Академический Документы

Профессиональный Документы

Культура Документы

Bridge Bearings

Загружено:

Kreen132Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Bridge Bearings

Загружено:

Kreen132Авторское право:

Доступные форматы

Bearing design spread sheet based on AASHTO 16th Edition 1197 Interim (Method A) AASHTO LRFD by ARP visit

www.pretread.com or email pretread@eim.ae for more information.

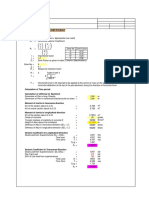

Elastomeric Bridge Bearing Design

Design spreadsheet based on AASHTO 16th Edition 1197 Interim (Method A) AASHTO LRFD Bearing type ( P - Plain R - reinforced Bearing type (F - Fixed, E - expansion ) Dead Load rotation. Dead Load ( unfactored) Live Load W/O impact (unfactored) Bearing design load Horizontal movement - long Shear modulus Load application parallel to bearing plain Inner layer thickness Cover layer thickness DESIGN CHECK Number of inner layers Total elastomer thickness DESIGN CHECK DESIGN CHECK Bearing length Bearing width Bearing area Shape factor ( Inner layers) Shape factor ( Cover layers) Average compressive stress Allowable compressive stress DESIGN CHECK Modifier constant Compression modulus ( Inner layer ) Compression modulus ( Cover layer ) Compressive strain ( Inner layer ) Compressive strain ( Cover layer ) Instantaneous deflection Allowable rotation DESIGN CHECK Average compressive stress (LL only) Allowable fatigue stress Shim steel grade Shim thickness DESIGN CHECK Total bearing height DESIGN CHECK CUSTOMER PROJECT M/s. Client Ref: Project . OK (Shim thickness)

R E DL LL P

FoS Radian [Slope of girder at the bearing] kips. kips. Kips. [ LL + DL ] ksi [AASHTO table 14.6.5.2-1] kips. kN 233.33 in. [ Arbitrary design value >= 0.40 in ] in. [ Arbitrary design value <= 0.7*hri ] % OK kN 1750 kN 990 kN 3288

1.2

s

G

Fxy

hri hrc

n

hrt 2s

ra L W A Si Sc

s all

Amin k Eci Ecc

ci cc c

All req

L

Fsr ts

ts min

T L/3

0.002 393.4 223 739 1.18 0.120 52.455 0.787402 0.23622 30.00 3 2.834646 2.362 7.78 31.49606 27.55906 868.0017 9.333 31.111 0.85158 1.12000 856 0.6 37.992 418.4933 0.019 0.002 0.044925 0.008554 0.007 0.256406 24 33 0.19685 0.06096 3.62205 10.49869

in. [ sum of range of movements from all sources]

hrc<= 70% of hri

Nos. [Arbitrary design value] in. (2hrc + n*hri)>= 2 Delta s OK OK hrt>= 2*Delta s ra=< 8

in. [Arbitrary design value] In.[Arbitrary design value] in. [ L* W] [ Si= LW/(2hri(L+W)) ] [ Sc = LW/(2hrc(L+W)) ] ksi. [

s= P/A ]

s <all 0.985789 Amin=<A

OK

ksi. [1.0*GS] OK [ AASHTO table 14.3.1 ] ksi. [ Eci = 3G(1+(2kSi)) ] ksi. [ 3G(1+(2kSc)) ] [ P/(A*Eci) ] [ P/(A*Ecc) ]

in.[c=chr][BOPP max=0.2in. in deck joint location] Radians [ All = OK kips. [ LL/A] kips. [AASHTO tab.10.3.1A category A over 200000 cycles] kips [1997 interim AASHTO Divi II,C18.4.1.1.2] in. [Arbitrary design value] BOPP min=11gage = 1/8" In. Meets AASHTO equations 14.6.5.3.7-1&2, & BOPP in. [Including shims] OK Qty. .25/1/XXXX T<=L/3

s/(0.5GS(L/hrt)]

Theta All>= Theta req.

Statutory Warning- The product details, calculations, design details and technical proposal as a whole is proprietary intellectual information created / generated by ARP and technical staff. This information should not be copied or transferred to other suppliers or any person/organization who could be a possible competitor.

Bearing design spread sheet based on AASHTO 16th Edition 1197 Interim (Method A) AASHTO LRFD by ARP visit www.pretread.com or email pretread@eim.ae for more information.

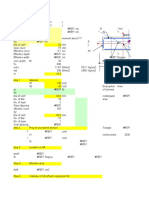

Elastomeric Bridge Bearing Design

Design spreadsheet based on AASHTO 16th Edition 1197 Interim (Method A) AASHTO LRFD

Inputs required for Bridge Bearing design: 1. DL Dead Load - by client 2. LL Live Load by client 3. Rotation in radians by client 4. FoS Factor of Safety by client 5. Horizontal movement by client 6. Load for above horizontal movement - by client 7. Available space determining bearing Length by client 8. Available space determining bearing Width - by client 9. Available space determining bearing Height by client 10. MS Shim thickness by bearing manufacturer 11. Internal Elastomer Layer thickness by bearing manufacturer 12. Cover layer thickness by bearing manufacturer 13. Value of Elastomer Shear Modulus. by client 14. Elastomer Hardness (Duro) by client Results available from ARP Spread Sheet 1. Inner layer thickness 2. Cover layer thickness 3. MS Shim thickness 4. Compression modulus ( Inner layer ) 5. Compression modulus (Cover layer ) 6. Compressive strain (Inner layer ) 7. Compressive strain (Cover layer ) 8. Instantaneous deflection 9. Allowable rotation 10. Average compressive stress 11. Allowable fatigue stress 12. Shape factor (Cover layers) 13. Shape factor (Inner layers) 14. Bearing stability against size. 15. Value of- P Total load.

Bearing design spread sheet based on AASHTO 16th Edition 1197 Interim (Method A) AASHTO LRFD by ARP visit www.pretread.com or email pretread@eim.ae for more information.

Check lists as results OK NO NA confirming to AASHTO LRFD requirements. 1. 2. 3. 4. 5. 6. 7. 8. 9. Cover layer thickness Total Elastomer thickness Cover layer /inner layer ratio Average compressive stress Allowable compressive stress Load against bearing area Allowable rotation against required MS Shim thickness against required. Bearing stability against size.

Вам также может понравиться

- Bearing Design Method AДокумент4 страницыBearing Design Method ADhurai KesavanОценок пока нет

- SS - 13.0 Bridge Design DocumentДокумент141 страницаSS - 13.0 Bridge Design Documentnc mathurОценок пока нет

- Bridge EngineeringДокумент2 360 страницBridge EngineeringStructural SpreadsheetsОценок пока нет

- Design Handbook IRC112Документ111 страницDesign Handbook IRC112zulfekharОценок пока нет

- Load Cal-2-PIN Bearing Final 42.755m SpanДокумент104 страницыLoad Cal-2-PIN Bearing Final 42.755m SpanRAJAT SHARMAОценок пока нет

- Calculation of Seismic Coefficient: ProjectДокумент1 страницаCalculation of Seismic Coefficient: Projectnandu523Оценок пока нет

- Comment - Draft - Comp Girder-26.34-R6Документ61 страницаComment - Draft - Comp Girder-26.34-R6Nilay GandhiОценок пока нет

- National Highways Authority of IndiaДокумент19 страницNational Highways Authority of IndiaPrabhnoor KaurОценок пока нет

- MJB - 704+195 La1 - 200423 - I1 - Check TP - 0.63 - 0.72Документ346 страницMJB - 704+195 La1 - 200423 - I1 - Check TP - 0.63 - 0.72VALAR MORGHULISОценок пока нет

- RCC Slab Bridge Design 10 M - 2022Документ7 страницRCC Slab Bridge Design 10 M - 2022erzahid ahmadОценок пока нет

- Lecture 8 - MR Vinay Gupta On Seicmic Isolation DevicesДокумент59 страницLecture 8 - MR Vinay Gupta On Seicmic Isolation DevicesSulabh GuptaОценок пока нет

- Elastomercic Bearing DN (14+872 MNB)Документ19 страницElastomercic Bearing DN (14+872 MNB)Ankur ChauhanОценок пока нет

- Bearings & Their Configurations in BridgesДокумент14 страницBearings & Their Configurations in BridgesAltomarОценок пока нет

- Basic data for well foundation designДокумент6 страницBasic data for well foundation designvishal guptaОценок пока нет

- Innovations in Tied Arch BridgesДокумент23 страницыInnovations in Tied Arch BridgesDhrubojyoti SenguptaОценок пока нет

- R0 - Design of Abutment A1 With Open FN MJB CH-599+190Документ124 страницыR0 - Design of Abutment A1 With Open FN MJB CH-599+190chiranjeevimd2991 MDОценок пока нет

- Code of Practice For Concrete Road Bridges IRC:112: Case Study 1 - Design of I GirderДокумент15 страницCode of Practice For Concrete Road Bridges IRC:112: Case Study 1 - Design of I GirderSony JsdОценок пока нет

- IndexДокумент93 страницыIndexrohit singhОценок пока нет

- Retrofitting Well Foundations for Heavy LoadsДокумент32 страницыRetrofitting Well Foundations for Heavy LoadsfaumijkОценок пока нет

- Design of Elastomeric BearingДокумент23 страницыDesign of Elastomeric Bearingsandeep patilОценок пока нет

- Bearing 1 PDFДокумент1 страницаBearing 1 PDFAnkit SuriОценок пока нет

- 2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementДокумент9 страниц2850-1992 KN S (Type - A1) Span P 51 Anti Uplift ArrangementGaurav PatilОценок пока нет

- REFRESHER COURSE ON APPLICATION OF NEW SEISMIC CODE FOR HIGHWAY BRIDGESДокумент69 страницREFRESHER COURSE ON APPLICATION OF NEW SEISMIC CODE FOR HIGHWAY BRIDGESNeeraj SharmaОценок пока нет

- SPH Bearing Draft (09.06.11)Документ38 страницSPH Bearing Draft (09.06.11)Dave ThompsonОценок пока нет

- IRC 112: Flexural analysis and design of beamsДокумент15 страницIRC 112: Flexural analysis and design of beamsravi kumarОценок пока нет

- Seismic Effects On Perofrmance of Bridges PDFДокумент18 страницSeismic Effects On Perofrmance of Bridges PDFkondaОценок пока нет

- Pot Bearing DrawingДокумент1 страницаPot Bearing DrawingMiguel Belda DiezОценок пока нет

- Chapter 10 Design of Prestressed 761661594169023Документ15 страницChapter 10 Design of Prestressed 761661594169023Puzzle ArtsОценок пока нет

- Trans Mainspan Updated ModifiedДокумент413 страницTrans Mainspan Updated ModifiedANKUR GHOSHОценок пока нет

- Elastomeric Bearing 13-09-13Документ27 страницElastomeric Bearing 13-09-13bulganinganguliОценок пока нет

- Transverse Deck DesignДокумент34 страницыTransverse Deck DesignSudip Kumar SwainОценок пока нет

- Bearing Design For ROB at Chainage 145+368 (47m CC of E.J.)Документ11 страницBearing Design For ROB at Chainage 145+368 (47m CC of E.J.)amitkuknaОценок пока нет

- Bearing Forces 5 BrgsДокумент17 страницBearing Forces 5 BrgsAmbrishОценок пока нет

- Design of Laminated Elastomeric Bearing for 20m SpanДокумент8 страницDesign of Laminated Elastomeric Bearing for 20m Spannaresh KUMARОценок пока нет

- IRC 6-2017 - CommentryДокумент368 страницIRC 6-2017 - CommentryRajan GuptaОценок пока нет

- Ductile DetailingДокумент8 страницDuctile DetailingShashank SrivastavaОценок пока нет

- Idspl B 2212 MNB 007+614DN 101Документ36 страницIdspl B 2212 MNB 007+614DN 101khushikaadi56Оценок пока нет

- Proposed ROB design documentДокумент22 страницыProposed ROB design documentAkhil BabuОценок пока нет

- Prestressed - Box Girder PDFДокумент49 страницPrestressed - Box Girder PDFSpirit SeekerОценок пока нет

- Pile CapДокумент7 страницPile CapBasava SrikanthОценок пока нет

- R2-Design of PSC I Girder 1x30.0m (10 Skew)Документ160 страницR2-Design of PSC I Girder 1x30.0m (10 Skew)chiranjeevimd2991 MDОценок пока нет

- Box Culvert 20mДокумент68 страницBox Culvert 20mV P GUPTAОценок пока нет

- Calculation of loads and stresses for a 16.5m steel girder bridge spanДокумент1 страницаCalculation of loads and stresses for a 16.5m steel girder bridge spansups madiОценок пока нет

- Substructure Modelling and Design As Per IRC112Документ66 страницSubstructure Modelling and Design As Per IRC112vaibhav dahiwalkar100% (1)

- Stress Check With ValuesДокумент83 страницыStress Check With ValuesruchitaОценок пока нет

- Explanatory Handbook To Irc: 112 February 2014: Ultimate Moment DiagramДокумент2 страницыExplanatory Handbook To Irc: 112 February 2014: Ultimate Moment DiagramBhavesh SavaniОценок пока нет

- PSC NotesДокумент77 страницPSC NoteschanakyaОценок пока нет

- Slab Culvert Irc 21 Irc 112Документ5 страницSlab Culvert Irc 21 Irc 112Rupendra palОценок пока нет

- (Paper) - Portal Frame PierДокумент23 страницы(Paper) - Portal Frame PierShaileshRastogiОценок пока нет

- Columns TheoryДокумент112 страницColumns TheoryJosé Gualavisí100% (1)

- Design of SubstructureДокумент226 страницDesign of SubstructureMrinal KoyalОценок пока нет

- DESIGN OF ABUTMENT 30m COMPOSITE GIRDER IN N F RAILWAY PDFДокумент33 страницыDESIGN OF ABUTMENT 30m COMPOSITE GIRDER IN N F RAILWAY PDFShashibhushan SinghОценок пока нет

- T. Viswanathan 3. Ultimate Limit State of Linear Elements (Modified 28-Jul)Документ69 страницT. Viswanathan 3. Ultimate Limit State of Linear Elements (Modified 28-Jul)Bridge DepartmentОценок пока нет

- Load Calculation For Substructure DesignДокумент39 страницLoad Calculation For Substructure Designarunkumar.mgsОценок пока нет

- (300 X 400 X 64) Elastomeric Bearing-15m For 0deg 8 CWДокумент12 страниц(300 X 400 X 64) Elastomeric Bearing-15m For 0deg 8 CWaniketОценок пока нет

- Seismic ArrestorДокумент8 страницSeismic ArrestorankitОценок пока нет

- AASHTO Elastomeric Bearing Design Program SummaryДокумент38 страницAASHTO Elastomeric Bearing Design Program SummaryxyztaaОценок пока нет

- BRG Pad ExampleДокумент16 страницBRG Pad ExamplecarlosestayОценок пока нет

- Design Example ASD GirderДокумент12 страницDesign Example ASD GirderEdward van MartinoОценок пока нет