Академический Документы

Профессиональный Документы

Культура Документы

Fluid Coupling

Загружено:

Balu SukumarОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fluid Coupling

Загружено:

Balu SukumarАвторское право:

Доступные форматы

Fluid coupling

From Wikipedia, the free encyclopedia

Jump to: navigation, search This article is not about hydrodyamic fluid complings, for "hydroviscous fluid couplings" see Viscous coupling unit. A fluid coupling is a hydrodynamic device used to transmit rotating mechanical power.[1] It has been used in automobile transmissions as an alternative to a mechanical clutch. It also has widespread application in marine and industrial machine drives, where variable speed operation and/or controlled start-up without shock loading of the power transmission system is essential.

Contents

1 History 2 Overview o 2.1 Stall speed o 2.2 Slip o 2.3 Hydraulic fluid o 2.4 Hydrodynamic braking 3 Applications o 3.1 Industrial o 3.2 Rail transportation o 3.3 Automotive o 3.4 Aviation 4 Calculations 5 Manufacture 6 See also 7 References and notes o 7.1 Notes o 7.2 References

[edit] History

The fluid coupling originates from the work of Dr. Hermann Fttinger, who was the chief designer at the AG Vulcan Works in Stettin.[2]. His patents from 1905 covered both fluid couplings and torque converters. In 1930 Harold Sinclair, working with the Daimler company, devised a transmission system using a fluid coupling and planetary gearing for buses in an attempt to mitigate the lurching he had experienced while riding on London buses during the 1920s.[2]

In 1939 General Motors Corporation introduced Hydramatic drive, the first fully automatic automotive transmission system installed in a mass produced automobile[2]. The Hydramatic employed a fluid coupling. The first Diesel locomotives using fluid couplings were also produced in the 1930s[3]

[edit] Overview

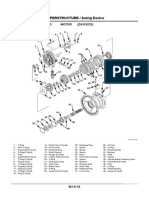

A fluid coupling consists of three components, plus the hydraulic fluid:

The housing, (which must have an oil tight seal around the drive shafts) - contains the fluid and turbines. (also known as the shell[4]) Two turbines (fan like components): [4] o One connected to the input shaft; known as the pump or impellor , primary [4] wheel input turbine o The other connected to the output shaft, known as the turbine, output turbine, secondary wheel[4] or runner

The driving turbine, known as the 'pump', (or driving torus[note 1]) is rotated by the prime mover, which is typically an internal combustion engine or electric motor. The impellor's motion imparts both outwards linear and rotational motion to the fluid. The hydraulic fluid is directed by the 'pump' whose shape forces the flow in the direction of the 'output turbine' (or driven torus[note 1]). Here, any difference in the angular velocities of 'input stage' and 'output stage' result in a net force on the 'output turbine' causing a torque; thus causing it to rotate in the same direction as the pump. The motion of the fluid is effectively toroidal - travelling in one direction on paths that can be visualised as being on the surface of a torus:

If there is a difference between input and output angular velocities the motion has a component which is circular (ie round the rings formed by sections of the torus) If the input and output stages have identical angular velocities there is no net centripetal force - and the motion of the fluid is circular and co-axial with the axis of rotation (ie round the edges of a torus), there is no flow of fluid from one turbine to the other.

[edit] Stall speed

An important characteristic of a fluid coupling is its stall speed. The stall speed is defined as the highest speed at which the pump can turn when the output turbine is locked and maximum input power is applied. Under stall conditions all of the engine's power would be dissipated in the fluid coupling as heat, possibly leading to damage. Step-circuit coupling

A modification to the simple fluid coupling is the step-circuit coupling which was formerly manufactured as the "STC coupling" by the Fluidrive Engineering Company. The STC coupling contains a reservoir to which some, but not all, of the oil gravitates when the output shaft is stalled. This reduces the "drag" on the input shaft, resulting in reduced fuel consumption when idling and a reduction in the vehicle's tendency to "creep". When the output shaft begins to rotate, the oil is thrown out of the reservoir by centrifugal force, and returns to the main body of the coupling, so that normal power transmission is restored [5].

[edit] Slip

A fluid coupling cannot develop output torque when the input and output angular velocities are identical.[6] Hence a fluid coupling cannot achieve 100 percent power transmission efficiency. Due to slippage that will occur in any fluid coupling under load, some power will always be lost in fluid friction and turbulence, and dissipated as heat. The very best efficiency a fluid coupling can achieve is 94%, that is for every 100 revolutions input, there will be 94 revolutions output.

[edit] Hydraulic fluid

As a fluid coupling operates kinetically, low viscosity fluids are preferred.[6] Generally speaking, multi-grade motor oils or automatic transmission fluids are used. Increasing density of the fluid increases the amount of torque that can be transmitted at a given input speed.[7]

[edit] Hydrodynamic braking

Fluid couplings can also act as hydrodynamic brakes, dissipating rotational energy as heat through frictional forces (both viscous and fluid/container). When a fluid coupling is used for braking it is also known as a retarder.[4]

[edit] Applications

[edit] Industrial

Fluid couplings are used in many industrial application involving rotational power[8][9], especially in machine drives that involve high-inertia starts or constant cyclic loading.

[edit] Rail transportation

Fluid couplings are found in some Diesel locomotives as part of the power transmission system.

[edit] Automotive

Fluid couplings were used in a variety of early semi-automatic transmissions and automatic transmissions. Since the late 1940s, the hydrodynamic torque converter has replaced the fluid coupling in automotive applications. In automotive applications, the pump typically is connected to the flywheel of the enginein fact, the coupling's enclosure may be part of the flywheel proper, and thus is turned by the engine's crankshaft. The turbine is connected to the input shaft of the transmission. While the transmission is in gear, as engine speed increases torque is transferred from the engine to the input shaft by the motion of the fluid, propelling the vehicle. In this regard, the behavior of the fluid coupling strongly resembles that of a mechanical clutch driving a manual transmission. Fluid flywheels, as distinct from torque converters, are best known for their use in Daimler cars in conjunction with a Wilson pre-selector gearbox. Daimler used these throughout their range of luxury cars, until switching to automatic gearboxes with the 1958 Majestic. Daimler and Alvis were both also known for their military vehicles and armored cars, some of which also used the combination of pre-selector gearbox and fluid flywheel.

[edit] Aviation

The most prominent use of fluid couplings in aeronautical applications was in the Wright turbocompound reciprocating engine, in which three power recovery turbines extracted approximately 20 percent of the energy or about 500 horsepower (370 kW) from the engine's exhaust gases and then, using three fluid couplings and gearing, converted low-torque high-speed turbine rotation to low-speed, high-torque output to drive the propeller.

[edit] Calculations

Generally speaking, the power transmitting capability of a given fluid coupling is exponentially related to pump speed, a characteristic that generally works well with applications where the applied load doesn't fluctuate to a great degree. The torque transmitting capacity of any hydrodynamic coupling can be described by the expression r(N2)(D5), where r is the mass density of the fluid, N is the impeller speed, and D is the impeller diameter.[10] In the case of automotive applications, where loading can vary to considerable extremes, r(N2)(D5) is only an approximation. Stop-and-go driving will tend to operate the coupling in its least efficient range, causing an adverse effect on fuel economy.

[edit] Manufacture

Fluid couplings are relatively simple components to produce. For example, the turbines can be aluminum castings or steel stampings, and the housing can also be a casting or made from stamped or forged steel. Manufacturers of industrial fluid couplings include Voith, TwinDisc,[11] Siemens,[12] PARAG,[13] Fluidomat,[14] and Reuland Electric.[15]

[edit] See also

Torque converter Water brake

[edit] References and notes

[edit] Notes

1. ^ a b A General Motors term

[edit] References

1. ^ Fluid coupling encyclopedia2.thefreedictionary.com 2. ^ a b c Light and Heavy Vehicle Technology, Malcolm James Nunney, p 317 (Google Books link) 3. ^ Illustrated Encyclopedia of World Railway Locomotives, Patrick Ransome-Wallis, p 64 (ISBN 0486412474, 9780486412474 Google Books link) 4. ^ a b c d e Fluid couplings glossary voithturbo.com 5. ^ Bolton, W.F., The Railwayman's Diesel Manual, 4th edition 1963, Ian Allan Publishing, pp97-98 6. ^ a b Why is the output speed of a turbo coupling always lower than the input speed? voithturbo.com from Voith - Fluid couplings FAQ 7. ^ Does the type of operating fluid influence the transmission behaviour? voithturbo.com from Voith - Fluid couplings FAQ 8. ^ Industry/Sector Industrial and other uses of fluid couplings voithturbo.com 9. ^ Process Uses of fluid coupling by process voithturbo.com 10. ^ Hydrodynamic couplings and converters. Automotive Handbook (3rd ed.). Robert Bosch. pp. 539. ISBN 0-8376-0330-7. 11. ^ TwinDisc: Fluid couplings, twindisc.com 12. ^ Siemens: Hydrodynamic couplings, automation.siemens.com 13. ^ PARAG Engineering: Fluid Couplings 14. ^ Fluidomat fluidomat.com 15. ^ Reuland Electric Co., Inc. Retrieved from "http://en.wikipedia.org/wiki/Fluid_coupling" Categories: Mechanical power transmission | Automotive transmission technologies

Views

Article Discussion Edit this page History

Personal tools

Try Beta Log in / create account

Navigation Search

Special:Search

Main page Contents Featured content Current events Random article

Go

Search

Interaction Toolbox

About Wikipedia Community portal Recent changes Contact Wikipedia Donate to Wikipedia Help

What links here Related changes Upload file Special pages Printable version Permanent link Cite this page

Languages

Espaol Esperanto Svenska

This page was last modified on 14 February 2010 at 23:41. Text is available under the Creative Commons Attribution-ShareAlike License; additional terms may apply. See Terms of Use for details. Wikipedia is a registered trademark of the Wikimedia Foundation, Inc., a non-profit organization. Contact us Privacy policy About Wikipedia Disclaimers

Вам также может понравиться

- C7 On-Highway Engine Electrical System: Nph1-Up Lbm1-Up SAP3956-UP Wax1-UpДокумент2 страницыC7 On-Highway Engine Electrical System: Nph1-Up Lbm1-Up SAP3956-UP Wax1-UpCiprian AndreescuОценок пока нет

- Southern Marine Engineering Desk Reference: Second Edition Volume IiОт EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiОценок пока нет

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideОт EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideРейтинг: 4 из 5 звезд4/5 (8)

- Report of Cam ShaftДокумент85 страницReport of Cam ShaftkotoyayОценок пока нет

- Diesel Mechanics by Frank SandersДокумент164 страницыDiesel Mechanics by Frank SandersMahdi HocineОценок пока нет

- Ship Power PlantДокумент141 страницаShip Power Plantnguyentrunghieu51dltt100% (2)

- Pounder's Marine Diesel Engines and Gas TurbinesОт EverandPounder's Marine Diesel Engines and Gas TurbinesРейтинг: 4 из 5 звезд4/5 (15)

- Pareto 1 - 27 Mei 2019Документ302 страницыPareto 1 - 27 Mei 2019SARTONO INDO FRANSОценок пока нет

- Engineering Encyclopedia: Centrifugal PumpsДокумент70 страницEngineering Encyclopedia: Centrifugal PumpsMajdi Belguith67% (3)

- s50mc Vol IIДокумент778 страницs50mc Vol IIcengiz kutukcu100% (2)

- Manual de Yanmar 4TNV106Документ84 страницыManual de Yanmar 4TNV106EduardoCastilloОценок пока нет

- Periodic Maintenance: S80, 100, 120FT S80, 100FTBCS S120FTS S120FTPRS (G004) H80, 90, 100, 110, 120FT (N005)Документ104 страницыPeriodic Maintenance: S80, 100, 120FT S80, 100FTBCS S120FTS S120FTPRS (G004) H80, 90, 100, 110, 120FT (N005)Fabricio FélixОценок пока нет

- Two Stroke EngineДокумент13 страницTwo Stroke EngineAaron PriceОценок пока нет

- MitsubishiДокумент7 страницMitsubishiJhon Sanchez LopezОценок пока нет

- Column Base Plates DesignДокумент19 страницColumn Base Plates Designccbserialk80% (5)

- Mitsubishi Forklift Fault Codes ExplainedДокумент6 страницMitsubishi Forklift Fault Codes ExplainedСергей Бондаренко100% (1)

- VOITH Variable Speed Fluid CouplingsДокумент20 страницVOITH Variable Speed Fluid CouplingsSamir BenabdallahОценок пока нет

- Fluid Coupling &torque ConverterДокумент5 страницFluid Coupling &torque ConverterArsh Gautam UD100% (1)

- Ket Vocabulary List PDFДокумент29 страницKet Vocabulary List PDFBalu Sukumar0% (2)

- Ket Vocabulary List PDFДокумент29 страницKet Vocabulary List PDFBalu Sukumar0% (2)

- Ket Vocabulary List PDFДокумент29 страницKet Vocabulary List PDFBalu Sukumar0% (2)

- Two Stroke EngineДокумент16 страницTwo Stroke EngineRam KarthikОценок пока нет

- Design of Hydraulic Platform LiftДокумент31 страницаDesign of Hydraulic Platform LiftzetseatОценок пока нет

- Catalog 6chl SeriesДокумент118 страницCatalog 6chl SeriesRizki Adrian MadridistaОценок пока нет

- 39 Design of V - Belt DrivesДокумент10 страниц39 Design of V - Belt DrivesPRASAD326100% (6)

- Aircraft SystemsДокумент40 страницAircraft SystemsRadu AndreiОценок пока нет

- Deutz 226B Operation ManualДокумент58 страницDeutz 226B Operation ManualThanh Secondheart84% (32)

- Term Paper On Fluid Coupling and Torques Converter Converted 1Документ24 страницыTerm Paper On Fluid Coupling and Torques Converter Converted 1OLUBABA100% (3)

- Thayer Scale Belt Conveyor Data SheetДокумент3 страницыThayer Scale Belt Conveyor Data SheetBalu Sukumar100% (1)

- Troubleshooting Turbine SystemsДокумент74 страницыTroubleshooting Turbine Systemsdaaanb100% (1)

- SIS News 3500 SeriesДокумент56 страницSIS News 3500 SeriesЕвгений АбрамовОценок пока нет

- E GTH-3514R From SN 10295 To 18904Документ208 страницE GTH-3514R From SN 10295 To 18904walmzaОценок пока нет

- Voith Coupling EngДокумент12 страницVoith Coupling Engrikumohan100% (1)

- 794 Ac m01 Opstation enДокумент30 страниц794 Ac m01 Opstation enDavidCPОценок пока нет

- Engine spare parts catalogue section and part codesДокумент185 страницEngine spare parts catalogue section and part codespgerbzmОценок пока нет

- Misc. Fluid MachinesДокумент17 страницMisc. Fluid MachinesJyotikrishna Gautam0% (1)

- TM Unit 6Документ5 страницTM Unit 6eyobОценок пока нет

- Fluid Coupling NotesДокумент13 страницFluid Coupling NotesDSKОценок пока нет

- Fluid Coupling and Tourque ConverterДокумент19 страницFluid Coupling and Tourque ConverterMD Mahmudul Hasan MasudОценок пока нет

- Cam ShaftДокумент9 страницCam ShaftashokkumarОценок пока нет

- Fluid Coupling EngineeringДокумент4 страницыFluid Coupling EngineeringPraveen KumaranrОценок пока нет

- Fluid Coupling Guide - Less Than 40 CharactersДокумент2 страницыFluid Coupling Guide - Less Than 40 CharactersKKDhОценок пока нет

- Seminar Report Final AzharДокумент37 страницSeminar Report Final AzharManjeet SinghОценок пока нет

- IC Engine Seminar ReportДокумент25 страницIC Engine Seminar Reportrupam_chanda75% (4)

- By Carlos RodriguezДокумент9 страницBy Carlos RodriguezMuzammilОценок пока нет

- Hydraulic drive system basicsДокумент6 страницHydraulic drive system basicsyamnul khairОценок пока нет

- Luid Ower Ngineering: TopicДокумент19 страницLuid Ower Ngineering: TopicMD Mahmudul Hasan MasudОценок пока нет

- Mixing FundaДокумент19 страницMixing FundaVinod SiramОценок пока нет

- Fluid Coupling Working Principle - Advantages of Fluid Coupling, TypesДокумент10 страницFluid Coupling Working Principle - Advantages of Fluid Coupling, Typessam abusiОценок пока нет

- Two-stroke Basics: How They Work and Their AdvantagesДокумент11 страницTwo-stroke Basics: How They Work and Their AdvantagesAfzal Shams100% (1)

- Transfl Spoj KRДокумент32 страницыTransfl Spoj KREmir MujićОценок пока нет

- Raising a New Generation of Fluid Machinery LeadersДокумент22 страницыRaising a New Generation of Fluid Machinery LeadersAtiba JoshuaОценок пока нет

- Rocker ArmДокумент3 страницыRocker ArmAries M. SuarezОценок пока нет

- 2 Descripción Motores ReciprocosДокумент53 страницы2 Descripción Motores ReciprocosAngel Julian HernandezОценок пока нет

- IC Engine Seminar ReportДокумент28 страницIC Engine Seminar ReportDiwakar Diwakar100% (1)

- Report On Cylinder DeactivationДокумент7 страницReport On Cylinder Deactivationsanchit333Оценок пока нет

- A Shock AbsorberДокумент5 страницA Shock Absorberriz2010Оценок пока нет

- Pimsat Colleges Engineering Materials 1Документ8 страницPimsat Colleges Engineering Materials 1Sev Anne T. GonzalesОценок пока нет

- NEVA93011FUДокумент21 страницаNEVA93011FUvictor.ansartОценок пока нет

- Two Stroke Engine 2016Документ11 страницTwo Stroke Engine 2016Happy singhОценок пока нет

- Hydraulic Torque Coverter: Shree Sa'D Vidya Mandal Institute of TechnologyДокумент17 страницHydraulic Torque Coverter: Shree Sa'D Vidya Mandal Institute of TechnologyReilyОценок пока нет

- Engine Intro Duction 5Документ10 страницEngine Intro Duction 5haithanh doanОценок пока нет

- Anm FullДокумент100 страницAnm FullramizОценок пока нет

- Function: Torque Converter ElementsДокумент2 страницыFunction: Torque Converter ElementsEdward StephenОценок пока нет

- MIVECДокумент5 страницMIVECbe_aeonОценок пока нет

- Vishnu Chaudhary HydraulicsДокумент17 страницVishnu Chaudhary Hydraulicsvishnu chaudharyОценок пока нет

- Vishnu Chaudhary HydraulicsДокумент17 страницVishnu Chaudhary Hydraulicsvishnu chaudharyОценок пока нет

- Automotive EngineДокумент4 страницыAutomotive Enginewilliameve2007Оценок пока нет

- 85 Air Compressor Engine NewДокумент61 страница85 Air Compressor Engine NewdmomshantiОценок пока нет

- Fluid Coupling in Belt Conveyor DrivesДокумент12 страницFluid Coupling in Belt Conveyor Drivesnoelaroboi100% (2)

- Rocker arm engine partДокумент10 страницRocker arm engine partseaОценок пока нет

- Transmission Mechanics ExplainedДокумент6 страницTransmission Mechanics ExplainedSelva KumarОценок пока нет

- Four-Stroke Four-Cylinder Engine Performance and Scuderi Split Engine DevelopmentДокумент19 страницFour-Stroke Four-Cylinder Engine Performance and Scuderi Split Engine DevelopmentJashanBassiОценок пока нет

- BSNL Mar 13 Bill PDFДокумент1 страницаBSNL Mar 13 Bill PDFBalu SukumarОценок пока нет

- Bill Mar 12Документ1 страницаBill Mar 12Balu SukumarОценок пока нет

- Mounting of Bearing PDFДокумент13 страницMounting of Bearing PDFBalu SukumarОценок пока нет

- CRISIL IER report on CMI Ltd highlights growth and working capital risksДокумент32 страницыCRISIL IER report on CMI Ltd highlights growth and working capital risksBalu SukumarОценок пока нет

- WPSДокумент2 страницыWPSBalu SukumarОценок пока нет

- KPMG Bribery Survey Report NewДокумент20 страницKPMG Bribery Survey Report NewBalu SukumarОценок пока нет

- What Young India Wants WeLearnFree PDFДокумент105 страницWhat Young India Wants WeLearnFree PDFkulz_kk716450% (4)

- Instructions and Application Form For GATE 2012Документ4 страницыInstructions and Application Form For GATE 2012Balu SukumarОценок пока нет

- Const - Pock 2Pg - Rom8FsssДокумент13 страницConst - Pock 2Pg - Rom8FsssBalu SukumarОценок пока нет

- HAL RecruitmentДокумент13 страницHAL RecruitmentPraveen Kumar ReddyОценок пока нет

- IS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StorageДокумент98 страницIS803 - Code of Practice For Design Fabrication and Erection of Vertical Mild Steel Cylinderical Welded Oil StoragePankaj DhimanОценок пока нет

- ReasoningLecture1W 12Документ15 страницReasoningLecture1W 12tamilanbaОценок пока нет

- Trouble Shooting - Noises: Bearings: Crosstrainer Service ManualДокумент3 страницыTrouble Shooting - Noises: Bearings: Crosstrainer Service ManualBalu SukumarОценок пока нет

- Me Gate 2012Документ22 страницыMe Gate 2012sauravkk245Оценок пока нет

- Trouble Shooting - Noises: Bearings: Crosstrainer Service ManualДокумент3 страницыTrouble Shooting - Noises: Bearings: Crosstrainer Service ManualBalu SukumarОценок пока нет

- Neyveli Lignite Corporation LTD, Barsingsar 2x125 MW Barsingsar Thermal Power Station Lignite Handling Plant Log Sheet For LHP, Barsingsar DateДокумент2 страницыNeyveli Lignite Corporation LTD, Barsingsar 2x125 MW Barsingsar Thermal Power Station Lignite Handling Plant Log Sheet For LHP, Barsingsar DateBalu SukumarОценок пока нет

- Monthly MHP ReportДокумент13 страницMonthly MHP ReportBalu SukumarОценок пока нет

- How To Prepare Competitive ExamsДокумент37 страницHow To Prepare Competitive ExamsNagarajesh NaraparajuОценок пока нет

- ME-Paper Code-A GATE 2011: Answer: - (B) ExplanationДокумент22 страницыME-Paper Code-A GATE 2011: Answer: - (B) ExplanationIMLOGANОценок пока нет

- Complete AutoCAD CommandsДокумент40 страницComplete AutoCAD Commandskamoteng100% (1)

- Raulic Thrusters Guide: Types, Capacities & Internal ViewsДокумент3 страницыRaulic Thrusters Guide: Types, Capacities & Internal ViewsBalu SukumarОценок пока нет

- Test of Reasoning...Документ63 страницыTest of Reasoning...ramavarshnyОценок пока нет

- CAT Word ListДокумент54 страницыCAT Word ListBalu SukumarОценок пока нет

- Avid Elixir Manual 2013Документ59 страницAvid Elixir Manual 2013Andrei Mosora0% (2)

- 1991 Mitsubishi Montero Electrical Components LocatorДокумент21 страница1991 Mitsubishi Montero Electrical Components LocatorAnimemanuel MuñozОценок пока нет

- Crankshaft Grinding Specifications: RG, RG34710,1176-19-19971023Документ1 страницаCrankshaft Grinding Specifications: RG, RG34710,1176-19-19971023иван ТрояновОценок пока нет

- Torque Transmission Drive Shaft Final Drive Unit Spiral Bevel Pinion Crown Wheel HypoidДокумент4 страницыTorque Transmission Drive Shaft Final Drive Unit Spiral Bevel Pinion Crown Wheel HypoidWaqasОценок пока нет

- Cummins - Engine Fault FindingДокумент188 страницCummins - Engine Fault Findingmanbtm2Оценок пока нет

- Contents and Components of the Parking Brake SystemДокумент15 страницContents and Components of the Parking Brake SystemRaphael Francisco PuttiniОценок пока нет

- Perhitungan Struktur TangkiДокумент2 страницыPerhitungan Struktur TangkiRizal GahtanОценок пока нет

- Engine Cranks But Will Not Start: Shutdown SIS Previous ScreenДокумент8 страницEngine Cranks But Will Not Start: Shutdown SIS Previous ScreenAHMED2ALIОценок пока нет

- Advanced Braking Systems BrochureДокумент12 страницAdvanced Braking Systems BrochureIonut Valentin Vlad100% (1)

- Kubota Kx41 2 Parts ManualДокумент20 страницKubota Kx41 2 Parts Manualneil100% (58)

- Opposed Piston Pulling Rod EngineДокумент38 страницOpposed Piston Pulling Rod Enginepaul20000Оценок пока нет

- Manual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Документ1 страницаManual de Taller Excavadora Hitachi Zx200 225 230 270 - 216Andi KaОценок пока нет

- Ducati 1098 2007 Parts List WWW - Manualedereparatie.infoДокумент116 страницDucati 1098 2007 Parts List WWW - Manualedereparatie.infodreamopenerОценок пока нет

- General Information OverviewДокумент48 страницGeneral Information OverviewKhalid AwanОценок пока нет

- Case Study on Pro/E Integration at Mercury MarineДокумент24 страницыCase Study on Pro/E Integration at Mercury MarineChris BellОценок пока нет

- 2012 Audi A6: ManualДокумент298 страниц2012 Audi A6: ManualTed ÖrkenrudОценок пока нет

- C87 Ent: Air InductionДокумент3 страницыC87 Ent: Air InductionValeriyОценок пока нет

- DEUTZ FL1011 Engine Overhaul Part ListДокумент11 страницDEUTZ FL1011 Engine Overhaul Part ListTong Hai WangОценок пока нет