Академический Документы

Профессиональный Документы

Культура Документы

Electric Fence

Загружено:

javier_valdivia_42Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Electric Fence

Загружено:

javier_valdivia_42Авторское право:

Доступные форматы

LECTRIC FENCESare widely used on farms to control livestock.

They can be set up quickly, are easily moved from place to place and they're much cheaper than permanentfencing. This new electric fence controller is suitable for fence runs up to about 5km long. We have mounted the controller in a section of 90mm plastic storm-water pipe fitted with standardend caps. This means it can be made waterproof and it canbe attachedto a fence post using standard90mm fittings. Our previous designwas basedon a standard12V ignition coil.'While this was a cheapapproachit did not have the output for longer fencesand was less effective againstlarger livestock such horsesand cattle. This new design has substantially

higher energy storageand should be adequate for fence runs up to 5km long. It is designedto comply with the relevantAustralian StandardAS/NZS 3729.

again just after the dump capacitor has been discharged. Now let's have a look at the full circuit which is shown in Fig.2.

Block diagram

The block diagram for the electric fence controller is shown in Fig.1. This comprises a 12V battery supply which is stepped up to 340VDC using aDC-DC converter. This chargesa 7pF dump capacitor. The charge in this capacitor is "dumped" through the step-up transformer once every second or so using a discharge circuit involving a Triac and pulse timer. The pulse timer controls both the DC-DC converter and the Triac. It switches off the converter each time it fires the Triac and then switches it on

Circuit description

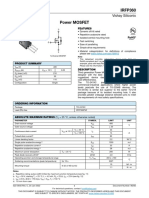

The DC-DCconverter comprisesa 7555timer (IC1),MosfetQ1 and transformerT1 plus diodesD1 and D2. IC1 is connected to oscillate at around 20ktlz, assetby the .0039pFcapacitor at pins 2 & 6 and the associated 4.7W1 and 6.8kQresistors. The 20kHz pulses from pin 3 arl usedto drive MosfetQ1 and this drives transformer T1 which steps up the voltage and drives a half-wave rectifier consisting of two fast recovery diodes,D1 & D2, connected in series. They are connectedin seriesbecause their 500V rating is insufficient to aIIow one diode to be usedbv itself.

StucottrCatp

VOI.TAGE

ON/OFF CONTROT

Fig. 1: you'll find it easy to follow the circuit description in the text ifyou refer to this block diagram and the circuit diagram overleaf.

The half-wave rectifier charges the 7pF 250VAC dump capacitor via the Iwo 22O{l resistors and the primary winding of transformer T2, The voltage stored in the dump capacitor is monitored by the error amplifier IC2a. The voltage is reduced by the voltage divider consisting of two

1.5MQ resistors and the LOkQresistor and this feeds pin 2 of ICZa. The non-inverting input of IC2a, pin 3, is connected to trimpot VR1 which taps off the reference voltage from the 4.7Y zener diode, ZD1. The gain of IC2a is set at 28 by the 10kQ resistor at pin 2 and the z7Dkdl

resistor between pins 1 & 2. The .OO471LF capacitor provides high frequency rolloff above 125H2.

Modulating the 7555

The error amplifier works in an unusual way to control the DC voltage across the dump capacitor at about

APRIL 1999 25

2x1N4936

7 250VAC

HT TO fENCE

GNDO?_

r6vw+

lFENCE GND

470L

/-\ E(. .)c

VIEWED FROM BEIOW lol

VOTTAGE I zDl VRIl0l I

TI

D Tol tl

^,TTT"

A2

ELECTRIC FENCE CONTROLLER

Fig. 2:,the circuit diagram shows iust how simple the electric fence controller is. Beware the cornponents on the secondary side ofTl: they bitel

340V DC. IC2a compares the voltage at its pin 2 with the preset voltage from VR1 and if it is higher, the output at pin 1 goes lower, pulling pin 5 of IC1 low via diode D4. Pin 5 is used to shift the upper and lower thresholds of the 7555 and thus changes the output frequency. When pin 5 is pulled lower, it reduces the time for the .0039pF capacitor at pins 2 & 6 to charge and discharge and this increases the frequency. More importantly, when pin 5 is pulled lower it reduces the pulse width fed to the gate of Q1 and so the drive to transformer T1 is also reduced and this lowers the output voltage.

Pulse timer

The pulse timer is a1.5Hz Schmitt trigger oscillator based on amp IC2b. The 10pF capacitor at pin 6 is charged via diode D2 and the 100kO resistor connecting to pin 7 and the 150kC, resistor from pin 6 to 7. When IC2b's output goes high, two 26 StucoN Cutp

things happen. Number one is that transistor Q2 is turned on to pull pin 4 of IC1 low. This stops IC1 from oscillating and so the DC-DC converter is disabled. Number two is that Q3, connected as an emitter follower, delivers a positive pulse to the gate of the Triac via the 2.2pF capacitor. This switches on the Triac which dumps the charge of the 7pF capacitor through the primary winding of transformer T2. This results in a high voltage pulse from the transformer's secondary winding, enough to repel any beastie which might be nuzzling up to the fence. Inductor L1 is connected in series with the transformer primary and this controls the rise time of the pulse cuttent from the dump capacitor. Without the inductor, the very rapid turn-on time of the Triac would mean that aburst of radio interference would be radiated by the electric fence every time it fired. When you consider how long the

antenna (ie, the fence) could be, it was essential that we remove this potential interference. The actual energy dumped into transformer T2 is given by the formula E =LlzCY2 With a dump capacitor of 7pF and a DC voltage of a+o[ the stored energy equatesto 0.4 Joules. Combined with the transformer's peak output of close to 3.6kV that's enough to give quite a belt to any animal.

Scope waveforms

We have included a number of oscilloscope waveforms in this article to illustrate the circuit operation. Fig.3 shows how IC1 is turned on and off by the pulse timer. The top trace shows the gated oscillation from pin 3 of IC1 while the bottom trace is the pulse waveform fed to pin 4. Each time the pulse is high, the oscillator output is disabled. Note that the top trace waveform shows severe quantising error and looks random because the 20kHz os-

cillation is much too fast for the scope's sampling rate which is set by the very low timebase sweep speed of 250ms per division (ie, one sweep takes 2.5 seconds). Fig.4 shows the charging and discharging of ihe dump capacitor every 1.5 seconds. The top trace is the waveform across the dump capacitor and as you can see,this builds up to 340V and then is abruptly dropped to zero. Each time it is to discharged to zero corresponds with the positive-going pulse on the bottom trace, This is the waveform at the emitter of Q3 which is used to trigger the Triac. Fig.S shows the high voltage waveform delivered by the secondary winding of transformer T2. It was measured via a 100:1 voltage divider and so the peak voltage is 3.6kV. Fig.6 shows the operation of the DC-DC inverter transformer, T1. The top trace shows the waveform at the

IY;Ul.,IJJli

Tek Run:200s/s

sample lIIfE r' -l*.'..---: ;-'-----{-".-----

Tek@E lMs/s

r-'-.--.-{--T---l-l

ch2 Period I . 5 4s ch2+width 1.05 s

.t.

'i i

!.

chr Pk-Pk 7 2 0V

t.

IE

chr Pk-Pk

I

'I i

.i:'

i .i

'I 'I 'i I

i:

qlff

tuuv

Ft

fulls

Lnt

.u lFab.lggg

Fig.3: how IC1 is turned on and offby the pulse timer. The top trace shows the gated oscillation from pin 3 of ICl while the bottom trace is the pulse waveform fed to pin +.

Tek Run:2oos/s sample IIIEI

2 ' l2 F e b I 9 9 S l:31:45

Fig.5: the high voltagewaveform delivered by the secondary winding of transformer T2. It was measured via a 100:1 voltage divider so the peak voltage is 3.6kV. lfus/s sampleinffl Run: Tek

13:I0:34

ch2 Period 1 . 5 4 5s Low siqnal ampliti|de ch2 +width 508.8ms Low siqnal amplitilde

ch2 Freq 22.A2kH" ch2 Ampl 124V

chl Pk-Pk 340 V

2 2 F e b1 9 9 S I l:30:25

2 2 F e bl 0 0 S I 3 : 38 : 5 8

Fig.4: the charging and discharging of the dump capacitor every 1.5 seconds.The top trace is the waveform across the dump capacitor and as you can see,this builds up to 340V and then is abruptly dropped to zero. Each time it is discharged to zero corresponds with the positivegoing pulse on the bottom trace.

Fig.6: the operation of the DC-DC inverter transformer, T1. The top trace shows the waveform at the drain of Mosfet Q1 while the boftom trace is the driving waveform from pin 3 of IC1, the 7555.

APRIL1999

27

drain of Mosfet Q1 while the bottom trace is the driving waveform from p i n 3 o f I C 1 ,t h e 7 5 5 5 . Note that the frequency of the bottom trace is 23WIz (nominally ZOWIz) and it is essentiallya clean pulse waveform. However the too trace shows evidence of ringing at i much higher frequency. What is happening? The clue is the peak voltage of the waveform: 124V. What is happening is that each time the waveform at pin 3 of IC1 goes positive, Mosfet Q1 turns on and feeds current through the primary winding of transformer T1,.About 20ps later it turns off abruptly and this causes a high voltage (ie, PaY) to appearacross the secondary and as shown in the scope trace, it also causesthe winding to "ring". The primary voltage is then stepped by the transformer turns ratio of 3 :1 to around 370V although ultimately, the voltage stored in the dump capacitor is set at 340V DC by trimpot VR1 and the error amplifier IC2a.

Construction

Our new Electric Fence Controller is built onto a PC board measuring 1 8 9x 7 7 m m a n d c o d e d1 1 3 0 3 9 9 1I.t i s housed in a 250mm length of 90mm diameter stormwater tube with caps fitted to seal off the ends. The comDonent overlay diagram for the PC boird is shown in Fig.7. You can begin construction by checking the PC board for any shorts or breaks in the tracks. Also check that the hole sizes for the fuseholder clips, transformers and cable ties for the 7pF capacitor are drilled sufficiently large for these components. Install the single link and then the resistors.You can use the colour codes in Table 1 when selecting the resistors for each position. Alternatively, you can use a dieital multimeter to check

TI PRIMARY 257 0./mn DIAENCU

SECONDARY START

srcoNolnv ztr

0.4mm DIAENCU

Fig. B: winding details for transformer T1. This one is the simpler of the two but take care with the starts and finishes and direction of winding. 28 StttcoN Cntp

each resistor value beT2 SECONDARY fore it is inserted in the TAPEIN POSITION INSUTATING PC board. Insert and solTUBING der in the PC stakes and the diodes, including vVIRE SECONDARY TAPE zener diode ZD1. START The capacitors can be frrEsroTlN mounted next, with the TO FORMER 7pF exception of the AIIOW TUBING TO StTEEIOW 250VAC dump capacitor. SURFACE Note that the electrolytic capacitors must be oriented with the correct 250T0.25mm DIA ENCU SECONDARY polarity. WOUNDIN TENTAYERS WITHINSUTATION LAYER ANDA 2nn TAPE BETWEEN EACH Be sure to orient the EACHENDOF THEWINDINGS GAP BETWEEN two ICs correctly when ANDTHE FORMER CHEEKS installing them and also SECONDARY be carefuIto put each one FINISH in the correct position. Fig. 9: winding details for Since they are both Btransformer T2. It's important to PRIMARY 5. pin ICs it is quite easy to flNtsH insulate the secondary properly put them in the wrong from the high to avoid flashover position - they don't voltage. The primary is wound work if you do that! on last - over the secondary Then insert the two winding and insulation. ENCU PRIMARY is an abbreviation for transistors. Mosfet and START I copper wire. enr-elled VR1. Triac and trimpot PRIMAR.Y 7T 0.4mm ENCU WOUNDOVERSECONDARY The fuse clips can be installed and are best mounted with the fuse By the way, dependingon where former. If the former is not marked clipped in placebefore soldering. Othyou buy your kit or the parts, the then use a pencil to label pin 1 yourin you clips might solder the erwise dump capacitormay be 6.5pFor 7pF self, as shown on Fig.7. back-to-front and their lugs will stop Now strip the enamel insulation off 25OVAC. you putting the fuse in. the end of the 0.4mm wire and solder The 7pF capacitor is mounted and Winding the transformers the wire onto pin 1. Wind on 25 turns held in place with two cable ties in the direction shown and terminate Transformer T1 is wound using wrapped around its body and through 0.4mm enamelled copper wire. Fig.B the end on pin 10, after stripping off the PC board. Attach the two wires to the enamel insulation. shows the winding details. the terminals on the PC board as Insulate the winding with a layer of Start by locating pin 1 on the coil shown.

tO 'tiR,

APHIL1999

1 PC board, x77mm code11303991,189 1 label, 125x 50mm(Electric FenceController) (Fence Terminals) 1 label, 85mmdiameter (lnputVoltage) 1 label, 85mmdiameter pipe 1 250mmlength of 90mmdiam.PVCstormwater 2 90mmdiameter end caps (bobbin, 2 E30transformer two coresand assemblies (seetextfor winding clips)(T1,T2) details) 1 ironpowdered toroidalcore 14.8mm OD x 8mm lD x 6.35mm, LO-1242, Neosid 17-732-22 Jaycar coreor (Ll ) equivalent 2280x 5mmcableties 6 PC stakes 2 3AG PC boardfuse clips 1 2A 3AGfuse 1 red bananasocket '1 greenbanana socket 1 red battery clip . 1 blackbattery clip grommet 1 cord-grip 1 2m length of figure-8 medium dutywire 1 1OOmm length insulated wire of brown250VAC 1 300mmlength insulated wire of blue250VAC 1 8m length of 0.4mmenamelled copper wire 1 15mlength of 0.25mm copper wire enamelled Semiconductors 1 7555, LMC555CN CMOS timer(lCl) 1 1M358 dualop amp (lC2) '1 lRF820 (Q1) 500V3A or P6N60E 600V6A Mosfet 1 BTA10-600 Triac(Triacl) (Q1,Q2) 28C337 NPNtransistors (D1,D2) 2 1N4936 500V1Afastdiodes (ZD1) 1 4.7V1W zener diode (D3,D4) 2 1N914,1N4148 switching diodes Capacitors 1 4701tF 16VWPC electrolytic PC electrolytic 3 1OpF 1 6.5pFor 7p.F 250VAC 16VWPC electrolytic .12.21tF 2 0.11tF MKTpolyester MKTpolyester 1 .0047pF 1 .0039pF MKTpolyester

2 1.sMO 4 100ko 1 4.7kA 1 3900

Resistors(0.25W, 1%) 1 270kO 5 1oko 12.2kA 2220f2 1 47C)

1 150kO 1 6.8kO 1 1kO 1 100C)

electrical tape before starting on the secondary. Now wind on 75 turns, starting at pin 5 and finishing at pin 6. Be sure to follow the winding directions as shown. Finish off with another layer of electrical tape. The transformer is assembled by sliding the two cores into the former and holding them together with a cable tie or clamp. Transformer T2 is wound using 0.25mm enamelled copper wire for the secondary and 0.4mm enamelled copper wire for the primary. Fig.9 shows the details. First, identify or mark pin 1. The secondary winding is wound first and the start is insulated with a 50mm length of sleeving which is held onto the bobbin with electrical tape. This end of the wire is not connected to the transformer pins because it is the high tension end and it would arc between pins otherwise. You will need to file down the cheek section of the transformer to allow the insulating tubing to sit flat on the inside winding area of the bobbin. Fix the insulation tubing in place as shown with insulation tape. Wind on about 10-turns neatly side by side to complete the filling of the first layer. Cover it in a layer of insulation tape. Always make sure that the wire passesout from the insulation as shown and with a 2mm clearance between winding and the cheeks of the former. Continue winding on another nine layers, with about 27 turns per layer and with insulation tape between each layer. Terminate the finish of the winding at pin 6. We must emphasise that the insulation and placement of the winding in the l0layers is most important, otherwise the transformer will suffer from flashover and ultimately, it won't work. Each layer must be insulated with a layer of electrical tape and be sure to start and end the tape at the top section of the bobbin rather than at the sides. The reason for this is to improve clearance between the windings and the ferrite cores which are slid in place after the windings are completed. Note also that the wire must not be started or finished beyond a 2mm clearancegap at each end of the winding area in the former. By comparison with the high voltage secondary, the primary winding is easy. Wind on 7 turns of 0.4mm enamelled copper wire between pins 5 and 10, as shown. Then slide the cores into the former and secure them with a cable tie or clips. Insert and solder the transformers in place, making sure that they are oriented with pin 1 as shown on the diagram ofFig.7. Inductor LL is wound using 6 turns of 0.4mm enamelled copper wire and these are terminated as shown on the PC board. You can secure the toroid in place with a cable tie or with a 3mm screw, nut and plastic washer or a small rubber grommet.

Miscellaneous 1 12V2.44hor larger clamps for 90mm battery;2 ground 1-32m longgalvanised conduit; stakes; selfinsulated timberpostsor steelpostsand insulators; fencetape,etc. 30 StttcoNCmp

Warning

Before applying power and commencing to test the unit, please heed the warning earlier in this article. Contrary to what you might think, the primary side of the output transformer is in fact more dangerous than the high voltage secondary.

we would prefernot to get Of course, acrosseither!

Testing

Having warned you about the high voltages, we can talk about testing the circuit. The first step is to wind trimpot VR1 fully anticlockwise. Then apply 1,2Yto the circuit and check that there is 12V between pins 1 and 8 of IC1 and between pins 4 and 8 of IC2. Switch off power. Temporarily tie pin 6 of IC2b to pin B with a 10kO resistor. This disables the pulse timer and means that IC1 operates continuously. Connect a multimeter between ground and the cathode of diode D2 with the meter set to read 4o0V DC or more. Now switch on the power and adjust VR1 slowly until the meter reads 340V. Switch off and wait for the voltage across the dump capacitor to discharge to below 12V. Disconnect the 10kQ resistor between pins 6 & 8 of IC2. We are now almost ready for the high voltage check and this should be a mere formality if you have been successful to this point.

This photo shows the completed electric fence controller immediately before final assembly inside its 90mm PVC stormwater pipe "case". cutters and bend the cut wires slightly apart so that you have a spark gap about Smm wide. Now apply 12Y to the circuit again and you should get a healthy spark every 1.5 seconds. Smith Electronics with catalog number H-2 865. Measuring 1'46x 222 x 55mm, this box has plenty of room for the PC board and the lid is fitted with neoprene gasket to ensure a water-tight seal. We understand thatthisbox wiIIbe included in the Dick Smith Electronics kit for this project. We have designed a number of labels for the Controller. As with the PC board pattern, they can be downloaded from the SILICoN CstP website, www. silicouchip. com.au

High voltage check . Don't reapplythe powerjust yet.

Instead connect a piece oftinned copper wire between the high voltage terminals on the PC board, ie, between terminals A & B. Then cut the wire with your side

Final assembly

While we built our prototype Electric Fence Controller into a length of 90mm plastic stormwater pipe, an alternative approach would be to house the PCboard in a sealedplastic weatherproofbox such as one sold by Dick

The two end caps in position, complete with labels. If used out in the open (ie without covering) it w-oyl$ hc a good idea to apply some siliione sealant inside the cap to waterproof the terminals and (especially) the power cable hole. APRIL 1.999 31

Finally, the completed controller. The caps are a push fit on the 90mm PVC pipe and are quite watertight. The label at the battery end states red and black for +12V and 0V: this ofcourse refers to the colour ofthe battery clips, not the wire! Incidentally, if you don't like the pretty pink pipe and groovy grey caps, they're also available in boring old white. The first measures 125 x 50mm and has the words "Electric Fence Controller". This can be glued to the pipe itself, as shown in our photos. There are also two 85mm diameter labels, one of which fits inside each end cap. One is labelled "Fence Terminals" and the other is "Input Voltage". When these are fitted to the end caps, you can drill the two holes for the fence terminals and cut out the hole for the cord grip grommet in the

ETECTRIC FENCE CONTROIIER

Fig.lo: here's how a typical electric fence installation goestogether. Note that for safety rea$ons,electric fences are always powered by battery. Battery charging should always be done "offline".

GROUND

'a

32

StucoN Cutp

other end cap. Attach the terminals and connect and solder the earth lead and the high tension lead. Solder a length offigure-8 cable to the 12V input PC stakes on the PC board. Feed the end of the cable through the stormwater pipe and the hole in the end cap and then place the assembledPCboard into the tube. The figure-8 cable is anchored in the end cap using the cord grip grommet. Both end caps can then be fitted onto the tube. To stop the board rattling inside the tube, you can wrap it in some foam rubber or bubble-wrap.

Em0mnruN0 ffi3ewenEn

Above: the label we prepared for the electric fence. It was glued onto the PVC pipe with spray adheiive. Right the tull-size PC board pattern for those who wish to make their own. You can also use this to check comrnercial boardF for etching defects. All t}ree labels and the PC board pattern are available for downloading from the SnrcoN CrilPwebsite, www.siliconchip.com. au

Attach the battery clips to the figure-8 cable,using red for positive and Don'tgetthesebackblack for negative. to-front otherwise you will blow the fuse. Then give the system another test, with the spark gap wires still acrossthe output terminals. Doesit still give a nice, juicy spark? Yep?Good.Now you can remove the spark gap wires beforefinal assembly (the fencewon't operatesatisfactorily with the spark gap Ieft in place). Use somesilicone sealaatto waterproof all joints around the end caps and wire entry point.

= ?EF c, {cl|-l

o tFti ({EF

f'! n lrl

$F

a

ct n

FI FI

ct

o o

An alternative mounting approach would be to use a sealed weatherproof case such as this one from Dick Smith Electronics. As luck would have it, the holes for one of the capacitor-holding cable ties line up perfectly with the mounting points moulded into the case. For seCurity, another cable tie should probably be used, necessitating a new pair ofholes drilled in the PC board. APRIL7999 33

tr tr tr tr tr tr tr tr tr tr tr tr tr

No. 2

'l 1 4 5 1 1 3 1 1 2 1 1

Value 1.sMO 27ok(t 150ko 100kc) 1okc) 6.8kc) 4.7ks' 2.2t(rr, 1kc) 390C2 220fJ 100cl 47A

(1%) 4-Band Code browngreengreen brown redvioletyellow.brown browngreenyellowbrown brownblackyellowbrown brownblackorangebrown blue grey red brown yellowviolet red brown red red red brown brownblack red brown orangewhitebrownbrown red red brown brown brown black brownbrown yellowvioletblackbrown

(1%) 5-Band Gode browngreenblackyellowbrown red violetblackorangebrown browngreenblackorangebrown brownblackblack orangebrown brownblackblackred brown bluegreyblackbrownbrown yellowviolet black brownbrown red red blackbrownbrown brownblack black brownbrown orangewhiteblackblackbrown red red blackblackbrown brownblack black black brown yellowvioletblackgoldbrown

By the way, don't be tempted to fix the end caps with PVC solvent glue you'll never get them off again if you do.

Installation

The controller is best installed inside a building in a position free from the risk of mechanical damage. If mounted outdoors, it should be clamped to a fence post, to minimise the risk of mechanical damage. Fig.10 shoyrs a typical installation. The controller should be fitted with separate earth electrodes and these should not be connected to any other earthing device.

Ualue 0.1pF 0.0047pF 0.0039pF

EIA 104 472 392

tEc

100n 4n7 3n9

suitable signs clamped to the wire or fastened to the posts at intervals not exceeding 90m. Such signs should bear the words 'ELECTRIC FENCE" in block letters SC no less than 50mm high.

GOMI]IG ]IEXT MO]ITH

All fence wiring shouldbe installed well away from any overhead power or telephone lines or radio aerials. Where the electric fence is installed in such a position that people might touch it and it is not using white or orange tape, it should be identified by

Wehave developed a number of lrom testers tocheck theoutput lence. this, orany other electric They range from very, very - and simple tovery all simple are easy tobuild.

tttSIRIS FtltCE IER1'|IIIAI'S

GROUND

(To Earth Stake)

INPUT VOLTAGE

12V DC @50mA BATTERY ONLY

I-1-l

n

\7

HIGH TENSION

(To Fence)

(+) BLAOK (-) RED

The two end labels, designed to fit inside a standard 90mm PVC (stormwater) pipe end cap. These labels can be photocopied or the originals downloaded from the SILICONCHIP website, rvww.siliconchip.com.au 34 StucoN Cutp

Вам также может понравиться

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Switching, Wah, Compresor Sustainer, TremoloДокумент20 страницSwitching, Wah, Compresor Sustainer, TremoloArif RamadhanОценок пока нет

- AV1000 + Assembly + ManualДокумент22 страницыAV1000 + Assembly + ManualAnonymous V1NW1Cm3w4100% (3)

- Metal DetectorДокумент24 страницыMetal Detectorramlala2591100% (1)

- SSM2166 - Compressor, Limiter and GateДокумент4 страницыSSM2166 - Compressor, Limiter and Gatedetroit_me2553Оценок пока нет

- Antenna Matching TransformerДокумент4 страницыAntenna Matching Transformerjhon100% (1)

- Power Electronics ProjectsДокумент5 страницPower Electronics ProjectsEngr FN AОценок пока нет

- Echivalente Tranzistori de PutereДокумент13 страницEchivalente Tranzistori de PutereAnonymous XoW23y58O100% (2)

- 12V DC To 220V AC Converter DesignДокумент7 страниц12V DC To 220V AC Converter DesigntintuvrОценок пока нет

- Amplificatoare Cu Tuburi Electronice Se Single Ended EL84 GU50 Class A Tube AmpДокумент4 страницыAmplificatoare Cu Tuburi Electronice Se Single Ended EL84 GU50 Class A Tube AmpalexibutoiОценок пока нет

- Induction Balance Metal Detector PDFДокумент6 страницInduction Balance Metal Detector PDFPerșinaru Robert100% (2)

- Metal Discriminator: Girish O Pranav AgarwalДокумент8 страницMetal Discriminator: Girish O Pranav AgarwallotarrОценок пока нет

- SMPS CKTДокумент5 страницSMPS CKTdkjena1Оценок пока нет

- Modification Yaqin AmpДокумент14 страницModification Yaqin Ampvinhson65-1100% (2)

- 1kw Mosfet Amp PDFДокумент17 страниц1kw Mosfet Amp PDFModesto Marcos Calderon Cruz100% (2)

- Wireless World 1995 09 S OCR PDFДокумент100 страницWireless World 1995 09 S OCR PDFMilton NastОценок пока нет

- TreasureHawk PDFДокумент2 страницыTreasureHawk PDFuser0% (1)

- Stuart1 150Документ6 страницStuart1 150Rafael PiccoОценок пока нет

- Electrical System COMMISSIONING PDFДокумент18 страницElectrical System COMMISSIONING PDFelrajilОценок пока нет

- SEMIKRON Product-Catalogue EN PDFДокумент126 страницSEMIKRON Product-Catalogue EN PDFAngelo Aco Mendoza100% (1)

- Elektor PA300 - November, 1995 PDFДокумент7 страницElektor PA300 - November, 1995 PDFKichiro Carvajal100% (1)

- Design Note: Optimizing Performance in Uc3854 Power Factor Correction ApplicationsДокумент42 страницыDesign Note: Optimizing Performance in Uc3854 Power Factor Correction ApplicationsidsufixОценок пока нет

- BeneviewT8 Service ManualДокумент228 страницBeneviewT8 Service Manualjavier_valdivia_42Оценок пока нет

- Arduino Based Pulse Induction Detector - LC-Trap - 3 StepsДокумент6 страницArduino Based Pulse Induction Detector - LC-Trap - 3 StepsMaribel Caricari ZuritaОценок пока нет

- Calibration CertificateДокумент3 страницыCalibration Certificatejavier_valdivia_4275% (4)

- Metal Detector Pulse Ar IIIДокумент15 страницMetal Detector Pulse Ar IIISneshko Snegic100% (3)

- Metal Detector Parts ListДокумент4 страницыMetal Detector Parts ListAlex AnthonyОценок пока нет

- American T R Metal DetectorДокумент11 страницAmerican T R Metal DetectorAkram KareemОценок пока нет

- HammerHead PI Metal Detector (HHv1p5)Документ15 страницHammerHead PI Metal Detector (HHv1p5)wladwolfОценок пока нет

- Pistol Detector - TOTeMДокумент10 страницPistol Detector - TOTeMValdenor Costa100% (1)

- Making CoilsДокумент9 страницMaking CoilsSleshi MekonnenОценок пока нет

- T.amp 4-1300, Power AmplifierДокумент56 страницT.amp 4-1300, Power AmplifiersoundicalОценок пока нет

- New High Performance Regenerative ReceiverДокумент2 страницыNew High Performance Regenerative Receiverrik206Оценок пока нет

- Gu 50 PDFДокумент2 страницыGu 50 PDFade abangОценок пока нет

- Costruzioni Elettroniche: Mod. KL 500-24 Linear AmplifierДокумент3 страницыCostruzioni Elettroniche: Mod. KL 500-24 Linear AmplifierPxistaОценок пока нет

- PI Polones 2019 Information Section Parts ListДокумент2 страницыPI Polones 2019 Information Section Parts Listwagner poltronieriОценок пока нет

- Twin LoopДокумент5 страницTwin LoopBalbalaManiuk100% (1)

- Abstract 2 TonesДокумент8 страницAbstract 2 TonesFilip FilipovicОценок пока нет

- EDN Design Ideas 1999Документ201 страницаEDN Design Ideas 1999chag1956100% (5)

- Earth ResistanceДокумент6 страницEarth ResistanceMoh'd M. GharbiehОценок пока нет

- 20 KW VHF Power AmplifierGU36Документ51 страница20 KW VHF Power AmplifierGU36verd leonardОценок пока нет

- SCR - Triac Controlled Automatic Voltage Stabilizer Circuit - Homemade Circuit ProjectsДокумент25 страницSCR - Triac Controlled Automatic Voltage Stabilizer Circuit - Homemade Circuit ProjectsANKUR RATHIОценок пока нет

- Wireless DoorbellДокумент8 страницWireless DoorbellnicklingatongОценок пока нет

- FM Transmitter PDFДокумент6 страницFM Transmitter PDFGoncalo EscusaОценок пока нет

- AM Radio Receiver Using The NE602 Balanced MixerДокумент7 страницAM Radio Receiver Using The NE602 Balanced MixerTarjo SutarjoОценок пока нет

- 300 Watt Quasi With 2N3773Документ3 страницы300 Watt Quasi With 2N3773chente_bОценок пока нет

- Pi PolonesДокумент47 страницPi PolonesSultan Backdoor100% (1)

- Video AmplifierДокумент13 страницVideo AmplifierPradyumna YambarОценок пока нет

- 3 Pulse Induction Metal DetectorДокумент3 страницы3 Pulse Induction Metal DetectorLuiz LuizОценок пока нет

- Manual All MultizetДокумент9 страницManual All MultizetalbundОценок пока нет

- A Set of Parts For Assembling The PIRATE Metal DetectorДокумент22 страницыA Set of Parts For Assembling The PIRATE Metal DetectorVegit RunОценок пока нет

- Flyback Transformer Tutorial Function and DesignДокумент5 страницFlyback Transformer Tutorial Function and DesignDany NewbyОценок пока нет

- RF Transistor List: Bipolar NPN Power TransistorДокумент5 страницRF Transistor List: Bipolar NPN Power TransistorAnonymous XoW23y58O100% (3)

- LRLДокумент1 страницаLRLLuis AlvarezОценок пока нет

- Triplett 630A Meter ManualДокумент29 страницTriplett 630A Meter Manualjdawson02Оценок пока нет

- An-995a 103Документ10 страницAn-995a 103Kendert BarrientosОценок пока нет

- Avalanche GeneratorДокумент3 страницыAvalanche GeneratorbarbosiОценок пока нет

- WMCДокумент65 страницWMCbhagathnagarОценок пока нет

- Experiment No: DateДокумент24 страницыExperiment No: DateChaitanya ShahОценок пока нет

- Conta Biil I Dad Aula CliДокумент7 страницConta Biil I Dad Aula CliPedroPablo GonzalezОценок пока нет

- Fly-Back Mode 150wДокумент17 страницFly-Back Mode 150wanon_4880132Оценок пока нет

- Slup083 PDFДокумент7 страницSlup083 PDFlu1agpОценок пока нет

- Chapter 4 - System Design and Simulation ResultДокумент12 страницChapter 4 - System Design and Simulation ResultHika TarikuОценок пока нет

- 13.8 V 15 A From A PC Power SupplyДокумент8 страниц13.8 V 15 A From A PC Power SupplyTibor NemethОценок пока нет

- SX4882 P0813 QSG WWДокумент22 страницыSX4882 P0813 QSG WWjavier_valdivia_42Оценок пока нет

- Pvm266am PДокумент39 страницPvm266am Pjavier_valdivia_42Оценок пока нет

- Amis Katalog 2006Документ40 страницAmis Katalog 2006javier_valdivia_42Оценок пока нет

- User Guide Tp-Link Td-w8901gДокумент73 страницыUser Guide Tp-Link Td-w8901gjavier_valdivia_42Оценок пока нет

- Industrial Electronic Timothy J MaloneyДокумент586 страницIndustrial Electronic Timothy J Maloneydfsdds29% (7)

- Novametrix 511 - User Manual PDFДокумент39 страницNovametrix 511 - User Manual PDFjavier_valdivia_42Оценок пока нет

- Medical Product Catalog Oct11 LRДокумент64 страницыMedical Product Catalog Oct11 LRjavier_valdivia_42Оценок пока нет

- Alesis Io14 Io26 Reference Manual RevcДокумент70 страницAlesis Io14 Io26 Reference Manual Revcjavier_valdivia_42Оценок пока нет

- Manual de Operador Panasonic CT20SL14JДокумент80 страницManual de Operador Panasonic CT20SL14Jjavier_valdivia_42Оценок пока нет

- Mini Med BrochureДокумент2 страницыMini Med Brochurejavier_valdivia_42Оценок пока нет

- 33023a Uso de PicДокумент688 страниц33023a Uso de Picjavier_valdivia_42Оценок пока нет

- RSView User Manual EngДокумент920 страницRSView User Manual Engjavier_valdivia_42Оценок пока нет

- Mamoray Classic Eos EngДокумент2 страницыMamoray Classic Eos Engjavier_valdivia_42Оценок пока нет

- Quality Images For Every Patient Every TimeДокумент2 страницыQuality Images For Every Patient Every Timejavier_valdivia_42Оценок пока нет

- Manual EZ4 AssemblyДокумент36 страницManual EZ4 Assemblyjavier_valdivia_42Оценок пока нет

- GMT Global Mixed Mode Tech G718TM1U - C356796Документ7 страницGMT Global Mixed Mode Tech G718TM1U - C356796BonetzОценок пока нет

- Is Now Part ofДокумент25 страницIs Now Part ofkilowatt СкворцовОценок пока нет

- 2SK241Документ7 страниц2SK241ytnateОценок пока нет

- Silicon Ingot Production: Czochralski-And Float-Zone TechniqueДокумент2 страницыSilicon Ingot Production: Czochralski-And Float-Zone TechniqueKarajá PtahОценок пока нет

- Lateral Monolayer MoSe2-WSe2 P-N Heterojunctions With Giant Built-In PotentialsДокумент7 страницLateral Monolayer MoSe2-WSe2 P-N Heterojunctions With Giant Built-In PotentialsNgô Gia QuyếtОценок пока нет

- XC6365 66Документ18 страницXC6365 66vetchboyОценок пока нет

- Advance PP3 Twin DC SupplyДокумент13 страницAdvance PP3 Twin DC SupplyJohn DosherОценок пока нет

- Flash MemoryДокумент5 страницFlash MemoryJoan CalderonОценок пока нет

- RT300MДокумент17 страницRT300MIonel SimaОценок пока нет

- LVDT TheoryДокумент13 страницLVDT Theorybnn123100% (1)

- Electronic Science SampleДокумент48 страницElectronic Science SampleDiwakar Entertainment DoseОценок пока нет

- KATS Universal ProgrammerДокумент6 страницKATS Universal ProgrammerdorudОценок пока нет

- Xtr116 (IC T o 4 - 20ma)Документ17 страницXtr116 (IC T o 4 - 20ma)IEA.BOD.I2 - Sơn, Vũ Văn - Giám đốc E&A - INTECH GROUPОценок пока нет

- Teacher's GuideДокумент3 страницыTeacher's GuideJamal Morelli0% (1)

- I - Research Articles: Chempluschem 78, 837 (2013)Документ111 страницI - Research Articles: Chempluschem 78, 837 (2013)forfunОценок пока нет

- Introduction To EXAFS Experiments and TheoryДокумент35 страницIntroduction To EXAFS Experiments and TheoryandyblablaОценок пока нет

- Centralized Mobile Detection in Examination Hall Using Arduino PDFДокумент14 страницCentralized Mobile Detection in Examination Hall Using Arduino PDFAkhil.PitlaОценок пока нет

- 2 Crystal StructureДокумент32 страницы2 Crystal StructureHesh JayatissaОценок пока нет

- Nano Technology 8260543Документ20 страницNano Technology 8260543Baskaran KathirvelОценок пока нет

- Argon Recovery From Silicon Crystal FurnaceДокумент7 страницArgon Recovery From Silicon Crystal FurnaceasdfqwerОценок пока нет

- Chapter12 Power AmplifiersДокумент107 страницChapter12 Power AmplifiersNikunj ShahОценок пока нет

- Industrial Electronics - 1 Marks - ECE-Polytechnic PDFДокумент14 страницIndustrial Electronics - 1 Marks - ECE-Polytechnic PDFSukesh RОценок пока нет

- Irfp 360Документ10 страницIrfp 360movick.25Оценок пока нет

- Complete Dual 18-Bit 16 Audio DAC AD1865 : Oversampling Per Channel 5 Volt OperationДокумент13 страницComplete Dual 18-Bit 16 Audio DAC AD1865 : Oversampling Per Channel 5 Volt OperationDarek BratnyОценок пока нет

- 8-Bit Gray Code Converter: by Martin Serena, Dang Ly, Khoa LyДокумент58 страниц8-Bit Gray Code Converter: by Martin Serena, Dang Ly, Khoa LyAndreSantosОценок пока нет

- Ac & DC CurrentДокумент11 страницAc & DC CurrentAniketОценок пока нет

- 50 TOP TRANSISTORS Questions and Answers PDFДокумент8 страниц50 TOP TRANSISTORS Questions and Answers PDFamadullah janОценок пока нет

- ALB DatasheetДокумент5 страницALB DatasheetSanti Diaz MonteroОценок пока нет