Академический Документы

Профессиональный Документы

Культура Документы

HM350-2 E060125 PDF

Загружено:

MikkeroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HM350-2 E060125 PDF

Загружено:

MikkeroАвторское право:

Доступные форматы

GROSS HORSEPOWER 304 kW 408 HP NET HORSEPOWER 294 kW 394 HP MAXIMUM GVW 63440 kg 139,900 lb

Standard equipment may vary for each country, and this specification sheet may contain attachments and optional equipment that are not available in your area. Please consult your Komatsu distributor for detailed information.

www.Komatsu.com

Printed in Japan 200601 IP.AD(10)

Photo may include optional equipment.

ARTICULATED DUMP TRUCK

CEN00082-00 Materials and specifications are subject to change without notice. is a trademark of Komatsu Ltd. Japan.

HM350-2

A R T I C U L AT E D D U M P T R U C K

ARTICULATED DUMP TRUCK

HM350-2

GROSS HORSEPOWER 304 kW 408 HP @ 2000 rpm NET HORSEPOWER 294 kW 394 HP @ 2000 rpm MAXIMUM GVW 63440 kg 139,900 lb

WALK-AROUND

The HM350-2 with new ecot3 engine, meets the EPA Tier 3 and EU Stage 3A emission regulations, offers all around maximum productivity with faster travel speed and many features that enhance efficiency, while reducing maintenance costs. From rough terrain construction sites to landfills - the HM350-2 has the competitive edge. Komatsu designed, electronically controlled transmission for a comfortable ride.

F6-R2 counter-shaft type transmission with K-ATOMiCS (Komatsu Advanced Transmission with Optimum Modulation Control System).Transmission shift hold button optimizes the operator control.

Tiltable cab can be tilted rearward

Building on the technology and expertise Komatsu has accumulated since its establishment in 1921, GALEO presents customers worldwide with a strong, distinctive image of technological innovation and exceptional value. The GALEO brand will be employed for Komatsus full lineup of advanced construction and mining equipment. Designed with high productivity, safety and environmental considerations in mind, the machines in this line reflect Komatsus commitment to contributing to the creation of a better world. Genuine Answers for Land & Environment Optimization 36 degrees to provide easy service.

Easy-to-load body

Heaped capacity 19.8 m3 25.9 yd3 Low loading height 2925 mm 97 High strength body constructed of thick wear-resistant steel having 400 Brinell hardness

Wide, spacious cab with excellent visibility

The wide cab offers a comfortable operator and passenger environment Viscous mounts support the cab while absorbing vibrations and noise Low-noise cab through improved sealing with integrated floor Interior noise level 76 dB(A) Additional front under view mirrors provide superior visibility Air suspension seat is standard Power window

Photo may include optional equipment.

Hydro-pneumatic suspension for all terrains.

The hydro-pneumatic suspension in both front and rear suspensions assures a comfortable ride even over rough terrain.

Maintenance-free oscillating hitch with tapered roller bearings

means lower operating costs by eliminating the need to lubricate the hitch.

High performance and environment-friendly SAA6D140E-5 ecot3 engine

Gross horsepower 304 kW 408 HP Meets North American EPA Tier 3 and EU Stage 3A emission regulations for 2006 Engine power mode selection system realizes both greater productivity and improved fuel economy Higher engine output and torque improve productivity in all applications

2

Fully hydraulic articulated steering

Light and easy operation Minimum turning radius 8.6 m 283

Interaxle & differential locks provide excellent traction in rough terrain.

The oil-cooled multiple-disc interaxle lock and differential locks can be turned on and off during travel. In addition, the differential locks can lock up all three axles differentials for maximum traction.

High capacity, reliable, continuously cooled, wet type multiple-disc brakes and retarder

Fully hydraulic controlled wet multiple-disc brake Retarder absorbing capacity (continuous descent) 472 kW 633 HP

HM350-2

A R T I C U L AT E D D U M P T R U C K

Hydro-pneumatic Suspension

ARTICULATED DUMP TRUCK

ARTICULATED DUMP TRUCK

HM350-1 HM350-2

PRODUCTIVITY FEATURES

The combination of high travel speeds and an efficient engine with low emissions delivers maximum productivity at the lowest cost.

Komatsu Technology Engine Power Mode Selection System

The system allows selection of the appropriate mode between two modes <High-power mode > or <Economy mode> according to each working condition. The mode is easily selected with a switch in the operators cab. High-power mode Great productivity can be attained by taking a full advantage of high output power. It is appropriate for job sites where larger production at uphill-hauling is required. Economy mode Engine speeds of the maximum output, downshift, and upshift are set to a lower level. It is appropriate for light Komatsu develops and produces all major components, such as engines, electronics and hydraulic components, in house. With this Komatsu Technology, and adding customer feedback, Komatsu is achieving great advancement in technology. To achieve both high levels of productivity and economical performance, Komatsu has developed the main components with a total control system. The result is a new generation of high performance and environment friendly machines. work on the flat ground.

The hydro-pneumatic suspension has been proven on Komatsus rigid dump trucks. The front axle hydro-pneumatic suspension employs "De Dion" type design, allowing the machine to ride more smoothly over bumps. The rear-axles are mounted on a dynamic equalizer structure equipped with hydro-pneumatic suspension. The entire vehicles suspension delivers a comfortable ride and maximizes productivity.

Large Capacity Body and Box Section Frame Structure

The 19.8 m3 25.9yd3 heaped capacity is among the highest in its class. The low loading height of 2925 mm 97 enables easy loading. The body is built of high strength wear-resistant steel with a Brinell hardness of 400, and the body shape provides excellent load stability. Rugged enough for the toughest jobs, the HM350s frame is designed using a rigid box structure with connecting torque tubes made of high strength low alloy steel.

High Performance Komatsu SAA6D140E-5 Engine

This engine delivers faster acceleration and higher travel speeds with the highest horsepower per ton in its class. Advanced technology, such as Common Rail Injection system (CRI), air to air aftercooler, and an efficient turbocharger enables the engine to meet the North American EPA Tier 3 and EU stage 3A emission regulations. High torque at low speed, impressive acceleration, and low fuel consumption ensure maximum productivity.

Komatsu Designed Electronically Controlled Countershaft Transmission

The Komatsu designed Electronically Controlled Transmission called K-ATOMiCS has been a success in Komatsus rigid dump trucks. The electronic clutch modulation system ensures proper clutch pressure when the clutch is engaged. The total control system controls both the engine and transmission by monitoring the vehicle conditions. This high technology system assures smooth shifts without shock and maximizes power train life.

Hydraulically Controlled Wet Multiple-Disc Brakes and Retarder

Wet multiple-disc brakes have been proven on Komatsu dump trucks and wheel loaders ensuring highly reliable and stable brake performance. The large-capacity, continuously cooled,wet-multiple disc brakes also function as a highly responsive retarder which gives the operator greater confidence at higher speeds when travelling downhill. Retarder Absorbing Capacity (continuous descent): 472 kW 633 HP

Articulated Steering

Fully hydraulic articulated steering offers low-effort operating performance and maneuverability. A minimum turning radius of only 8.6 m 283 provides ability to work in tight areas.

8.6 m 28'3" 4.2 m 13'9"

Komatsu Designed Interaxle and Differential Locking Systems The full-time six-wheel drive system reduces slippage. A wet multiple-disk interaxle clutch also locks the three axles in unison for greater traction. The interaxle lock and differential locks can be switched on and off while the truck is travelling, thereby boosting productivity. In addition, the differential lock switch, which is a three position switch, can lock up the rear axle differentials only, or all axles for maximum performance in the worst conditions.

HM350-2

A R T I C U L AT E D D U M P T R U C K

Built-in ROPS/FOPS

ARTICULATED DUMP TRUCK

HM350-2

OPERATOR ENVIRONMENT

Komatsu has developed a state-of-the-art, wide comfortable cab. The low level of vibration and noise ensure maximum productivity from the operator.

Low-noise Designed Cab

Integrated cab and floor provide airtight cab. Engine room is also sealed. The low noise and sound insulated muffler /exhaust pipe contribute to reducing sound levels. All these together offer a quiet and comfortable operator environment.

Air Suspension Seat is Standard

The air suspension, fabric-covered seat which is adjustable to the operators weight is provided as standard. The air suspension seat dampens vibrations transmitted from the machine and reduces operator fatigue as well as holding the operator securely to assure confident operation.

These structures conform to ISO 3471 and SAE J1040-1988c standards.

Hydro-pneumatic Suspension for All Terrains

The hydro-pneumatic suspension assures a comfortable ride even over rough terrain and ensures maximum productivity and operator confidence.

Electric Body Dump Control Lever

The low effort lever makes dumping easier than ever.

Viscous Cab Mounts

Viscous mounts reduce the noise transmitted to the cab and achieve a quiet 76 dB(A) noise level.

Supplementary Steering and Secondary Brakes

Supplementary steering and secondary brakes are standard features. Steering: ISO 5010-1992, SAE J1511 Brakes: ISO 3450-1996, SAE J1473

Wide, Spacious Cab with Excellent Visibility

The wide cab provides a comfortable space for the operator and a full size buddy seat. Large electrically operated window and the operators seat positioned to the left side ensures superior visibility.

Ergonomically Designed Cab

The ergonomically designed operators compartment makes it very easy and comfortable for the operator to use all the controls. The result is more confident operation by operators and greater productivity. The front under view mirrors are increased to two from one, and the rear view mirrors increased to four from two. Newly employed laminated glass in the windshield assures safe operation. In addition, electric heated rear window facilitates defrosting.

Easy-to-See Instrument Panel

The instrument panel makes it easy to monitor critical machine functions. In addition, a caution light warns the operator of any problems that may occur. This Komatsu on-board monitoring system makes the machine very friendly and easy to service.

Steering Wheel and Pedals

Low effort pedals reduce operator fatigue when working continuously for long periods. The tiltable, telescoping steering column enables operators to maintain the optimum driving position at all times.

HM350-2

A R T I C U L AT E D D U M P T R U C K

ARTICULATED DUMP TRUCK

HM350-2

EASY MAINTENANCE

The HM350-2 has been designed to keep service time down and productivity up by having a maintenance-free oscillating hitch, a reduced number of grease points, easy access to filters, and longer intervals between oil changes.

Tiltable Cab

The cab can be tilted rearward 36 degrees to provide easy maintenance/service for the engine and transmission. Note: An external hydraulic pump is required to tilt the cab or a service crane can be used after easily removing only eight bolts...

SPECIFICATIONS

ENGINE Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Komatsu SAA6D140E-5 Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Water-cooled, 4-cycle Aspiration . . . . . . . . . . . . . Turbo-charged, after-cooled, cooled EGR Number of cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140 mm 5.51" Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165 mm 6.50" Piston displacement . . . . . . . . . . . . . . . . . . . . . . . . 15.24 ltr 930 in3 Horsepower SAE J1995 . . . . . . . . . . . . . . . . . . . . . . . . Gross 304 kW 408 HP ISO 9249 / SAE J1349 . . . . . . . . . . . . . . . . . Net 294 kW 394 HP Rated rpm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2000 rpm Fan drive type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mechanical Maximum torque . . . . . . . . . . . . . . . . . . . . . . . 203 kgm 1,468 lb. ft Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Direct injection Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . Electronically controlled Lubrication system Method . . . . . . . . . . . . . . . . . . . . . . . Gear pump, force-lubrication Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Full-flow type Air cleaner. . . . . . . . . . . . . . . . . . Dry type with double elements and precleaner(cyclonpack type), plus dust indicator MAIN FRAME Type . . . . . . . . . . . . . . . . . . . . . . . . . Articulated type, box-sectioned construction on front and rear Connected by strong torque tubes.

BODY Capacity: Struck . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.6 m3 19.1 yd3 Heaped (2:1, SAE) . . . . . . . . . . . . . . . . . . . . . . . 19.8 m3 25.9 yd3 Payload . . . . . . . . . . . . . . . . . . . . . 32.3 metric tons 35.6 U.S. tons Material . . . . . . . . . . . . . . . . . . . . . . . . . . . 130 kg/mm2 185,000 psi high tensile strength steel Material thickness: Bottom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 mm 0.63" Front. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 mm 0.31" Sides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 mm 0.47" Target area (inside length x width) . . . . . . . . 5495 mm x 2935 mm 18'0" x 9'8" Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . Exhaust heating (option)

Oil seal

Taper roller bearing

TRANSMISSION Torque converter . . . . . . . . . . . . . . . . . 3-elements, 1-stage, 2-phase Transmission . . . . . . . . . . . . . . . . . Full-automatic, counter-shaft type Speed range . . . . . . . . . . . . . . . . . . 6 speeds forward and 2 reverse Lockup clutch . . . . . . . . . . . . . . . . . . . . . . . . . Wet, single-disk clutch Forward . . . . . . . . . . . . . . . . . . . . Torque converter drive in 1st gear, direct drive in 1st lockup and all higher gears Reverse. . . . . . . . . Torque converter drive and direct drive in all gear Shift control . . . . . . . . . . . . . . . Electronic shift control with automatic clutch modulation in all gear Maximum travel speed . . . . . . . . . . . . . . . . . . 57.1 km/h 35.5 mph HYDRAULIC SYSTEM Hoist cylinder . . . . . . . . . . . . . . . . . . . . Twin, 2-stage telescopic type Relief pressure . . . . . . . . . . . . . . . . . 20.6 MPa 210 kg/cm2 2,990 psi Hoist time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 sec

Fewer Grease Points

The number of grease points are minimized by using maintenance-free rubber bushings and a maintenance-free oscillating hitch.

CAB Dimensions comply with ISO 3471 and SAE J1040-1988c ROPS (Roll-Over Protective Structure) standards

Extended Service Intervals

In order to minimize operating costs, service intervals have been extended: Engine oil 500 hours Transmission oil 1000 hours Engine oil filters 500 hours Transmission oil filters 1000 hours

AXLES Full time all wheel drive with 100% differential lock in all axles. Final drive type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Planetary gear Ratios: Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.231 Planetary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.941 WEIGHT (APPROXIMATE) Empty weight . . . . . . . . . . . . . . . . . . . . . . . . . . 31060 kg 68,500 lb Gross vehicle weight. . . . . . . . . . . . . . . . . . . . . 63440 kg 139,900 lb Weight distribution: Empty: Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57.4% Center axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.6% Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21.0% Loaded: Front axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.8% Center axle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.2% Rear axle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.0%

Hitch Frame

Guards

The following guards are provided as standard: Protective grille for rear window Engine underguard Heavy duty transmission underguard Propeller shaft guards Exhaust thermal guard Fire prevention covers

SUSPENSION SYSTEM Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydro-pneumatic suspension Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Combined hydro-pneumatic and rubber suspension system

TIRES STEERING SYSTEM Type . . . . . . . . . . . . . . . Articulated type, fully hydraulic power steering with two double-acting cylinders Supplementary steering . . . . . . . . . . . . . . . . . . Automatically actuated, electrically powered Minimum turning radius, wall to wall . . . . . . . . . . . . . . . . . 8.6 m 28'3" Articulation angle . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 each direction Standard tire. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26.5 R25

SERVICE REFILL CAPACITIES Fuel tank. . . . . . . . . . . . . . . . . . . . . . . . . . . . 493 ltr. 130.3 U.S. Gal Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50 ltr. 13.2 U.S. Gal Torque converter, transmission and retarder cooling . . . . . . . . . . . . . . . . . . . . . 115 ltr. 30.4 U.S. Gal Differentials (total) . . . . . . . . . . . . . . . . . . . . . 81.5 ltr. 21.5 U.S. Gal Final drives (total) . . . . . . . . . . . . . . . . . . . . . . . 38 ltr. 10.0 U.S. Gal Hydraulic system. . . . . . . . . . . . . . . . . . . . . . . 180 ltr. 47.6 U.S. Gal Suspension (total) . . . . . . . . . . . . . . . . . . . . . . 21.2 ltr. 5.6 U.S. Gal

BRAKES Service brakes . . . . . . . . . . . . . . . . . . Full-hydraulic control, oil-cooled multiple-disc type on all wheels Parking brake . . . . . . . . . . . . . . . . . . . Spring applied, caliper disc type Retarder. . . . . . . . . . . . . . Front and center axle brakes act as retarder

HM350-2

A R T I C U L AT E D D U M P T R U C K

ARTICULATED DUMP TRUCK

HM350-2

DIMENSIONS

STANDARD EQUIPMENT FOR BASE MACHINE ENGINE: Alternator, 50A /24V Batteries, 2 x 12V/136Ah Engine, Komatsu SAA6D140E-5 Exhaust muffler Starting motor, 1 x 11.0 kW CAB: Air conditioner Ashtray Cigarette lighter Cup holder Electronic maintenance display/monitoring system Heated rear window Operator seat, reclining, air suspension type with retractable 78 mm 3 width seat belt Passenger seat Power window (L.H) Space for lunch box Steering wheel, tilt and telescopic Sun visor, front window Tiltable ROPS cab with FOPS, sound suppression type Two doors, left and right LIGHTING SYSTEM: Back-up light Hazard lights Headlights with dimmer switch Indicator, stop and tail lights GUARD AND COVERS: Engine underguard Exhaust muffler thermal guard Fire prevention covers Propeller shaft guards, front and rear Transmission underguard SAFETY EQUIPMENT: Alarm, backup Anti-slip material on fenders Automatic supplementary steering Coolant temperature alarm and light Hand rails for platform Horn, electric Ladders, left and right hand side Protective grille for rear window Rearview mirrors Steering joint locking assembly Under view mirrors BODY: Electronic hoist control system TIRES: 26.5 R25 OTHER: Centralized greasing Differential locks in all axles, clutch type Electric circuit breaker, 24V Mud guards Side marker

45

860

0m

m2

8'3

"

1600 mm 5'3"

5250 mm 17'3"

70

3600 mm 11'10"

6.

5 R25

6.

5 R25

6.

5 R25

3170 mm 10'5" 2590 mm 8'6" 3250 mm 10'8"

1350 mm 4'5" 4350 mm 14'3" 10270 mm 33'8" 11145 mm 36'7"

1850 mm 6'1" 620 mm 2'0"

720 mm 2'4" 2925 mm 9'7"

585 mm 1'11"

7035 mm 23'1"

3190 mm 10'6"

420 m1 0m 3'9 "

2

2 2

OPTIONAL EQUIPMENT CAB: Power window (R.H) Radio, AM/FM Radio, AM/FM with cassette BODY: Body exhaust heating kit Body liner Rock body Tail gate, wire type Upper side extension, 200 mm 8 LIGHTING SYSTEM: Back work lights, left and right side Fog lights Yellow beacon SAFETY: Rear view camera and monitor GAUGE: Engine oil filter warning alarm and light TIRES: 800/65 R29 OTHER: Alternator, 75A/24V Fire extinguisher Gas charge tool Radiator shutter, canvas type Spare parts for first service Tool kit Vandalism protection

TRAVEL PERFORMANCE

x103 lb x103 kg 50

BRAKE PERFORMANCE

GRADE DISTANCE : CONTINUOUS DESCENT

GROSS WEIGHT

0

70

3 180 x10 lb 3 80 x10 kg

GROSS WEIGHT

70 30 80 90 100 110 120 130 40 50 60 150

50 10 20 30

EMPTY

100 40 50 60

150 70 80 -50

LOADED

200 90 -45

x103 lb

3 100 x10 kg

100 80

40 30 60 F1 40 30 20 10 9 8 7 6 5 4 3 5 F6 4 3 2 1 2 F5 20

35.0 30.0 25.0

TOTAL RESISTANCE (GRADE + ROLLING) (%)

-35 -30

F1

F2

20.0 15.0 14.0 13.0 12.0 11.0 10.0 9.0 8.0 7.0 6.0 5.0 4.0 3.0

RIMPULL

F3

-25 -20

F2

10

F4

-15

F3 F4 F5 F6

2.0

-10 -5

0 0 0 5 10 10 20 15 30 20 40 25 30 50 35 60 40 70 km/h MPH

0 0

10

20 10

30 20

40

50 30

60 40

70

80 50

90

100 km/h 60 MPH

TRAVEL SPEED

TRAVEL SPEED

10

TOTAL RESISTANCE (GRADE + ROLLING) (%)

EMPTY

LOADED

-40

11

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Dental PulpДокумент19 страницDental PulperisaxhaferajОценок пока нет

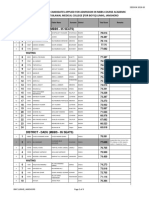

- Pro Meritlist PDFДокумент9 страницPro Meritlist PDFAamir khanОценок пока нет

- Sproket Ratio CalculatorДокумент2 страницыSproket Ratio CalculatorH3liax100% (6)

- Pathophysiology of AsthmaДокумент71 страницаPathophysiology of AsthmaChin ChanОценок пока нет

- Dance Literature (Tinikling)Документ2 страницыDance Literature (Tinikling)Ryan Oppos14% (7)

- Catch Me If You CanДокумент4 страницыCatch Me If You CanChanida AamatmontreeОценок пока нет

- Bard - College of Requiems PDFДокумент3 страницыBard - College of Requiems PDFstekelОценок пока нет

- The History of Combinatorial Game TheoryДокумент13 страницThe History of Combinatorial Game TheoryAdaОценок пока нет

- Your Grace Is Enough by Chris Tomlin Guitar Tab (PG 1 of 2)Документ2 страницыYour Grace Is Enough by Chris Tomlin Guitar Tab (PG 1 of 2)Jaderussel NonesОценок пока нет

- Small Sided GamesДокумент67 страницSmall Sided GamesSoccerCTC100% (14)

- VKH Current Stock (Aug03,18)Документ2 страницыVKH Current Stock (Aug03,18)sdfgdfkgqОценок пока нет

- D 5 EcДокумент8 страницD 5 EcAngeline MatutinoОценок пока нет

- Name:Khok Chiu Yin Kelas: HSK 1 DVM Speech Outline: Speech Title /topic Opening Attention GetterДокумент3 страницыName:Khok Chiu Yin Kelas: HSK 1 DVM Speech Outline: Speech Title /topic Opening Attention GetterflakkaОценок пока нет

- Sekaiichi Hatsukoi - Animate No BaaiДокумент105 страницSekaiichi Hatsukoi - Animate No BaaiScarlett Sura LeytonОценок пока нет

- Excel Gantt Chart Template: Make Impressive Powerpoint Gantt Charts For Important MeetingsДокумент20 страницExcel Gantt Chart Template: Make Impressive Powerpoint Gantt Charts For Important MeetingsAmin MarwanОценок пока нет

- 6 The Divinity Drive Interactive MapsДокумент4 страницы6 The Divinity Drive Interactive MapsbОценок пока нет

- Jeff Tamolang Ballistic1Документ6 страницJeff Tamolang Ballistic1edionОценок пока нет

- Hesjing - D&D 5eДокумент4 страницыHesjing - D&D 5esupiОценок пока нет

- 2 3 Zone PDFДокумент12 страниц2 3 Zone PDFkelson hedilanОценок пока нет

- Free Knitting Pattern Lion Brand Wool-Ease Chunky Saturday Morning HoodieДокумент5 страницFree Knitting Pattern Lion Brand Wool-Ease Chunky Saturday Morning HoodieMatteo OrciariОценок пока нет

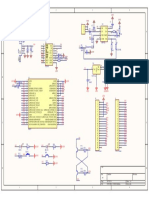

- ESPduino 32sДокумент1 страницаESPduino 32srigsapanama100% (1)

- Hyster H6.00 - H7.00X4Документ880 страницHyster H6.00 - H7.00X4Gebre BelayОценок пока нет

- Soal Ulangan Kls 10Документ5 страницSoal Ulangan Kls 10Krisna JegegОценок пока нет

- The Yogi Bhajan Library of Teachings® - Sat Kriya Workout - Intermediate - ©the Teachings Yogi BhajanДокумент10 страницThe Yogi Bhajan Library of Teachings® - Sat Kriya Workout - Intermediate - ©the Teachings Yogi BhajanNatalina Dass Tera LodatoОценок пока нет

- "Sports Medicine. Medical Control. The Methods of Sportsmen InvestigationДокумент24 страницы"Sports Medicine. Medical Control. The Methods of Sportsmen InvestigationLatika ChoudhuryОценок пока нет

- KhkghkjghkjghohoiДокумент9 страницKhkghkjghkjghohoiY a n i. A h m e dОценок пока нет

- XK8 1997 Elec GuideДокумент123 страницыXK8 1997 Elec Guidewho_we_lookin_for100% (5)

- Enzo Ferrari Biografia ResumidaДокумент8 страницEnzo Ferrari Biografia Resumidaafllfsbxu100% (1)

- E-Commerce Lab: Trinity Institute of Professional StudiesДокумент45 страницE-Commerce Lab: Trinity Institute of Professional StudiesPulkit AggarwalОценок пока нет

- Description Size Cat. Usage Description Ft-Lbs N-M: Torque Specification NumberДокумент5 страницDescription Size Cat. Usage Description Ft-Lbs N-M: Torque Specification NumberSuperlativo IgvОценок пока нет