Академический Документы

Профессиональный Документы

Культура Документы

Remote Control of ESP

Загружено:

M.IBRAHEEMИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Remote Control of ESP

Загружено:

M.IBRAHEEMАвторское право:

Доступные форматы

1

Electrostatic Precipitator

Remote Controls

Description

Following for guidance only

Electrostatic precipitator

Gateway communication

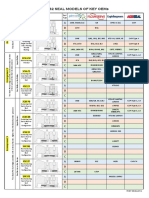

This is illustrated below. The picture shows a medium size ESP with 3 fields and 6 bus sections connected to the plant computer system via the so-called gateway communication. The HV power supply energizing each bus section consists of a T/R set controlled by a PIACS DC control unit. The PIACS DC controls the corona power delivered to the corresponding section in a closed loop regulation of the precipitator current, according to the existing operating conditions. Furthermore, the PIACS DC may control the rapping mechanisms and heaters. These functions are performed by advanced control strategies incorporated in the software of the control unit. Plant control system

PIACS DCs System PIACS PLC converter manager Gateway Flue gas

ESP

Plant PLC

PIACS communication bus In the recent years with increasing plant automation and more advanced operator interfaces available in the control room, the integration of the precipitator control in the plant computer system is an increasing demand. This integration is performed in the following way: The PIACS DC and Coromax control units are interfaced to a common communication bus (BitBus 1), by a low cost unit, the PIACS converter. Being at the BitBus level it is easy to interface to the plant computer system by using a PIACS Gateway unit. There are standard gateway units allowing interface to PLC systems of the most common makes.

From the operator stations in the control room the following is possible: - start/stop of the T/R sets - reading of currents, voltages, spark rate, etc. in the different bus sections - trend analysis of PIACS DC signals - reading and change of relevant settings of the PIACS DC units Other control functions concerning the auxiliary equipment can be incorporated in an special unit, the PIACS I/O, which has a built-in interface to the BitBus.

1

BitBus is a trademark of Intel Corp.

PIACS Manager

F.L.Smidth Airtech has its own supervisory computer control for ESPs, which is marketed under the trade name PIACS Manager. This has been implemented in a PC running under Windows NT and includes a SCADA package taking care of the man-machine interface (MMI) with the ESP. This is a low-cost system intended for remote supervision and control of the PIACS controllers from F.L.Smidth Airtech, and therefore it incorporates simple and predefined mimics displays for the operation of the system.

Stand-alone

The PIACS Manager is normally implemented as a stand-alone system interfaced to the PIACS control units. Its modularity, based on modules from Brodersens System 2000, makes it possible to control several ESPs simultaneously, dependent on the total number of bus-bar sections. Its capacity is about 100 bus-sections. The system is shown below. The picture shows the PIACS Manager controlling a 6 bus-sections ESP. The T/R sets and rappers in each field are controlled by a PIACS DC control unit. These control units communicate with the PIACS Manager through a converter, the so-called PIACS converter, which interfaces the PIACS Bus to BitBus. The PC interfaces with the BitBus by means of a PC board or Gateway module and they act as the System Manager in the BitBus communication.

PC Windows NT PIACS DCs PIACS Converter

AI-DI

Flue gas

ESP

I/O signals

PIACS communication bus

Process signal acquisition is also possible. If needed this function can be performed by standard modules from the system 2000 having analog and digital I/Os. In this way the system can provide all the relevant data for remote operation.

Integrated with the plant computer system

As an option, the PIACS Manager can be interfaced to the plant PLC by using the gateway principle, shown in below figure. This picture shows the supervision of a 6 bus-sections ESP, where a PLC gateway module from the system 2000 is incorporated for interfacing the BitBus to the plant computer system

Plant control system

Plant PLC

PC Windows NT PIACS DCs PLC Gateway

Flue gas

ESP

PIACS Converter

AI-DI I/O signals (Optional)

PIACS communication bus The PIACS Manager includes a simple configurable graphic interface for operation of the system. This features: mimic displays trending of all signals and PIACS parameters alarm handling automatic recording and display of i-v curves The operation of the system is performed by means of a number of mimic displays. From here it is possible to start/stop the T/R sets and rappers and to reset alarms as seen in Fig. 4, Furthermore, the access to the PIACS parameters for display and change is possible. Besides, there are bargraphs showing the mean current and the mean and the minimum voltage of each bus-section. The PIACS Manager is implemented on a PC having the following data: Pentium processor/Windows NT 4.0 64 Mb RAM 3.2 Gb hard disk CD ROM drive 15 color monitor

PIACS Remote

In the field of ESP computer supervision a new facility has been gaining acceptance among customers. The principle is to incorporate a process data acquisition facility and then to connect the PC to the company headquarters via a modem. This facility allows the ESP specialist to get in contact with the automatic control units and if the process conditions are known, then the ESP performance can be assessed. Preventive maintenance and up to a certain extent, advice regarding corrective maintenance can be possible, making possible a better after-sales service, and in same cases a specialist visit can be avoided. In other words, the aim with this system is to allow service performed remotely from the ESP supplier's main office, providing optimization of the settings of the automatic control equipment, planning preventive maintenance and trouble-shooting. FLS milj has developed such a system, which is based on the PIACS Manager and marketed under the trade name PIACS Remote.

System architecture Stand-alone

The system is shown below. The picture shows the PIACS Remote system, which to operates on a PC in a Windows NT environment. The PIACS Remote is normally implemented as a standalone system interfaced to the PIACS control units. Its modularity, based on modules from Brodersens System 2000, makes it possible to control several ESPs simultaneously dependent on the total number of bus-bar sections. The capacity of the system is about 100 bus-sections. PC Windows NT

PIACS DCs

PIACS Converter AI-DI Modem

Flue gas

ESP

Process signals

FLS milj Modem

PIACS communication bus

A PIACS DC control unit can control the T/R sets and rappers in each field. These control units communicate with the PIACS Remote through a converter, the so-called PIACS converter, which interface the PIACS Bus to BitBus. The PC interfaces with the BitBus by means of a PC board or Gateway module and they act as the System Manager in the BitBus communication.

The system can be remotely accessed through one of the serial ports by a modem connection. Standard modules, from the system 2000 having analog and digital I/Os perform process signal acquisition. In this way the system can provide all the relevant data for a remote operator working in assessing the performance of the ESP, eventual problems, etc. The typical input signals from the process (power utility) may be: Stack emission Coal feed rate Total air flow Inlet gas temperature Outlet gas temperature SO2 content O2 content

Integrated with the plant computer system

The picture below shows the PIACS Remote system interfaced to the plant PLC by using the gateway principle, i.e. incorporating a PLC gateway module for interfacing the BitBus to the plant computer system. Plant control system

Plant PLC

PLC Gateway PC Windows NT

PIACS DCs

PIACS Converter

BitBus

Flue gas

ESP

AI-DI Process signals

Modem

Modem

PIACS communication bus

The PIACS Remote like the PIACS Manager includes a simple configurable graphic interface for operation of the system. This features: mimic displays trending of all signals and parameters alarm handling automatic recording and display of i-v curves The operation of the system is performed by means of a number of mimic displays. From here it is possible to start/stop the T/R sets and rappers, to reset alarms and to access the PIACS parameters for display and setting. The system has incorporated the necessary software for the configuration of the system and the MMI according to the particular plant.

BitBus is a trademark of Intel Corp.

F.L.Smidth Airtech is continuously improving its electrostatic precipitators and therefore reserves the right to change its technical specifications without prior warning. This description including appertaining sketches is a general description containing various options and solutions, which are not necessarily enclosed in a specific quotation. For details of the specific quotation please refer to the actual technical specifications. VicR/EMB Rev1A

Вам также может понравиться

- Computer System Planning FormДокумент2 страницыComputer System Planning Formlastowl100% (3)

- Flue Gas Co CaptureДокумент28 страницFlue Gas Co CaptureVlad LaskachОценок пока нет

- 2013 GDS CatalogДокумент72 страницы2013 GDS CatalogAl Dizdar NazarОценок пока нет

- Internship Report On Embedded System and IoT Technology.Документ72 страницыInternship Report On Embedded System and IoT Technology.manish80% (10)

- ESP For Bagasse Fired Steam Generators SeminarДокумент14 страницESP For Bagasse Fired Steam Generators SeminarManikandan100% (2)

- 18-70-05 Fillets Welds Allowable LoadsДокумент6 страниц18-70-05 Fillets Welds Allowable LoadsJKKОценок пока нет

- Fluid CorrДокумент68 страницFluid CorrSiddiqui Muhammad AshfaqueОценок пока нет

- 2) ESP BasicsДокумент60 страниц2) ESP BasicsRafki Ismed GhifariОценок пока нет

- 3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsДокумент10 страниц3-77-06 Field Weld Ends Pumps& Valves Conrolled Circulation & CC UnitsJKKОценок пока нет

- LPPJFF RL - Envi - 2013 04 04Документ10 страницLPPJFF RL - Envi - 2013 04 04Petros IosifidisОценок пока нет

- 53-75-09 Butt Welded Joints Details & AssemblyДокумент3 страницы53-75-09 Butt Welded Joints Details & AssemblyJKKОценок пока нет

- 8 95 01 Weld Procedure Spec ChattanoogaДокумент40 страниц8 95 01 Weld Procedure Spec ChattanoogaJKKОценок пока нет

- Guide To Furnace SootblowingДокумент40 страницGuide To Furnace SootblowingnarayananaliveОценок пока нет

- Condenser 69-83Документ15 страницCondenser 69-83DIPAK VINAYAK SHIRBHATEОценок пока нет

- Cooler 171110 (r0) Seleccion de Enfriador y Calculo Tlr-4225-UДокумент1 страницаCooler 171110 (r0) Seleccion de Enfriador y Calculo Tlr-4225-UloretoОценок пока нет

- Design of Ejector Parameters and Geometr PDFДокумент6 страницDesign of Ejector Parameters and Geometr PDFlkumar4454Оценок пока нет

- Hydraulic Oil CoolerДокумент19 страницHydraulic Oil CoolerSAKDA MAPRADITKULОценок пока нет

- 750-286 Sample Cooler 2013Документ8 страниц750-286 Sample Cooler 2013kangsungjinОценок пока нет

- HBDs 01Документ4 страницыHBDs 01deepdaman18891Оценок пока нет

- 234-76-11 Longitudinal & Circumferencial Weld Joints & Seams For Pipes, Drums& VesselsДокумент3 страницы234-76-11 Longitudinal & Circumferencial Weld Joints & Seams For Pipes, Drums& VesselsJKKОценок пока нет

- Sjae ParameterДокумент296 страницSjae Parameterrizka nur failaОценок пока нет

- Furnace 01490Документ83 страницыFurnace 01490JKKОценок пока нет

- 16-77-03 Field Welding of Fusion Welded PanelsДокумент3 страницы16-77-03 Field Welding of Fusion Welded PanelsJKKОценок пока нет

- Design of Condenser: 1) Heat Balance 2) Temeprature DifferenceДокумент1 страницаDesign of Condenser: 1) Heat Balance 2) Temeprature DifferenceBhawani Pratap Singh PanwarОценок пока нет

- Company Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Документ2 страницыCompany Name: Facility Name: Dust Collection Emissions - Particulate (PM 10)Kumaran GopalОценок пока нет

- DEMZ-Engineering LTD: Electrostatic PrecipitatorsДокумент10 страницDEMZ-Engineering LTD: Electrostatic PrecipitatorsAndie AviОценок пока нет

- Evaporation Principles and Black Liquor Properties: David T. Clay, PH.DДокумент6 страницEvaporation Principles and Black Liquor Properties: David T. Clay, PH.DJKKОценок пока нет

- Swas Sample CoolerДокумент4 страницыSwas Sample CoolerBhargav ChaudhariОценок пока нет

- 8-65-19 ''Pulsed Arc '' MIG Welding Stright Tubes in ChattanoogaДокумент9 страниц8-65-19 ''Pulsed Arc '' MIG Welding Stright Tubes in ChattanoogaJKKОценок пока нет

- Steam Condensation ReportДокумент17 страницSteam Condensation ReportKingsley EdemidiongОценок пока нет

- H Vs V CondensersДокумент1 страницаH Vs V CondensersParth PurohitОценок пока нет

- Subject: External Static Losses Summary: Al-Diyar ConsultantsДокумент10 страницSubject: External Static Losses Summary: Al-Diyar ConsultantsFasil EОценок пока нет

- Damper Applications GuideДокумент20 страницDamper Applications GuideNabil RamehОценок пока нет

- Studi Numerik Variasi Volume Pasir Terhadap Efisiensi Boiler Circulation Fluidized Bed CombustionДокумент12 страницStudi Numerik Variasi Volume Pasir Terhadap Efisiensi Boiler Circulation Fluidized Bed CombustionBrianОценок пока нет

- Energy Balance:: Logarithmic Mean Temperature Difference (LTMD)Документ3 страницыEnergy Balance:: Logarithmic Mean Temperature Difference (LTMD)Rae Nikka May PabloОценок пока нет

- 1 TPH 10.54 KG, Vapi Care PharmaДокумент16 страниц1 TPH 10.54 KG, Vapi Care PharmashastrysnОценок пока нет

- Api 682 Cross ReferenceДокумент1 страницаApi 682 Cross ReferenceLuis BassoОценок пока нет

- Insul & RefractoryДокумент8 страницInsul & RefractoryJKK0% (1)

- 50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsДокумент6 страниц50-83-02 Spec. For Arc & Capacitor Discharge Weldingt of Pr. & Non-Pr. PartsJKKОценок пока нет

- Particle Collection AnismsДокумент42 страницыParticle Collection AnismsStefanos DiamantisОценок пока нет

- FD Fan Sizing CalculationДокумент3 страницыFD Fan Sizing CalculationkumarananyarupeshОценок пока нет

- 11005312-IBR Pipe CalculationДокумент40 страниц11005312-IBR Pipe CalculationTrishul Nath PallayОценок пока нет

- 10-87-02 Spec For Ceramic Fibre Blanket InsulationДокумент5 страниц10-87-02 Spec For Ceramic Fibre Blanket InsulationlightsonsОценок пока нет

- APTI413 PP Ch9Документ56 страницAPTI413 PP Ch9Stefanos DiamantisОценок пока нет

- Az - Zour R&M Furnace Dimensions - AДокумент1 страницаAz - Zour R&M Furnace Dimensions - AShameer MajeedОценок пока нет

- 238-76-04 Pulverised Fuel Piping WeldsДокумент3 страницы238-76-04 Pulverised Fuel Piping WeldsJKKОценок пока нет

- 01 Raw Material RSP1 5.0X1400 OKДокумент21 страница01 Raw Material RSP1 5.0X1400 OKTARUNKUMARОценок пока нет

- 58-75-02 Field Welding Accessibility For Header Butt Weld JointДокумент3 страницы58-75-02 Field Welding Accessibility For Header Butt Weld JointJKKОценок пока нет

- Husk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Документ28 страницHusk Based Power Plant 6T 32 KG FBC With Single Stage Turbine - For Finance, Subsidy & Project Related Support Contact - 9861458008Radha Krishna SahooОценок пока нет

- FTP PDFДокумент16 страницFTP PDFPankaj RaneОценок пока нет

- Condensate System 04012022Документ43 страницыCondensate System 04012022VARCHAS MITTALОценок пока нет

- 235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsДокумент3 страницы235-76-02 Det. & Assembly For Disk Type Orifice & Butt Welded Tube JointsJKKОценок пока нет

- Ejma7r2 Bellows Worksheet 1Документ8 страницEjma7r2 Bellows Worksheet 1NamıkОценок пока нет

- HAT Horiz Vessel VolДокумент1 страницаHAT Horiz Vessel VolJ.SIVIRAОценок пока нет

- Disha Publication Classification Past PapersДокумент14 страницDisha Publication Classification Past PapersJanaki KrishnanОценок пока нет

- CE-105 12 Air Pollution - Numerical Problems 1Документ8 страницCE-105 12 Air Pollution - Numerical Problems 1Ayush0% (1)

- Hydro MPCДокумент92 страницыHydro MPCGiancarlo Cervantes100% (2)

- Croll Reynold's Scrubber CatalogueДокумент4 страницыCroll Reynold's Scrubber Cataloguevarunpassi100% (1)

- Heater 10m2 (ASME Tubesheet)Документ17 страницHeater 10m2 (ASME Tubesheet)Omil RastogiОценок пока нет

- Digital PID ControllersДокумент21 страницаDigital PID Controllerssopan saОценок пока нет

- Dcs BtechДокумент55 страницDcs BtechGlan Devadhas100% (1)

- Opto22 0991 White Paper Pipeline IndustryДокумент9 страницOpto22 0991 White Paper Pipeline IndustryBarry KostinerОценок пока нет

- 348Документ1 страница348M.IBRAHEEMОценок пока нет

- 346Документ1 страница346M.IBRAHEEMОценок пока нет

- 343Документ1 страница343M.IBRAHEEMОценок пока нет

- 345Документ1 страница345M.IBRAHEEMОценок пока нет

- 344Документ1 страница344M.IBRAHEEMОценок пока нет

- 347Документ1 страница347M.IBRAHEEMОценок пока нет

- 1Документ1 страница1M.IBRAHEEMОценок пока нет

- 342Документ1 страница342M.IBRAHEEMОценок пока нет

- 339Документ1 страница339M.IBRAHEEMОценок пока нет

- 337Документ1 страница337M.IBRAHEEMОценок пока нет

- 341Документ1 страница341M.IBRAHEEMОценок пока нет

- 338Документ1 страница338M.IBRAHEEMОценок пока нет

- 340Документ1 страница340M.IBRAHEEMОценок пока нет

- 335Документ1 страница335M.IBRAHEEMОценок пока нет

- 329Документ1 страница329M.IBRAHEEMОценок пока нет

- 336Документ1 страница336M.IBRAHEEMОценок пока нет

- 333Документ1 страница333M.IBRAHEEMОценок пока нет

- 332Документ1 страница332M.IBRAHEEMОценок пока нет

- 326Документ1 страница326M.IBRAHEEMОценок пока нет

- 334Документ1 страница334M.IBRAHEEMОценок пока нет

- 331Документ1 страница331M.IBRAHEEMОценок пока нет

- 328Документ1 страница328M.IBRAHEEMОценок пока нет

- 330Документ1 страница330M.IBRAHEEMОценок пока нет

- 327Документ1 страница327M.IBRAHEEMОценок пока нет

- 323Документ1 страница323M.IBRAHEEMОценок пока нет

- 321Документ1 страница321M.IBRAHEEMОценок пока нет

- 324Документ1 страница324M.IBRAHEEMОценок пока нет

- 325Документ1 страница325M.IBRAHEEMОценок пока нет

- 322Документ1 страница322M.IBRAHEEMОценок пока нет

- 320Документ1 страница320M.IBRAHEEMОценок пока нет

- Ecdl Slides Module 1Документ102 страницыEcdl Slides Module 1dr gawdat100% (3)

- RN ReleaseNotes iDX20xx Combined RevI 042911 PDFДокумент79 страницRN ReleaseNotes iDX20xx Combined RevI 042911 PDFSandro Omar Lizano GuzmanОценок пока нет

- AirPrime EM74xx-MC74xx at Command Reference r3Документ168 страницAirPrime EM74xx-MC74xx at Command Reference r3Milton Leonel Lizardo GarciaОценок пока нет

- Pipe Leak Detection Chapter07-GB-2013Документ13 страницPipe Leak Detection Chapter07-GB-2013rommelleyvaОценок пока нет

- Unofficial Manual For Telstra Smart Modem Gen 2 (LH1000 Model)Документ61 страницаUnofficial Manual For Telstra Smart Modem Gen 2 (LH1000 Model)aussiebear22Оценок пока нет

- Danish Ahmed 0611184407Документ26 страницDanish Ahmed 0611184407bhaavОценок пока нет

- Izar Center Usermanual enДокумент52 страницыIzar Center Usermanual enscribd_stefanoОценок пока нет

- HF TXДокумент15 страницHF TXMuhammad Sharif JanjuaОценок пока нет

- Chapter 2 Strategies For An Effective Information TechnologyДокумент58 страницChapter 2 Strategies For An Effective Information TechnologyMark Lawrence YusiОценок пока нет

- Advanced Communication Solutions: CDM-625 Satellite Modem Training ManualДокумент274 страницыAdvanced Communication Solutions: CDM-625 Satellite Modem Training Manualbusiness 1Оценок пока нет

- Eagle Pro Mesh Router M32 REVA MANUAL v1.00 WWДокумент159 страницEagle Pro Mesh Router M32 REVA MANUAL v1.00 WWJai Sri HariОценок пока нет

- Peer To PeerДокумент14 страницPeer To PeerPatrick John LarenaОценок пока нет

- Promo Certificate 10102022..Документ5 страницPromo Certificate 10102022..Glezel BañaОценок пока нет

- Internet and World Wide WebДокумент13 страницInternet and World Wide WebMuhammad Iqrash Awan0% (1)

- Digital Image Processing - Pages-122-126Документ5 страницDigital Image Processing - Pages-122-126Faheem KhanОценок пока нет

- Enercon Scada Remote 3 Manual enДокумент141 страницаEnercon Scada Remote 3 Manual enMladenОценок пока нет

- ECG Machine Manual - ELI-150 - Mass General - INO-PD-P3-2014 - 050051 PDFДокумент34 страницыECG Machine Manual - ELI-150 - Mass General - INO-PD-P3-2014 - 050051 PDFMV FranОценок пока нет

- Airtel Free Gprs SettingsДокумент4 страницыAirtel Free Gprs SettingsbabakababaОценок пока нет

- Idr C LCT User Manual 04Документ122 страницыIdr C LCT User Manual 04TelMee100% (1)

- A' Level Computing Notes: ©mikey Holder, 2006Документ3 страницыA' Level Computing Notes: ©mikey Holder, 2006Edzai Nyasha TarupiwaОценок пока нет

- Wpa2 Wi-Fi Password I-TonicsДокумент4 страницыWpa2 Wi-Fi Password I-TonicsHarish KumarОценок пока нет

- Transferencia de Proyectos HMI ProfaceДокумент74 страницыTransferencia de Proyectos HMI ProfacekimatosuyakaОценок пока нет

- Netgear Dgn2200 Modem Router Setup GuideДокумент2 страницыNetgear Dgn2200 Modem Router Setup GuidearrachetoiОценок пока нет

- Ambulance Tracking and Patient Health Monitoring Using GPS and GSMДокумент7 страницAmbulance Tracking and Patient Health Monitoring Using GPS and GSMKarthick MОценок пока нет

- Bpac NoteДокумент17 страницBpac NoteSampreeth Nambisan Perigini100% (1)

- Hacking The Cable Modem PDFДокумент18 страницHacking The Cable Modem PDFRettas OthmaneОценок пока нет

- Kubandbuc SyssolДокумент52 страницыKubandbuc SyssoledgarlibanioОценок пока нет

- Analog and Digital Communication SystemsДокумент25 страницAnalog and Digital Communication SystemsGourav100% (1)