preduprezhdeniya (Corrosion and Corrosion Protection of Oil Field Equipment), Moscow: Nedra, 1976.

6. Ovodov, A.I., Study of the Corrosion and Electrochemical Behavior of Steel in the ElectrolyteHydrocarbon System at Elevated CO2 Pressures, Cand. Sci. (Tech.) Dissertation, Moscow: Inst. Fiz. Khim., Akad. Nauk SSSR, 1969. 7. Kuznetsov, V.P., Nauchno-Tekh. Ref. Sb., Ser.: Korroz. Zashch. Neftegazov. Prom-sti, Moscow: VNIIOENG, 1978, no. 2, p. 3. 8. Markin, A.N. and Legezin, N.E., Zashch. Met., 1993, vol. 29, no. 3, p. 452. 9. Schmitt, G., Advances in CO2 Corrosion, Houston: NACE, 1984, vol. 1, p. 1; 10. 10. De Waard, C., Lotz, U., and Milliams, D.E., CorrosionNACE, 1991, vol. 47, no. 12, p. 976. 11. Kuznetsov, V.P. and Chernaya, N.G., Nauchno-Tekh. Ref. Sb., Ser.: Korroz. Zashch. Neftegazov. Prom-sti, Moscow: VNIIOENG, 1980, no. 8, p. 2. 12. Crolet, J.-L. and Samaran, J.-P., Corrosion-NACE, 1993, Paper no. 102, p. 16. 13. Videm, K. and Dugstad, A., Corrosion-NACE, 1988, Paper no. 186; 1993, Paper no. 83. 14. Videm, K. and Dugstad, A., Mater. Perform., 1989, vol. 28, no. 3, p. 63; no. 4, p. 46. 15. Moiseeva, L.S. and Kuznetsov, Yu.I., Zashch. Met., 1996, vol. 32, no. 6, p. 565. 16. Moiseeva, L.S. and Kuznetsov, Yu.I., Zh. Prikl. Khim., 1998, vol. 71, no. 6, p. 950. 17. Bregman, J.I., Corrosion Inhibitors, New York: McMillan, 1963. 18. French, E.C., Martin, R.L., and Dougherty, J.A., Corrosion-NACE, 1989, Paper no. 435. 19. Fuki, T.A., Myakisheva, G.I., and Stoyanovskaya, L.I., Ref. Sb.: Korroz. Zashch. Skvazhin, Truboprov., Oborudov. Morsk. Sooruzh. Gazov. Prom-sti, Moscow: VNIIGazprom, 1983, no. 5, p. 1. 20. Rozenfeld, I.L., Ingibitory korrozii (Corrosion Inhibitors), Moscow: Khimiya, 1974. 21. Legezin, N.E., Obz. Inf., Ser.: Korroz. Zashch. Neftegazov. Prom-sti, Moscow: VNIIOENG, 1978. 22. Ter-Karapetova, S.A., Denisov, A.N., and Kazakov, K.M., Ekspress Inf., Ser.: Korroz. Zashch. Okruzh. Sredy, Moscow: VNIIOENG, 1984, no. 4, p. 25. 23. Khimicheskaya Entsiklopediya (Chemical Encyclopedia), Moscow: Bolshaya Rossiiskaya Entsiklopediya, 1998, vol. 5, p. 52. 24. Ramsden, E.N., Basics of Modern Chemistry: A Reference Book, Leningrad: Khimiya, 1989, p. 294; 296. 25. Zezekalo, I.G., Creation and Application of Inhibitors for the Protection of Gas Field Equipment from Corrosion by Natural Gas Enriched with Carboxylic Acids, Cand. Sci. (Tech.) Dissertation, Moscow: VNIIGAZ, 1986. 26. Belevskii, V.S., Kudelin, Yu.I., Lisov, S.F., and Timonin, V.A., Fiz.-Khim. Mekh. Mater., 1990, no. 6, p. 16. 27. Mitina, A.P., Gorichev, I.G., Khoroshilov, A.V., et al., Teoreticheskie osnovy karbonatnoi korrozii stali (Theoretical Foundations of Carbonate Corrosion of Steel), Moscow: VNIIGazprom, 1992. 28. Moiseeva, L.S. and Tereshina, R.M., Zashch. Met., 1994, vol. 30, no. 4, p. 410.

PROTECTION OF METALS Vol. 41 No. 1 2005

CARBON DIOXIDE CORROSION 29. Moiseeva, L.S. and Rashchevskaya, N.S., Zh. Prikl. Khim., 2002, vol. 75, no. 10, p. 1659. 30. Dunlop, A.K., Hassell, H.L., and Rhodes, P.R., Advances in CO2 Corrosion, Houston: NACE, 1984, vol. 1, p. 52. 31. De Waard, C. and Lotz, U., Corrosion-NACE, Houston: NACE, 1993, Paper no. 69. 32. Gonik, A.A., Ekspress Inf., Ser.: Zashch. Korroz. Okhr. Okruzh. Sredy, Moscow: VNIIOENG, 1993, no. 3, p. 5. 33. Wieckowski, A., Ghali, E., Szklarczyk, M., and Sobkowski, J., Electrochim. Acta, 1983, vol. 28, p. 1619. 34. Ogundele, G.I. and White, W.E., Corrosion, 1986, vol. 42, no. 2, p. 71; no. 72, p. 398. 35. Murata, T., Sato, E., and Matsuhashi, R., in Advances in CO2 Corrosion, Houston: NACE, 1985, p. 64. 36. Mentire, G., Lippert, J., and Yudelson, J., CorrosionNACE, 1990, vol. 46, no. 2, p. 91. 37. Lunev, A.F., Rozova, E.D., and Gerasimenko, N.A., Trudy Vsesoyuznoi mezhvuzovskoi nauchnoi konferentsii po voprosam borby s korroziei (Proc. All-Union Scientic Conf. of Schools of Higher Education on Corrosion Control), Moscow: Gostopizdat, 1962, p. 46. 38. Rakhmankulov, D.L., Bugai, D.E., et al., Ingibitory korrozii (Corrosion Inhibitors), Ufa: Reaktiv, 1997, vol. 1. 39. Remy, H., Lehrbuch der anorganischen Chemie, Leipzig: Akademische Verlagsgesellschaft Geest und Portig, 1961, vol. 2. 40. Butler, J.N., Ionic Equilibria, Leningrad: Khimiya, 1973. 41. Bulakh, A.G. and Bulakh, K.G., Fiziko-khimicheskie svoistva mineralov i komponentov gidrotermalnykh rastvorov (Physicochemical Properties of Minerals and the Components of Hydrothermal Solutions), Leningrad: Nedra, 1978. 42. Fokin, M.N., Bulygin, E.V., and Oshe, E.K., Izv. Vyssh. Uchebn. Zaved., Khim. Khim. Tekhnol., 1986, no. 12, p. 119. 43. Lubenskii, S.A. and Petrov, N.A., Ekspress Inf., Ser.: Zashch. Korroz. Okhr. Okruzh. Sredy, Otechestv. Opyt, Moscow: VNIIOENG, 1992, no. 2, p. 1. 44. Gabitov, A.I., Itogi i perspektivy v teorii i praktike borby s korroziei (Theory and Practice of Corrosion Control: Advances and Prospects), Ufa: Reaktiv, 1998, vol. 1, p. 12. 45. Podobaev, A.N., Lebedev, V.M., Dzhanibakhsheva, L.E., Ekspress Inf., Ser.: Zashch. Korroz. Okhr. Okruzh. Sredy, Moscow: VNIIOENG, 1993, no. 3, p. 1.

83

46. Heusler, K.E., Z. Elektrochem. Ber. Bunsenges. Phys. Chem., 1958, vol. 62, no. 6, p. 582. 47. Bockris, J.OM., Drasic, D., and Despic, A.R., Electrochim. Acta, 1961, vol. 6, no. 4, p. 325. 48. Lorbeen, P. and Lorenz, M.J., Electrochim. Acta, 1980, vol. 25, no. 25, p. 375. 49. Kolotyrkin, Ya.M., Metall i korroziya (Zashchita metallov ot korrozii) (Metal and Corrosion. Metal Protection from Corrosion), Moscow: Metallurgiya, 1985. 50. Florianovich, G.M., Kolotyrkin, Ya.M., and Sokolova, L.A., Trudy III Mezhdunarodnogo kongressa po korrozii metallov (Proc. III Int. Congr. on Metal Corrosion), Moscow: Mir, 1968, vol. 1. 51. Videm, K., Progress in the Understanding and Prevention of Corrosion, Cost, J.M. and Mercer, A.D., Eds., Pub. Inst. Mater., 1993, Book 550, vol. 1, p. 504. 52. Kurahashi, H., Kurisu, T., Sone, I., Wada, K., and Nakai, I., Corrosion (Houston), 1985, vol. 41, no. 4, p. 211. 53. Popperling, R., Schwenk, W., and Venkateswarlu, J., Werkst. Korros., 1985, vol. 36, no. 9, p. 389. 54. Burke, P.A., Advances in CO2 Corrosion, Houston: NACE, 1984, vol. 1, p. 3. 55. Eriksrud, E. and Sonlvedt, T., in Advances in CO2 Corrosion, Houston: NACE, 1984, vol. 1, p. 20. 56. Dawson, J.L., Shin, C.C., and Bartlett, P.K.N., Progress in the Understanding and Prevention of Corrosion, London, 1993, Book 556, vol. 1, p. 513. 57. Nesic, S., Progress in the Understanding and Prevention of Corrosion, London, 1993, Book 556, vol. 1, p. 539. 58. Schwenk, W., Werkst. Korros., 1983, vol. 34, no. 6, p. 287. 59. Melsetdinova, R.A., Altshuler, B.N., and Legezin, N.E., Ekspress Inf., Ser.: Borba Korroz. Zashch. Okruzh. Sredy, Moscow: VNIIOENG, 1987, no. 10, p. 5. 60. Vezirova, V.V., Vovchenko, N.F., Krasilov, A.M., and Dadasheva, A.M., Ekspress Inf., Ser.: Korroz. Zashch. Okruzh. Sredy, Moscow: VNIIOENG, 1985, no. 10, p. 1. 61. Valand, T., Proc. 6th Eur. Symp. on Corrosion Inhibitors, Ferrara, 1985, vol. V, suppl. no. 8, p. 1401. 62. Valand, T. and Sjowall, P.A., Electrochim. Acta, 1989, vol. 34, no. 2, p. 273. 63. Frolova, L.V. and Zorina, V.E., Abstracts of Papers, Zonalnaya nauchno-tekhnicheskaya konferentsiya (Regional Sci. Tech. Conf.), Ufa, 1990, p. 14. 64. Crolet, J.-L. and Bonis, M., Offshore, 1990, no. 8, p. 67. 65. Gutman, E.M., Markin, A.N., Sivokon, I.S., et al., Zashch. Met., 1991, vol. 27, no. 5, p. 767.

PROTECTION OF METALS

Vol. 41

No. 1

2005

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Berat Jenis LogamДокумент6 страницBerat Jenis LogamBumi NayakaОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Lecture 2 Lipids 4Документ21 страницаLecture 2 Lipids 4Caamir Dek HaybeОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Chemistry General Objectives: 1. Separation of Mixtures and Purification of Chemical SubstancesДокумент13 страницChemistry General Objectives: 1. Separation of Mixtures and Purification of Chemical SubstancesSara alnaserОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Experiment 7: Qualitative Analysis of Cations Purpose: Develop A Systematic Scheme of Separation and Analysis of A Selected Group of CationsДокумент11 страницExperiment 7: Qualitative Analysis of Cations Purpose: Develop A Systematic Scheme of Separation and Analysis of A Selected Group of CationsMayankОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Different Types of Dyes.Документ10 страницDifferent Types of Dyes.Imran Anwar100% (3)

- P Block Short NotesДокумент22 страницыP Block Short Notesthapliyaldivyanshu274Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Chemical Resistance GuideДокумент20 страницChemical Resistance GuideDarien EdwardsОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- ACTIVITY 7 Milk of MagnesiaДокумент4 страницыACTIVITY 7 Milk of Magnesiadaven25% (4)

- 6 2021 09 15!05 15 28 PM PDFДокумент36 страниц6 2021 09 15!05 15 28 PM PDFJonella Mae ChanОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- Revision Notes For Class 12 Chemistry Chapter 16 - Chemistry in Everyday Life (1) MДокумент5 страницRevision Notes For Class 12 Chemistry Chapter 16 - Chemistry in Everyday Life (1) MBENJAMIN NANDAОценок пока нет

- Ocr 33977 PP 09 Jan L Gce 2813 01Документ12 страницOcr 33977 PP 09 Jan L Gce 2813 01Philip_830Оценок пока нет

- Tetrabutylammonium Oxone - Oxidations Under Anhydrous Conditions - Trost1988Документ6 страницTetrabutylammonium Oxone - Oxidations Under Anhydrous Conditions - Trost1988javasoloОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Phytochemical Screening and Evaluation of Polyphenols, Flavonoids and Antioxidant Activity of Prunus Cerasoides D. Don LeavesДокумент7 страницPhytochemical Screening and Evaluation of Polyphenols, Flavonoids and Antioxidant Activity of Prunus Cerasoides D. Don LeavesFlorynu FlorinОценок пока нет

- Euxyl ECO 910 - 20200331Документ27 страницEuxyl ECO 910 - 20200331Kitra KiaraОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Classification of PolymersДокумент11 страницClassification of Polymerssayon.ghosh1001Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Kalinga University Organo-transition & bioinorganic QuizДокумент13 страницKalinga University Organo-transition & bioinorganic QuizLokesh BhoiОценок пока нет

- Common Compounds Acids: Chemical Name Chemical Formula Common Name/S CH Cooh CH Cooh H Bo H Co HCL HCN Hno H So 1 Part Hno: 3 Parts HCLДокумент3 страницыCommon Compounds Acids: Chemical Name Chemical Formula Common Name/S CH Cooh CH Cooh H Bo H Co HCL HCN Hno H So 1 Part Hno: 3 Parts HCLFrederick FranciscoОценок пока нет

- Anderson Greenwood Conventional Relief ValvesДокумент56 страницAnderson Greenwood Conventional Relief ValvesHenry Alfaro BermudezОценок пока нет

- Cement Hydration Inhibition With SucroseДокумент8 страницCement Hydration Inhibition With SucroseJaq Plin PlinОценок пока нет

- Colour of Compounds FINALДокумент5 страницColour of Compounds FINALSHAMS QUAMARОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Azo Dye Project 1Документ18 страницAzo Dye Project 1sohamkapooriitОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Daftar Obat Obgyn Nama Obat Harga ObatДокумент8 страницDaftar Obat Obgyn Nama Obat Harga ObatAnonymous 7Tg0sUkОценок пока нет

- Chap03 CarbonylsДокумент10 страницChap03 CarbonylsAPLCTNОценок пока нет

- Revision Notes For Class 12 CBSE Chemistry, Biomolecules - TopperlearningДокумент14 страницRevision Notes For Class 12 CBSE Chemistry, Biomolecules - TopperlearningRishabh Bhandari100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- cARBOXYLIC ACID DerivativesДокумент171 страницаcARBOXYLIC ACID DerivativesRaymond OforiОценок пока нет

- Alkanes and CycloalkanesДокумент5 страницAlkanes and CycloalkanesAlineОценок пока нет

- Healer'S Lab. (Unit Ii) : Plot No. 33 Hpsidc Exten. Baddi, Distt-Solan (H.P.)Документ14 страницHealer'S Lab. (Unit Ii) : Plot No. 33 Hpsidc Exten. Baddi, Distt-Solan (H.P.)Subhash ChandОценок пока нет

- Poisoning and Deactivation of Palladium CatalystsДокумент12 страницPoisoning and Deactivation of Palladium CatalystsDana NashОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Solubility Tests On Organic CompoundsДокумент6 страницSolubility Tests On Organic CompoundsVanessaOlgaJ.Dagondon0% (2)

- Pharm Chem 1 Lec PF Unit Vii - Topical Agents 092015Документ6 страницPharm Chem 1 Lec PF Unit Vii - Topical Agents 092015davenОценок пока нет