Академический Документы

Профессиональный Документы

Культура Документы

Dimensional & Material Standards For Piping Components

Загружено:

Abdulateaf Abdulrazig SattiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dimensional & Material Standards For Piping Components

Загружено:

Abdulateaf Abdulrazig SattiАвторское право:

Доступные форматы

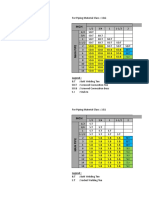

DIMENSIONAL STANDARDS FOR PIPING COMPONENTS By Peter Smith from Piping Materials Guide: Selection and Applications Type

of Component 90 long radius (LR) elbow 90 short radius (SR) elbow 45 Elbow 180 return Equal tee Reducing tee Reinforced branch (O'let) Eccentric reducer Concentric reducer Flanges Flanges Couplings Unions Spectacle blinds, spades and spacers Function Change direction Change direction Change direction Change direction Change direction Change direction and size Change direction and size Change size Change size Join pipe and components Join pipe and components Join pipe and components Join pipe and components Isolation Butt-Weld Ends ASME B16.9 (1/2-48 in.) ASME B16.28 (1/2-48 in.) ASME B16.9 (1/2-48 in.) ASME B16.9 (1/2-48 in.) ASME B16.9 (1/2-48 in.) ASME B16.9 (1/2-48 in.) Manufacturer's standard ASME B16.9 (1/2-48 in.) ASME B16.9 (1/2-48 in.) ASME B16.5 (1/2-48 in.) ASME B16.47 (26-60 in.) N/A N/A Threaded-Socket-Weld Ends ASME B16.11 (1/2-4 in.) Not applicable ASME B16.11 (1/2-4 in.) Not applicable ASME B16.11 (1/2-4 in.) ASME B16.11(1/2-4 in.) Manufacturer's standard ASME B16.11 (1/2-4 in.) ASME B16.11 (1/2-4 in.) ASME B16.5 (1/2-24 in.) N/A ASME B16.11 (1/2-4 in.) BS 3799 Material Standard

Held between Flanges API 590 or company's standards

B16.1 Cast Iron Pipe Flanges and Flanged Fittings

B16.3 Malleable Iron Threaded Fittings, Class 150 and 300 B16.4 Cast Iron Threaded Fittings, Classes 125 and 250 B16.5 Pipe Flanges and Flanged Fittings B16.9 Factory Made Wrought Steel Buttwelding Fittings B16.10 Face to Face and End to End Dimensions of Valves B16.11 Forged Fittings, Socket Welding and Threaded B16.12 Cast Iron Threaded Drainage Fittings B16.14 Ferrous Pipe Plugs, Bushings and Locknuts with Pipe Threads B16.15 Cast Bronze Threaded Fittings Class 125 and 250 B16.18 Cast Copper Alloy Solder Joint Pressure Fittings B16.20 Ring Joint Gaskets and Grooves for Steel Pipe Flanges B16.21 Nonmetallic Flat Gaskets for Pipe Flanges B16.22 Wrought Copper and Copper Alloy Solder Joint Pressure Fittings B16.23 Cast Copper Alloy Solder Joint Drainage Fittings DWV B16.24 Cast Copper Alloy Pipe Flanges and Flanged Fittings Class 150, 300, 400,600, 900, 1500 and 2500 B16.25 Buttwelding Ends B16.26 Cast Copper Alloy Fittings for Flared Copper Tubes B16.28 Wrought Steel Buttwelding Short Radius Elbows and Returns B16.29 Wrought Copper and Wrought Copper Alloy Solder Joint Drainage Fittings DWV B16.32 Cast Copper Alloy Solder Joint Fittings for Sovent Drainage Systems B16.33 Manually Operated Metallic Gas Valves for Use in Gas Piping systems Up to 125 psig (sizes through 2) B16.34 Valves Flanged, Threaded and Welding End B16.36 Orifice Flanges B16.37 Hydrostatic Testing of Control Valves B16.38 Large Metallic Valves for Gas Distribution (Manually Operated, NPS 2 to 12, 125 psig maximum) B16.39 Malleable Iron Threaded Pipe Unions, Classes 1150, 250 and 300 B16.40 Manually Operated Thermoplastic Gs Shutoffs and Valves in Gas Distribution Systems B16.42 Ductile Iron Pipe Flanges and Flanged Fittings, Class 150 and 300 B16.47 Large Diameter Steel Flanges (NPS 26 through NPS 60)

B36.10 Welded and Seamless Wrought Steel Pipe B36.19 Stainless Steel Pipe Other ASME or ANSI B73.1 Horizontal, End Suction Centrifugal Pumps B73.2 Vertical In-line Centrifugal Pumps B133.2 Basic Gas Turbine The difference between piping codes and piping standards can be defined as: Piping Codes: Piping codes defines the requirements of design, fabrication, use of materials, tests and inspection of pipes and piping systems. A code has a limited jurisdiction defined by the code. Piping Standards: Piping standards define application design and construction rules and requirements for piping components as flanges, elbows, tees, valves etc. A standard has a limited scope defined by the standard.

Вам также может понравиться

- Codes Standards For YANBU ProjectДокумент7 страницCodes Standards For YANBU ProjectBehçet Serdal CanbazОценок пока нет

- SpecificationsДокумент7 страницSpecificationsMarine SleimanОценок пока нет

- (DS2-010112) Y:/Proyecto/2090/PLANOS/04-Piping/Estandares/En Trabajo/4C/4C-01.03 C Rev-0Документ3 страницы(DS2-010112) Y:/Proyecto/2090/PLANOS/04-Piping/Estandares/En Trabajo/4C/4C-01.03 C Rev-0Christian Martínez G.Оценок пока нет

- Standards in The Valve IndustryДокумент2 страницыStandards in The Valve IndustryessnelsonОценок пока нет

- 1824 000 PI SPC 0003 - 7 - IFP - CleanedДокумент22 страницы1824 000 PI SPC 0003 - 7 - IFP - CleanedJudith HidalgoОценок пока нет

- 4C-01-02 Rev 2Документ5 страниц4C-01-02 Rev 2Christian Martínez G.Оценок пока нет

- Projects Engineering Department Engineering Standard: BES-L001Документ42 страницыProjects Engineering Department Engineering Standard: BES-L001Fox Alpha DeltaОценок пока нет

- Ed M 01.00 I 05Документ18 страницEd M 01.00 I 05joseellargo100% (1)

- 1 Engg DBD PP 010Документ19 страниц1 Engg DBD PP 010sanketОценок пока нет

- BOA Group Axial Expansion JointsДокумент24 страницыBOA Group Axial Expansion JointsA_ValsamisОценок пока нет

- Configure SPM 2012 On Windows 7 LaptopДокумент7 страницConfigure SPM 2012 On Windows 7 Laptopcgf_arОценок пока нет

- Standards and Specifications: ANSI (American National Standards Institute)Документ5 страницStandards and Specifications: ANSI (American National Standards Institute)norhazarudinОценок пока нет

- AbrivationsДокумент1 страницаAbrivationsArkhan KhanОценок пока нет

- Piping Specification: Piping Class: A2AДокумент30 страницPiping Specification: Piping Class: A2AAbhijeet WayaseОценок пока нет

- Flanged Duplex Strainers GuideДокумент1 страницаFlanged Duplex Strainers GuideRoshan ShanmughanОценок пока нет

- AsmeДокумент1 страницаAsmesimplexmОценок пока нет

- 347 Stainless Steel Class 2500 Piping SpecificationДокумент3 страницы347 Stainless Steel Class 2500 Piping SpecificationTrevor KanodeОценок пока нет

- Standards Scope PDFДокумент6 страницStandards Scope PDFaravindhcamОценок пока нет

- Butt Weld Stainless Steel FittingsДокумент16 страницButt Weld Stainless Steel Fittingsbayu susiloОценок пока нет

- PIPING CODES AND STANDARDS GUIDEДокумент299 страницPIPING CODES AND STANDARDS GUIDENaresh Sharma0% (1)

- Valve Material ApplicationДокумент16 страницValve Material ApplicationMuhammadShabbirОценок пока нет

- SPREADSHEETS SERIES No. 0009S - 2Документ4 страницыSPREADSHEETS SERIES No. 0009S - 2Emma DОценок пока нет

- Applicable Valve StandardsДокумент21 страницаApplicable Valve StandardsMatthew KuttikadОценок пока нет

- Part 2 - Roy A. Parisher, Robert A. Rhea - Pipe Drafting and Design-Gulf Professional Publishing (2022)Документ240 страницPart 2 - Roy A. Parisher, Robert A. Rhea - Pipe Drafting and Design-Gulf Professional Publishing (2022)Numan KashifОценок пока нет

- Presentation On: Internal Attachments - ABSORBERДокумент14 страницPresentation On: Internal Attachments - ABSORBERmuraliОценок пока нет

- Piping Material Class Comparison ChartДокумент5 страницPiping Material Class Comparison ChartAbu Akhmad BusanaОценок пока нет

- VMS PaliДокумент61 страницаVMS Palichintan100% (2)

- Valve Material ApplicationДокумент16 страницValve Material Applicationswapneel_kulkarniОценок пока нет

- Udhe 2.standardsДокумент1 страницаUdhe 2.standardsom dhamnikarОценок пока нет

- Needle ValveДокумент8 страницNeedle ValveMuhammad Chilmi100% (1)

- Piping SpecificationДокумент3 страницыPiping SpecificationArun KumarОценок пока нет

- How To Create A Reinforcing Pad in Branch Table PDFДокумент1 страницаHow To Create A Reinforcing Pad in Branch Table PDFnirgaОценок пока нет

- Velan Forged Steel Gate Globe Checks PDFДокумент25 страницVelan Forged Steel Gate Globe Checks PDFsunil kumarОценок пока нет

- Buttweld Fittings Accesorios SoldadosДокумент5 страницButtweld Fittings Accesorios SoldadosJuan CadenaОценок пока нет

- PVE Piping Layout Presentation - Part 2Документ117 страницPVE Piping Layout Presentation - Part 2Nguyen Quang NghiaОценок пока нет

- Piping Engineering.nДокумент6 страницPiping Engineering.nAjay KumarОценок пока нет

- PP Lined Pipe PDFДокумент27 страницPP Lined Pipe PDFNILADRI BHATTACHARYYAОценок пока нет

- American National Standards Institute - STD LISTДокумент15 страницAmerican National Standards Institute - STD LISTRajesh ChoudharyОценок пока нет

- AB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersДокумент1 страницаAB-031A Minimum Required Information Form The Submitter For Pressure Vessels Heat Exchangers and BoilersTrung NguyenОценок пока нет

- ANSI FlangeДокумент10 страницANSI FlangemechftpОценок пока нет

- 6-76-0002 Bolt Tension For FlangesДокумент33 страницы6-76-0002 Bolt Tension For Flangesrovergamma100% (1)

- Pi Ups 1004Документ39 страницPi Ups 1004JOEL ARNAO CORTEGANAОценок пока нет

- ISCO HDPE Product Catalogo-Fittings Section PDFДокумент72 страницыISCO HDPE Product Catalogo-Fittings Section PDFJorge Santos RomeroОценок пока нет

- List of StandardsДокумент3 страницыList of Standardssumant.c.singh1694Оценок пока нет

- Asme B16.36 Int PDFДокумент3 страницыAsme B16.36 Int PDFRuben Dario Mamani ArellanoОценок пока нет

- Flange Pipe Support for 4-36Документ1 страницаFlange Pipe Support for 4-36indeskeyОценок пока нет

- 316/316L Stainless Steel Spec SheetДокумент3 страницы316/316L Stainless Steel Spec SheetLinnie McleodОценок пока нет

- Line Number Format: Piping Specification Pipe Line IdentificationДокумент2 страницыLine Number Format: Piping Specification Pipe Line IdentificationAkmal Hazuan SulaimanОценок пока нет

- Valves, fittings and gasketsДокумент32 страницыValves, fittings and gasketsPeter RodriguezОценок пока нет

- ASME Piping Dimensional StandardsДокумент2 страницыASME Piping Dimensional StandardsKrunalpanchalОценок пока нет

- Piping TechniquesДокумент8 страницPiping TechniquespiglitОценок пока нет

- General Q and AДокумент10 страницGeneral Q and AmohamedqcОценок пока нет

- Piping Codes and Standards - The Piping Engineering BlogДокумент5 страницPiping Codes and Standards - The Piping Engineering BlogSalman KhanОценок пока нет

- Codes TableДокумент2 страницыCodes TablejesamsonОценок пока нет

- Codes and StandardsДокумент6 страницCodes and StandardsZaid ImranОценок пока нет

- Material Selection 1Документ21 страницаMaterial Selection 1yulianus_srОценок пока нет

- PipingДокумент21 страницаPipingsubashОценок пока нет

- Codes and Standards: ASME B31 Piping CodesДокумент44 страницыCodes and Standards: ASME B31 Piping CodesMuthukumar ThangaiahОценок пока нет

- ASMEДокумент2 страницыASMEjensdcvОценок пока нет

- API 570 Mock Exam Closed BookДокумент17 страницAPI 570 Mock Exam Closed BookaasattiОценок пока нет

- PTR 1Документ3 страницыPTR 1aasattiОценок пока нет

- API 570 DEC 2009 ClosedДокумент19 страницAPI 570 DEC 2009 Closedaasatti100% (1)

- Api Exam-Part 2Документ2 страницыApi Exam-Part 2aasattiОценок пока нет

- 5 - Sept 2013 Exam MemoryДокумент3 страницы5 - Sept 2013 Exam Memoryaasatti100% (1)

- API 570 piping inspection exam questionsДокумент19 страницAPI 570 piping inspection exam questionsaasattiОценок пока нет

- API 570 Mock Exam Closed BookДокумент17 страницAPI 570 Mock Exam Closed BookaasattiОценок пока нет

- 570 امتحانДокумент3 страницы570 امتحانaasatti100% (1)

- SAIC-A-2003 Rev 0Документ3 страницыSAIC-A-2003 Rev 0bluelions_19Оценок пока нет

- Verify Test Prep and EquipmentДокумент3 страницыVerify Test Prep and EquipmentaasattiОценок пока нет

- New Microsoft Word DocumentДокумент5 страницNew Microsoft Word DocumentaasattiОценок пока нет

- SAIC-A-2004 Rev 0Документ1 страницаSAIC-A-2004 Rev 0Kristine Caye DatarioОценок пока нет

- API 570 Exam Publications Effectivity SheetДокумент1 страницаAPI 570 Exam Publications Effectivity SheetaasattiОценок пока нет

- Important - Accept Because Progression in SMAW Is Non-Essential Variable. - 300 S/sДокумент1 страницаImportant - Accept Because Progression in SMAW Is Non-Essential Variable. - 300 S/saasattiОценок пока нет

- SAIC-A-2001 Rev 0Документ3 страницыSAIC-A-2001 Rev 0bluelions_19Оценок пока нет

- 1 SATIP-A-004-01 Pneumatic Pressure Testing-Rev1 PDFДокумент2 страницы1 SATIP-A-004-01 Pneumatic Pressure Testing-Rev1 PDFbth8320Оценок пока нет

- Dimensional & Material Standards For Piping ComponentsДокумент3 страницыDimensional & Material Standards For Piping ComponentsaasattiОценок пока нет

- Basic Calculations Piping System Design PDFДокумент14 страницBasic Calculations Piping System Design PDFjeff_shawОценок пока нет

- Money Transfer PDFДокумент1 страницаMoney Transfer PDFaasattiОценок пока нет

- NPSHA For PumpДокумент11 страницNPSHA For PumpHariharan KandasamyОценок пока нет

- API Standards For RefiningДокумент3 страницыAPI Standards For Refiningaasatti100% (2)

- Field Welding Inspection GuideДокумент15 страницField Welding Inspection Guideranjit.rajappa19709872100% (19)

- Non Destructive TestingДокумент62 страницыNon Destructive Testingjoescribd55Оценок пока нет

- Certification Program: Aws - CwiДокумент5 страницCertification Program: Aws - CwiaasattiОценок пока нет

- Selection of Pump Type and Pump2Документ14 страницSelection of Pump Type and Pump2gpskumar22Оценок пока нет

- Example of Pipe Wall Thickness CalcДокумент1 страницаExample of Pipe Wall Thickness CalcaasattiОценок пока нет

- Saudi Aramco NDT Methods Application On Heat ExchangersДокумент30 страницSaudi Aramco NDT Methods Application On Heat Exchangersaasatti100% (1)

- HEAT - EXCHANGERS - in - Saudi - Aramco PDFДокумент27 страницHEAT - EXCHANGERS - in - Saudi - Aramco PDFMohammad Sazid Alam78% (9)

- NPSHA For PumpДокумент11 страницNPSHA For PumpHariharan KandasamyОценок пока нет

- Caesar II Applications GuideДокумент308 страницCaesar II Applications Guidebanjinolimit8299100% (5)