Академический Документы

Профессиональный Документы

Культура Документы

RA 90 220 Rexroth Hydraulic Fluids On A Petroleum Oil Basis PDF

Загружено:

eng13Исходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

RA 90 220 Rexroth Hydraulic Fluids On A Petroleum Oil Basis PDF

Загружено:

eng13Авторское право:

Доступные форматы

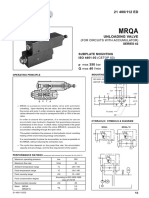

RA 90220/08.

97

Hydraulic Fluids on a Petroleum Oil Basis for Axial Piston Units

Brueninghaus Hydromatik

RA 90220/08.97

replaces 05.93

General

In order to guarantee trouble-free and efficient operation, the hydraulic fluid in a hydrostatic system should be selected carefully according to the following points in mind during the design of the system. If all requirements cannot be met, i.e. for reasons of price, each application must be considered individually. For a short time while starting, a high viscosity is permissible. This must be low enough to prevent damage to the unit. Depending on the product resp. the sizes the following max. values are valid: I : start 7400 SUS (1600 mm2/s), at min. perm. temperature of t min = - 40F (- 40C), II : start 4600 SUS (1000 mm2/s), at min. perm. temperature of t min = - 13 F (- 25C). (see selection diagram, page 3) In the operating range a fully functional operating viscosity must be guaranteed at 100% duty. operating = 80...460 SUS (16100 mm2/s). The optimum operating range gives the highest degree of efficiency and economy at: opt = 80...170 SUS (1636 mm2/s). For this reason, systems with high operating pressures require higher viscosity and systems with large flows lower viscosity. In certain cases the viscosity has to be chosen on an overall loading pattern. In addition, marginal lubrication limits the lower permissible viscosity depending on the product resp. the sizes to (short term): I : min 42 SUS (5 mm2/s), at max. perm. temperature of tmax = + 240F (+ 115C) II : min 60 SUS (10 mm2/s), at max. perm. temperature of tmax = + 195F (+ 90C) (see selection diagram, page 3). In order to simplify selection, different viscosity grades have been created. The identifying code relates to average viscosity in mm2/s at 104F (40C) . Viscosity grades (VG) 22 to 100 are in most common use. (A): for arctic conditions or for extremely long pipelines VG 32 (W): for winter conditions VG 46 (S): for summer conditions or for enclosed areas VG 68 (T): for tropical conditions or for areas with high temperatures VG 100 (U): for excessively high temperatures VG 22 Hydraulic fluids with a higher viscosity index (VI>140) so-called HVLP fluids and multi grade engine fluids are particularly suitable for larger temperature ranges (mobile applications). Mixing viscosities are possible, but please consult us. For very low ambient temperatures, the pour point given consideration. must also be

Energy Transfer

All petroleum fluids (even those containing air) transfer energy and pressures quickly (by means of high velocity sound ) although this is cushioned by the favourable damping factor . Fluids of low viscosity, be it by nature or through increased temperature, have a higher compressibility, thus making the system softer. Large volumes of fluid, hoses and undissolved gases (in accumulators) also decrease system stiffness. The question as to whether to employ a system which is stiff and which will transmit forces accurately but which will put heavy stresses on materials, or to use a soft system which yields and protects materials but which may also lead to oscillations occurring, is not normally decided from the physical data of the fluid. The compressibility of the installation must be considered and suitable steps taken to accommodate it.

Dynamic Attitude

The viscosity or viscosity-temperature ratio (viscosity index) are of primary importance as are the viscosity-pressure relationship , the density and the pour point . Higher viscosities (thicker fluids) deteriorate the mechanicalhydraulic efficiency. The leakage losses are instead smaller. The following adverse results are: When the pressure is low, bearing clearances are not fully filled causing considerable wear to occur. On the suction side, filling losses occur which cause cavitation damage due to implosion occurring. If the viscosity is too low, higher leakages will occur and thinner fluids films lead to higher bearing wear. In contrast to water, the viscosity of petroleum fluids falls with rising temperature (dependent upon the viscosity index) . This makes selection of fluid difficult. Dependent upon the application, the following criteria must also be taken into consideration: The design of the hydraulic pumps and motors: In conjunction to the normal EP additives in the fluid, the close tolerances to which our units are manufactured permit very low viscosity fluids to be used. The type of installation and the duty it must perform: Friction losses in the pipelines, natural heat dissipation and additional cooling output interact with the operating data. Viscosity is always measured at normal pressure (atmospheric pressure). In the high pressure range, the viscosity-pressure relationship leads to increased viscosity (double at 5800 psi [400 bar]), which must be taken into consideration.

Selection of viscosity grade is made on the basis of starting viscosity with ambient temperature (consider pour point where necessary) and optimum operating viscosity according to system and operating data (collective load) see page 3.

RA 90 220/08.97 Hydraulic fluids on a petroleum oil basis for axial piston units

Wear Reduction

Pressure-wear relationship is generally determined by FZG test (pressure ratings 0-3) and in special cases by a pump test. Pressure grading is according to DIN nominal pressures . Pressure rating 0 Nominal pressure 1160-1810 psi (80-125 bar), damage force rating zero or < 5. Pressure rating 1 Nominal pressure 1810-2900 psi (125-200 bar), damage force rating 5 - 6. Pressure rating 2 Nominal pressure 2900-3600 psi (200-250 bar), damage force rating 7 - 9 Pressure rating 3 Nominal pressure 3600-4640 psi (250-320 bar), damage force rating 10 (wear < 0.27 mg/kWh) Peak pressure is pressure x 1,25. Pressure ratings 1 and 2 correspond to HL fluids. Pressure rating 3 corresponds to HLP fluids .

Interaction with System Components

CORROSION Anti-corrosion additives protect the components during storage or operation from condensation or water from leaking coolers. Corrosion is intensified due to acid formation resulting from oxidization processes (diesel effect). Petroleum fluids without these corrosion inhibitors do not offer satisfactory protection. On large systems which are continuously monitored, it is of advantage to use demulsifying fluid with good water eliminating characteristics . Water can be drained from the sump. On smaller systems (mobile applications, for example) where monitoring is infrequent, emulsifying fluid with additives (e.g. engine fluid) is more suitable. Only use fluids with corrosion protection. SEALS should be kept to a minimum Changes in hardness or volume by selecting compatible of fluid . At temperatures above 176F (80C) FPM seals (specially for the shaft seal) are recommended. Compatibility with the seal material must be considered.

AIR When commissioning the system, it must be ensured that no air pockets remain. All fluid is saturated with air dependent upon its normal pressure . When subject to negative pressure, this air is released, or further air sucked in via leakage points. Cavitation (implosion of the bubbles) can occur in the negative pressure zone, and loss of compression (and explosion of the air fluid mixture i.e. diesel effect) in the high pressure zone. The effect is erosion of material. Suitable reservoir design, with de-aerating valves can gradually reduce this air content. A good air separation characteristic (LAV) thicker fluids are naturally poorer - is a prime requirement. Anti foam additives only prevent surface foam and reduce air separation by allowing small bubbles to remain. Prevent erosion damage by means of de-aerating valves.

Operating Conditions and Aging of Fluid

Increases of the acid level (neutralization number) and polymerization (resinification , clogging of filters and throttles) results mainly from the diesel effect. An exact indication of aging may be determined for example by comparing the neutralization number, viscosity and colour number. A further possibility is to determine the additive reserve (EP additives). The best quality basic refined fluid gives a good starting point. It is, however, necessary to add oxidization inhibitors to the fluid. Operating temperatures over 176F (80C) reduce the service life by half for every 50F (10C) temperature increase, and should therefore be avoided. Operating of 4000 to 8000 hours dependent upon the type of unit (based on 2900 psi / 200 bar) can easily be for the fluid content of achieved for units with a recycling time at least 1 minute and good filing and bleed characteristics. For applications with little fluid volumes, e.g. mobile applications, the first fluid change must be carried out after 300-500 hours. With large fluid volumes, e.g. in industrial applications, a regular survey of the fluid as well as an exchange of fluid in case of need has to be effected.

Filtration

The finer the filtration the better the achieved purity grade of the pressure fluid and the longer the life of the axial piston unit. To ensure the functioning of the axial piston unit a minimum purity grade of: 9 to NAS 1638 6 to SAE 18/15 to ISO/DIS 4406 is necessary. In this case we recommend, depending on system and application filter element 20 100. With the rising differential pressure at the filter element the -value must not decrease. At very high temperatures of the hydraulic fluid (195F to max. 240F / 90C to max. 115C) at least cleanless class 8 to NAS 1638 5 to SAE 17/14 to ISO/DIS 4406 is necessary.

RA 90 220/08.97 Hydraulic fluids on a petroleum oil basis for axial piston units

Selection of Fluids

All petroleum oil based fluids are suitable to a greater or lesser degree for applications with axial piston units. Their basic classification of application results from what has already been said due to the water, viscosity and temperature relationships, with consideration of oxidization and corrosion protection, material compatibility, air and water separation characteristics. Fluid Classification: Standard: Fluids types HLP and HVLP to DIN 51524, parts 2 and 3 HD engine fluids to API-SF or CD resp. MIL-L-2104 C and MIL-L-46152 B ATF fluids Special fluids: Aviation fluids Marine fluids Lubricating fluids Environmentally acceptable hydraulic fluids HETG, HEPG, HEES for axial piston units see RA 90221. Axial piston units for use with HF-fluids see RA 90223. The following fluids are particularly suitable for mobile applications: Multi-grade fluids (hydraulic and engine fluids), HLP fluids with detergent properties, ATF fluids.

Selection Diagram

A W S T U = = = = = for arctic conditions or for extremely long pipelines for winter conditions in Central Europe for summer conditions in Central Europe or for enclosed areas for tropical conditions or for areas with high temperatures for excessively high temperatures (e.g. due to internal combustion engines)

(-40) (1600) (1000)

(600) (400)

(-20)

(0)

(20)

(40)

(60)

(80)

(100)

7000 5000 3000 2000 1000

W S T U

7400 (1600) 4600 (1000)

max. perm. viscosity (short term) 1) max. perm. viscosity (short term) 1)

0 10 G V 68 G V 46 G V 32

VG

viscosity v SUS (mm2/s)

500 300 200 150 100 80 70 60 50

(100) (60) (40)

170 (36)

opt.

(20)

80 (16)

(10)

II

60 (10)

40

(5)

I

(-40)

-40

(-25)

-13 0

(-10) (0) (10)

20 40 60

(30)

80

(50)

120

(70)

160

(90)

195

42 (5) (115)

240

temperature t in F (C)

tmin = -40F (-40C)

fluid temperature range

tmax = +240F (+115C)

1)

Depending on the product resp. the sizes the following viscosity ranges are valid: I : 42 SUS (tmax = +240F) 7400 SUS (tmin = -40F) / 5 mm2/s (tmax = +115 C) 1600 mm2/s (tmin = - 40 C), II: 60 SUS (tmax = +195F) 4600 SUS (tmin = -13F) / 10 mm2/s (tmax = +90 C) 1000 mm2/s (tmin = - 25 C) (Please find the max. permissible viscosity range in the catalogue sheets of the singular products)

optimum operating viscosity range optimum efficiency

(200)

22

min. perm. viscosity (short term) 1)

min. perm. viscosity (short term) 1)

RA 90 220/08.97 Hydraulic fluids on a petroleum oil basis for axial piston units

Physical Formulae

Velocity of sound in petroleum oil c = 1320 m/s Compressibility factor (Bulk modulus) V 1 = = 3 to 8 105 V p bar Viscosity-temperature characteristic U1 U2 Gradient n = where U = ar sinh ln 2,303 (lg T2 lg T1) Viscosity index VI (Calculation to DIN ISO 2909) Viscosity-pressure characteristic (dynamic viscosity ) p = o e p (p in bar) mPa s 20 C = 0,00240 bar1 50 C = 0,00205 bar1 100C = 0,00147 bar1 (after: Druckflssigkeiten (Fluids) by Dipl. Ing. Horst Dietterle, The Shell Organisation) Bunsen-Coefficient for air in petroleum oil 0,09 p2 VL 0,09 Voil p1

Measuring Techniques and Standards

Kinematic viscosity in mm2/s Typically measured with an "Ubbelohde" viscosity meter to Density at 15 C in g/cm3 with an areometer to Viscosity index (VI) For HLP-fluids For HVLP-fluids Viscosity classification (to ISO) Pourpoint (on attaining liquid limit, at 3 C higher than solidifying point) FZG standard test A/8, 3/90 (Gears loaded in 12 stages at 90 C starting temperature and 8,3 m/s circumferential speed) Pressures - terms - ratings Air elimation characteristic Corrosion protection of steel (process A) Corrosion protection of copper Demulsifying characteristics Water content

DIN 51562

DIN 51757 DIN ISO 2909 DIN 51524 part 2 DIN 51524 part 3 DIN 51519

DIN ISO 3016

DIN 51354 part 2 DIN 24312 DIN 51381

VL Voil p2 p1

= Volume of air dissolved in oil in cm3 = Oil volume in cm3 = Final pressure in bar = Start pressure in bar

Recycling ratio qV i= rpm Vsystem This is the reciprocal of the recycling time

DIN 51585 DIN 51759 DIN 51599 DIN ISO 3733

qV in L/min (pump flow) V in L (oil content of the system)

Compatibility with seal materials DIN 53538 part 1 in combination with DIN 53521 and DIN 53505 Neutralization number in Conradson test ATF (Automatic-Transmission-Fluid) Aviation fluids mg KOH g DIN 51558 part 1 DIN 51551 AQ A Suffix A MIL-H-5606 A Nato-H-515 Nato-H-540 DIN 51517 sheet 3

Marine fluids Lubricating oils

Mannesmann Rexroth Corporation Rexroth Hydraulics Div., Industrial, 2315 City Line Road, Bethlehem, PA 18017-2131 Tel. (610) 694-8300 Fax: (610) 694-8467 Rexroth Hydraulics Div., Mobile, 1700 Old Mansfield Road, Wooster, OH 44691-0394 Tel. (330) 263-3400 Fax: (330) 263-3333

All rights reserved Subject to revision Printed in U.S.A.

RE 90220-1/07.97

Hydraulic Fluids on a Mineral Oil Basis for Axial Piston Units

Brueninghaus Hydromatik

RE 90220-1/09.97

replaces 07.97

Table of mineral oils included in groups HLP(HM) and HVLP to DIN 51524, parts 2 and 3

The following table is not necessarily exhaustive and no recommendation is implied. Subject to revision!

ISOViscosity Class Maker ADDINOL VG 22 HLP Hydraulikl HLP 22 Hydraulikl HVLP 32 AGIP OSO 22 ARNICA 22 Precis HLP 22 ARAL Aral Vitam GF 22 Aral Vitam HF 32 AVIA AVILUB RSL 22 AVILUB HVI 32 AVILUB RSL 32 AVILUB HVI 46 Avia Fluid ZAD 46 BP Energol HLP 22 Bartran HV 32 Bartran HVX 22 Bucher & CIE COREX Motorex AG HLP 22 COREX EP VI 360 CASTROL HYSPIN AWS 22 HYSPIN AWH 32 CHEVRON Hydraulic Oil AW 22 Mechanism LPS 32 COFRAN Cofraline extra 22 S Hydroline Equigrade 32 Speziale 32 DEA Astron HLP 22 Astron Z HLP 32 Astron HLP 32 Astron Z HLP 46 Cofraline 32 S Hydroline Equigrade 46 Astron HLP 46 Astron Z HLP 68 Hydraulic Oil AW 32 Mechanism LPS 46 Cofraline extra 46 S Hydroline Equigrade 68 Speziale 68 Astron HLP 68 Astron HLP 100 HYSPIN AWS 32 HYSPIN AWH 46 Hydraulic Oil AW 46 Mechanism LPS 68 Cofraline extra 68 S Cofraline extra 100 S Bartran HVX 32 COREX HLP 32 COREX EP VI 510 HYSPIN AWS 46 HYSPIN AWH 68 Hydraulic Oil Hydraulic Oil AW 68 AW 100 Energol HLP 32 Bartran HV 46 Bartran HVX 46 COREX HLP 46 COREX EP VI 610 HYSPIN AWS 68 HYSPIN AWS 100 Energol HLP 46 Bartran HV 68 Bartran HVX 68 COREX HLP 68 COREX HLP 100 Energol HLP 68 Energol HLP 100 ARNICA 32 Precis HLP 32 Aral Vitam GF 32 Aral Vitam HF 46 AVILUB RSL 46 AVILUB HVI 68 AVILUB RSL 68 AVILUB RSL 100 OSO 32 ARNICA 46 H Lift 46 HVLP VG 32 HLP Hydraulikl HLP32 Hydraulikl HVLP 46 OSO 46 ARNICA 68 Precis HLP 46 Aral Vitam GF 46 Precis HLP 68 Aral Vitam GF 68 Aral Vitam GF 100 HVLP VG 46 HLP Hydraulikl HLP 46 Hydraulikl HVLP 32 OSO 68 OSO 100 HVLP VG 68 HLP Hydraulikl HLP 68 VG 100 HLP Hydraulikl HLP 100

RE 90220-1/09.97 Hydraulic Fluids on a Mineral Oil Basis for Axial Piston Units

ISOViscosity Class Maker ELF

VG 22 HLP ELFOLNA 22 ELFOLNA DS 22 HVLP

VG 32 HLP ELFOLNA 32 ELFOLNA DS 32 HYDRELF DS 32 HVLP

VG 46 HLP ELFOLNA 46 ELFOLNA DS 46 HYDRELF DS 46 HVLP

VG 68 HLP ELFOLNA 68 ELFOLNA DS 68 HYDRELF DS 68

VG 100 HLP ELFOLNA 100 ELFOLNA DS 100

ENGEN ESSO NUTO H 22

Engen TQH 10/32

Engen TQH 20/32 NUTO H 32

Engen TQH 10/46

Engen TQH 20/46 NUTO H 46

Engen TQH 10/68

Engen TQH 20/68 NUTO H 68

Engen TQH 20/100 NUTO H 100

UNIVIS N 32 FINA HYDRAN 22 TS 22 HYDRAN 32 TS 32

UNIVIS N 46 HYDRAN 46 TS 46

UNIVIS N 68 HYDRAN 68 TS 68 HYDRAN 100 TS 100

HYDRAN HV 32 TSX 32

HYDRAN HV 46 TSX 46

HYDRAN HV 68 TSX 68

FUCHS

RENOLIN MR 5 VG 22 RENOLIN B5 VG 22 RENOLIN MR 32 MC RENOLIN B 32 HVI RENOLIN ZAF 22 B RENOLIN ZAF 32 MC

RENOLIN MR 10 VG 32 RENOLIN B10 VG 32 RENOLIN MR 46 MC RENOLIN B 46 HVI RENOLIN ZAF 32 B RENOLIN ZAF 46 MC LAMORA HLP 32

RENOLIN MR 15 VG 46 RENOLIN B15 VG 46 RENOLIN MR 68 MC RENOLIN B 68 HVI RENOLIN ZAF 46 B RENOLIN ZAF 68 MC LAMORA HLP 46 Q8 Haydn 46 Holst 46 Hydraulik S46 Q8 Hndel 46 Q8 Hndel 68 HLP 46 ISO HVLP 46 ISO HVLP 68 ISO Mobil DTE 25 Mobil DTE Excel 46 Mobil DTE 15 M Mobil DTE 16 M

RENOLIN MR 20 VG 68 RENOLIN B 20 VG 68

RENOLIN MR 30 VG 100 RENOLIN B 30 VG 100

RENOLIN ZAF 68 B

RENOLIN ZAF 100 B

KLBER KUWAIT Petroleum Q8 Q8 Haydn 22

LAMORA HLP 68 Q8 Haydn 68 Holst 68 Hydraulik S68 Q8 Haydn 100

Q8 Haydn 32 Holst 32 Hydraulik S32 Q8 Hndel 32

LIQUI MOLY

HLP 22 ISO HVLP 32 ISO

HLP 32 ISO

HLP 68 ISO

HLP100 ISO

MOBIL

Mobil DTE 22 Mobil DTE Excel 22 Mobil DTE 13 M

Mobil DTE 24 Mobil DTE Excel 32

Mobil DTE 26

Mobil DTE 27

Mobil Mobil DTE Excel 68 DTE Excel 100

RE 90220-1/09.97 Hydraulic Fluids on a Mineral Oil Basis for Axial Piston Units

ISOViscosity Class Maker MOL RT Ungarn

VG 22 HLP HVLP

VG 32 HLP HVLP

VG 46 HLP HVLP

VG 68 HLP

VG 100 HLP

HIDROKOMOL HIDROKOMOL HIDROKOMOL HIDROKOMOL HIDROKOMOL HIDROKOMOL HIDROKOMOL HIDROKOMOL P-22 HV-U 32 P-32 HV-U 46 P-46 HV-U 68 P-68 P-100 U-22 U-32 U-46 U-68 U-100 D-32 D-46 D-68 HLP 22 HLP-M 32 HLP 32 ZNF 32 HLP-M 46 HLP-S ZNF 46 Premium Plus AW 46 Purity FG AW 46 E-46 Shell Tellus Oil T 46 Shell Tellus Oil TD 46 Shell Tellus Oil 46 Shell Tellus Oil DO 46 Shell Tellus Oil S 46 Azolla ZS 46 Equivis ZS 46 Tribol 771 Tribol 1840/22 Tribol 943 AW 22 Tribol 1840/32 Tribol 943 AW 32 HFO 32 Vesta HLP 32 Vesta HV 32 Vesta HV 46 WIOLAN HS 32 WIOLAN HX 32 WIOLAN HV 32 WIOLAN HV 46 YORK 772 VG 32 YORK 775 VG 32 YORK 779 VG 32 YORK 775 VG 46 YORK 779 VG 46 SAE 10 W SAE 10 W 30 YORK 772 VG 46 YORK 775 VG 68 YORK 779 VG 68 SAE 10 W 30 SAE 20 W 20 SAE 30 WIOLAN HS 46 WIOLAN HX 46 WIOLAN HV 68 YORK 772 VG 68 YORK 772 VG 100 Tribol 772 Tribol 1840/46 Tribol 943 AW 46 HFO 46 Vesta HLP 46 Vesta HV 68 WIOLAN HS 68 WIOLAN HX 68 WIOLAN HS 100 WIOLAN HX 100 Equivis ZS68 Tribol 773 Tribol 1840/68 Tribol 943 AW 68 HFO 68 Vesta HLP 68 HFO 100 Vesta HLP 100 Tribol 775 Shell Tellus Oil T 68 Shell Tellus Oil TD 46 Premium HVI 60 ZNF 68 AW 68 Purity FG AW 68 E-68 Shell Tellus Oil 68 Shell Tellus Oil DO 68 Shell Tellus Oil S 68 Azolla ZS 68 E-100 Shell Tellus Oil 100 Shell Tellus Oil DO 100 Shell Tellus Oil S 100 Azolla ZS 100 AW 100 HLP 46 HLP-M 68 HLP 68 HLP 100

MV

PETROCANADA

AW 22 Premium HVI 22

Premium HVI 36

AW 32 Purity FG AW 32

REPSOL Spain SHELL

E-22 Shell Tellus Oil 22 Shell Tellus Oil DO 22 Shell Tellus Oil S 22 Shell Tellus Oil T 32 Shell Tellus Oil TD 46

E-32 Shell Tellus Oil 32 Shell Tellus Oil DO 32 Shell Tellus Oil S 32 Azolla ZS 32 Equivis ZS 32

TOTAL

Azolla ZS 22

TRIBOL

UNIL VERKOL

HFO 22 Vesta HLP 22

WINTERSHALL

WIOLAN HS 22 WIOLAN HX 22

YORK Ginouves

YORK 772 VG 22

SAEMotor Oils

SAE 5W

RE 90220-1/08.96 Hydraulic Fluids on a Mineral Oil Basis for Axial Piston Units

Mannesmann Rexroth Corporation Rexroth Hydraulics Div., Industrial, 2315 City Line Road, Bethlehem, PA 18017-2131 Tel. (610) 694-8300 Fax: (610) 694-8467 Rexroth Hydraulics Div., Mobile, 1700 Old Mansfield Road, Wooster, OH 44691-0394 Tel. (330) 263-3400 Fax: (330) 263-3333

All rights reserved - Subject to revision Printed in U.S.A.

Вам также может понравиться

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingОт EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingРейтинг: 5 из 5 звезд5/5 (3)

- Rcoa1806 03 03Документ36 страницRcoa1806 03 03Fernando Sabino100% (1)

- Webex Nr12Документ35 страницWebex Nr12Carlos VandréОценок пока нет

- Axial Piston Motors: Series Fixed Displacement M24 Design D Goldcup M30 Design A Service InformationДокумент24 страницыAxial Piston Motors: Series Fixed Displacement M24 Design D Goldcup M30 Design A Service InformationjosueОценок пока нет

- Ficha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFДокумент36 страницFicha Técnica Control de Accionamiento de Traslación de Vehículos de Ruedas DRC Bosch Rexroth Inglés PDFvivsОценок пока нет

- Ronald Luis Quisurco PDFДокумент5 страницRonald Luis Quisurco PDFmoisesОценок пока нет

- Pet RainingДокумент57 страницPet Rainingeddie2166100% (1)

- Partial Delivery Lecture - Hydraulic CircuitsДокумент39 страницPartial Delivery Lecture - Hydraulic CircuitsAbdelkader EldjouОценок пока нет

- Axial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Документ48 страницAxial Piston Fixed Motor A4Fm: Replaces: - . - English Series 1 and 3Anonymous bVi38aVОценок пока нет

- M4 Spool Replacement PDFДокумент11 страницM4 Spool Replacement PDFMira RedaОценок пока нет

- Fixed Displacement Pump Technical SpecsДокумент20 страницFixed Displacement Pump Technical SpecsTaz Juan GОценок пока нет

- RE 10 436 Direct Controlled Vane PumpДокумент8 страницRE 10 436 Direct Controlled Vane Pumpado_22Оценок пока нет

- Hägglunds - Choice of Hydraulic Fluid PDFДокумент2 страницыHägglunds - Choice of Hydraulic Fluid PDFAnibal RiosОценок пока нет

- Eaton EN-0201 ® Hydraulic MotorДокумент8 страницEaton EN-0201 ® Hydraulic Motormemelo3Оценок пока нет

- Re 15190Документ24 страницыRe 15190Ahmed Abd ElhakeemОценок пока нет

- Re92060 2014-04Документ28 страницRe92060 2014-04Ibrahim GökmenОценок пока нет

- Pump Unload Pilot Valve SUN QPABДокумент2 страницыPump Unload Pilot Valve SUN QPABankesh_ghoghariОценок пока нет

- A17FOДокумент16 страницA17FOJose SalvadorОценок пока нет

- Re 10460Документ20 страницRe 10460Ahmed Abd ElhakeemОценок пока нет

- Válvula Direcional RexRothДокумент22 страницыVálvula Direcional RexRothrfcardОценок пока нет

- 15 05 025 - Modification and Refurbishment ReportДокумент9 страниц15 05 025 - Modification and Refurbishment ReportEngineersEDGE CoimbatoreОценок пока нет

- Spare Parts List: R901352448 R961005926 Drawing: Material NumberДокумент4 страницыSpare Parts List: R901352448 R961005926 Drawing: Material NumberMohamed HusseinОценок пока нет

- Cat Hy14 1600 Denison Products PDFДокумент438 страницCat Hy14 1600 Denison Products PDFEmiliano MercadoОценок пока нет

- Regulating Pumps for Open Loop SystemsДокумент24 страницыRegulating Pumps for Open Loop SystemsxxshОценок пока нет

- Hänchen Overview PDFДокумент19 страницHänchen Overview PDFBruno CecattoОценок пока нет

- Spare Parts List: B1517222382 Drawing: Material NumberДокумент6 страницSpare Parts List: B1517222382 Drawing: Material NumberAgus YulfizarОценок пока нет

- TRITORC New 2017 Hydraulic and Bolting Catalogue PDFДокумент45 страницTRITORC New 2017 Hydraulic and Bolting Catalogue PDFSun ChenОценок пока нет

- t7-t67-t6 Vane Service Kits 02-EN-SVC VANE KITS-H1 2003 MAY PDFДокумент12 страницt7-t67-t6 Vane Service Kits 02-EN-SVC VANE KITS-H1 2003 MAY PDFosamaОценок пока нет

- A (A) 10vso18-140 Series 3x PDFДокумент36 страницA (A) 10vso18-140 Series 3x PDFR.Ranjan PradhanОценок пока нет

- Bomba Pistao Variavel A4vg PDFДокумент72 страницыBomba Pistao Variavel A4vg PDFtawfeeqsylanОценок пока нет

- Hydraulic TechnologyДокумент76 страницHydraulic TechnologyOgulcan CafОценок пока нет

- Moog G122-829A DS A4 v2Документ4 страницыMoog G122-829A DS A4 v2Hammad AshrafОценок пока нет

- ME597 Lecture5 13Документ34 страницыME597 Lecture5 13bee1406763181Оценок пока нет

- Moog G122-829-001 - Catalog1Документ2 страницыMoog G122-829-001 - Catalog1Jean-Roch JacquesОценок пока нет

- Accumulator Unloading Valve, Type MRQAДокумент2 страницыAccumulator Unloading Valve, Type MRQALibinОценок пока нет

- Atos - Modular Relief Valve - HMP HM KMДокумент4 страницыAtos - Modular Relief Valve - HMP HM KMClaudecir PereiraОценок пока нет

- Re 91401Документ20 страницRe 91401JozefОценок пока нет

- METRUS Test Bench Overview 2017Документ8 страницMETRUS Test Bench Overview 2017Ozawa MagooОценок пока нет

- Duplex Filter PDFДокумент4 страницыDuplex Filter PDFmd abОценок пока нет

- S1 AM019 C DenisonДокумент25 страницS1 AM019 C DenisonEmerson MazzaroloОценок пока нет

- Denison Calzoni Type MRT Mrte MRTFДокумент24 страницыDenison Calzoni Type MRT Mrte MRTFSilvio RomanОценок пока нет

- A2FE + ID Br61Документ1 страницаA2FE + ID Br61muhammadОценок пока нет

- Salami Catalog Group3 Zupcaste PumpeДокумент32 страницыSalami Catalog Group3 Zupcaste Pumpeado_22Оценок пока нет

- Denison Hydraulics Pressure Relief Valves: Series R1E02Документ5 страницDenison Hydraulics Pressure Relief Valves: Series R1E02Leonardo ViilalobosОценок пока нет

- Application Center Fork-Lift TrucksДокумент10 страницApplication Center Fork-Lift TrucksQXNОценок пока нет

- Product Manual for Hägglunds Drives Viking Hydraulic MotorsДокумент26 страницProduct Manual for Hägglunds Drives Viking Hydraulic MotorsKOSTAS100% (1)

- Technical Manual ICVD 1111Документ24 страницыTechnical Manual ICVD 1111Angelo MedinaОценок пока нет

- 7 Hydraulic CKT 18P2Документ17 страниц7 Hydraulic CKT 18P2M RazzaqueОценок пока нет

- RE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMДокумент8 страницRE 22 371/03.98 - 4/3 and 4/2 directional control valves with hand lever Type WMMAhmed Abd ElhakeemОценок пока нет

- HydraulicsДокумент253 страницыHydraulicsvelavansuОценок пока нет

- Proportional Pressure Relief Valve R4V DENISONДокумент15 страницProportional Pressure Relief Valve R4V DENISONBerenice Bautista BelmontesОценок пока нет

- 10 01 Breather Filters GBДокумент8 страниц10 01 Breather Filters GBosuengОценок пока нет

- ME597 Lecture4 07Документ36 страницME597 Lecture4 07Neville McBeanОценок пока нет

- Power Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Документ64 страницыPower Control LR2, LR3, LR2N and LR3N: Replaces: 05.95Irina VarzouОценок пока нет

- Hydraulic Cylinder Demonstration at Cairo University Mechanical Engineering DepartmentДокумент21 страницаHydraulic Cylinder Demonstration at Cairo University Mechanical Engineering DepartmentengmomoОценок пока нет

- P1 PD CompensatorsДокумент13 страницP1 PD CompensatorsxxshОценок пока нет

- HRB Hydrostatic Regenerative Braking System TheДокумент7 страницHRB Hydrostatic Regenerative Braking System ThexxshОценок пока нет

- Hydro Fluid EngДокумент6 страницHydro Fluid EngИлья РадзивиновичОценок пока нет

- Hydraulic Pump ParkerДокумент6 страницHydraulic Pump Parkermecamb100% (1)

- RA 90 221 Rexroth Environmentally Acceptable Hydraulic Fluids PDFДокумент8 страницRA 90 221 Rexroth Environmentally Acceptable Hydraulic Fluids PDFeng13Оценок пока нет

- Mobility Measurements PDFДокумент2 страницыMobility Measurements PDFeng13Оценок пока нет

- LDS ApplicationsДокумент16 страницLDS Applicationseng13Оценок пока нет

- Indoor Passby SystemДокумент6 страницIndoor Passby Systemeng13Оценок пока нет

- Wind Gearbox BearingsДокумент2 страницыWind Gearbox Bearingseng13Оценок пока нет

- Aerodinamic Noise PDFДокумент8 страницAerodinamic Noise PDFeng13Оценок пока нет

- Wind Energy BearingsДокумент1 страницаWind Energy Bearingseng13Оценок пока нет

- Webtrak - : My NeighbourhoodДокумент2 страницыWebtrak - : My Neighbourhoodeng13Оценок пока нет

- Kurtosis Analisys PDFДокумент8 страницKurtosis Analisys PDFeng13Оценок пока нет

- Complex Modulus Estimation PDFДокумент8 страницComplex Modulus Estimation PDFeng13Оценок пока нет

- Webtrak - : My NeighbourhoodДокумент2 страницыWebtrak - : My Neighbourhoodeng13Оценок пока нет

- Bearings - CylindricalДокумент8 страницBearings - Cylindricaleng13Оценок пока нет

- Bearings - Grease Check PDFДокумент2 страницыBearings - Grease Check PDFeng13Оценок пока нет

- Bearings For Bottle and Beverage IndustryДокумент2 страницыBearings For Bottle and Beverage Industryeng13Оценок пока нет

- Wind Main RotorДокумент2 страницыWind Main Rotoreng13Оценок пока нет

- Food Designed BearingsДокумент2 страницыFood Designed Bearingseng13Оценок пока нет

- Bearings Seafood IndustryДокумент2 страницыBearings Seafood Industryeng13Оценок пока нет

- Interchange TableДокумент6 страницInterchange Tableeng13Оценок пока нет

- Reliable Packaging Equipment Design Should Not Be Kept Under WrapsДокумент2 страницыReliable Packaging Equipment Design Should Not Be Kept Under Wrapseng13Оценок пока нет

- Mounted Bearings UnitsДокумент2 страницыMounted Bearings Unitseng13Оценок пока нет

- Precision Machine Tool BearingДокумент4 страницыPrecision Machine Tool Bearingeng13Оценок пока нет

- Food Processing BearingsДокумент2 страницыFood Processing Bearingseng13Оценок пока нет

- Industrial Electrical HandbookДокумент122 страницыIndustrial Electrical Handbookeng13100% (3)

- Advanced Bearing Technologies & Value-Added ServicesДокумент5 страницAdvanced Bearing Technologies & Value-Added Serviceseng13Оценок пока нет

- Vibration Test Apllications B&KДокумент16 страницVibration Test Apllications B&Keng13Оценок пока нет

- Bearings For The Food and Beverage IndustriesДокумент7 страницBearings For The Food and Beverage Industrieseng13Оценок пока нет

- Mounted Bearings Unit - Corrosion Resistant SeriesДокумент6 страницMounted Bearings Unit - Corrosion Resistant Serieseng13Оценок пока нет

- LDS ApplicationsДокумент16 страницLDS Applicationseng13Оценок пока нет

- LDS ApplicationsДокумент16 страницLDS Applicationseng13Оценок пока нет

- Bearing For GearboxДокумент32 страницыBearing For Gearboxeng13100% (1)

- Lux MeterДокумент4 страницыLux MeterNmg KumarОценок пока нет

- The Eukaryotic Replication Machine: D. Zhang, M. O'DonnellДокумент39 страницThe Eukaryotic Replication Machine: D. Zhang, M. O'DonnellÁgnes TóthОценок пока нет

- Whirlpool FL 5064 (ET)Документ8 страницWhirlpool FL 5064 (ET)long_kongo100% (1)

- Small Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Документ20 страницSmall Healthcare Organization: National Accreditation Board For Hospitals & Healthcare Providers (Nabh)Dipti PatilОценок пока нет

- How To Approach To Case Study Type Questions and MCQsДокумент4 страницыHow To Approach To Case Study Type Questions and MCQsKushang ShahОценок пока нет

- Lab 1 Handout Electrical MachinesДокумент23 страницыLab 1 Handout Electrical Machinesvishalsharma08Оценок пока нет

- Documentation For UStarДокумент26 страницDocumentation For UStarthunder77Оценок пока нет

- TM500 Design Overview (Complete ArchitectureДокумент3 страницыTM500 Design Overview (Complete ArchitectureppghoshinОценок пока нет

- DLP Din8Документ2 страницыDLP Din8KOUDJIL MohamedОценок пока нет

- Technology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural ProductsДокумент14 страницTechnology and Livelihood Education: Agri - Fishery Arts (Agricultural Crops Production) Marketing Agricultural Productslana del rey100% (1)

- 21 Great Answers To: Order ID: 0028913Документ13 страниц21 Great Answers To: Order ID: 0028913Yvette HOUNGUE100% (1)

- MAPEH 6- WEEK 1 ActivitiesДокумент4 страницыMAPEH 6- WEEK 1 ActivitiesCatherine Renante100% (2)

- Lec08 (Topic 4 Define Classes)Документ33 страницыLec08 (Topic 4 Define Classes)huaiencheengОценок пока нет

- Pnas 1703856114Документ5 страницPnas 1703856114pi. capricorniОценок пока нет

- Dewatering Well PointsДокумент4 страницыDewatering Well Pointssalloum3Оценок пока нет

- Movement Joints (NHBC)Документ5 страницMovement Joints (NHBC)hemendraengОценок пока нет

- MST 2 ReviewerДокумент4 страницыMST 2 ReviewerAizha NarioОценок пока нет

- Timeline of Internet in The PhilippinesДокумент29 страницTimeline of Internet in The PhilippinesJhayson Joeshua Rubio100% (1)

- Critical Thinking Essay-Animal Testing: Rough DraftДокумент10 страницCritical Thinking Essay-Animal Testing: Rough Draftjeremygcap2017Оценок пока нет

- Confirmation Form: Pillar Regional Conference (NCR)Документ1 страницаConfirmation Form: Pillar Regional Conference (NCR)Llano Multi-Purpose CooperativeОценок пока нет

- Naaqs 2009Документ2 страницыNaaqs 2009sreenОценок пока нет

- Calculating Molar MassДокумент5 страницCalculating Molar MassTracy LingОценок пока нет

- U1L2 - Definitions of 21st Century LiteraciesДокумент19 страницU1L2 - Definitions of 21st Century LiteraciesJerry Glenn Latorre CastilloОценок пока нет

- Drag Embedded AnchorsДокумент6 страницDrag Embedded AnchorsrussellboxhallОценок пока нет

- Lecture 6Документ16 страницLecture 6Dina Saad EskandereОценок пока нет

- Measuring Algorithm Efficiency Using Time and Space ComplexityДокумент8 страницMeasuring Algorithm Efficiency Using Time and Space ComplexityGovind RathoreОценок пока нет

- Campbell Soup Case-StudyДокумент3 страницыCampbell Soup Case-StudyraghudeepaОценок пока нет

- Design of Hydraulic Structures Seepage TheoryДокумент13 страницDesign of Hydraulic Structures Seepage TheorySuleman FaisalОценок пока нет

- Dball-Gm5 en Ig Cp20110328aДокумент18 страницDball-Gm5 en Ig Cp20110328aMichael MartinezОценок пока нет

- (Math 6 WK 5 L9) - Problems Involving Addition and or Subtraction of DecimalsДокумент43 страницы(Math 6 WK 5 L9) - Problems Involving Addition and or Subtraction of DecimalsRhea OciteОценок пока нет

- University of Chicago Press Fall 2009 Distributed TitlesОт EverandUniversity of Chicago Press Fall 2009 Distributed TitlesРейтинг: 1 из 5 звезд1/5 (1)