Академический Документы

Профессиональный Документы

Культура Документы

Fabric Duct Brochure

Загружено:

Jeferson Binay-anАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fabric Duct Brochure

Загружено:

Jeferson Binay-anАвторское право:

Доступные форматы

P olyester Vinyl Polyethylene

Fabric Duct Air Handling Systems

Wide open interior spaces pose a challenge when it comes to energy

management. There are people to keep comfortable, products to protect and processes that must keep functioning.

Fabric Duct Air Diffusers are

the most cost-effective, and attractive, way to evenly distribute heated or cooled air throughout large open interior areas.

A fabric duct system improves distribution of heated or cooled air

Fabric duct is attached at one end to an air handler, and then unrolled and suspended by cables throughout the service area. The supply fan creates the air that inflates the cylinder-shaped ducts. The air is then diffused evenly from the full length of the tubes.

A fabric duct system is an innovative alternative to exposed metal duct work

With its simple hookup and suspension system, fabric duct air diffusers cost less to install than metal duct work. Plus, theres no metal to scratch or dent.

Fabric duct is quiet, flame retardant, does not collect condensation, is washable, is easy to maintain, comes completely prefabricated and is ready to install.

A fabric duct system is a no-fuss system

USE IN Gyms, Pools, Schools, Restaurants, Offices, Retail Stores, Manufacturing Plants, Factories, Warehouses, Auditoriums, Churches, Supermarkets, Health Clubs, Studios, Museums, etc.

Page 2

A fabric duct system can help save energy costs by utilizing existing heat within a building

Fresh make-up air is brought into the building by a fan and forced into the fabric distribution duct. Cool outside air is blended with heat that naturally accumulates at the ceiling. This stratified heat is saved and reused rather than wasted.

A fabric duct system helps eliminate negative air pressure within a building

When used in conjunction with a Powered Aire Inc. Make Up Air Fan (MAF), this fabric duct system relieves negative air pressure caused by exhaust fans that are used to eliminate fumes or other contaminated air.

A fabric duct system can improve the quality of air

A fabric duct system can improve air quality by replacing contaminated air with cooler air as the warmer, contaminated air is exhausted by ceiling fans.

CONSTRUCTION: 300 denier acrylic coated polyester MELT TEMPERATURE: 350 degrees F. FLAME RESISTANCE: California State Fire Marshall ASTM E84 Class A Material TONGUE TEAR: Warp 43 lb. / Weft 48 lb. ASTM D2261-96

Polyester

FABRIC OPTIONS

WEIGHT: 7.5 oz. per sq. yard COLORS: Green, yellow, orange, red, pink, purple, blue, grey, black, white Launder in small sections

When looks as well as effectiveness are a factor, choose a polyester fabric duct system. Coated polyester is an impressive way to maintain your buildings interior environment. Used for machine washability, high temperature applications and aesthetics.

COLORS: Natural, white, CONSTRUCTION: 10x10 woven HDPE scrim grey, blue, MELT TEMPERATURE: 180 degrees F. dark green FLAME RESISTANCE: CAN/ULC S-109, Cal. Fire Marshall, NFPA-701 CPAI-84, Boston Fire Marshall Clean with spray hose and brush TONGUE TEAR: Warp 56 lb. 248 N / Weft 60 lb. 267N, ASTM D2261-96

Woven Polyethylene is a super tough, rip-stop fabric. It is coated for non-permeability and to improve wearability.

Polyethylene

WEIGHT: 6 oz. per sq. yard

CONSTRUCTION: 10x10 500x500 denier MELT TEMPERATURE: 180 degrees F. FLAME RESISTANCE: California State Fire Marshall, ASTM E84 Class A Material

V inyl

WEIGHT: 10 oz. per sq. yard COLORS: Green, yellow, red, blue, Clean with grey, black, spray hose white, Tan and brush

Vinyl is a flexible thermoplastic material that is both durable and resilient.

CONSTRUCTION: Polyester-based anti-static fabric MELT TEMPERATURE: 180 degrees F. FLAME RESISTANCE: ASTM E84 Class 1

A nti-static

Premium Fabric

COLORS: Blue, grey, white Launder in small sections

CONSTRUCTION: Coated fiberglass fabric MELT TEMPERATURE: 500 degrees F. FLAME RESISTANCE: ASTM E84 Class 1 Classified by UL Page 3

High temperature

Melt Temp of 500o F!!

COLORS: Grey

AIR DISTRIBUTION OPTIONS

Our fabric duct systems feature discharge options, differentiated by the size and number of ports that distribute the air, and the static pressure required.

Power-Ports are the largest airflow ports and can throw air 10 to 40 feet beyond the diffuser duct. A typical use of this design is to provide cooling ventilation in very hot work environments.

POWER- PORT

MINI-PORT

Mini-Port has smaller air distribution openings than Power-Port, which allow it to diffuse air more quickly and over broad areas with less noticeable air movement. Air movement range is 2 to 10 feet beyond the duct. This design is used where comfort or sensitive processes are a consideration.

Permeable fabric air diffusers have millions of tiny air jets that diffuse very quickly and within 2 inches of the diffuser surface. Primarily used in confined areas, where drafts cannot be tolerated. ..

................ .... .. .. .... .. .... .. .... ... .. ....... . . . . . .... . . . . . . . ...... . . ................................................... . ........ ........ ........ . . ........ ........ ........ . ........ ........ ......... ............. ................ . .. .............. . ..... ......... ..... . . . . .............. . . . . ...

PERMEABLE FABRIC

Page 4

A Continuous Flow fabric duct air handling system features vents, rather than ports, down the entire length of the duct. This results in a constant, gentle flow of air. It may also create a laminar effect.

CONTINUOUS FLOW

This air handling system is used where ceiling height is a concern. Air movement is between 5 and 20 feet from the duct.

FLUSH MOUNT

ADD-ONS

LOGOS

AIR JET PLUGS DRAW CORD

FABRIC DAMPER

CONDENSATE DRAIN

Want to promote your business, school, etc.? Logos can be applied as vinyl adhesive, screen printed or digitally printed, depending on logo and fabric type. Use to close off port openings. Easy to install and available in sizes from 1.5 to 6. Also can be used to downsize larger port openings. Use to adjust volume of air coming out of a diffuser port. Use to regulate the flow of air in a fabric duct system. Can be used to regain some static pressure in a system. Use when there is a possibility of moisture collecting on the inside of the fabric duct. Both of these can be used to connect sections of fabric duct or fittings to facilitate installation or cleaning.

ZIPPER / VELCRO

INTERNAL END CAP

Use to reduce uneven air pressure in a loop fabric duct system.

Page 5

APPLICATIONS

Distribution Facility Pool

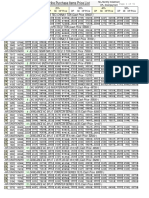

Comparison is based on 15,000 CFM air system delivered at .5-inch WG static pressure; 36-inch diffuser

POWER PORT

1 to 6 100 150

Approx. 200 FPM at 10-ft. from diffuser 10-40 ft. from diffuser Polyethylene Polyester Vinyl Coated Polyester Anti-Static/ Anti-Miicrobial High Temperature Cable Rail Premium Rail Manufacturing Industrial Warehouse Gyms Pools Retail Grocery stores Temp. Structures

MINI PORT .25 to .75

Less than .5 3,000

Less than 50 FPM at 3-ft. from diffuser

PERMEABLE CONTINUOUS FLOW FABRIC

420,000 per square foot of surface

Vent size, diameter to be determined in design phase

Diffuser Port Diameter CFM per Diffuser Port Number of Ports in Diffuser Port Velocity Noticeable Air Movement Suggested Fabric

Less than .00004 500 million

Diffused within 6 of surface Not noticeable beyond a few inches Polyester (It is important to use a filter in conjunction with this port)

------

------

-----5 to 20 ft. from diffuser Polyester Vinyl Coated Polyester Anti-Static/ Anti-Microbial

2-10 ft. from diffuser Polyethylene Polyester Vinyl Coated Polyester Anti-Static/ Anti-Microbial High Temperature Cable Rail Premium Rail Flush Rail Office Space Restaurant Food Processing Auditoriums Pools Churches Classrooms

Suspension Suggested Application

Cable Rail Premium Rail Flush Rail Office Space Telecommunications Food Processing Classroom Clean Rooms Test Labs Other sensitive areas

Cable Rail Premium Rail Flush Rail Office Space Restaurant Retail Grocery stores

Page 6

TYPICAL MOUNTING OPTIONS

A fabric duct work system is designed to be installed within, and to complement, existing open ceiling architecture. It can be installed in a straight line or angled to follow the curvature of the ceiling or other structural elements. A suspension system is used to mount the duct to the ceiling.

Single Cable

Single Rail

Double Cable

Double Rail

Economical galvanized, stainless steel or vinyl coated tension cable Single up to 30 duct; double up to 48duct * Snaphooks: Plastic or Stainless Steel; spaced 36 System: 3/16 cable, turnbuckle, eyebolts, clamps

CABLE MOUNT

Economical plastic rails or premium anodized aluminum rails Single up to 30duct; double up to 48duct * Plastic gliders spaced 36 on center System: Rail, support brackets, cou plers, end caps, vertical supports Bends available FITTINGS INCLUDE

Elbows Tees Wye branches Take-off ports Reductions

RAIL MOUNT

FLUSH MOUNT

Anodized aluminum rail for mounting close to ceiling Special duct required 6-18 radius duct (12-36 wide) Double rail system (flat ceiling or T-bar required) System: Flush mount rail, end piece Bends available

1.5 wide fabric support straps also available

* Triple Suspension Available -- Consult factory for details

Industrial

Factory

Page 7

MAKE UP AIR FANS A Positive Approach to Negative Air Pressure

Negative pressure results when air is removed from the inside of a building by an exhaust system. With a HI-velocity diffuser system connected to a Powered Aire make up air unit, incoming air can be distributed evenly over a large interior area, reversing the negative air pressure.

Powered Aire Make Up Fan

Negative air pressure creates

Drafts at floor level Back drafting down furnace stacks Cold spots in work areas Exhaust fans that are less efficient Strong air rushing in when a door is opened

EXAMPLE

85F 70F

How Powered Aires Make Up Air Fans Work

When the Powered Aire Model MAF fan is turned on, the damper opens and air is drawn through the shutters and forced into the distribution duct. The duct tube inflates and air is discharged out of the holes at high velocity. This high velocity air mixes with the stratified heat at the ceiling, making use of heat already within the building and normally wasted

RECIRCULATION DAMPER

COLD WORK AREA

55F

WITHOUT MAKE-UP AIRE SYSTEM

INTAKE HOOD INTAKE DAMPER

FAN AND MOTOR

Fresh air provided by a Powered Aire Make Up Air Fan fills the diffuser tube and is forced out of the tubes ports where it mixes with the stratified heat that naturally accumulates at the ceiling. This blending of air results in a uniform temperature throughout the building.

DISTRIBUTION DUCT OUTSIDE WALL

WARM WORK AREA

70F

WITH MAKE-UP AIRE SYSTEM

For more information contact:

3/2008

Powered Aire Inc.

1-800-321-AIRE (2473)

www.poweredaire.com

Page 8

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- AEP-LB-U12W: Product Data SheetДокумент1 страницаAEP-LB-U12W: Product Data SheetJeferson Binay-anОценок пока нет

- A Field Guide Gas Stations in TexasДокумент148 страницA Field Guide Gas Stations in TexasKasi XswlОценок пока нет

- LF - TS 120S - Asia - EN PDFДокумент2 страницыLF - TS 120S - Asia - EN PDFJeferson Binay-anОценок пока нет

- Victaulic 27.03Документ2 страницыVictaulic 27.03Jeferson Binay-anОценок пока нет

- HDPE Pipe InstallationДокумент7 страницHDPE Pipe InstallationJeferson Binay-an100% (1)

- Norsok Pipe Details PDFДокумент41 страницаNorsok Pipe Details PDFAli BariОценок пока нет

- Seismic Design and Retrofit of Piping SystemsДокумент119 страницSeismic Design and Retrofit of Piping Systemsv100% (1)

- Piping Guide b03Документ8 страницPiping Guide b03Jeferson Binay-anОценок пока нет

- DUCT-SOX Manual Ingenieria y DiseñoДокумент20 страницDUCT-SOX Manual Ingenieria y DiseñoJeferson Binay-anОценок пока нет

- Standpipe and Hos 20 SystemsДокумент1 страницаStandpipe and Hos 20 SystemsJeferson Binay-anОценок пока нет

- Snamprogetti-Desing For Piping Support-2001-138pagesДокумент138 страницSnamprogetti-Desing For Piping Support-2001-138pagesShi LarryОценок пока нет

- Engineering CookbookДокумент107 страницEngineering CookbookJose TabisiОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Studi Eksperimental Pengaruh Penambahan Twisted Tape Terhadap Perpindahan Kalor Dan Penurunan Tekanan Pada Water To Air HeatДокумент7 страницStudi Eksperimental Pengaruh Penambahan Twisted Tape Terhadap Perpindahan Kalor Dan Penurunan Tekanan Pada Water To Air Heatsulaiman rasyidОценок пока нет

- Evo Transmission InformationДокумент13 страницEvo Transmission InformationReynaldo Juanito Ludo LafortezaОценок пока нет

- BS Hinges 2Документ22 страницыBS Hinges 2Peter MohabОценок пока нет

- Is 1786Документ5 страницIs 1786Jeevan ShendreОценок пока нет

- HPДокумент51 страницаHPKhan Basit KhanОценок пока нет

- Cat Engine 3512bДокумент9 страницCat Engine 3512bPrasanna BhattacharyaОценок пока нет

- An Industry Project Report 2Документ64 страницыAn Industry Project Report 2Meet PanchasaraОценок пока нет

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Документ2 страницыPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazОценок пока нет

- Slides. Rear Axle RTS2370A. TextoДокумент16 страницSlides. Rear Axle RTS2370A. TextoJorge Ricce YngaОценок пока нет

- Mechanical SealДокумент16 страницMechanical SealRAJEDIA ABDULLAHОценок пока нет

- Brake SystemДокумент42 страницыBrake SystemeduamaОценок пока нет

- Outline Design Specification of Phase IV (March 2019) 01042019 PDFДокумент164 страницыOutline Design Specification of Phase IV (March 2019) 01042019 PDFBilal A BarbhuiyaОценок пока нет

- Flow Types: - Base of SpillwayДокумент6 страницFlow Types: - Base of Spillwaygizem cenikОценок пока нет

- Tennant s20Документ64 страницыTennant s20Umar ShamsudinОценок пока нет

- Fluid Flow Operation - 130502Документ2 страницыFluid Flow Operation - 130502sanjayОценок пока нет

- PHYA10 - Physics I (Physical Sciences) Practical Worksheet #05Документ2 страницыPHYA10 - Physics I (Physical Sciences) Practical Worksheet #05Sabine MohamadОценок пока нет

- Ational Etrochemical Efiners Ssociation Treet Uite AshingtonДокумент16 страницAtional Etrochemical Efiners Ssociation Treet Uite AshingtonVijayakumarNarasimhanОценок пока нет

- Electrical Equipment: Passenger Compartment Connection UnitДокумент233 страницыElectrical Equipment: Passenger Compartment Connection UnitEeeps100% (2)

- 06 - Computational Fluid Dynamics and Heat Transfer Emerging TopicsДокумент506 страниц06 - Computational Fluid Dynamics and Heat Transfer Emerging TopicsNevzat ŞadoğluОценок пока нет

- Course Plan HMTДокумент3 страницыCourse Plan HMTparameshОценок пока нет

- Aircycle 5.1 - Heat Recovery UnitДокумент2 страницыAircycle 5.1 - Heat Recovery UnitValentin MalihinОценок пока нет

- CHAPTER 2 - Part 1 Air Conditioning System PDFДокумент77 страницCHAPTER 2 - Part 1 Air Conditioning System PDFazmie100% (1)

- Service Parts List: M18™ 1/4" Hex Impact Driver - Single SpeedДокумент2 страницыService Parts List: M18™ 1/4" Hex Impact Driver - Single SpeedhiramfgarciaОценок пока нет

- Link-Tkif Technische Daten 2020 Hb50 6p OnlineДокумент6 страницLink-Tkif Technische Daten 2020 Hb50 6p OnlineDaohua Li100% (1)

- Joyce CatalogДокумент174 страницыJoyce CatalogPajserchinaОценок пока нет

- PLB-0384-DAT-4830-ME-0005: ABB India LTDДокумент3 страницыPLB-0384-DAT-4830-ME-0005: ABB India LTDAlex Labraña RojoОценок пока нет

- Horn Sea Wind Farm 02 Offshore Substation Cooling Pipe & Instrumentation Diagrams (P&Id) All DecksДокумент6 страницHorn Sea Wind Farm 02 Offshore Substation Cooling Pipe & Instrumentation Diagrams (P&Id) All DeckskristianОценок пока нет

- Lesson Learned: Solution of The ProblemДокумент1 страницаLesson Learned: Solution of The ProblemRadovanZivanovicRashaОценок пока нет

- Know MoreДокумент6 страницKnow MoreramkumarОценок пока нет