Академический Документы

Профессиональный Документы

Культура Документы

X DIN 6885

Загружено:

jmaf_terИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

X DIN 6885

Загружено:

jmaf_terАвторское право:

Доступные форматы

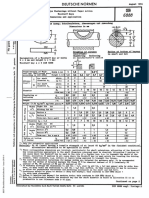

Nodtdnt*. owdi auti*o*walM, m* mit0n*J>mtgwnfl 4m OIN OwIim IimHM fOr Nomtvng .V, B.Hin 30,tottt.

Page 2

DIN 6885 Part 1

*""

Material: for parallel key heights h up to 25 am: St 50-1K according to DIN 1652

special agreement.

other grades of steel, e.g. quality steels and high-grade steels, are subject to

for parallel key heights h over 25 ma: St 60-2 Xaccording to DIN 1652;

1) If parallel keys of Types A and B are to be provided with holes for jacking screws (8), this shall be

specially indicated when ordering. In this ease the^deeignation reads, for example:

Parallel key AS 12 * 8 * 56 DIN 6885

) Types A and B can also be combined with one end round and the other square* In this ease the designation reads, for examples Parallel key AB 12 x 8 x56 DIN 6885

*) If parallel keys of Types B and F from the 12 v 8 sine upwards are required to be supplied minus holes

for jacking screws (oS) this must be specially stated when ordering. In this case the designation

reads, for example:

U

Parallel key EoS 12x8x56 DIN 6885

) Where mating dimensions are concerned, and particularly those of parallel shaft ends, the correlation

of parallel key cross-sections to shaft nominal diameters must be observed without fail. The correlation

of parallel key cross-sections to coned shaft ends and the dimensions for the keyway depth are to be

taken from the standards dealing with coned shaft ends.

") The Indicated tolerance sones for keyway widths hold good as the normal case for milled keyways. Other

tolerance sones must be indicated specially. For widths of broached keywaya, ISA class IT 8 is recommended

instead of IT9 (that is to say P8 instead of P9. No* Instead of N9 and JS8 instead of JS9). For sliding

fits, tolerance zone H9 is recommended for the shaft keyway and D10 for the hub keyway.

) In workshop drawings the dimensions t1 and (d1 - t^) as well as t^ and (d1 + t2) can be shown side by side. In many cases, however, the dimensions t1 and (d1 + tp) are sufficient. At the same time, the

permissible variations and machining allowances on the shaft and hub bore are to be taken into account as appropriate. ) The hub keyway depth with oversize is intended for special cases, in which the parallel key is made to

fit in a finishing operation.

7

8

) The values for d2 correspond to the smallest diameter of parts which can be pushed over the parallel key

concentrically.

*) Lengths over *K>0 and Intermediate lengths (to be avoided where possible) are to be chosen according to

DIN 3* In borderline cases intermediate lengths are subject to the permissible variation for the next

greater length I.

The weight data do not take account of holes for retaining screws, jacking screws and spring dowel

sleeves.

Explanations

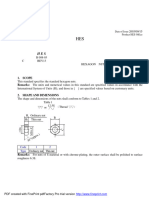

The content of this Standard agrees essentially with the conclusions of Technical Committee ISO/TC16

"Keys" on which the following ISO draft is based:

Draft ISO Recommendation No 1084 Rectangular or square parallel keys and their corresponding keyways

Clavetage par clavettes paralitica carres ou rectangulaires

Pafifedern

The following amendments and additions should be noted compared with the February 1956 issue of

DIN 6885 Part 1:

a) Some of the keyway depths in shaft and hub have been altered. As a result of this, however, the inter-

changeability of the parallel keys is either not jeopardised at all, or is only at risk in a few border-

line cases which are unlikely to arise in practice. The Table below compares the keyway depths previously

specified with the new ones. This comparison shows the borderline cases in which overaire is possible if the parts being mated are unfavourably disposed in the tolerance bands. This appliea only to parallel keys with back clearance. b) The values for chamfering and radiusing the keys and for radiusing the keyway bottom have been altered

in some cases, but this has not adversely affected interchangeability. c) As far as Types A and B are concerned, footnotes 1 and 2 state that these can also be supplied with

holes for jacking screws or with both types of end combined in the same key. Appropriate examples of designations are included. Reference has also been made to the fact that the position and number of

holes must be agreed where applicable.

d) la contrast with the previous provisions, the hole for the jacking screw in the case of Types B and F

has been moved from the mid-point of the key length to a position nearer one end of the key. This onesided position of the key is intended to make it easier to lift.

e) The previously standardised parallel counterbore in the tapped hole to take the jacking screw has been

replaced by a conical countersink (Section M-N).

f) IS0ACl6does not specify keyway depths with overaise. The previously specified hub keyway depths with

oversise have been re-calculated on the basis of the shaft keyway depths modified according to the

ISO proposal so that the oversises necessary for final fitting are restored. They correspond to those for keys according to DIN 6886 (ISO draft No. 1085).

g) The J9 tolerance sone for hub keyway widths has been changed to JS9. Since the specified tolerances

the normal type, and not - as previously - as a guideline. Tolerances differing from them must be

specially indicated.

are also recognised internationally they now count under the coverage of this Standard (Tootnote 5) as

h) The previous lengths 315 *nd 355 mm have been replaced by lengths 320 and 360 mm.

1) The weights of the keys have been checked and corrected to the extent that this was necessary, e.g.

owing to the new lengths 320 and 360 mm. The weight deduction for Type A has been corrected for certain slses.

DIN 6885 Part 1 Page 5

k) The counterbores for retaining screws have been chosen according to the "medium" range of DIN 74 Part 2 because the previous "close" range was often not sufficient - owing to the close fit in the through hole

to compensate for the toleranclng of the centre distances when two retaining screws are used. In the future, cheese-head screws according to DIN 84, DIN 6912 and DIN 7984 are to have standard head diameters

and they are therefore optional alternatives aa retaining screws.

1) The depth of tapped holes in the shaft and<the lengths of the retaining screws have been so specified

that the length of insertion is about 1 x thread diameter.

m) The correlation of spring dowel sleeves has been changed in some cases and diameter 13 replaced by 12.

The hole dimensions have been so specified that the dowel sleeve has 1 dowel diameter projecting

equally into the key and the shaft.

n) For the various keyway forms occurring in practice it has been decided to adopt symbols so that these forms can be designated on the basis of the standard where necessary. Types N1 and N2 represent the conventional forms of keyway. Type N3 arises when the keyway is made by a keyway cutter having a diameter smaller than the keyway width such as is widely used on special keyway milling machines.

o) The material data have been taken over from the new issue of DIN 6880.

Width b

2

2

3 3

4

4

5

5

6 6

8

7

10

8

12

8

14

9

16 10

18

11

20

12

22 14

Height h

*w* ,.y..y

depth t1

Hub keyway depth t.>

Prt*iossly

new

previously -....,.

1,1

U

1

17

13

2,4

2,5

2,9

3

3,5

3.5

4,1

4

47

5

4,9

5

5,5

5J5

65

6

63

7

73 7fi

8,5

9

1.4 M

-

17

XI

23

23

-

3,4

3,3

0

35

3,6 33

-

3,9 a

-

43

47 4.9

-

53

with baSk clearancnew

possible over-

13

-

2,3

-

3,3

-

3,3

-

4,4

-

5A

0.1

sise when

aated

ol*t haft

-

***AUD

Minimum to minimum

neWf shaft old| hu0

0.1

* ., , i_ P**.ll*l key

Width b

Height h

25 14

28

32

36

20

40

22

45 25

50

28

56

32

63 32

70 36

80 40

90

100

16

18

45

50

Shaft keyway

<iPtn tn

Hub keyway

previously 87

new

previously

""

9,9

10

11.1

11

12,3

12

133

13

15,3

15

17 17

193

20

193

20

22 22

243

25

273

28

30,4

31

5,4

5,4

-

65

6A

-

7,1 7A

-

7,9

8,4

depth tj with back clearance"'" possible over, .

87 9A

-

9,9

10,4

-

1U 11,4

-

12,9

123

145

143

-

153

177

193

12,4

03

12,4

0

153

0

173

0.1

193

0.1

m.

-

sine when mated

Minimum

to minimum

old haft hub

new, shaft

old, hub

0,1

03

0,1

Вам также может понравиться

- DIN-6888-Wood Ruff Key Dim and ApplicatioinДокумент2 страницыDIN-6888-Wood Ruff Key Dim and ApplicatioinManikandan Veerasekaran100% (3)

- ANSI-ASME B17.1-1967 (R 2003) Keys and KeyseatsДокумент19 страницANSI-ASME B17.1-1967 (R 2003) Keys and KeyseatsChristian Pazmiño86% (7)

- Asme B18.3.2M 1982Документ12 страницAsme B18.3.2M 1982adilshahzad2001Оценок пока нет

- Iso 7380Документ8 страницIso 7380pradelles100% (1)

- Din 6885Документ1 страницаDin 6885Riadini Anis Hade50% (2)

- Ansiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFДокумент190 страницAnsiasme B1.2-1983 (Revision of Ansi B1.2-1974) PDFrzurabaezaОценок пока нет

- Iso 286-2Документ55 страницIso 286-2Alexander Zuñiga Valbuena100% (2)

- Din 6885 KeysДокумент3 страницыDin 6885 KeysJJ100% (2)

- 5480 2Документ40 страниц5480 2Ashutosh Singh80% (10)

- Din 5463Документ4 страницыDin 5463Joel Sousa100% (1)

- Iso 4035Документ10 страницIso 4035xcvОценок пока нет

- Din 5480-1 - 2006-03Документ24 страницыDin 5480-1 - 2006-03gkhn50% (2)

- Internal and External Spline Teeth - Gears - Internal and External Spline Teeth, Spline Connections With Involute Flanks, Spline Connections With Straight FlanksДокумент13 страницInternal and External Spline Teeth - Gears - Internal and External Spline Teeth, Spline Connections With Involute Flanks, Spline Connections With Straight Flankssrinivas raghavanОценок пока нет

- DIN - 3852-1-2002 - Bujão PDFДокумент8 страницDIN - 3852-1-2002 - Bujão PDFMarcelo100% (2)

- External Snap Rings To DIN 7993 Part AДокумент2 страницыExternal Snap Rings To DIN 7993 Part ARajaSekarsajja0% (1)

- Technical Data of DIN 1481Документ1 страницаTechnical Data of DIN 1481Kemal DekanovićОценок пока нет

- Din 2353 EgДокумент10 страницDin 2353 Egxuanphuong2710100% (1)

- BS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled BushesДокумент14 страницBS ISO 3547-6-2007 Plain Bearings. Wrapped Bushes. Measurement of Wall Thickness of Thin-Walled Bushesxuanphuong2710Оценок пока нет

- Asme B18.2.2 - 2010Документ40 страницAsme B18.2.2 - 2010Tri Vo100% (2)

- Sae J1926-4 2009 (En)Документ13 страницSae J1926-4 2009 (En)Oh No Potato100% (1)

- BS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper KeysДокумент26 страницBS 4235-1-1972 Specification For Metric Keys and Keyways. Parallel and Taper Keysjaffliang100% (5)

- ISO 7-1 Pipe ThreadsДокумент11 страницISO 7-1 Pipe ThreadsFarzad SadrОценок пока нет

- Asme B18.3Документ75 страницAsme B18.3CamoColton100% (2)

- Sk6 ToleranceДокумент1 страницаSk6 Tolerancen1ghtfallОценок пока нет

- Asme B 1.9Документ37 страницAsme B 1.9Marcel BurlacuОценок пока нет

- B29-2M Edtn 2007Документ46 страницB29-2M Edtn 2007Arun Cherian75% (4)

- DIN3975 - Terms Worm GearsДокумент15 страницDIN3975 - Terms Worm GearsGonçalo Nogueira100% (2)

- Keyway DIN 6885 - Parallel Metric Keys and Keyway DimensionsДокумент2 страницыKeyway DIN 6885 - Parallel Metric Keys and Keyway DimensionsHenrique MarquesОценок пока нет

- Hydraulic Fitting Thread Chart - Hydraulics DirectДокумент18 страницHydraulic Fitting Thread Chart - Hydraulics DirectM DhafinОценок пока нет

- Splines Standards and Calculation - Rudolf OchДокумент10 страницSplines Standards and Calculation - Rudolf Ochlogonwheeler50% (8)

- DIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralДокумент24 страницыDIN 5480-1-2006 Involute Splines Based On Reference Diameters GeneralFranciscoОценок пока нет

- Din76 2 84Документ3 страницыDin76 2 84Luis TestaОценок пока нет

- Fasteners DIN en ISO StandardsДокумент32 страницыFasteners DIN en ISO StandardsNo NameОценок пока нет

- Iso 2338Документ6 страницIso 2338stanyeah100% (2)

- General Purpose Semi-Tubular Rivets, Full Tubular Rivets, Split Rivets, and End CapsДокумент22 страницыGeneral Purpose Semi-Tubular Rivets, Full Tubular Rivets, Split Rivets, and End CapsIliyaОценок пока нет

- Din 509 PDFДокумент6 страницDin 509 PDFLuciano FontesОценок пока нет

- DIN ISO Equivalent FastenersДокумент12 страницDIN ISO Equivalent FastenersGunnie PandherОценок пока нет

- SAE J518-1993 液压分体法兰 PDFДокумент13 страницSAE J518-1993 液压分体法兰 PDFliu zhao liu zhaoОценок пока нет

- Ansi B92.1Документ10 страницAnsi B92.1idrisbooks0% (2)

- Din2098 1Документ4 страницыDin2098 1amir8100Оценок пока нет

- 6885 1Документ1 страница6885 1ajeshОценок пока нет

- DIN 3760 - RetentoresДокумент13 страницDIN 3760 - RetentoresJosé100% (1)

- Ansi B92 1Документ10 страницAnsi B92 1Shai KvetnyОценок пока нет

- Din 8140-1Документ5 страницDin 8140-1main46prairieОценок пока нет

- BS 436Документ8 страницBS 436Raja RaoОценок пока нет

- 2 - PDFsam - Din-6885 KeyДокумент2 страницы2 - PDFsam - Din-6885 KeyDiaconu Vlad CatalinОценок пока нет

- Bolt & Nut TolerancesДокумент1 страницаBolt & Nut Tolerancesanon_510171829Оценок пока нет

- Asme Sec Viii D1 Ma App 2 Part2 PDFДокумент21 страницаAsme Sec Viii D1 Ma App 2 Part2 PDFjuanfco1965Оценок пока нет

- Riveted JointДокумент62 страницыRiveted JointRicky petraОценок пока нет

- Tube Fittings: Product Catalogue 2019Документ14 страницTube Fittings: Product Catalogue 2019jonoОценок пока нет

- Chap 03-Rotary Percussive Drilling Accessories PDFДокумент12 страницChap 03-Rotary Percussive Drilling Accessories PDFpnakurОценок пока нет

- Asme App 2 PDFДокумент21 страницаAsme App 2 PDFFabio TemporiniОценок пока нет

- Hes B008-03 Hexagon NutsДокумент5 страницHes B008-03 Hexagon NutsPreetam KumarОценок пока нет

- V-Machine Design 1Документ37 страницV-Machine Design 1roamer10Оценок пока нет

- Hydraulic Press Chapter 2Документ49 страницHydraulic Press Chapter 2PMV DeptОценок пока нет

- Tube To Header JointsДокумент4 страницыTube To Header Jointsshabbir626Оценок пока нет

- DIN-2605-2-95 StandartДокумент9 страницDIN-2605-2-95 StandartGürolОценок пока нет

- Tema EnqДокумент24 страницыTema Enqabhishek198327Оценок пока нет

- Piping Joint HandbookДокумент66 страницPiping Joint HandbookPuiu VoicuОценок пока нет

- ASME B18.8.8M-1994 Headed Clevis Pins (Metric Series)Документ6 страницASME B18.8.8M-1994 Headed Clevis Pins (Metric Series)hcsharma1967Оценок пока нет

- Din 509-2006Документ11 страницDin 509-2006jagan_san1067% (3)

- Planetary Travel&Hoist Drivespdf PDFДокумент9 страницPlanetary Travel&Hoist Drivespdf PDFbee140676Оценок пока нет

- Planetary Travel&Hoist Drivespdf PDFДокумент9 страницPlanetary Travel&Hoist Drivespdf PDFbee140676Оценок пока нет

- Hydraulics Products Guide enДокумент36 страницHydraulics Products Guide enbee140676Оценок пока нет

- 29 Life Expectancy of Piston Type Pumps and MotorsДокумент2 страницы29 Life Expectancy of Piston Type Pumps and Motorsbee140676Оценок пока нет

- 67 Troubleshooting Tips For Closed Loop Hydrostatic SystemsДокумент2 страницы67 Troubleshooting Tips For Closed Loop Hydrostatic Systemsbee140676Оценок пока нет

- Keyence 3D MittausasemaДокумент28 страницKeyence 3D Mittausasemabee140676Оценок пока нет

- Rexroth Pump Operation-Instructions 92701-bДокумент8 страницRexroth Pump Operation-Instructions 92701-bbee140676100% (1)

- 04 Shickel Design Considerations For A More Efficient Power UnitДокумент43 страницы04 Shickel Design Considerations For A More Efficient Power Unitbee140676Оценок пока нет

- Modeling Mechanical Hydraulic Systems in SimscapeДокумент42 страницыModeling Mechanical Hydraulic Systems in Simscapebee1406760% (1)

- Dash SizingДокумент2 страницыDash SizingPraveen KumarОценок пока нет

- Instrumentation and Equipment ListДокумент148 страницInstrumentation and Equipment ListAnonymous zCqjvFRОценок пока нет

- Shot PeeningДокумент5 страницShot PeeningRam KumarОценок пока нет

- BISON CatalogДокумент251 страницаBISON Catalogjserna_22Оценок пока нет

- CNC Codes and LettersДокумент48 страницCNC Codes and LettersIvo DimitrovОценок пока нет

- DrillingДокумент48 страницDrillingSushilendra MutalikdesaiОценок пока нет

- D10 11M-D10 11-2007PVДокумент6 страницD10 11M-D10 11-2007PVFiroj KhanОценок пока нет

- WPS Dissimilar 11.08 MM Max.Документ4 страницыWPS Dissimilar 11.08 MM Max.Sripathy50% (2)

- Eahs Technology & Engineering: UNC - UNF ChartДокумент1 страницаEahs Technology & Engineering: UNC - UNF ChartCHAD BOSLEYОценок пока нет

- Sem 1 Brazing With Oxyacetylene WeldingДокумент3 страницыSem 1 Brazing With Oxyacetylene WeldingKamarul Nizam100% (1)

- DMV20163 CADCAM AS02 JJ2023 StudentДокумент9 страницDMV20163 CADCAM AS02 JJ2023 StudentAmmar HarithОценок пока нет

- Unit1 - Tolerance and Fits NumericalДокумент16 страницUnit1 - Tolerance and Fits NumericalnapatilОценок пока нет

- MOLEX Barrier Terminal Blocks and AccessoriesДокумент1 страницаMOLEX Barrier Terminal Blocks and AccessoriespolikarpaОценок пока нет

- MBN 10105 2014-10Документ7 страницMBN 10105 2014-10조준장Оценок пока нет

- 2018 - UMC-1000 2016 - NewДокумент16 страниц2018 - UMC-1000 2016 - NewAbhishek VelagaОценок пока нет

- TOOL AND DIE STEEL FinalДокумент73 страницыTOOL AND DIE STEEL FinalSapan KansaraОценок пока нет

- Central Machinery Multi Purpose Machine Model 44142Документ34 страницыCentral Machinery Multi Purpose Machine Model 44142G3090% (1)

- How To Make A Coin RingsДокумент4 страницыHow To Make A Coin RingsPeter Snyder100% (1)

- CNC Programming CyclesДокумент8 страницCNC Programming CyclesParveen KumarОценок пока нет

- MPS5a - GrindingДокумент2 страницыMPS5a - GrindingMark julius garciaОценок пока нет

- ImperialДокумент6 страницImperialVinoth ShankarОценок пока нет

- Polycrystalline Diamond - PCD Tools - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerДокумент3 страницыPolycrystalline Diamond - PCD Tools - Sigma Toolings, Fine Boring Tools, Cutting Tools ManufacturerSigma ToolingsОценок пока нет

- Combi 200Документ3 страницыCombi 200arunradОценок пока нет

- Lathe Gab Bed ChinaДокумент10 страницLathe Gab Bed ChinaErossjap 84Оценок пока нет

- Threading SECOДокумент32 страницыThreading SECOAGPLTTОценок пока нет

- Bollhoff Helicoil Plus 2Документ49 страницBollhoff Helicoil Plus 2Ace Industrial SuppliesОценок пока нет

- Case HardeningДокумент31 страницаCase HardeningTanuj BanerjiОценок пока нет

- A 389 - A389m - 93 R98 Qtm4os05m1i5oaДокумент3 страницыA 389 - A389m - 93 R98 Qtm4os05m1i5oaPatricia J ÁngelesОценок пока нет

- The Ceramic Shell Mold ProcessДокумент18 страницThe Ceramic Shell Mold ProcessAbhishek KumarОценок пока нет

- UNIT-1 Locating and Clamping: S.Dharani KumarДокумент86 страницUNIT-1 Locating and Clamping: S.Dharani KumarSaivineeth Gampa100% (1)