Академический Документы

Профессиональный Документы

Культура Документы

Reg Apr May 06 PDF

Загружено:

prk74Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Reg Apr May 06 PDF

Загружено:

prk74Авторское право:

Доступные форматы

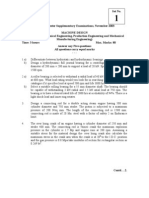

Code No: RR320305

Set No. 1

III B.Tech II Semester Regular Examinations, Apr/May 2006 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks 1. (a) Distinguish between full and partial journal bearings. [4]

(b) Design a journal bearing for a steam turbine, whose shaft is supported on two bearings one at each side of the turbine, and is coupled with a generator for power production. The weight of turbine with shaft is measured as 40 kN and the shaft rotates at 1500 rpm. Diameter of the shaft is 100 mm. [12] 2. (a) What is the most important advantage gained in using needle bearing? [2] (b) A 6203 single row deep groove ball bearing has a basic static load rating of 4500 N and basic dynamic load rating of 7350 N. If it is subjected to radial load of 1350 N and axial load of 1260 N, what is the rated life with outer ring stationary? [8] (c) What is the nominal life in working hours of a deep groove ball bearing 6308, which is carrying a constant radial load of 2.82 kN at a speed of 800 rpm? [6] 3. Enumerate the design procedure for the connecting rod section considering it as a simple compression or tension member subjected to uctuating load [16] 4. What are the stresses to which an over hanging shaft is subjected to? How would you proceed to design such a crank shaft. [16] 5. (a) Classify various types of springs with sketches and give their applications. [8] (b) A helical spring is made from a wire of 6 mm diameter and has outside diameter of 75 mm. If the permissible shear stress is 350 Mpa and modulus of rigidity 84kN/mm2 , nd the axial load which the spring can carry and the deection per active turn. [8] 6. (a) List out the advantages and disadvantages of V - belts [4] (b) A workshop crane is lifting a load of 25 kN through a wire rope and a hook. The rope drum diameter may be taken as 30 times the diameter of the rope. The load is to be lifted with an acceleration of 1 m/s2 . Calculate the diameter of the wire rope. Take a factor of safety of 6 and youngs modulus for the wire rope 80 kN/mm2 . The ultimate stress may be taken as 1800 MPa. The cross - sectional area of the wire rope may be taken as 0.38 times the square of the wire rope diameter. [12] 7. Design a cast iron spur gear drive for a crane hoist to transmit 3.75 kW at 1440 rpm. Maximum gear ratio in the gear box is 4. Each gear is expected to work 2 hours/day for 10 years. Determine the minimum centre distance, required face width and module of the gear. [16] 1 of 2

Code No: RR320305

Set No. 1

8. Design a simple screw jack to lift a load of 100 kN having a maximum lift of 260 mm. The screw is made of 40 Ni 14 steel and the nut of phosphor bronze grade A. The stresses for these materials are given below: [16] Ultimate tensile/ Shear stress 2 Compressive strength(N/mm ) N/mm2 Steel screw 40Ni14 800 340 Phosphor bronze Grade A nut 552 260 Allowable bearing pressure between screw and nut = 15 N/mm2 . Material Factor of safety 4 5

2 of 2

Code No: RR320305

Set No. 2

III B.Tech II Semester Regular Examinations, Apr/May 2006 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks 1. (a) Dene the following i. Eccentricity of journal bearing ii. Minimum lm thickness (b) Design a journal bearing for a centrifugal pump running at 1440 rpm. Diameter of the journal is 10 cm and load on each bearing is 2000 kg. The factor ZN/P may be taken as 2800 for centrifugal pump bearings. Assume the followings. [12] o Atmospheric temperature = 30 C Operating temperature = 75o C Energy dissipation coecient = 0.00125 C/D ratio = 0.001 L/D ratio = 1.5 2. (a) What is equivalent static load. [2] (b) The radial reaction on a bearing is 9000 N. It also carries a thrust of 5000 N. The speed of the shaft is 1000 rpm. The outer ring stationary. Expected average life of bearing is about 25,000 hours. The load on the bearing is smooth, the service is 8 hours/day. Select, [14] i. Suitable roller bearing ii. What is the rated 90% life of selected bearing? iii. Compute the probability of the selected bearing surviving 25,000 hours 3. Enumerate the design procedure for the connecting rod section considering it as a simple compression or tension member subjected to uctuating load [16] 4. Design a plain carbon steel crankshaft for a 0.40 m by 0.60m single acting 4-stroke diesel engine to operate at 200 rpm. The mean eective pressure is 0.49 MPa, and the maximum combustion pressure is 2.624MPa at a maximum torsional moment. When the crank angle is 36o , the gas pressure is 0.975 MPa. The ratio of connecting rod length to crank radius is 4.8. The ywheel is used as a pulley the weight of the ywheel 54.50kN and the total belt pull is 6.75kN. Assume the suitable values for the missing data. [16] 5. (a) Classify various types of springs with sketches and give their applications. [8] (b) A helical spring is made from a wire of 6 mm diameter and has outside diameter of 75 mm. If the permissible shear stress is 350 Mpa and modulus of rigidity 84kN/mm2 , nd the axial load which the spring can carry and the deection per active turn. [8] 1 of 2 [4]

Code No: RR320305

Set No. 2

6. (a) Prove that the centrifugal tension must be 1/3rd of the maximum tension for maximum power transmission. [6] (b) Design a cross belt drive having 1.5 m center distance between the two pulleys The diameter of bigger and smaller pulleys are D and d respectively. The smaller pulley rotates at 1000 r.p.m. and the bigger pulley at 500 r.p.m. The at belt is 6 mm thick and transmits 7.5 kW power at belt speed of 13 m/s approximately. The coecient of belt friction is 0.3 and the density of belt material is 950 kg/m3 . The permissible tensile stress for the bet material is 1.75 MPa. [10] 7. It is desired to determine the proportions of a spur gear drive to transmit 8kW from a shaft rotating at 1200rpm to a low speed shaft, with a reduction of 3:1. Assume that the teeth are 20o full depth involute, with 24 teeth on pinion. The pinion is to be of 40C8 Steel and gear of 30C8 steel. Assume that the starting torque is 130 percent of rated torque. [16] 8. The screw of a press has square threads and is of 60 mm nominal diameter. The maximum unsupported length is 400 mm. The screw is made of 25C4 steel and the nut is of phosphor bronze. Determine the capacity of the press and length of the nut. If the coecient of friction for the threads is 0.15 and 0.14 for the thrust collar, determine the necessary torque, taking outside and inside diameters of thrust collar to be 100 mm and 30 mm respectively. [16]

2 of 2

Code No: RR320305

Set No. 3

III B.Tech II Semester Regular Examinations, Apr/May 2006 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks 1. (a) What factors should be considered when selecting bearings? (b) Design a full journal bearing for the following specications. Radial load =30 kN Journal diameter = 120 mm Speed of the journal = 500 rpm Minimum oil lm thickness = 0.025 mm [4] [12]

2. (a) A roller bearing is selected to withstand a radial load of 40 kN and life of 1200 hrs at 600 rpm. What load rating would you look for in searching from manufacturers catalogue if it species loud at speed 500 rpm and life 3000 hrs [8] (b) Select a suitable rolling bearing for a 55 mm diameter shaft. The bearing should be capable of withstanding 3 kN radial and 1.5 kN axial load at 750 rpm. The bearing is to have a desired rated life of 2000 hrs at a reliability of 94% . There is a light shock load and inner ring rotates. [8] 3. Enumerate the design procedure for the connecting rod section considering it as a simple compression or tension member subjected to uctuating load [16] 4. (a) (b) (c) (d) What is the function of a crank shaft? Explain the dierent stresses induced in crank pin. Explain the dierent stresses induced in crank Web. How crank shaft bearings are lubricated? [4x4=16]

5. A solenoid brake is to be actuated by a helical compression spring of free length 350mm and is to exert a maximum force of 10kN when compressed by 80mm. The outside diameter of the spring should not exceed 180mm. What is the wire diameter, coil diameter and number of coils? [16] 6. (a) Write the procedure for designing a wire rope. [8] (b) Select a wire rope for a vertical mine hoist to lift a load of 55kN from a depth 300 meters. A rope speed of 500 meters/min is to be attained in 10 seconds. [8] 7. (a) Explain how the eect of dynamic load is considered in gear design. [4] (b) A shaft running at 250 rpm is driven by a 15kW motor running at 876 rpm through a pairs of 20o full depth spur gears. If the central distance is to be approximately 400 mm ( 3mm allowed), design the spur gear drive. Use C30 and C45 Steels for pinion and gear respectively. [12] 1 of 2

Code No: RR320305

Set No. 3

8. A sluice gate weighing 600 kN is raised and lowered by means of two 70 mm square thread screws. The screws are operated by an electric motor running at 600 rpm. A ball thrust bearing is used, reducing the apparent friction coecient to 0.003 on a 50 mm radius. Bronze nuts and fair lubrication are used. If the gate must be raised at the rate of 10 mm/s, determine: (a) the number of revolutions per minute of the screws, (b) the power of the motor required to raise the gate, assuming a mechanical eciency of 0.85 for the speed reduction mechanism, and (c) the power required to lower the gate. [16]

2 of 2

Code No: RR320305

Set No. 4

III B.Tech II Semester Regular Examinations, Apr/May 2006 DESIGN OF MACHINE MEMBERS-II ( Common to Mechanical Engineering and Production Engineering) Time: 3 hours Max Marks: 80 Answer any FIVE Questions All Questions carry equal marks 1. (a) Dene the following i. Eccentricity of journal bearing ii. Minimum lm thickness (b) Design a journal bearing for a centrifugal pump running at 1440 rpm. Diameter of the journal is 10 cm and load on each bearing is 2000 kg. The factor ZN/P may be taken as 2800 for centrifugal pump bearings. Assume the followings. [12] Atmospheric temperature = 30o C Operating temperature = 75o C Energy dissipation coecient = 0.00125 C/D ratio = 0.001 L/D ratio = 1.5 2. (a) A roller bearing is selected to withstand a radial load of 40 kN and life of 1200 hrs at 600 rpm. What load rating would you look for in searching from manufacturers catalogue if it species loud at speed 500 rpm and life 3000 hrs [8] (b) Select a suitable rolling bearing for a 55 mm diameter shaft. The bearing should be capable of withstanding 3 kN radial and 1.5 kN axial load at 750 rpm. The bearing is to have a desired rated life of 2000 hrs at a reliability of 94% . There is a light shock load and inner ring rotates. [8] 3. Enumerate the design procedure for the connecting rod section considering it as a simple compression or tension member subjected to uctuating load [16] 4. Give design consideration in determining (a) Diameter of crank pin (b) Web section (c) Crank shaft diameter 5. (a) Derive an expression for energy stress in helical springs of circular wire. [6] [6+6+4=16] [4]

(b) A closely coiled helical spring is made of 10 mm diameter steel wire, the coiled consisting of 10 complete turns with a mean diameter of 120 mm. The spring carried an axial pull of 200 N. Determine the shear stress induced in the spring neglecting the eect of stress concentration. Determine also the deection in the spring, its stiness and strain energy stored by it if the modulus of rigidity of the material is 80 kN/mm2 . [10] 1 of 2

Code No: RR320305 6. (a) Write the procedure for designing a wire rope.

Set No. 4

[8]

(b) Select a wire rope for a vertical mine hoist to lift a load of 55kN from a depth 300 meters. A rope speed of 500 meters/min is to be attained in 10 seconds. [8] 7. Design a cast iron spur gear drive for a crane hoist to transmit 3.75 kW at 1440 rpm. Maximum gear ratio in the gear box is 4. Each gear is expected to work 2 hours/day for 10 years. Determine the minimum centre distance, required face width and module of the gear. [16] 8. Design a simple screw jack to lift a load of 100 kN having a maximum lift of 260 mm. The screw is made of 40 Ni 14 steel and the nut of phosphor bronze grade A. The stresses for these materials are given below: [16] Ultimate tensile/ Shear stress 2 Compressive strength(N/mm ) N/mm2 Steel screw 40Ni14 800 340 Phosphor bronze Grade A nut 552 260 Allowable bearing pressure between screw and nut = 15 N/mm2 . Material Factor of safety 4 5

2 of 2

Вам также может понравиться

- rr320305 Design of Machine Members IIДокумент8 страницrr320305 Design of Machine Members IISrinivasa Rao GОценок пока нет

- 4363 111 Machine Design IДокумент6 страниц4363 111 Machine Design Iyogesh_b_k100% (2)

- 07a6ec05 Designofmachinemembers IIДокумент11 страниц07a6ec05 Designofmachinemembers IIzahid_polyОценок пока нет

- Supp Nov 2009Документ10 страницSupp Nov 2009prk74Оценок пока нет

- WWW - Manaresults.co - In: (Mechanical Engineering)Документ2 страницыWWW - Manaresults.co - In: (Mechanical Engineering)Mohammed SohailОценок пока нет

- Machine Design-I Exam Guide for University of Pune StudentsДокумент56 страницMachine Design-I Exam Guide for University of Pune Studentsavinash119870% (1)

- r05320305 Design of Machine Members IIДокумент11 страницr05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- PMD ModelДокумент8 страницPMD ModelDamodara SatyaDeva MadhukarОценок пока нет

- rr320305 Design of Machine Members IIДокумент8 страницrr320305 Design of Machine Members IISRINIVASA RAO GANTAОценок пока нет

- rr321401 Principles of Machine DesignДокумент8 страницrr321401 Principles of Machine DesignSRINIVASA RAO GANTAОценок пока нет

- 12 Me 5dcdm2Документ3 страницы12 Me 5dcdm2Abhyudaya SinghОценок пока нет

- Design of Machine Elements - IIДокумент8 страницDesign of Machine Elements - IIprasaad26Оценок пока нет

- 05-04 Machine Design & Cad-II (Me)Документ2 страницы05-04 Machine Design & Cad-II (Me)Abdul AhadОценок пока нет

- DMM Ii (2015)Документ35 страницDMM Ii (2015)gorijalaОценок пока нет

- Design of Transmission SystemsДокумент3 страницыDesign of Transmission SystemsSaravanan KumarОценок пока нет

- rr312404 Design of Machine ElementsДокумент8 страницrr312404 Design of Machine ElementsSRINIVASA RAO GANTAОценок пока нет

- rr321401 Principles of Machine DesignДокумент8 страницrr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- Machine Design-II Question BankДокумент32 страницыMachine Design-II Question BankAbhishek SakatОценок пока нет

- B.Tech Exam Design of Machine Members QuestionsДокумент8 страницB.Tech Exam Design of Machine Members Questionsprk74Оценок пока нет

- r05320305 Design of Machine Members IIДокумент9 страницr05320305 Design of Machine Members IISRINIVASA RAO GANTAОценок пока нет

- 12ME5DCDM2Документ3 страницы12ME5DCDM2Abhyudaya SinghОценок пока нет

- DME Model QuesДокумент3 страницыDME Model QuesSiva RamanОценок пока нет

- Design of Machine Members II R5320305 Set 3Документ2 страницыDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiОценок пока нет

- Design of Machine Members-II Feb 2022Документ3 страницыDesign of Machine Members-II Feb 2022Anand KedhariОценок пока нет

- MD II Machine Design AssignmentsДокумент5 страницMD II Machine Design Assignmentsrishabhk28995Оценок пока нет

- Dme Model Key 2019Документ25 страницDme Model Key 2019Siva RamanОценок пока нет

- 9A14503 Principles of Machine DesignДокумент8 страниц9A14503 Principles of Machine DesignsivabharathamurthyОценок пока нет

- DTS ND06-QPДокумент3 страницыDTS ND06-QPsrajapratyОценок пока нет

- 2019 May ME402-A - Ktu QbankДокумент3 страницы2019 May ME402-A - Ktu Qbankbilalfocus0% (1)

- 08 r05310305 Design of Machine Members IДокумент9 страниц08 r05310305 Design of Machine Members IKrupanandareddyYarragudiОценок пока нет

- Design Machine Elements ExamДокумент2 страницыDesign Machine Elements ExamPraba KaranОценок пока нет

- DMM-2 3 1 Q&aДокумент6 страницDMM-2 3 1 Q&aAnand vinayОценок пока нет

- Dme Model QPДокумент3 страницыDme Model QPCody LeeОценок пока нет

- Makalah GTWДокумент8 страницMakalah GTWfaisalОценок пока нет

- NR 320301 Machine DesignДокумент8 страницNR 320301 Machine DesignSrinivasa Rao GОценок пока нет

- WWW Manaresults Co inДокумент4 страницыWWW Manaresults Co inGod deva123Оценок пока нет

- WWW - Manaresults.Co - In: (Common To Ame, Me)Документ3 страницыWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakОценок пока нет

- DME Chapter Three: or (Summer 15)Документ7 страницDME Chapter Three: or (Summer 15)honeyfunnyОценок пока нет

- Design of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsДокумент3 страницыDesign of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsHariharanAutoОценок пока нет

- Design of Machine Elements-II Exam QuestionsДокумент9 страницDesign of Machine Elements-II Exam QuestionsPrasinОценок пока нет

- Dmm1 Mar2007Документ8 страницDmm1 Mar2007prk74Оценок пока нет

- r05321403 Principles of Machine DesignДокумент8 страницr05321403 Principles of Machine DesignSRINIVASA RAO GANTAОценок пока нет

- Design of Transmission Systems Model ExamДокумент3 страницыDesign of Transmission Systems Model ExamrajkumardotcomОценок пока нет

- Design of Machine Elements Model ExamДокумент3 страницыDesign of Machine Elements Model ExamChandrasekhar PrabhakaranОценок пока нет

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMДокумент5 страницME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rОценок пока нет

- Imp Qoestions MDДокумент3 страницыImp Qoestions MDvenuedОценок пока нет

- Dme Model 2Документ6 страницDme Model 2YashwanthI-StyleKuttiОценок пока нет

- Snist Dom Previous PaperДокумент9 страницSnist Dom Previous PaperKapil Siddhant DevulapalliОценок пока нет

- r05312401 Design of Machine ElementsДокумент8 страницr05312401 Design of Machine ElementsSrinivasa Rao GОценок пока нет

- Sathyabama University: Register NumberДокумент3 страницыSathyabama University: Register NumberSecret SecretОценок пока нет

- Mechatronics exam with questions on control systems and PLC applicationsДокумент62 страницыMechatronics exam with questions on control systems and PLC applicationshaptooorОценок пока нет

- B.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Документ3 страницыB.Tech Degree S8 (S, FE) / S6 (PT) (S, FE) Examination June 2023 (2015 Scheme)Venkitaraj K PОценок пока нет

- QB Unit-3,4,5Документ7 страницQB Unit-3,4,5Agranshu BhardwajОценок пока нет

- Automobile Design Rev2015Документ6 страницAutomobile Design Rev2015Rithik Raj RanjuОценок пока нет

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringДокумент3 страницы1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishОценок пока нет

- Mech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsДокумент5 страницMech-nd-2020-Me 8593-Design of Machine Elements-334300796-X10703 (Me8593) Design of Machine ElementsARIGARAN SОценок пока нет