Академический Документы

Профессиональный Документы

Культура Документы

In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement Concrete

Загружено:

A M Yasin ArmanИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

In Uence of Coarse Aggregate On The Permeation, Durability and The Microstructure Characteristics of Ordinary Portland Cement Concrete

Загружено:

A M Yasin ArmanАвторское право:

Доступные форматы

Construction and Building

Construction and Building Materials 19 (2005) 682690

MATERIALS

www.elsevier.com/locate/conbuildmat

Inuence of coarse aggregate on the permeation, durability and the microstructure characteristics of ordinary Portland cement concrete

L. Basheer *, P.A.M. Basheer, A.E. Long

School of Civil Engineering, Queens University Belfast, Belfast BT7 1NN, Northern Ireland, UK Received 12 February 2005; received in revised form 12 February 2005; accepted 22 February 2005 Available online 26 April 2005

Abstract Reinforced concrete structures in marine and similar environmental conditions have to withstand severe exposures. Due to this, the mix design procedures have to be revised to include durability as a primary criterion along with strength and workability. In line with this need, an investigation was carried out at Queens University Belfast with the nancial help of the Department of Environment, Transport and the Regions, UK. The main objective of the research was to understand the inuence of mix parameters on workability, strength, durability and microstructure and to propose a new mix design procedure within which durability has a higher priority. The present paper reports part of this study, which investigates the eect of size and grading of the coarse aggregate on the durability and the microstructure characteristics of concrete. The durability tests carried out included air permeability test, freeze thaw/salt scaling resistance test and an accelerated carbonation test. The microstructure study was carried out using a scanning electron microscope (SEM) and included image analysis of the interfacial transition zone (ITZ) around the coarse aggregate. The results indicated that as the proportion of larger size aggregate increases in the mix, the local porosity at the ITZ increases and the overall durability decreases. It has also been found that reducing the average aggregate size in a mix improves the pore structure and enhances the durability of the concrete. 2005 Elsevier Ltd. All rights reserved.

Keywords: Concrete; Durability; Microstructure; SEM; ITZ

1. Introduction Most of the important properties of hardened concrete are related to the quantity and characteristics of various types of pores in the cement paste and aggregate components of the concrete. For example, the engineering properties of concrete, such as strength, durability, shrinkage and permeability, are directly inuenced or controlled by the number, type and size of pores present [1]. The total volume of pores, not their size or continuity aect the strength and elasticity of concrete, whereas

*

Corresponding author. Tel.: +28 90974027; fax: +28 90663754. E-mail address: l.basher@qub.ac.uk (L. Basheer).

concrete permeability is inuenced by pore volume, size and continuity. It is believed that capillary voids larger than 50 lm, referred to as macro pores, are detrimental to strength and impermeability, whereas voids smaller than 50 lm, referred to as micro pores, are more related to drying shrinkage and creep [2]. The movement of gases, liquids and ions through concrete is important because of their interactions with concrete constituents and the pore water which can alter the integrity of concrete directly and indirectly, leading to the deterioration of structures. In reinforced concrete this deterioration is mainly due to the corrosion of reinforcement, freezethaw attack or chemical attack. In the recent past the cost of repair of structures due to such

0950-0618/$ - see front matter 2005 Elsevier Ltd. All rights reserved. doi:10.1016/j.conbuildmat.2005.02.022

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690

683

deterioration has been high. This has led to eorts by researchers and engineers to understand concrete better so that durable concrete can be produced in the future. Concrete has a highly heterogeneous and complex structure. At the macroscopic level concrete may be considered to be a two-phase material, consisting of aggregate particles dispersed in a matrix of cement paste. At the microscopic level, a third phase the transition zone may be identied (2). This transition zone exists as a thin shell, called the interfacial transition zone (ITZ), between aggregate particles and hydrated cement paste (hcp). It has been established that the ITZ is profoundly dierent from the bulk cement paste in terms of morphology, composition and density [210]. There have been suggestions that the strength of the cement aggregate bond may be the limiting factor in the determination of the ultimate strength of concrete [11]. Furthermore, as the porosity of the ITZ is higher than that of bulk paste [610], the ITZ has a signicant eect on the permeability and durability of concrete. This paper reports a study carried out to ascertain the eect of coarse aggregate grading and size on the permeation properties and durability of concrete. The investigation involved a study of the pore structure characteristics of the ITZ, with the objective of linking the pore structure characteristics to the permeation properties and the durability of ordinary Portland cement concretes. 1.1. Characterisation of interfacial transition zone Back scattered electron (BSE) imaging technique can be used to characterise the pore structure of the ITZ. Low viscosity epoxy impregnated polished samples of concrete are used for BSE imaging. The underlying principle is that the contrast of the BSE images depends on the mean atomic number of the concrete constituents. In the BSE images anhydrous phases of the unreacted cement particles appear bright, the calcium hydroxide light grey, the other hydration products as various shades of darker grey with the epoxy impregnated pores appearing black [8]. Consequently by processing images of polished sections it has been possible to determine the distribution of the phases in hydrated cement paste [12]. Furthermore, these images can also be utilised to ascertain porosity characteristics of the ITZ including the porosity gradient [10] and the amount of penetrable

pores [8,13]. Hence, this technique is used in this work for studying the ITZ pore structure.

2. Experimental programme 2.1. Variables Table 1 gives the mix variables used in the investigation. To obtain a range of coarse aggregate grading the proportion of 10 and 20 mm aggregate was varied. For the aggregate size eect, 10 and 20 mm single size aggregates were used. A constant watercement ratio of 0.6 and aggregatecement ratio of 6 was used in all the cases. Mixes with two dierent ne aggregate-coarse aggregate ratios (FA/CA) were used for both the permeation and durability studies. For the micro structural study only 0.5 FA/CA was used. 2.2. Materials used Class 42.5 N Portland cement [14], medium graded [15] natural sand and crushed basalt coarse aggregate were used for manufacturing the concrete samples. The various properties of the aggregates are summarised in Table 2. To control the moisture condition of the aggregate, all aggregates were oven-dried at a temperature of 40 C. The coarse aggregate was dried for 1 day and the ne aggregate for 2 days. Before the aggregates were used to make concrete they were allowed to cool for at least 1 day. The saturated surface dry 1-hour water absorption values [16] were also measured. This allowed a corrected water quantity to be calculated when batching the materials, to ensure that the aggregate in the concrete was in a saturated surface-dry condition.

Table 2 Properties of aggregates used Aggregate type Fine aggregate (sand) 10 mm crushed basalt 20 mm crushed basalt 1 h absorption (%) 1 0.5 0.5 Specic gravity 2.72 2.93 2.88 Fineness modulus 2.6 5.92 7.04

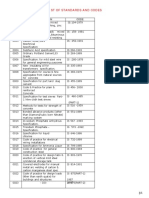

Table 1 Variable used for the investigation Variable FA/CA Coarse aggregate grading and notation Levels 0.5 100% 10 mm (10 mm) 0.7 67% 10 mm + 33% 20 mm (10/20 = 2) 33% 10 mm + 67% 20 mm (10/20 = 0.5) 100% 20 mm (20 mm)

Note: FA/CA ne aggregatecoarse aggregate ratio.

684

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690

2.3. Manufacture of test specimens Six 250 250 100 mm blocks and three 100 mm cubes were cast for each of the variables in Table 1. The blocks were used for the permeation and durability studies and the three cubes were used to obtain the compressive strength (the slump and cube compressive strength values are given in Table 3). One sample from each mix was used for the micro structural study. For each mix the required quantities were batched by mass. These quantities were then mixed together using a pan mixer in accordance with BS 1881: Part 125: 1986 [17]. For both blocks and cubes the concrete was cast in two layers. A vibrating table was used to compact the concrete. Full compaction was considered to have been achieved when air bubbles stopped appearing on the concrete surface. After vibrating, the concrete surface was nished smooth using a metal oat and then covered with a polythene sheet to prevent evaporation of water from the concrete. Approximately, 6 h after the concrete had been cast the moulds were covered with a damp hessian. The moulds were stripped next day and the hardened concrete samples were placed in a constant temperature (20 C) water bath for 3 days. The specimens were then transferred into a storage laboratory kept at a constant temperature of 18 C (2 C) and a relative humidity of 60% ( 5%). When the blocks were 14 days old they were placed in a drying cabinet at a temperature of 40 C and a relative humidity of 20%. This was done to remove moisture from the surface of the concrete in order to eliminate the eect of moisture on the permeation results. After 14 days of drying the specimens were ready for testing. For this they were transferred to a testing laboratory (kept at a constant temperature of 20 C (0.5 C) and relative humidity of 50% ( 5%)) and tested on the following day. The cubes were cured and conditioned in the same way as the slabs in order to ensure that the compressive strength and other parameters were measured using similar concrete. The cubes were then crushed to determine the concrete compressive strength.

2.4. Test methods 2.4.1. Air permeability test The air permeability of concrete was measured on the preconditioned blocks using the Autoclam Permeability system [18]. This test has been used in research for more than a decade and has proved to be very reliable and easy to use. Details of the test can be obtained in [18]. The test provides a relative measure of the air permeability of concrete in Ln(Bar)/min. 2.4.2. Salt scaling test The freezethaw/salt scaling test was carried out according to the RILEM test procedure [19]. The specimens for the test were 100 mm diameter cores taken from the slabs used for the Autoclam air permeability test. The cores were dried for 2 weeks in a fan-assisted cabinet maintained at 40 C and 20% relative humidity. The curved surfaces of these cores were then coated with an epoxy emulsion. These cores were then kept in a 3% sodium chloride solution for 7 days, with the test surface (mould nished face) touching the solution. The face of the cores opposite to the test surface was then coated with the epoxy emulsion. The samples were then transferred to test cells again with the test surface in contact with the 3% salt solution. The cells were then placed in an automatic environmental chamber and subjected to test cycles as shown in Fig. 1. At the end of every two cycles, the specimens were taken out of the chamber and the loose particles removed by means of an ultrasonic bath. The loose particles collected were dried at 100 C for 24 h and then weighed. These measurements were continued for 28 cycles. 2.4.3. Accelerated carbonation test The carbonation resistance of dierent mixes was determined by carrying out an accelerated carbonation test on 100 mm cores removed from the blocks used for the permeability tests. The cores used for the test were dried in a fan-assisted cabinet for 2 weeks at 40 C and 20% relative humidity. These were then coated with epoxy emulsion on the curved surface and the trowel-nished face. When the epoxy was cured,

Table 3 Slump and 28-day compressive strength the study No: 1 2 3 4 5 6 7 8 CA-G 10 mm 10/20 = 2.0 10/20 = 0.5 20 mm 10 mm 10/20 = 2.0 10/20 = 2.0 20 mm FA/CA 0.5 Slump (mm) 35 56 79 103 18 28 23 61 Strength (N/mm2) 46.9 44.1 44.2 42.9 50.1 45.2 45.4 44.9

+20.00 C Time (Hours)

0.00 C

0.7

-20.00C 4.0 Temperature (0 C) 3.0 4.0 1.0

Note: CA-G coarse aggregate grading.

Fig. 1. Freezethaw cycle used for RILEM salt scaling test.

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690

685

the cores were placed in an electronically controlled carbonation chamber in an environment of 5 0.1% carbon dioxide at 20 0.5 C and 65 1% relative humidity. At the end of 3 weeks, the samples were taken out and split longitudinally. The freshly broken surface was sprayed with a phenolphthalein indicator solution. After 24 h the depth of the pink coloration was measured to the nearest millimetre at six dierent locations. An average of these values was used for comparing different mixes. 2.4.4. Electron microscopic study of the ITZ Cores of 50 mm diameter were cut from the blocks used for the permeation studies. The cores were then cut along their diameter and a slice of size 25 mm 25 mm 2 mm was removed from the mouldnished face of each core. The slices were then wrapped in thin polythene sheets to prevent any carbonation taking place. These thin slices were dried under vacuum and then impregnated with an ultra low viscosity epoxy. After the epoxy had cured the specimens were polished with diamond grit of progressively ner sizes down to 0.25 lm. The polished samples were then coated with carbon to 10 nm thickness. The carbon-coated samples were placed under a scanning electron microscope (SEM) and 20 backscatter images from around the coarse aggregate present in the slice were collected at random. The image magnication used was 400 times and the electron beam was kept at a distance of 15 mm away from the top of the specimen in all cases. Each image consisted of a small part of aggregate on the left hand side of the picture and the rest was the matrix of cement paste and mortar (Fig. 2(a)). The overall size of each image was 336 262 lm. The porosity gradient was determined using an image analysis computer software programme NIH Image. In order to do this, thresholding of the grey scale to identify pores from the rest was essential. This was done by trial and error and by carrying out a sensitivity analysis. Once the threshold grey scale was decided, the software enabled the determination of porosity in a strip of 10 lm thickness away from the face of the aggregate (Fig. 2(a)). This strip was moved on an incremental basis by 10 lm width away from the face of the coarse aggregate and each time the porosity of the 10 lm thick strip was determined as a percentage of the total area of the strip. Once the strip reached the end of the image, the analysis was repeated on other images collected from the same sample. Therefore, for each 10 lm increment strip away from the coarse aggregate, there were 20 porosity values and an average of these values was reported as the porosity of this 10 lm thick strip of concrete. The average porosity values were then plotted against the distance from the face of the aggregate to determine the characteristics of the interfacial zone (Fig. 2(b)).

Fig. 2. (a) Segmentation using histogram. (b) Typical porosity distribuation curve.

3. Results and discussion 3.1. Slump and compressive strength The slump and 28-day compressive strength results of each mix are presented in Table 3. An increase in slump and marginal decrease in cube compressive strength can be noted with an increase in the proportion of 20 mm aggregate in the mix. The reduction in water demand with an increase in the size of coarse aggregate is well documented [2]. In this experimental programme when the proportion of 20 mm aggregate increased for a given watercement ratio, the reduction in water demand led to the increase in slump. However, as the watercement ratio was not changed, the strength did not vary signicantly. 3.2. Air permeability Tables 4 and 5 give the results of the air permeability test as AP index [18]. When the eect of coarse aggregate grading is considered, it can be seen that as the proportion of 20 mm aggregate increases in the concrete air permeability increases, indicating a reduction in durability [20]. This is seen for both FA/CA ratios. In Table 5,

686

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690

Table 4 The eect of aggregate grading on air permeability, salt scaling resistance and carbonation resistance Coarse aggregate grading 10/20 2 10/20 0.5 20 mm 10/20 2 10/20 0.5 20 mm FA/CA 0.5 AP index (Ln(mBar)/min) 0.114 0.139 0.181 0.06 0.105 0.115 Cumulative scaling wt (g) 148.6 406.9 642.3 67.02 53.05 86.05 Depth of carbonation (mm) 12.7 13.1 13.7 12.8 11.3 12.4

0.7

Table 5 The eect of aggregate size on air permeability, salt scaling resistance and carbonation resistance Coarse aggregate size (mm) 10 20 10 20 FA/CA 0.5 0.7 AP index (Ln(mBar)/min) 0.11 0.181 0.076 0.115 Cumulative scaling wt (g) 46.2 642.3 78.05 86.05 Depth of carbonation (mm) 11.1 13.7 11.2 12.4

the eect of increasing the size of coarse aggregate from 10 to 20 mm is to increase the air permeability. There are two possible reasons for these results. When the size of coarse aggregate increases, there is a reduction in the tortuosity of the ow path, which tends to increase the permeability. The second reason is that when larger size coarse aggregates are used, the possibility of the bleed water getting collected below the coarse aggregate increases, which leads to an increase in local watercement ratio and hence the porosity. An increase in porosity around the aggregate would increase the permeability of the concrete. However, Table 6 indicates that only moderate variations in air permeability occurred and all the samples used for this study fall in the region of medium risk concretes in terms of durability [20]. It can also be seen from Tables 4 and 5 that, as the ne aggregatecoarse aggregate ratio was increased from 0.5 to 0.7, the air permeability of the concrete decreased. This is quite unexpected because when the FA/ CA increases, the increase in sand volume for a given aggregatecement ratio would increase the area of interfacial transition zone, which in turn reduce the tortuosity of the ow path. This means that the air permeability should have increased. In Table 3, there is a reduction in slump and an increase in compressive strength with the

increase in FA/CA, which would suggest that when the FA/CA increased, there was an associated decrease in watercement ratio. This might have been the result of increased absorption of mix water by sand over and above that was accounted in mix proportioning. Nevertheless, it can be concluded that the reduction in eective watercement ratio associated with the increase in ne aggregate content is responsible for the reduction in air permeability. Fig. 3 shows the eect of average aggregate size on the air permeability. (The average aggregate size was obtained from the sieve analysis data, using standard procedures). As the average aggregate size in the mix increases the air permeability index increases. A straight line, with a regression coecient of 0.87, can represent this increase. The combined eect of aggregate size, its relative proportion in a mix and the quantity of ne aggregate in the mix on air permeability was obtained by plotting air permeability against the average size of aggregate in Fig. 3. The gure would suggest that the permeability (and hence the durability) of concrete could be improved by reducing the average size of the combined ne and coarse aggregates.

Table 6 Risk rating of durability based on Autoclam air permeability index (20) Air permeability index (Ln(mBar)/min) Range <0.1 0.10.5 0.50.9 >0.9 Rating Low Medium High Very high

0.2 0.18 0.16 0.14 0.12 0.1 0.08 0.06 0.04 0.02 0 0 0.5 1 1.5

AP Index x 102 Ln(Bar)/min

y = 0.0627x - 0.0191 2 R = 0.871

2.5

3.5

Average aggregate size (mm)

Fig. 3. Eect of average aggregate size on air permeablity index.

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690

687

n1

porosity % porosity %

n1

n2

(a)

ITZ1 ITZ2 Distance (micron)

(b)

ITZ2 Distance (micron)

Fig. 4. Two dierent types of porosity gradients.

3.3. Salt scaling The salt scaling test gave results similar to those of the air permeability test (Tables 4 and 5). As the proportion of the 20 mm aggregate increases in the mix the cumulative salt scaling also increases, indicating a decrease in durability (Table 4). A similar trend can also be seen in Table 5 when the results of 10 and 20 mm

coarse aggregate mixes are compared for both the FA/ CA ratios. However, the eect of an increase in ne aggregatecoarse aggregate ratio from 0.5 to 0.7 is to improve the salt scaling resistance of the concrete. As in the case of air permeability, it is possible to conclude that an increase in the proportion of smaller size fractions of aggregate in a mix would improve its salt scaling resistance when the watercement ratio is kept constant. However, it has to be pointed out that the eect of the average aggregate size is not as signicant a factor as the watercement ratio of a mix. In a previous study, a lower water cement ratio (0.45) concrete withstood 100 cycles of freezing and thawing [21] compared to 0.6 watercement ratio concrete which only withstood about 28 cycles. 3.4. Carbonation In Table 4, there was no consistent eect of coarse aggregate grading and the FA/CA on the depth of

Fig. 5. (a) Aggregate grading and porosity. (b) Aggregate grading and ITZ thickness. (c) Aggregate grading and total porosity percentage.

688

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690

carbonation. Russell and co-workers [22] showed that the depth of carbonation is primarily dependent on the watercement ratio. For the mixes in Table 4, the watercement ratio was kept constant. Therefore, the depth of carbonation remained almost the same for all the mixes. However, Table 5 shows that the depth of carbonation increases when the aggregate size is increased. This is similar to the results reported by Basheer et al. [23]. The increase in the size and porosity of the ITZ around the coarse aggregate due to the increase in size of the coarse aggregate might have contributed to this increase in depth of carbonation. 3.5. ITZ properties The percentage porosity distributions at the ITZ, obtained from SEM analysis, were used for a comparative study of the ITZ in samples from each mix. In general, the distribution of porosity obtained across the ITZ can be divided in to three sections (Fig. 4(a) and (b)):

region of peak porosity (n1) which is about 40 lm thick (ITZ1), a transient porosity region (n2) which is about 160 lm thick (ITZ2), the bulk porosity region (n). The area under the curve in the peak porosity region is termed as A1 and that in the transient porosity region is termed as A2. These values give a combined eect of the percentage porosity and the ITZ. In some cases n2 and the corresponding ITZ1 and A1 values are not present (Fig. 4(b)). Although for microstructure studies in the literature, other researchers have reported the thickness of the ITZ as 1050 lm [8,15,16], a more open approach was used for analysing the results in this paper. This was to avoid losing any valuable information from the results. Fig. 5(a)(c) present the ITZ data versus aggregate grading for mixes of FA/CA ratio 0.5. Results indicate that as the proportion of 20 mm aggregate increases so does the porosity values (n1, n2 and n) (Fig. 5(a)).

Fig. 6. (a) Aggregate size and porosity. (b) Aggregate size and ITZ thickness. (c) Aggregate size and total porosity.

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690

689

This eect is more apparent at the ITZ region and is only marginal for the bulk porosity. These result correlate well with the previous three test results given in Sections 3.23.4. When the ITZ thicknesses are compared for these mixes (Fig. 5(b)), it can be seen that as the proportion of 20 mm aggregate increased in the mix, the ITZ thickness also increased. This is more evident in ITZ2 than in ITZ1. Results from this study and a parallel study with dierent watercement ratios and aggregatecement ratios [24] indicate that the ITZ2 value is an important parameter, which has to be considered during the analysis of ITZ results obtained from SEM analysis. From Fig. 5(c) it can be seen that the total porosity percentage, both A1 and A2, increased as the proportion of 20 mm aggregate increased in the mix. Therefore, it can be concluded that when the proportion of course aggregate is increased, there will be an associated increase in interfacial transition zone porosity volume. Fig. 6(a)(c) show the eect of aggregate size on percentage porosity values and ITZ thicknesses. As obtained for the permeation and durability results, reported in Sections 3.23.4, increasing the coarse aggregate size in the mix resulted in an increase in the percentage porosity values (Fig. 6(a)) and the ITZ thicknesses (Fig. 6(b)). These results and the results given in the above paragraphs indicate that the microstructure study using SEM and image analysis give a clear picture of the pore structure distribution at the aggregate interface, which reects the air permeability and durability of the concretes. This is apart from the fact that these images only give a two dimensional picture of the pore structure. Also, there could be error introduced in the SEM analysis because of the fact that it is not known at what angle to the coarse aggregate the concrete was sliced when the samples were prepared. However, Scrivener and Nemati [9] suggest that a correction factor of 0.81 can be applied to the ITZ thickness measured using random sections in order to estimate the average normal distance of the ITZ, provided that sucient number of areas are analysed and averaged [7]. As one sample only was analysed for each variable in this study, this correction factor was not applied.

(ii) Unlike other published work on the eect of ne aggregate content on the air permeability of concrete, when the ne aggregate content increased the air permeability decreased. The increase in tortousity is considered to have contributed to this eect. (iii) The salt scaling resistance followed a trend similar to that of the air permeability reported in (i) and (ii). The eect of aggregate grading and FA/CA on depth of carbonation was insignicant. However, the increase in size of aggregate led to an increase in the depth of carbonation. (iv) The micro structural analysis at the ITZ clearly indicates that the coarser the aggregate the more porous it is at the ITZ. This is in line with the results given by permeability and durability studies. (v) Therefore, in order to design durable concretes using oPc, it is preferable to use smaller size aggregate and a low average aggregate size for the combined ne and coarse aggregate.

Acknowledgements The funding to carryout this project was provided by the Department of Environment, Transport and the Regions, UK. The facilities to carryout this research was provided by the school of Civil Engineering and the Electron microscopic unit at Queens University Belfast. Both these are gratefully acknowledged.

References

[1] Verbeck G. Pore structure signicance of tests and properties of concrete and concrete making materials. ASTM special technical publication No:169A, 1982, p. 2119. [2] Mehta PK, Monterio PJM. Concrete structure, properties and materials, vol. 2. New Jersey: Prentice Hall; 1993. p. 548. [3] Barnes BD, Diamond S, Dolch WL. Micromorphology of the interfacial zone around aggregates in Portland cement mortar. J Am Ceram Soc 1979;62:2134. [4] Lange DA, Jennings HM, Shah SP. Image analysis techniques for characterisation of pore structure of cement-based materials. Cement Concrete Res 1984;24(5):84153. [5] Mindess S. Interfaces in concrete, Material science of concrete. Am Ceram Soc Sympos 1988;114:8995. [6] Scrivener KL, Gariner EM. Microstructural gradients in cement paste around aggregate particles. Mater Res Soc Sympos Proc 1988;114:7785. [7] Scrivener KL, Crumbie AK, Pratt PL. A study of the interfacial region between cement paste and aggregate in concrete, bonding in cementatious composites. Proc Mat Res Soc Sympos 1988;114:879. [8] Scrivener KL. Use of back scattered electron microscopy and image analysis to study the porosity of cement paste, Proceedings: pore structure and permeability of cementatious materials. Mater Res Soc 1989;137:12940.

4. Conclusions On the basis of results presented in this paper, the following conclusions can be drawn: (i) The air permeability of concrete can be improved by resorting to mixes with a low average aggregate size. When the size of coarse aggregate and the proportion of larger size coarse aggregate increases in a mix, there is an associated increase in air permeability.

690

L. Basheer et al. / Construction and Building Materials 19 (2005) 682690 [18] Basheer PAM, Long AE, Montgomery FR. The Autoclam a new test for permeability, concrete. J Concrete Soc 1994(July/ August):279. [19] Setzer MJ, Fegerlund G, Janssen DJ. CDF test test method for the freezethaw resistance of concrete-tests with sodium chloride solution (CDF). Mater Struct 1996;29(Nov):5238. [20] Autoclam Permeability System Version IV. Operation Manual, Amphora NDT Limited, Belfast, 2004, 21 p. [21] Cleland DJ, Basheer L. Assessing the freeze thaw durability of surface treated concrete. In: Setzer MJ, Auberg R, Keck HJ, editors. Frost Resistance of Concrete. Proceedings of the international RILEM workshop. RILEM Publications S.A.R.L; 2002. p. 35966. [22] Basheer PAM, Russel DP, Rankin GIB. Service life design of concrete to resist carbonation. In: Lacasse MA, Vanier DJ, editors. Eighth international conference on durability of building materials and components. Proceedings of the international conference, 30 May to 3rd June, vol. 1. NRC Research Press; 1999. p. 42345. [23] Basheer PAM, Montgomery FR, Long AE. Factorial experimental design for concrete durability research. Build Struct 1994;104(4):44962. [24] Basheer PAM, Basheer L, Lange DA, Long AE. Role of thresholding to determine the size of interfacial transition zone, ACI Special Publication SP-189, ACI Spring convention, March 1999, Chicago, USA, p. 16486.

[9] Scrivener KL, Nemati KM. The percolation of pore space in the cement paste/aggregate interfacial zone of concrete. Cement Concrete Res 1996;26(1):3540. [10] Zhang X, Groves GW, Rodger SA. The microstructure of cement aggregate interfaces, Bonding in cementitious composites. Mater Res Soc Sympos 1988;114:8995. [11] Maso JC. The bond between aggregates and hydrated cement paste. In: Proceedings of seventh international congress on the chemistry of cement, vol. 1, Paris, 1980. p. VII.1/3VII1/5. [12] Scrivener KL, Pratt PL. The characterisation and quantication of cement and concrete microstructures. In: Maso JC, editor. Proceedings, pore structure and construction materials properties, Cong. RILEM/AFREM, 1987. p. 618. [13] Larbi JA. Microstructure of the interfacial zone around aggregate particles in concrete. Heron 1993;38(1). [14] British Standards Institution, Specication for Portland Cements, BSI London, BS 12:1991, 7 p. [15] British Standards Institution, Specication for aggregates from natural sources for concrete, BSI London, BS 882:1992. [16] British Standards Institution, Testing aggregates, Methods for determination of physical properties, BSI London, BS 812: Part 2:1975. [17] British Standards Institution, Methods for mixing and sampling fresh concrete in the laboratory, BSI London, BS 1881: Part 125 1986.

Вам также может понравиться

- 766 1358 1 SMДокумент17 страниц766 1358 1 SMEliasTalaAllcaОценок пока нет

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsОт EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsОценок пока нет

- Durability of Concrete With Differential Concrete Mix DesignДокумент10 страницDurability of Concrete With Differential Concrete Mix Designshoyeeb ahmedОценок пока нет

- Effective Applications of Retarding Admixture To Improve TheДокумент13 страницEffective Applications of Retarding Admixture To Improve Thegtarun22guptaОценок пока нет

- Time-Dependent Behaviour of High Performance Concrete: Influence of Coarse Aggregate CharacteristicsДокумент8 страницTime-Dependent Behaviour of High Performance Concrete: Influence of Coarse Aggregate CharacteristicsElakkiya KarthicОценок пока нет

- 4N5 Ijeset0202520 PDFДокумент8 страниц4N5 Ijeset0202520 PDFBia MughalОценок пока нет

- The Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsДокумент11 страницThe Influence of Different Curing Conditions On The Pore Structure and Related Properties of Fly-Ash Cement Pastes and MortarsTarek ChikerОценок пока нет

- Review On Change The Properties of Concrete by Adding Rice Husk Ash and MetakaolinДокумент7 страницReview On Change The Properties of Concrete by Adding Rice Husk Ash and MetakaolinIJRASETPublicationsОценок пока нет

- Research Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaДокумент4 страницыResearch Paper Variation Pattern in Ingredients Quantities Due To Superplasticizer and Fly Ash in Concrete Mixes Designed As Per Is Code Address For Correspondence, CG, IndiaahmedanyОценок пока нет

- E3sconf Arfee2018 02004Документ4 страницыE3sconf Arfee2018 02004mk779900mkОценок пока нет

- 5 AmornpunyapatДокумент17 страниц5 Amornpunyapatmahdi najafzadehОценок пока нет

- Effect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsДокумент8 страницEffect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsgeostaterОценок пока нет

- Influence of Recycled Aggregate On Slump and Bleeding of Fresh ConcreteДокумент8 страницInfluence of Recycled Aggregate On Slump and Bleeding of Fresh ConcreteAlfredo Landaverde GarcíaОценок пока нет

- Investigation of Abrasion Test and Mechanical Properties of Concrete Using Fly Ash As A Partial Replacement of CementДокумент11 страницInvestigation of Abrasion Test and Mechanical Properties of Concrete Using Fly Ash As A Partial Replacement of CementIJRASETPublicationsОценок пока нет

- Sustainability 02 01204Документ22 страницыSustainability 02 01204Phil MarceloОценок пока нет

- Literature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. HeДокумент9 страницLiterature Review: Nova John (2013) Examined The Strength Properties of Metakaolin Admixed Concrete. Henutan acharyaОценок пока нет

- Chapter-1: 1.1 GENERALДокумент55 страницChapter-1: 1.1 GENERALvineela saiОценок пока нет

- Combined Effect of Latex and Crumb Rubber On Mechanical Properties of Concrete For Railway ApplicationДокумент9 страницCombined Effect of Latex and Crumb Rubber On Mechanical Properties of Concrete For Railway ApplicationJee Hock LimОценок пока нет

- Study On Durability Characteristic Strength of Recycled Waste Concrete As Fine Aggregates in Self-Compacting ConcreteДокумент8 страницStudy On Durability Characteristic Strength of Recycled Waste Concrete As Fine Aggregates in Self-Compacting ConcreteIJRASETPublicationsОценок пока нет

- Relationships Between Functional Properties of Pervious ConcreteДокумент13 страницRelationships Between Functional Properties of Pervious ConcreteBenj FigueroaОценок пока нет

- Improving Strength of Concrete Using Crushed Tiles and Nylon FiberДокумент16 страницImproving Strength of Concrete Using Crushed Tiles and Nylon FiberIJRASETPublicationsОценок пока нет

- Flexural Behavior of Reinforced Self Compacting Concrete Containing GGBFSДокумент6 страницFlexural Behavior of Reinforced Self Compacting Concrete Containing GGBFSAarohiShirkeОценок пока нет

- Concrete Mix Design Beng 2021Документ31 страницаConcrete Mix Design Beng 2021musinguzi robertОценок пока нет

- Investigation of Concrete PropertiesДокумент9 страницInvestigation of Concrete PropertiesAlberto ForteОценок пока нет

- Relation Between Density and Compressive Strength of Hardened ConcreteДокумент9 страницRelation Between Density and Compressive Strength of Hardened ConcreteMohd NasimОценок пока нет

- No Fines ConcreteДокумент8 страницNo Fines ConcreteshurookОценок пока нет

- Alfa Hammed ProjectДокумент47 страницAlfa Hammed ProjectOyekunle GbohunmiОценок пока нет

- Effect of Aggregate Type On Compressive Strength of ConcreteДокумент10 страницEffect of Aggregate Type On Compressive Strength of ConcreteamelialoritaОценок пока нет

- A Study On Properties of Concrete With The Use of Jute FiberДокумент22 страницыA Study On Properties of Concrete With The Use of Jute Fibergaur_shashikant4432Оценок пока нет

- Investigation of The Effect of Water-Cement Ratio On The Modulus of Rupture of ConcreteДокумент8 страницInvestigation of The Effect of Water-Cement Ratio On The Modulus of Rupture of ConcreteRevati PatilОценок пока нет

- Microstructure As A Critical Factor of Cement Mortars' Behavior: The Effect of Aggregates' PropertiesДокумент11 страницMicrostructure As A Critical Factor of Cement Mortars' Behavior: The Effect of Aggregates' PropertiesKhang LaiОценок пока нет

- Experimental Studies On High Strength Concrete by Using Recycled Coarse AggregateДокумент10 страницExperimental Studies On High Strength Concrete by Using Recycled Coarse AggregateinventyОценок пока нет

- A Review The Effect and Behaviour of Concrete Using Lime Stone PowderДокумент6 страницA Review The Effect and Behaviour of Concrete Using Lime Stone PowderIJRASETPublicationsОценок пока нет

- Kshuboo 2nd PaperДокумент5 страницKshuboo 2nd PaperPriyanshiОценок пока нет

- Mechanical and Elastic Behaviour of Concretes Made of Recycled-ConcreteДокумент5 страницMechanical and Elastic Behaviour of Concretes Made of Recycled-ConcreteIvan NikolaevОценок пока нет

- Journalofphysicsiop Nicosanjaya2021Документ8 страницJournalofphysicsiop Nicosanjaya2021Muhammad Sholahuddin AliyОценок пока нет

- HO - CB 352 CM Part - 4A - Fresh Properties of ConcreteДокумент8 страницHO - CB 352 CM Part - 4A - Fresh Properties of ConcreteAmjad Wael Yahia FayedОценок пока нет

- Effect of Lathe Waste Review 1Документ22 страницыEffect of Lathe Waste Review 1dreamboy87Оценок пока нет

- Water Absorption Capacity of Concrete Cubes With Sorptivity CoefficientДокумент7 страницWater Absorption Capacity of Concrete Cubes With Sorptivity CoefficientfurqanОценок пока нет

- Journal of Building EngineeringДокумент16 страницJournal of Building EngineeringVeronika PrymОценок пока нет

- Application of Ductile FiberДокумент8 страницApplication of Ductile FiberAndreea BadulescuОценок пока нет

- Construction and Building MaterialsДокумент8 страницConstruction and Building MaterialsVeronika PrymОценок пока нет

- Effect of Fly Ash On Durability of Leightweight ConcreteДокумент10 страницEffect of Fly Ash On Durability of Leightweight ConcreteRadna kurniasariОценок пока нет

- Strength Behavior of Sisal Fibre Concrete With Fine Construction Waste AggregateДокумент8 страницStrength Behavior of Sisal Fibre Concrete With Fine Construction Waste AggregatevempadareddyОценок пока нет

- Fresh Properties With Fly AshДокумент10 страницFresh Properties With Fly AshSaulatJillaniОценок пока нет

- Sriravindrarajah2012 PDFДокумент8 страницSriravindrarajah2012 PDFLokesh KОценок пока нет

- Ajwad Et Al 2018 - Assessing Strengthening ConcreteДокумент4 страницыAjwad Et Al 2018 - Assessing Strengthening ConcreteJavsarОценок пока нет

- Mechanical Properties of Plastic Concrete Containing BentoniteДокумент7 страницMechanical Properties of Plastic Concrete Containing Bentonitejuan muneraОценок пока нет

- Self Compacting Concrete For Slip Form PavingДокумент7 страницSelf Compacting Concrete For Slip Form PavingNaufal Pawa NajibОценок пока нет

- Effect of Recycled Aggregate On The Compressive Strength of ConcreteДокумент20 страницEffect of Recycled Aggregate On The Compressive Strength of ConcreteHuzaifa ZafarОценок пока нет

- Partial Replacement of Laterite As A CoaДокумент7 страницPartial Replacement of Laterite As A Coaslalitha.613Оценок пока нет

- Introduction To Self Compacting ConcreteДокумент39 страницIntroduction To Self Compacting ConcreteAyesha ShaikhОценок пока нет

- The Rheology of Cementitious MaterialsДокумент6 страницThe Rheology of Cementitious MaterialsAi VietОценок пока нет

- Performance Optimization of Hybrid Fiber Concrete - Felxural - Compullout - High Temp.Документ18 страницPerformance Optimization of Hybrid Fiber Concrete - Felxural - Compullout - High Temp.Prasanth SekarОценок пока нет

- Concrete Mix Design Using Crushed SandДокумент22 страницыConcrete Mix Design Using Crushed SandOlaolu Olalekan50% (2)

- Article Text 463742 1 10 20190116 2Документ7 страницArticle Text 463742 1 10 20190116 2Jiu ShitzukiОценок пока нет

- Influence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariДокумент4 страницыInfluence of Silica Fume On Concrete: Prof. Vishal S. Ghutke, Prof. Pranita S.BhandariBia MughalОценок пока нет

- Review of Related LiteratureДокумент5 страницReview of Related LiteratureEloisa FabroaОценок пока нет

- Bendable ConcreteДокумент8 страницBendable ConcreteAnees CalicutОценок пока нет

- N. JNT F. JNT N. JNT F. JNT: Member1 Member2Документ3 страницыN. JNT F. JNT N. JNT F. JNT: Member1 Member2A M Yasin ArmanОценок пока нет

- Non Destructive TestДокумент15 страницNon Destructive TestA M Yasin ArmanОценок пока нет

- Project Management: Dr. Ron Lembke Operations ManagementДокумент63 страницыProject Management: Dr. Ron Lembke Operations ManagementA M Yasin ArmanОценок пока нет

- Basic Relationships in Elasticity Theory: I. NomenclatureДокумент5 страницBasic Relationships in Elasticity Theory: I. NomenclatureA M Yasin ArmanОценок пока нет

- Plane Stress Vs StrainДокумент53 страницыPlane Stress Vs StrainWondwosen A. LakewОценок пока нет

- Blow in Essar 15.2.10Документ18 страницBlow in Essar 15.2.10TheleapInoblivionОценок пока нет

- ReviewДокумент24 страницыReviewhunters eОценок пока нет

- Condensia Catalogue BrochureДокумент24 страницыCondensia Catalogue Brochure吉启周Оценок пока нет

- GET Wear SystemsДокумент19 страницGET Wear SystemsIvanОценок пока нет

- Construction TechniquesДокумент24 страницыConstruction TechniquessreepriyaОценок пока нет

- List of Standards and Codes For Power PlantДокумент3 страницыList of Standards and Codes For Power PlantS.KAMBANОценок пока нет

- Basic Calculations PDFДокумент1 страницаBasic Calculations PDFSanthosh Kumar100% (1)

- 2 Literature ReviewДокумент11 страниц2 Literature Reviewsantkabir100% (1)

- Steam BlowingДокумент21 страницаSteam BlowingAbhishek JainОценок пока нет

- MCHW Vol 1 1000 - Web PDFДокумент51 страницаMCHW Vol 1 1000 - Web PDFalejandraoy9Оценок пока нет

- Drilled Shaft in Rock Analysis and Design - Part3Документ109 страницDrilled Shaft in Rock Analysis and Design - Part3rshaghayan100% (2)

- Design of Hollow Block Slabs: Dr. Hamed HadhoudДокумент19 страницDesign of Hollow Block Slabs: Dr. Hamed HadhoudFady Abdel AzizОценок пока нет

- New Example 14 Simple FrameДокумент6 страницNew Example 14 Simple FrameminnОценок пока нет

- 12-SDMS-02 REV. 02: Saudi Electricity CompanyДокумент20 страниц12-SDMS-02 REV. 02: Saudi Electricity CompanyMichael Camit EsoОценок пока нет

- Analisa Kabel Fire Alarm - KlarifikasiДокумент1 страницаAnalisa Kabel Fire Alarm - KlarifikasiDafam KalijudaОценок пока нет

- Brown White Minimalist Home Decoration PresentationДокумент110 страницBrown White Minimalist Home Decoration PresentationMiMipan DRОценок пока нет

- KLOCKE - Abrasive Machining of Advanced Aerospace Alloys and CompositesДокумент24 страницыKLOCKE - Abrasive Machining of Advanced Aerospace Alloys and CompositesLuis Fillipe Lopes TorresОценок пока нет

- Ts-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMДокумент2 страницыTs-Po16392-2cx10mm, 3CX6MM, 3CX10MM, 4CX6MM, 4CX16MMmohd darusОценок пока нет

- Sintex UPVC Windows PPTR1 (Compatibility Mode)Документ43 страницыSintex UPVC Windows PPTR1 (Compatibility Mode)Artegress GroupОценок пока нет

- SIMULATION PROFESSIONAL ModДокумент101 страницаSIMULATION PROFESSIONAL Modhod meОценок пока нет

- CE 302 - Conc - Lecture 4 - Wk4Документ18 страницCE 302 - Conc - Lecture 4 - Wk4IsraelОценок пока нет

- Technical Manual Hdpe Pipes PDFДокумент64 страницыTechnical Manual Hdpe Pipes PDFM.Sreeram Sanjay100% (1)

- Lee Et Al (2007) PDFДокумент11 страницLee Et Al (2007) PDFMarco F. GallegosОценок пока нет

- Finite Element (FE) Shear Modeling of Woven Fabric Textile CompositeДокумент7 страницFinite Element (FE) Shear Modeling of Woven Fabric Textile Compositeranim najibОценок пока нет

- Dasco Linear Bargrilles&RegistersДокумент28 страницDasco Linear Bargrilles&Registersblue airОценок пока нет

- Flow of Real FluidДокумент52 страницыFlow of Real FluidADIL BAHОценок пока нет

- Formula 6-P: Technical Data SheetДокумент1 страницаFormula 6-P: Technical Data SheetBernardo HoffmannОценок пока нет

- Etag004 Fg004 Etics Fin2Документ87 страницEtag004 Fg004 Etics Fin2Serban RaduОценок пока нет

- Showroom Interior QuotationДокумент1 страницаShowroom Interior QuotationAngith Menon (Avi)0% (1)

- Non Return ValvesДокумент10 страницNon Return ValvesDevendra Bangar100% (1)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyОт EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansРейтинг: 4.5 из 5 звезд4.5/5 (21)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)От EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Оценок пока нет

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОт EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОценок пока нет

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeОт EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeРейтинг: 4.5 из 5 звезд4.5/5 (59)

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownОт EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownОценок пока нет

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetОт EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Structural Cross Sections: Analysis and DesignОт EverandStructural Cross Sections: Analysis and DesignРейтинг: 4.5 из 5 звезд4.5/5 (19)

- Geotechnical Engineering Calculations and Rules of ThumbОт EverandGeotechnical Engineering Calculations and Rules of ThumbРейтинг: 4 из 5 звезд4/5 (17)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesОт EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesОценок пока нет

- Rock Fracture and Blasting: Theory and ApplicationsОт EverandRock Fracture and Blasting: Theory and ApplicationsРейтинг: 5 из 5 звезд5/5 (2)

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementОт EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementОценок пока нет