Академический Документы

Профессиональный Документы

Культура Документы

Activity

Загружено:

Sasi VimalnathИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Activity

Загружено:

Sasi VimalnathАвторское право:

Доступные форматы

Class room activity for IT final year students

Dear students, Get the autograph from your friends which are relevant to their character within the given time. Person should not sign more than one time. Be careful while getting sign from your friends. Your time starts now. Here we go! Ice-cream lover Chubby cheeks Like to go movie wit dad, but still waiting Madly in need of big earrings Need more jewels to wear n interested in construction Waiting to taste pizza Vijay movies lover Chutti TV watcher(esp. Jackie Chan cartoon) Face problem easily Like silence n so Im Kashmir born Silent boy Im a cricketer Want baby pink color dress Want baby pink color dress Believe only in friends Like APJ n waiting to get his book to read Van n auto driver interested in maths & programming Dint watch ajith movie in theater Keeping everyone happy Only blue n black color pens till now for semester Like Hemachandra very much, but havent heard full song Love dad & mom Love maths I like English movie but dont like to watch Like noodles Bit serious person but never reacted I have good smile I like to learn Hindi I hate chocolate Dedicated devotee of Lord Shiva

1.

The concept of total quality control, i.e. that quality must be attended to at all stage of the industrial cycle and throughout the organization, is the creation of which of the following pioneers? W Edwards Deming Joseph M Juran Genichi Taguchi

Class room activity for IT final year students

Armand Feigenbaum

2.

The so-called 'Quality Gurus' of total quality management (TQM) do NOT include one of the following: Bill Cosby W Edwards Deming Kaoru Ishikawa Joseph M Juran

3.

The specific concerns of total quality management (TQM) include a number of aspects. Which is not normally associated with TQM? Meeting the needs and expectations of customers Covering all parts of the organization Inclusion of every person in the organization Primarily a worker rather than a management activity

The preferred method for achieving total quality in process output is: Perform inspection at the next process 4. Rely on operator self-inspection and selfcorrection Build and install an error-proof process and maintain it Rely on a team of highly trained and dedicated inspectors Total quality management (TQM) programmes are more likely to remain effective if a number of prescriptions are followed. Which of the following prescriptions should not be followed? TQM does not become a separate 'bolt-on' set of activities TQM should become a substitute for normal managerial leadership Slogans and exhortations about TQM's effectiveness are avoided Quality improvement relates to operation's performance objectives Which of the following would not normally be considered as a costs of quality? Prevention costs Marketing costs Warranty costs Research and development costs Inspection costs Internal failure costs

5.

6.

7.

Which one of the following would normally be considered as one of the costs of quality? Research and development costs Internal failure costs

Class room activity for IT final year students

12. A fundamental attribute of TQM is Drawing control charts Having team meetings Top management's direct involvement Meeting ISO 9000 audit All of the above 13. Drawing control charts requires Calculation of statistics from data Adjusting the machines Teamwork training of workers Top management involvement Meetings with suppliers 14. Inspection assures that The process is in control Workers are motivated Product meets specification Quality problems are solved Supplier quality is acceptable 15. A control chart displays Whether workers are motivated Top management takes interest in quality Inspectors are doing their job Process variability Process capability 16. Process capability =1 indicates that Suppliers can be trusted Workers are motivated Process is in control There are no random variations Some fraction of production is outside specs 17. SPC helps determine If assignable causes are disturbing the process If vendor performance is falling If customers are happy If customers are motivated If top management is involved 18. Vision states Where the workers want to go after work Whether we should use SPC Whether we should use inspection Where the company wants to be in the long run That customers are the boss 19. Quality is wanting generally because Workers lack team spirit No competition exists People dont know statistics 20. A stakeholder is generally Someone who manages the company People who run the company's payroll Interested in the success of the enterprise Only the customer Only the vendor 21. Systematic problem solving requires Motivating the worker Defining the problem to be solved Drawing control charts Keeping management informed Keeping tab on the environmental impact 22. ISO 9000 determines If the company practices its written procedures If vendors are performing well Process capability The kind of control chart to be used Random causes of variation 23. An example of a random cause is Absenteeism Shortage of material supplies Photocopy machine failure Small vibrations in the equipment Word Processor not having Spellchecker 24. An assignable cause is generally known to Vendors Top management Product designer Workers Customers 25. Flow charts indicate Causes of process variation The kind of forms to fill out Who reports to whom How inputs get processed into outputs How samples are rejected 26. A sampling plan helps in Keeping the process in control Keeping workers motivated Tuning the machines Adjusting ovens in the kitchen Rejecting lots that are of unacceptable quality 27. Process Diagnosis determines If the workers are doing their job The possible cause of a failure If control charts are in control When top management should talk to vendors If vendors are motivated 28. Team orientation means Workers having lunch with their families Workers getting daily briefing Working collectively toward a common goal Cooperation with government regulators

Class room activity for IT final year students

ISO 9000 orientation meetings 29. Creativity requires Control charts Complete knowledge of vendor'scapability Managing the quality of ideas generated Facilitation .Physical exercise 30. Problem identification requires Flow charting the process Monitoring customer complaints Knowing how to draw control charts Team meetings Maintaining clean cafeterias 31. Problem solving begins with Team discussions SPC Design of experiments Problem identification Punching time clock 32. Benchmarking determines Customer requirements Process capability How company is doing relative to others Getting ISO 9000 audit done If management is motivated 33. Control charts help in Reaching six sigma Rejecting parts supplied by vendors Keeping workers motivated Deciding when to investigate the process Zero defect production 34. Seven tools include Team meetings Management meeting regularly with workers Workers' toolkit Histogram All above 35. A Pareto chart shows That the process is in control The vital few from the trivial many Process capability A line drawn as production proceeds Fraction defective 36. Individuals who have no role in quality management Teachers in universities Government regulators Workers ISO 9000 trainers Vendors 37. Quality management requires ISO 9000 certification Workers not working overtime Printing promotional brochures Keeping internal customers satisfied Keeping oil off the floor 38. A problem definition should include A control chart Names of members of the team What the problem is and what it is not Who was operating the machine that day Ideas to solve the problem 39. The role of R&D is To improve working conditions in the lab To keep top management informed of competition To regularly study control charts To determine how processes work To keep the company competitive 40. Efficiency means There are no defects in the output Process is capable Cost of quality is low Resources are made the most of Workers arrive on time 41. The case of waiting too long at the elevator is A well-structured problem A candidate for control charts Indication of timely arrival at work Ignoring external customers None of the above 42. The difference between manufacturing and service is Nonexistent Products cannot be inventoried Service can't be backordered Production is instantaneous Service is consumed as Produced 43. Service quality cannot be managed when No vendors are involved Customer expectations are not known Workers don't meet regularly with management Consultants are not consulted Histogram cannot be drawn 44. Accuracy can be improved by Use of Xbar charts Team meetings TQM principles Management talking to workers Customer visits 45. Design of Experiments implies Good instruments used in the lab Team meetings in product trials A method to find factor effects Aesthetic quality of products Careful recording of data

Class room activity for IT final year students

46. Cause-effect diagram is used in Problem identification Field visits Vendor surveys Problem analysis Negotiating with unions 47. Cost of quality is really A way to prioritize actions Cost of production Cost of sales Cost of high-quality products An accounting jargon 48. The Baldrige Award is A ISO 9000 requirement An indication of SPC being used Indication of no competition Indication that TQM programs are effective All of the above 49. TQM does not imply Strong external customer orientation Partnership with vendors Meticulously re-stocking defective products Training Team meetings 50. Precision in production means Workers are well-trained Hi-tech equipment is used Instruments are kept clean Parts produced have little or no variation Shop uses control charts 51. Accuracy implies We know customer targets Computerized machines Average performance is on target All products are of same size 52. Six sigma is Latest Japanese Quality Theory A BMW Cpk = 2.0 53. The American model for TQM is ISO 9000 ISO 14000 The Baldrige Award criteria Use of control charts Use of quality circles in the shop 54. Six Sigma implies A statistical method A trouble-shooting method Teams are effective 3 defects per million in output All above 55. A service cannot be Stored Inspected Targeted Appraised Flowcharted

56. SPC implies Statistical process control Use of control charts Fixing assignable causes 57. Sometimes leaving the process alone All above 58. A Stable Process has No defects in output 3 ppm output Good control on vendors Motivated workers . No variation with time in Output 59. Fishbone diagrams are drawn To find customer needs To find the cost of quality To brainstorm causes of an effect To screen workers suggestions To explain what the process does 60. Process Flow Charts help explain Process steps and their relationship Cost of quality A clause in ISO 9000 Customer complaints Assignable causes 61. Quality control does not apply to Drawing flow charts Drawing control charts Driving Idea generation PTA meetings 62. Strategy implies What level of quality the customers want What the company has to do to reach its vision How competitive we are Practices on the shop floor Workers can talk to management 63. QFD is the way to Fix typing errors Fix sampling plans Conduct quality circle meetings Develop product specs 64. A key reason for lost productivity is Not implementing TQM Mgmt. not listening to workers The hidden factory

65. Most auto accidents are Correlated with fuel efficiency

Class room activity for IT final year students

Caused by chance Preventable At 6 sigma level Caused by bad design 66. A system involves Components An overall objective or mission Humans, procedures, technology Environment in which it operates All above 67. A process is predictable if We can forecast its output It is always at the same level It has no humans involved The data can be plotted on a chart The same workers stay employed 68. Range of 1, 2, 3, 4, 5 is 69. 5 4 3 2 0 70. The quantity sigma (s) indicates Trend in the process Dispersion in the data Lack of attention by workers Average Range Workers overzealous 76. TQM is part of Strategic management ISO 9000 certification QS 9000 certification Hospital management Project reviews 77. The word target in quality means The specification The control limits Xbar points on the chart The ideal quality requirement Six sigma production 78. Six sigma requires Process knowledge An indulging mindset Action on causes of defects DOE trials All above 79. Spec limits are used for Talking to workers about quality Adjusting control charts Finding process capability Drawing R charts Troubleshooting 80. ISO 9002 requires Constantly holding meetings with customers Frequent vendor visits Getting production and inspection/installation methods certified Getting final inspection methods shipshape Team deliberations for quality 81. Quality is a problem because Modern processes are too complex Workers dont do the job It is expensive to control All processes have some variation Management do not fund projects 82. A Reaction Plan is A flow chart An afterthought A way to produce good products A checklist to use when things dont look right A way to check incoming parts 83. The best strategy in quality is To inspect the output before shipment To aim to produce on target To check machines every day To keep workers relaxed To hold training meetings every week 84. DOE identifies Causes of delayed shipments Factors that affect the output Traffic congestion points Control limits Why meetings are not running smoothly 85. Interaction implies

71. When you have too many factors on a fish-bone chart, then Take top ten Take top five Inquire to find which factors are suspected to be significant Conduct design of experiments Talk to customers 72. The word Control implies Inspecting every item Plotting charts Using a signal to adjust the process Management by Objectives Team control the shop 73. QFD is a method for Controlling quality in production Controlling quality in restaurants Finding out what customer wants Translating customer needs to product specs Quality circles 74. A Capable Process Is never outside control limits Meets or exceeds spec requirements Has no defects in output Has good management support Is ISO 9000 certified 75. DOE may fail because Control charts are incorrectly drawn No team involvement A key factor has been left out Top management not visible

Class room activity for IT final year students

Effect of one factor depends on where some other factor is set Managers moving about Team meetings Xbar and R charts looking similar Teamwork

86. Weather variation is difficult to explain because Atmosphere is too large a system We cannot plot temperature on Xbar charts Dont understand the process behind it Experts have not taken trouble to explain weather TV channels use graphics 87. Cost of quality is affected by Workers performance Field failures Calibration of instruments Preventive actions All above 88. Quality of education can be impacted by Surplus in federal budget Sports programs Attention to details Parents meeting with city officials Kids having friends Closer tab on principals 89. Study methods can be improved by Benchmarking Improved note taking Vacations Sitting in the front row Buying books

90. Expand MBNQA

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Basics in Clo3D BrochureДокумент2 страницыBasics in Clo3D BrochureKarthik Clo100% (1)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Peter Lindbergh. On Fashion Photography. 40th Anniversary Edition - PhotographyДокумент5 страницPeter Lindbergh. On Fashion Photography. 40th Anniversary Edition - Photographydupedisu0% (4)

- Did You Know-Highly Sensitive Child 1-08Документ15 страницDid You Know-Highly Sensitive Child 1-08Narel_1100% (3)

- C V C V C V C V: Urriculum Itae Urriculum Itae Urriculum Itae Urriculum ItaeДокумент1 страницаC V C V C V C V: Urriculum Itae Urriculum Itae Urriculum Itae Urriculum ItaeFandrio PermataОценок пока нет

- Interpreting Remainders LessonДокумент14 страницInterpreting Remainders Lessonapi-529488210Оценок пока нет

- Mis VacacionesДокумент6 страницMis VacacionesYliana MoraОценок пока нет

- 49 14371 Form CorДокумент1 страница49 14371 Form CorYhan San BuenaventuraОценок пока нет

- Goleman 1995 Inteligencia Emocional PDFДокумент3 страницыGoleman 1995 Inteligencia Emocional PDFKristen0% (1)

- Case Study - Challenger Ethical IssuesДокумент7 страницCase Study - Challenger Ethical IssuesFaizi MalikzОценок пока нет

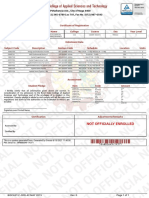

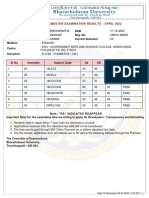

- BHUVANESHWARI M (CB21C 82639) - Semester - Result (1) 22Документ1 страницаBHUVANESHWARI M (CB21C 82639) - Semester - Result (1) 22AllwinОценок пока нет

- National Strength and Conditioning Association.1Документ19 страницNational Strength and Conditioning Association.1Joewin EdbergОценок пока нет

- Action Plan RemedialДокумент1 страницаAction Plan RemedialRonnie TambalОценок пока нет

- Mt1Pwr-Iia-I-5.1: Blend Specific Letters To Form Syllables and WordsДокумент2 страницыMt1Pwr-Iia-I-5.1: Blend Specific Letters To Form Syllables and WordsKris LynnОценок пока нет

- GMath2Q3Week7Day1 4Документ15 страницGMath2Q3Week7Day1 4Jerick JohnОценок пока нет

- Diasporic Sensibilities in Jhumpa Lahiri's WorksДокумент2 страницыDiasporic Sensibilities in Jhumpa Lahiri's WorksMd. Sheraz ButtОценок пока нет

- EDT 323 Ass # 1-LeeДокумент7 страницEDT 323 Ass # 1-LeeLeedon HepoeОценок пока нет

- Method 1 of Educational PsychologyДокумент3 страницыMethod 1 of Educational PsychologyRobert VallenteОценок пока нет

- Arvinius + Orfeus - September 2021Документ12 страницArvinius + Orfeus - September 2021ArtdataОценок пока нет

- Learning For Success (LFS) : Sajeevta FoundationДокумент5 страницLearning For Success (LFS) : Sajeevta FoundationGautam Patel100% (1)

- JS PROM PscriptДокумент5 страницJS PROM PscriptSerafinesОценок пока нет

- Aviral Mishra: Education SkillsДокумент1 страницаAviral Mishra: Education SkillsAVIRAL MISHRAОценок пока нет

- Syllabus For IEE 572 Fall 2011Документ5 страницSyllabus For IEE 572 Fall 2011zazaidiОценок пока нет

- Homeroom Guidance Learner'S Development Assessment School Year 2021 - 2022 GRADE 4-6 (Intermediate Level) Cherry Belle F. Del Rosario, Ed.DДокумент2 страницыHomeroom Guidance Learner'S Development Assessment School Year 2021 - 2022 GRADE 4-6 (Intermediate Level) Cherry Belle F. Del Rosario, Ed.Dpatrick henry paltepОценок пока нет

- MyELT Documentation For TeachersДокумент5 страницMyELT Documentation For TeachersdanieljrymerОценок пока нет

- Ielts Writing Task 2Документ3 страницыIelts Writing Task 2Nhu NguyenОценок пока нет

- RLIT 6310.90L Children's and Adolescent Literature: Textbook And/or Resource MaterialДокумент10 страницRLIT 6310.90L Children's and Adolescent Literature: Textbook And/or Resource MaterialTorres Ken Robin DeldaОценок пока нет

- Lac SessionДокумент11 страницLac SessionANDREA OLIVASОценок пока нет

- ISHAANДокумент4 страницыISHAANAlliah OrdanОценок пока нет

- NSTP 1 Mac & Sac Syllabus 1st Sem 16-17Документ2 страницыNSTP 1 Mac & Sac Syllabus 1st Sem 16-17Arriel TingОценок пока нет

- Lesson 2 Texts and Authors From Each Region (Part 1) (Autosaved)Документ71 страницаLesson 2 Texts and Authors From Each Region (Part 1) (Autosaved)Rommel LegaspiОценок пока нет