Академический Документы

Профессиональный Документы

Культура Документы

Condensate Recovery System - Technical Guide

Загружено:

pptmnltОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Condensate Recovery System - Technical Guide

Загружено:

pptmnltАвторское право:

Доступные форматы

Technical Guide

Condensate Recovery System

Steam Traps are essentially valves which differentiate between steam and condensate. They open to discharge condensate, but do not allow steam to escape. A steam trap has three important functions: To remove the condensate formed either within the steam pipework or within the process equipment. To prevent large amounts of steam escaping. To enable any air and other gases in the system to escape.

Figure 2. Ball Float Steam Trap

What is it?

(Image courtesy of Amarinth)

Dearation Tank

Condensate Recovery Systems are specifically designed equipment to recover condensate from steam installations in order to maximise their overall energy efficiency. Condensate Recovery Systems considered to include the following: equipment are

Condensate Recovery Vessels These are designed to handle hot condensate, which is commonly returned for use as boiler feedwater. Steam Traps Are devices which allow the discharge of condensate without the release of steam from steam lines in a steam and condensate system. Deaeration Tanks Remove oxygen and other dissolved gasses from steam boiler feedwater to reduce corrosion and improve efficiency in the steam system.

(Image courtesy of Spirax Sarco)

In a Deaeration Tank boiler feedwater is trickled down over perforated plates, low pressure steam is passed upwards to strip off oxygen and other dissolved gasses. The steam and gas rise to the top of the tank and are then vented to atmosphere. In another type of deaeration tank low pressure steam is injected into the stored feedwater again the steam and gas rise to the top of the tank and are then vented to atmosphere. Depending on the size of the installation the deaeration tank also acts as the feedwater storage tank.

Figure 3. Dearation Tank

Steam Trap

(Image courtesy of Spirax Sarco)

How does it work?

A Condensate Recovery Unit is a Figure 1. Condensate Recovery Unit vessel which receives condensate from all practical points in a process plant or heating system where condensate is produced. The vessel stores the condensate and mixes it with fresh make up water prior to it being used as boiler feedwater.

(Image courtesy of Spirax Sarco) (mage courtesy of Spirax Sarco)

What are the energy saving benefits?

Installing energy efficient technologies on an existing standard steam and condensate installation is a means of improving boiler performance without having to replace the entire steam boiler or system. Typical Energy savings for each of the technologies are listed below: Condensate Recovery Vessels 6 8% reduction in fuel costs Typical payback periods 1 - 4 years Reduced carbon emissions b) c) d)

be passed through a heat exchanger to recover heat energy. Steam Traps a) It is essential to select the correct size and type of trap for both starting and normal operating loads. It is particularly important to size the trap to accommodate the increased condensate capacity at start-up, an incorrectly sized trap may not operate correctly and start-up times are likely to increase. Trap sizing is based upon - normal operational load - (kg/h of condensate) - start-up load - (kg/h of condensate) - Condensate temperature (max/min) - Steam Pressure (max/min) - Back pressure the trap must operate against Consult a reputable manufacturer for specific design and installation information. All types of steam trap fail if they are not properly maintained or protected. The best method for ensuring correct trap operation and efficiency is a planned preventative maintenance programme. Failure monitoring of steam traps notifies user when a steam trap has failed.

Steam Traps 2-3% reduction in fuel costs Typical payback periods 2 - 4 years Shorter start-up times Reduced carbon emissions

Deaeration Tanks 1-2% reduction in fuel costs Typical payback periods 4 - 6 years Reduced risk of corrosion failures Reduced water treatment costs Reduced carbon emissions

e)

Deaeration Tanks a) b) c) Sufficient space has to be available within or near to the boiler house to accommodate the deaeration tank. Deaeration must be used in conjunction with other water treatment measures. Monitoring of the water condition must be carried out regularly, automatically or by sampling.

Issues to consider when choosing a Condensate Recovery System: Condensate Recovery Vessels a) Where very long pipe runs would be required to return condensate to the boiler house, condensate recovery may not be viable in energy terms. Even where long pipe runs make energy recovery uneconomic condensate recovery may still be viable when the water treatment costs and water replacement costs are taken into account. If the condensate can be contaminated by contact with process materials it can cause fouling of the heat transfer surface in the boiler. In such circumstances the condensate should

Wilton Park House, Wilton Place, Dublin 2 Teach Phirc Wilton, Pls Wilton, Baile tha Claith 2

b)

c)

Energy efficient Localised Steam Generator Systems are eligible for the ACA (Accelerated Capital Allowance) and included on the Triple E product register. More information can be found at www.seai.ie/Your_Business/ Triple_E_Product_Register/

T. +353 1 808 2100 F. +353 1 808 2002

info@seai.ie www.seai.ie

The Sutainable Energy Authority of Ireland is partly nanced by Irelands EU Structural Funds Programme co-funded by the Irish Government and the European Union.

Вам также может понравиться

- Direct Condensation of Hydrocarbon VaporsДокумент10 страницDirect Condensation of Hydrocarbon VaporsManju Lata Kapur100% (1)

- Steam - IV TranscriptДокумент12 страницSteam - IV TranscriptirwanОценок пока нет

- Boiler Feed PumpДокумент32 страницыBoiler Feed PumpAli Bari100% (1)

- Module 2 - Boilers - Steam SystemДокумент29 страницModule 2 - Boilers - Steam Systemmadan karkiОценок пока нет

- Energy Solutions Heat RecoveryДокумент4 страницыEnergy Solutions Heat RecoveryyaserbadrОценок пока нет

- Steam and Condensate SystemsДокумент29 страницSteam and Condensate Systemsareeb078Оценок пока нет

- Deaerators in Industrial Steam Systems: Additional BenefitsДокумент5 страницDeaerators in Industrial Steam Systems: Additional BenefitsNaОценок пока нет

- HVAC Chapters 1 5Документ57 страницHVAC Chapters 1 5Mcilwaine Dela CruzОценок пока нет

- Condensate Recovery White PaperДокумент20 страницCondensate Recovery White PaperJustin Gentry100% (1)

- Energy Efficiency in Steam Systems - CHE - Facts - 0409Документ1 страницаEnergy Efficiency in Steam Systems - CHE - Facts - 0409John UrdanetaОценок пока нет

- Mep August 2022Документ12 страницMep August 2022Subham SamantarayОценок пока нет

- Ehandbook Strategize Your Steam SystemДокумент18 страницEhandbook Strategize Your Steam SystemMPham100% (1)

- Don't Send Money Down The Drain: Steam ManagementДокумент3 страницыDon't Send Money Down The Drain: Steam ManagementAnonymous lqsJIe6l5Оценок пока нет

- Ehandbook Strategize Your Steam SystemДокумент18 страницEhandbook Strategize Your Steam Systemoritas100% (1)

- Energy Engineering (15ME71) : Module 2: Diesel Engine Power System, Hydro Electric EnergyДокумент32 страницыEnergy Engineering (15ME71) : Module 2: Diesel Engine Power System, Hydro Electric EnergyChirayu JanamattiОценок пока нет

- Evaluating Deaerator OperationДокумент5 страницEvaluating Deaerator OperationYanuar KrisnahadiОценок пока нет

- Heat Economy in Textile MillsДокумент6 страницHeat Economy in Textile MillsshariqfareedОценок пока нет

- Energy Savings From Steam Losses On An Oil RefineryДокумент11 страницEnergy Savings From Steam Losses On An Oil RefineryidigitiОценок пока нет

- Air Cooled CondensersДокумент6 страницAir Cooled CondensersruchiajmerОценок пока нет

- Clayton Heat Recovery4 PDFДокумент6 страницClayton Heat Recovery4 PDFAdriánMuñozLópezОценок пока нет

- 3 4Документ32 страницы3 4cheesewizzОценок пока нет

- Preheater Lores PDFДокумент8 страницPreheater Lores PDFamjed_de_enimОценок пока нет

- Checklists & Tips For Energy Efficiency in Thermal UtilitiesДокумент3 страницыChecklists & Tips For Energy Efficiency in Thermal UtilitiesEjaz AhmedОценок пока нет

- Optimizing Pressure Relief SystemsДокумент6 страницOptimizing Pressure Relief SystemssgrsthОценок пока нет

- All Types of Waste IncineratorsДокумент12 страницAll Types of Waste IncineratorsNiyati Mihir PatelОценок пока нет

- Steam DistillationДокумент3 страницыSteam DistillationkhanasifalamОценок пока нет

- Drum Dryer Heat Transfer Heat RecoveryДокумент3 страницыDrum Dryer Heat Transfer Heat RecoveryRajendra GuptaОценок пока нет

- Engineering Manual - Industrial BoilersДокумент32 страницыEngineering Manual - Industrial BoilersYoussry Elsayed MohamedОценок пока нет

- Power Plant EngineeringДокумент54 страницыPower Plant Engineeringoiswaryanag2000Оценок пока нет

- A Report of Training in ONGCДокумент52 страницыA Report of Training in ONGCtarunbnsl81% (16)

- Objective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutДокумент5 страницObjective:-Identify The Routine Maintenance Parts of The Coal Fired Thermal Power Plant LayoutSuraj KumarОценок пока нет

- The Low-Carbon Steam Plant Room BrochureДокумент8 страницThe Low-Carbon Steam Plant Room BrochureFernando CeballosОценок пока нет

- Steam Boiler Feedwater Storage Technology White PaperДокумент16 страницSteam Boiler Feedwater Storage Technology White PaperchristiancandidoОценок пока нет

- Steam Systems II TranscriptДокумент14 страницSteam Systems II TranscriptirwanОценок пока нет

- A Report of Training ONGCДокумент33 страницыA Report of Training ONGCmohan_17Оценок пока нет

- I3 Steam Systems 16 20Документ5 страницI3 Steam Systems 16 20qayoom5629Оценок пока нет

- Reliance - Flare Gas Recovery IMPДокумент6 страницReliance - Flare Gas Recovery IMPsvnaik14Оценок пока нет

- Diverter Damper Systems - BrochureДокумент8 страницDiverter Damper Systems - Brochuregionizz100% (1)

- Thermal Energy ManagementДокумент8 страницThermal Energy ManagementlucasОценок пока нет

- Clayton Heat RecoveryДокумент6 страницClayton Heat RecoveryJenniferValleОценок пока нет

- Design Guide 13: "Use Available Data To Lower System Cost"Документ12 страницDesign Guide 13: "Use Available Data To Lower System Cost"EjubОценок пока нет

- Condensate Recovery Pump: Recovering Maximum Possible EnergyДокумент4 страницыCondensate Recovery Pump: Recovering Maximum Possible EnergySupport, SP Tech SolutionsОценок пока нет

- Analysis of The Fccu Emissions SourcesДокумент4 страницыAnalysis of The Fccu Emissions SourcesMarcelo Varejão CasarinОценок пока нет

- Sabardairy Training ReportДокумент18 страницSabardairy Training ReportniravОценок пока нет

- Organic Rankine Cycles: IIT BombayДокумент19 страницOrganic Rankine Cycles: IIT BombayShubham PunjabiОценок пока нет

- Components of Coal-Fired Steam Power PlantДокумент5 страницComponents of Coal-Fired Steam Power PlantDanBenedictAcuzarОценок пока нет

- Lesson 4 - Industrial Steam v3Документ85 страницLesson 4 - Industrial Steam v3JHON LHOYD CORPUZОценок пока нет

- Boiler - FinalДокумент73 страницыBoiler - FinalMohit GauttamОценок пока нет

- Chapter 2.3: Steam System: Part-I: Objective Type Questions and AnswersДокумент7 страницChapter 2.3: Steam System: Part-I: Objective Type Questions and Answersmaran2786Оценок пока нет

- Heat Recovery Steam Generators: Capability BrochureДокумент20 страницHeat Recovery Steam Generators: Capability BrochureMartin Olowe100% (1)

- Methanol TechnologyДокумент8 страницMethanol TechnologybltzkrigОценок пока нет

- Steam System Spirax SarcoДокумент12 страницSteam System Spirax Sarcoashwinmoi100% (1)

- Ministory of Education: West Yangon Technological University Department of Mechanical EngineeringДокумент23 страницыMinistory of Education: West Yangon Technological University Department of Mechanical EngineeringThaungShanHtet PalatarОценок пока нет

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingОт EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingРейтинг: 5 из 5 звезд5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОт EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitОценок пока нет

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryОт EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryОценок пока нет

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"От EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Оценок пока нет

- Key Note Address: Organised byДокумент4 страницыKey Note Address: Organised bySarang BondeОценок пока нет

- Speech On World Environment Day in A SocietyДокумент6 страницSpeech On World Environment Day in A SocietySarang BondeОценок пока нет

- Steam System Audit: Vandana.Y Gajjar1, Omkar G.Ghodke, Krishna KumarДокумент3 страницыSteam System Audit: Vandana.Y Gajjar1, Omkar G.Ghodke, Krishna KumarSarang BondeОценок пока нет

- Curriculum Viate: S/O MalleswararaoДокумент4 страницыCurriculum Viate: S/O MalleswararaoSarang BondeОценок пока нет

- Writing The Effective Resume: The First Step Toward Landing Your Next JobДокумент32 страницыWriting The Effective Resume: The First Step Toward Landing Your Next JobSarang BondeОценок пока нет

- Partex Denims LTD.: Operation & Maintenance ManualДокумент43 страницыPartex Denims LTD.: Operation & Maintenance ManualSarang BondeОценок пока нет

- Aluminium SulphateДокумент21 страницаAluminium SulphateSarang BondeОценок пока нет

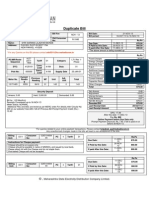

- Duplicate Bill: For Any Queries On This Bill Please Contact Sdo0311@ho - Mahadiscom.inДокумент1 страницаDuplicate Bill: For Any Queries On This Bill Please Contact Sdo0311@ho - Mahadiscom.inSarang BondeОценок пока нет