Академический Документы

Профессиональный Документы

Культура Документы

2009 Boiler Code Checklist

Загружено:

Alvaro Muñoz Vinueza0 оценок0% нашли этот документ полезным (0 голосов)

48 просмотров8 страницBOILER INSPECTION GUIDELINES for drum level INSTRUMENTATION Per Section I of the ASME Code. ASME SECTION I WATER GAGE REQUIREMENTS UNDER 400 PSIG At Least 1 Direct Reading Gage 400 PSIG and ABOVE 2 Direct Reading Gages.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документBOILER INSPECTION GUIDELINES for drum level INSTRUMENTATION Per Section I of the ASME Code. ASME SECTION I WATER GAGE REQUIREMENTS UNDER 400 PSIG At Least 1 Direct Reading Gage 400 PSIG and ABOVE 2 Direct Reading Gages.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

48 просмотров8 страниц2009 Boiler Code Checklist

Загружено:

Alvaro Muñoz VinuezaBOILER INSPECTION GUIDELINES for drum level INSTRUMENTATION Per Section I of the ASME Code. ASME SECTION I WATER GAGE REQUIREMENTS UNDER 400 PSIG At Least 1 Direct Reading Gage 400 PSIG and ABOVE 2 Direct Reading Gages.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 8

BOILER INSPECTION GUIDELINES FOR

DRUM LEVEL INSTRUMENTATION

Per Section I of the ASME Code

COURTESY OF

Updated to include the 2008 Code Addenda

Effective January 1, 2009

ASME SECTION I WATER GAGE REQUIREMENTS

UNDER 400 PSIG

At Least 1 Direct Reading Gage

400 PSIG and ABOVE

2 Direct Reading Gages OR

1 Direct Reading Gage and

2 Indirect (Remote) Reading Gages

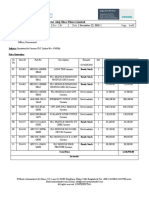

Figure 1

Note: When two Indirect Reading Gages are used to meet Section I requirements, the Direct Reading Gage may be

valved off, but must be maintained in serviceable condition.

GAGE VISIBILITY

GOOD PRACTICE IS TO LOCATE ALL ALARMS AND CUTOUTS WITHIN

WATER GAGE GLASS VISIBILITY

WATER COLUMNS

1 NPS minimum vessel connections

NPS minimum drain connection

The steam connection may come out of the top

of the vessel (4 on Figure 1))

The line for the steam connection from the

vessel to the water column should be level or

slope downward from the drum to the water

column (3)

The line for the water connection from the

vessel to the water column should be level or

upward from the vessel to the water column (2)

Water columns are defined as Standard

Pressure Parts or Standard Welded Parts in

Subsection PG-11. Therefore, a Manufacturers

Data report or Code Stamp is not required.

Water columns are not permitted to be

constructed from austenitic stainless steel.

WATER GAGE VALVES

Minimum NPS connection to the water

column

The Shutoff valves between the drum and the

water column must be OS&Y, of through-flow

design and orientation.

Must show position as open or closed, and

have lock open capabilities.

Must have an unrestricted drain opening.

GAGE GLASS

Upper visibility to be no higher than lower

edge of the steam connection to the drum (6)

Lower visibility to be no lower than the upper

edge of the water connection to the drum (5)

The lowest visible part of the gage glass (1)

must be at least 2 above the lowest

permissible water level (Level A)

Transparent or tubular glass gage glasses

that relay on observing the steam-water

interface and have multiple sections, must

have a minimum of 1 overlap of the visible

portions.

Internal lateral structural supports (webs) in

a transparent gage glass that obstruct the

viewing of the level are prohibited.

Ported type water gage glasses must be

fitted with proper illumination to provide visual

discrimination between water and steam.

Gage Cocks (Try Cocks)

Not required (Since 1991)

If used, must be minimum NPS to the

vessel.

REMOTE LEVEL INDICATOR

NPS minimum vessel connections

When used as a water column, the vessel

connections must be 1 NPS minimum.

NPS minimum drain connection

When used as a water column, the drain

connection must be NPS minimum.

When the two remote level indicators are

used at 400 PSIG and above, the remaining

gage glass may be shut off, but must be

maintained in the serviceable condition.

The display of the two indirect indicators

must be continuously visible in the operators

control area.

Conductivity probe devices, when properly

outfitted, meet Section I requirements for

Remote Level Indicators. See Figure 2 below.

MAGNETIC WATER LEVEL GAGE

Considered an indirect level indicator because

the actual water line can not be viewed

Does not replace the required direct reading

gage glass

Limited use to 900 PSI

Switches or accessories for control purposes are

prohibited

Can not be used as a water column for the

attachment of water gage glasses or other

instruments.

Indication scale must comply to PG-60

requirements regarding gage glass placement for

viewing range.

NPS minimum vessel connections

Can be fitted with a 4-20 mA transmitter for

remote transmission.

Material of construction may include certain types

of stainless steel (refer to PG-5.5)

NPS minimum drain connections

Can be fitted with a 4-20 mA transmitter for

remote transmission.

Figure 2

WATER COLUMN ISOLATION SHUTOFF VALVES

Y-pattern globe valves are acceptable as long

as the lowest edge of the seat is at least 25% of

the inside diameter below the centerline of the

valve. See Figure 3 below.

Figure 3

HRSG DESUPERHEATER DRAIN POTS

Drain pots that are installed to detect and

remove unvaporized water shall include

automatic detection of water and automatic

operation of the drain pot valves. See Figure 4

below.

Figure 4

COMMON NON-COMPLIANT DRUMLEVEL EQUIPMENT

ARRANGEMENTS

Magnetic Gages being used as direct reading gages. Magnetic Gages are permitted as a local

indirect gage or as a remote level indicator when used with a 4-20mA transmitter to a control area

indicator. The Magnetic gage can not replace the direct reading gage glass.

When the over 400 PSI Code option arrangement is used (two indicators for the one gage glass),

the two indirect indicators must be continuously visible in the operators control area and the gage

valves may be isolated. Viewing the boiler level on a plant operation control system computer

screen does not qualify as a continuously visible indicator unless it is always on the screen. If

keystrokes or mouse clicks are required to view the indirect indicator it does not meet the Code as

an indirect indicator.

When the over 400 PSI Code Option Arrangement is used, the existing gage glasses must be able

to be brought into service without further action other than opening the isolation valves, closing the

drain valve, and turning on illuminators. Gage glasses that can not be turned on without repairs do

not meet ASME Code requirements.

Bi-color ported type water gages must be fitted with proper illumination to provide visual

discrimination between water and steam. If not, the gages are not in Code compliance.

Not having two independent indirect reading gages when the gage glass image is not directly

visible in the operators control area or transmitted to the operators control area by means of a

camera, fiber optic system, or mirrors.

RECOMMENDATIONS

The following are not required by ASME Code, but are recommended for safe operation:

1. Chain Operators should always be used to provide a safe means of operating gage glass

isolation valves under normal conditions and in the event of glass leakage.

2. A conductivity probe system combined with a 4-20 mA transmitter, or, two conductivity probe

systems provide the best reliability due to the redundancy of probe systems. The use of two or

three differential pressure transmitters (redundant devices) is not recommended due to the

likelihood of simultaneous common mode failure due to environmental variations (especially

freeze-up) or loss of device sensing leg primes.

3. Trip and alarm points should fall within the visible range of the gage glass for visual

verification.

4. Freeze protection for outdoor applications should be provided to prevent damage to the level

instrumentation devices.

5. Transparent gage glass illumination should be provided to give optimum viewing of the drum

level, especially in low lit areas and when the transparent gage is elevated above the viewing

platform.

6. Exposed piping to the gage glass, especially the upper steam piping, should be insulated to

minimize any level density error due to cooling and condensate formation.

COURTESY OF

For questions, consult your local

Boiler Inspector, Insurance Carrier,

or a Reliance Applications Engineer.

CONTROL ROOM

INDICATORS

12 PROBE ELECTRO

EYE HYE SYSTEM

12 PROBE ELECTRO

EYE HYE SYSTEM

SIMPLIPORT BI-COLOR

DIRECT READING GAGE

Typical Code Compliant

installation for pressures

over 400 PSIG

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Eccentric FootingДокумент3 страницыEccentric FootingVarunn VelОценок пока нет

- EPW, Vol.58, Issue No.44, 04 Nov 2023Документ66 страницEPW, Vol.58, Issue No.44, 04 Nov 2023akashupscmadeeaseОценок пока нет

- Tribes Without RulersДокумент25 страницTribes Without Rulersgulistan.alpaslan8134100% (1)

- ChatGPT & EducationДокумент47 страницChatGPT & EducationAn Lê Trường88% (8)

- Life and Works of Jose Rizal Modified ModuleДокумент96 страницLife and Works of Jose Rizal Modified ModuleRamos, Queencie R.Оценок пока нет

- Press Statement - Book Launching Shariah Forensic 27 Oct 2023Документ4 страницыPress Statement - Book Launching Shariah Forensic 27 Oct 2023aОценок пока нет

- Aditya Academy Syllabus-II 2020Документ7 страницAditya Academy Syllabus-II 2020Tarun MajumdarОценок пока нет

- 11-Rubber & PlasticsДокумент48 страниц11-Rubber & PlasticsJack NgОценок пока нет

- 7 - Monte-Carlo-Simulation With XL STAT - English GuidelineДокумент8 страниц7 - Monte-Carlo-Simulation With XL STAT - English GuidelineGauravShelkeОценок пока нет

- BIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Документ32 страницыBIOAVAILABILITY AND BIOEQUIVALANCE STUDIES Final - PPTX'Md TayfuzzamanОценок пока нет

- SDS ERSA Rev 0Документ156 страницSDS ERSA Rev 0EdgarVelosoCastroОценок пока нет

- Job Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeДокумент16 страницJob Satisfaction of Library Professionals in Maharashtra State, India Vs ASHA Job Satisfaction Scale: An Evaluative Study Dr. Suresh JangeNaveen KumarОценок пока нет

- Designed For Severe ServiceДокумент28 страницDesigned For Severe ServiceAnthonyОценок пока нет

- Expression of Interest (Eoi)Документ1 страницаExpression of Interest (Eoi)Mozaffar HussainОценок пока нет

- Week 3 Lab Arado, Patrick James M.Документ2 страницыWeek 3 Lab Arado, Patrick James M.Jeffry AradoОценок пока нет

- WWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeДокумент8 страницWWW Ranker Com List Best-Isekai-Manga-Recommendations Ranker-AnimeDestiny EasonОценок пока нет

- Misc 8DNL 8MPL 8MPN B PDFДокумент41 страницаMisc 8DNL 8MPL 8MPN B PDFVesica PiscesОценок пока нет

- Class 12 Physics Derivations Shobhit NirwanДокумент6 страницClass 12 Physics Derivations Shobhit Nirwanaastha.sawlaniОценок пока нет

- LC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Документ2 страницыLC For Akij Biax Films Limited: CO2012102 0 December 22, 2020Mahadi Hassan ShemulОценок пока нет

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyДокумент12 страницIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsОценок пока нет

- Documentation Report On School's Direction SettingДокумент24 страницыDocumentation Report On School's Direction SettingSheila May FielОценок пока нет

- Configuration Guide - Interface Management (V300R007C00 - 02)Документ117 страницConfiguration Guide - Interface Management (V300R007C00 - 02)Dikdik PribadiОценок пока нет

- CycleMax IntroДокумент13 страницCycleMax IntroIslam AtefОценок пока нет

- OTP User Manual For English) v1,0Документ15 страницOTP User Manual For English) v1,0auyinОценок пока нет

- Executive Summary: 2013 Edelman Trust BarometerДокумент12 страницExecutive Summary: 2013 Edelman Trust BarometerEdelman100% (4)

- Control ValvesДокумент95 страницControl ValvesHardik Acharya100% (1)

- MSDS Buffer Solution PH 4.0Документ5 страницMSDS Buffer Solution PH 4.0Ardhy LazuardyОценок пока нет

- Trucks Part NumbersДокумент51 страницаTrucks Part NumbersBadia MudhishОценок пока нет

- SSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Документ22 страницыSSC Gr8 Biotech Q4 Module 1 WK 1 - v.01-CC-released-09May2021Ivy JeanneОценок пока нет

- Intelligent Status Monitoring System For Port Machinery: RMGC/RTGCДокумент2 страницыIntelligent Status Monitoring System For Port Machinery: RMGC/RTGCfatsahОценок пока нет