Академический Документы

Профессиональный Документы

Культура Документы

Turbine and Accessories

Загружено:

pavankumar001Исходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Turbine and Accessories

Загружено:

pavankumar001Авторское право:

Доступные форматы

2.

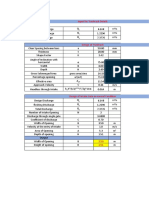

TURBINE AND ACCESSORIES 36.68** 3 UNITS VALUE m /sec

3

2.1 Guaranteed technical particulars Water discharge at rated turbine output ITEM DESIGNATION 3.0 1 1.1 3.1 1.2 3.2 3.2.1 1.3 1.4 General

REMARKS In new condition

Maximum leakage through wicket gate at m /sec Manufacturer maximum static head of head of 186 m Place of Manufacturer Efficiency Turbine efficiency , discharge & gate opening at rated net head of 176.47 m and Type/designation rated speed -at 110 % continuous rated output Applicable Standard -at 100 % continuous rated output -at 75 % continuous rated output -at 50 % continuous rated output Main Data Turbine rated output at rated net of Weighted average efficiency (as head per the 176.47 m, Technical within 90% guide vane opening Particular Specifications) and at rated speed Turbine efficiency, discharge & gate head Maximum continuous output at rated opening at maximum net head of 182.20 of 176.47m 186 m and rated speed Best efficiency output at rated head -at 110 % continuous rated output 176.47m -at 100 % continuous rated output Output atcontinuous Min net head of output 173.80 m & at -at 75 % rated rated speed -at 50 % continuous rated output Output at Max net head of 182.20 186.0 m Turbine efficiency, & at rated speed discharge & gate opening at minimum net head of 173.80 m Speed and rated speed Specific Speed Rated Speed Critical speed for combined turbine & generator Maximum (VH Comment -stationary) rpm Runway speed at rated net head of 176.47 m Direction of rotation (viewed from top) % % % % % kW kW % kW % % kW % kW

~ 0.33 Voith Hydro India, Germany Brazil Vetical Shaft Francis 96.11** Please see 96.37** Technical description 94.4** of Turbine 89.21** 95.23 60914 67005 61433 96.38** 96.09** 65283 93.87** 88.14** 67005

2 3.2.2 2.1 2.2 3.2.3 2.3 2.4 2.5 3.2.4 2.6 a. b. c. 2.7

RpmkW-m rpm

127.89 333.33 >700 545

at rated output and rated head.

Section 2 Sheet 1

2.8

CW

-at 110 % continuous rated output maximum gate opening

96.14**

-at 100 % continuous rated output -at 75 % continuous rated output -at 50 % continuous rated output 3.3 Speed rise at rated net head of 176.47 m caused by load rejection from

% % %

96.34** 94.51** 89.52**

Maximum gate opening referred to 110% rated output corresponding to rated net head of 176.47 m

Section 2 Sheet 2

3.3.1 3.10 3.3.2 3.10.1 3.3.3 3.3.4 3.3.5 3.10.2 3.4 3.11 3.5 3.11.1 3.6 3.11.2 3.7 3.7.1 3.11.3 3.7.2 3.8 3.11.4 3.9 3.11.5 3.9.1 3.9.2 3.11.6 3.9.3 3.9.4

Maximum temperature rise of guide 110% full load to zero ( VH Comment bearing above cooling medium, -simultaneous closure of both machines) measured by embedded temperature Full load to zero detectors at maximum 75% full loadcontinuous to zero rated operation 50% full load to zero

% % C % %

50.6 < 50.6 <45 < 50.6 < 50.6 < 50.6 <50 Considering cooling medium temp of 25 C

at most unfavorable operating conditions as 25% full load to zero % C specified Maximum water hammer overpressure when all the 2 units at 110% full load % simultaneously rejecting load Hydraulic Flow velocity in Turbine : 3 (For Q = 37.67 m /sec) Cavitation guarantee based on 24 months kg or 8000 hrs of operation 3 At Inlet to Scroll Casing m /sec Maximum noise level at any place at dB(A) distance of 1 m Maximum guide bearing temperature In Runner (In m/sec)operating range of under permissible turbine Metal temperature Absolute at inlet Oil temperature Losses in the bearing at rated operating Peripheral conditionsat inlet Capability of guide bearing to withstand Relative at inlet at runaway speed with cooling water at rated speed without cooling water Absolute at outlet at runaway speed without cooling water at stresses resulting from operation of unit with three adjacent guide vanes in closed position

Considering cooling 30% of medium temp maximum of 25 C static head 2.7 For Runner

To be informed ~95 during detail engg To be informed during detail engg <70 At rated speed m/sec To be C informed <65 At rated speed during C detail engg ~6 m/sec To be kW informed during detail engg m/sec To be 30 informed Min during detail 30 engg Min m/sec To be 15 informed Min during during detail engg Yes/No detailed engg.

Section 2 Sheet 3

3.11.7

Peripheral at outlet

m/sec

3.11.8

Relative at outlet

m/sec

To be informed during detail engg To be informed during detail engg To be informed during detail engg To be informed during detail engg To be informed during detail engg

3.11.9

Draft Tube

3.11.10 Velocity of water at liner end

3.11.11 Velocity of water at exit

3.12 3.12.1

Material standard / Class / Grade / Type Runner ASTM A 743 CA 6 NM/Equi. n.a. ASTM A 743 CA 6 NM/Equi. ASTM A 743 CA 6 NM/Equi. ASTM A 743 CA 6 NM/Equi. integral

3.12.2 3.12.3

Runner cone Rotating labyrinth (upper) and (lower)

3.12.4

Fixed labyrinth (upper) and (lower) Guide vanes

3.12.5

Section 2 Sheet 4

3.12.6

Lining of head cover

ASTM A 240 304 L/Equi. ASTM A 240 304L/Equi. n.a

3.12.7

Lining of bottom ring

3.12.8

Discharge ring cladding / Lining

3.12.9

Bottom ring

E250B IS 2062/Equi E250B IS 2062/Equi ASTM A 240 304 L/Equi. E250B IS 2062/Equi. DIN EN 10250-2 S355/Equi. E250B IS 2062/Equi. DIN EN 10250, C35E /Grade D ASTM A 668 EN 10083, 42CrMo4/E qui ASTM A 240 304 L/Equi. HGW 2082 Mo/Equi

3.12.10 Head cover 3.12.11 Discharge ring

3.12.12 Draft tube cone 3.12.13 Spiral casing 3.12.14 Stay ring 3.12.15 Turbine shaft

3.12.16 Coupling bolts

3.12.17 Shaft seal sleeve/liner 3.12.18 Shaft seal

Section 2 Sheet 5

3.12.19 Guide bearing lining

Babbitt Tego V 840/Equi E250B IS 2062/Equi Servomotor of Reputed make ASTM A 106/Equi. CuproNickel

3.12.20 Guide bearing housing 3.12.21 Guide vane servomotor body, piston and rings

3.12.22 Pressure pipes 3.12.23 Cooler tubes 2.2. ITEM 1 1.1 1.2 1.3 Informative data DESIGNATION General Manufacturer Place of manufacture Applicable standards

UNITS VALUE Voith Hydro India, Germany Brazil Please see Technical description of Turbine During detail Engg 2645 2122 ~46 15

REMARKS

2 2.1 2.2 2.3 2.4 2.5

Turbine Runner Inner inlet diameter Outer inlet diameter Discharge diameter Peripheral velocity Number of blades mm mm mm m/s Nos.

Referes to inlet edge of blade

Corresponds to outer inlet dia

Section 2 Sheet 6

2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 3 3.1 3.2 3.3 3.4

Method of fabrication Runner inlet height Total height Height of runner above C/L of distributor Depth of runner below C/L of distributor Weight Preventive coating against hydro abrasion Transport Dimensions(lxbxh) Turbine Shaft Shaft diameter Internal bore dia Length Critical speed of Turbine mm mm mm rpm m mm mm mm mm kg

Cast welded During detail Engg During detail Engg During detail Engg During detail Engg ~10000 Optional (Hard + Soft) ~2.7x2.7x1.3

600 150 ~3400 Refere 2.6 c above. Critical speed is always calc for whole power unit.

3.5

Type of coupling with generator Turbine shaft and turbine runner Flange diameter No. and diameter of flange bolts Type of bolts Weight Main Shaft Seal

Type

During detailed engg ~1100 During detailed engg. Low Alloy Steel 8

3.6 3.7 3.8 3.9 4

mm No. /mm Tonnes

Section 2 Sheet 7

4.1

Type of gland and location

n.a.

Refer turbine technical description for sealing principle of Hydro static shaft seal

4.2 4.3 4.4

Cooling water flow rate Cooling water pressure Material of Gland seal

Lpm Mpa

~60 0.2 to 0.3 n.a. Refer turbine technical description for sealing principle. During detailed engg. Phynolic rasine seal ring creates sealing surface against SS liner on shaft.

4.5

Provision of Instrumentation

Spiral Casing Method of fabrication Welded mm Nos. 2200 4 to 5 Excluding stay ring

5.1 5.2 5.3

Internal diameter of inlet Number of prefabricated sections of spiral casing Main dimensions(as per IS 12800 Part-1) -A -B -C -D -E -F

mm mm mm mm mm mm

2200 ~ 2986 ~3499 ~3847 ~2946 During detail Engg

Section 2 Sheet 8

-G -H Plate thickness 5.4 5.5 5.6 5.7 5.8 5.9 Maximum design working pressure Test pressure Total weight of spiral casing Weight of heaviest section No of Packages for transport Method of embedded scroll casing in concrete Nos. of joints to be welded at site and total joint length Quantity of electrode for the site welding, specifications & make Stay Ring Method of fabrication

mm mm mm bars bars Tonnes Tonnes

During detail Engg During detail Engg During detail Engg 25.3 38.0 ~15 ~6 4 to 5 During detailed engg. During detailed engg. During detailed engg. Welded or Cast welded Excluding stay ring

5.10

5.11 6 6.1

6.2 6.3 6.4 6.5 6.6

Outer diameter Inner diameter Height Number of stay vanes PCD of stay vanes

mm mm mm Nos. Nos.

~4250 ~3400 ~470 26 n.a. Height of stay vanes

Section 2 Sheet 9

6.7

Number of sections

Nos.

Finalization during detailed engg after final root survey

6.8 6.9 6.10 7 7.1 7.2 7.3 7.4

Maximum design working pressure Test pressure Weight per section Head Cover Outer diameter Inner diameter Height Number of sections

bars bars kg

25.3 38.0 14000

mm mm mm Nos.

~3600 ~1200 ~600 1 Finalization during detailed engg after final root survey

7.5 7.6 7.7 8 8.1 8.2 8.3 8.4

Weight per section Method of Removal Means of drainage of leakage water from head cover Bottom Ring Outer diameter Inner diameter Height Number of sections

kg

~11000 Top removal Yes

mm mm mm Nos.

~3600 ~2200 ~650 1 Finalization during detailed engg after final root survey

8.5

Weight per section

kg

~5000

Section 2 Sheet 10

Discharge Ring

Discharge ring is being understood as a SS part of draft tube cone. mm mm mm Nos. kg ~2600 ~2150 ~600 1 ~800

9.1 9.2 9.3 9.4 9.5 10 10.1 10.2 10.3 10.4 10.5 10.6 11 11.1 11.2 11.3 11.4 11.5 11.6 11.7

Outer diameter Inner diameter Height Number of sections Weight per section Turbine pit liner Inside diameter Minimum plate thickness Elevation of highest point Elevation of lowest point No. of section Weight of fully assembled liner Guide Bearing Type Number of pads (in case of segmented type) Running clearance Diameter Height Distance from reference level to guide bearing centerline No. of coolers

mm mm m m

3650 10 792.88 788.86 2

kg

~4500

Tilting pad Nos. mm mm mm mm Nos 8 ~0.1 600 160 ~1300

Height of bearing pad Reference level being c/l of distributor

Section 2 Sheet 11

11.8

Maximum safe working pressure

bars

During detailed engg. ~25 ~4 kW

11.9 11.10 11.11 11.12 12 12.1

Cooling water requirement Losses in the bearing at rated operating condition Oil specification grade and make Capacity of bearing oil reservoir Guide Vanes PCDxHtxWt of each

Lpm

ISO VG46 ~100

mmxkg

2965x465x3 Ht=feather 65 height Wt=feather width 26 ~180

12.2 12.3 13 13.1 13.2 13.3 13.4 13.5 13.6 13.7 13.8

Number of guide vanes Weight per guide vane Guide Vanes Operating Mechanism Type of servomotor Number of servomotors Full stroke Active volume Maximum operating pressure Minimum operating pressure Provision for servomotor lock provided Weight of servomotor

No. kg

Nos. mm cm

3

Double acting 2 200 3530+2650 = 6180 120 80 Yes During detailed engg. Manual

bars bars Yes/No kg

14 14.1 14.2

Guide Vane Servo Motors Nos.xbore dia m x full stroke length mm Normal working pressure Kg/cm

2

2x150x200 80-120

Section 2 Sheet 12

Section 2 Sheet 13

14.3

Rating of capacity Material of servo motor body, piston rings Draft Tube Diameter of draft tube elbow top Length of draft tube elbow Height of Draft tube at exit Width of draft tube at exit Elevation of lowest point (Datum) Length of draft tube exit from unit centre line Draft Tube Cone Height Top diameter Bottom diameter Weight of the draft tube cone (removable) Centralized grease lubrication system Capacity and rating of equipment Type and make of pump Rating of pump Capacity of grease reservoir Provision of Manual operated pump Unit Dewatering Connection Penstock gravity dewatering valve, type x size x material pressure rating x location Draft tube dewatering valve type x size x material x pressure rating x location No of Valve

Kg m

During detailed engg. During detailed engg

14.4 15 15.1 15.2 15.3 15.4 15.5 15.6 16 16.1 16.2 16.3 16.4 17 17.1 17.2 17.3 17.4 17.5 18 18.1 18.2 18.3

mm mm mm mm m m

~2800 10800 4000 5150 779.17 18.485 Steel liner from unit c/l

m mm mm kgs

~3.6 ~2100 2800 3500 N/A

Upper cone + lower cone ID ID

kW Litres Yes/No

During detailed engg. During detailed engg. During detailed engg.

Section 2 Sheet 14

18.4 18.5 18.5.1

Scroll casing dewatering valve, type x size x material x pressure rating x location Size of piping for dewatering Penstock

During detailed engg. During detailed engg. During detailed engg. During detailed engg. Reputed make Reputed make Reputed make Reputed make Reputed make Reputed make Reputed make

18.5.2

Scroll casing

18.5.3

Draft tube

19 19.1 19.2 19.3 19.4

Make and Type of Pressure Gauge Pressure Transducer Turbine discharge flow-meter Flow meter for Shaft Seal

19.5 19.6 19.7 20 20.1

Dial type thermometer Resistance temperature detector Moisture detector Dimensions Maximum diameter, length and designation of turbine part to be removed through generator stator bore. mm

3600, head cover/ distributor

Section 2 Sheet 15

20.2

Maximum transportation dimension (L x W X H) and designation of turbine part to be transported Minimum distance between centerlines of adjacent units Recommended setting elevation Maximum Upward/Downward Hydraulic axial thrust Pressure fluctuations (% of rated head) spiral case inlet

mm x mm x mm

4300x 3250 x 3500, Stayring 14000 788.5 825

If transported in single piece.

20.3 20.4 21 22 22.1

mm m KN

1.3

Within continuous operating range

22.2

draft tube cone (after runner)

3.5

Within continuous operating range

22.3 23 23.1 23.2 23.3 23.4 24 24.1 24.1.1 24.1.2

draft tube outlet Transient behavior Guide vanes opening time Guide vanes closing time Maximum Pressure rise Maximum Speed rise Characteristic Data Maximum steady state runaway speed at following head at maximum net head of 182.20 186 m at rated net head of 176.47 m

n.a

s s % %

~ 15 ~ 11 See 3.4 See 3.3.1

rpm rpm

560 545

Section 2 Sheet 16

24.1.3 24.1.4

at Minimum net head of 173.80 m Vibration amplitude at the shaft

rpm microns (peak to peak)

540.5 Less than line B-C, ISO 79195 36.68** 40.46** 23.05** 3.99**

24.2 24.2.1 24.2.2 24.2.3 24.2.4 24.3 24.3.1

(Expected)Turbine water discharge at Rated output at rated net head Maximum output at rated net head Maximum runaway condition at maximum net head No-load at rated net head Time of guide vane opening for increasing load from zero to Full gate output / Rated load / 75% / 50% / 25% rated load sec ~ 15 sec for full gate ouptut/Dur ing detail engg m /sec m /sec m /sec m /sec

3 3 3 3

24.4 24.4.1

Time of guide vane closure for decreasing load to zero from Full gate output / Rated load / 75% / 50% / 25% rated load sec ~ 11 sec from full gate ouptut/Dur ing detail engg

Section 2 Sheet 17

24.5

(Expected)Guide vane opening at rated speed for no-load condition at rated head of 176.47 m Rated output at net head of 176.47 m Maximum gate output at net head of 176.47 m % % % 10.48** 90.4** 100** Maximum gate opening referred to 110% rated output corresponding to rated net head of 176.47 m

24.5.1 24.5.2 24.5.3

24.6

Time taken to reach runaway speed from normal speed in case of failure of governing system Total load on thrust bearing generated from turbine From turbine rotating parts From maximum downward hydraulic thrust From maximum upward hydraulic thrust

sec.

During detail engg.

24.7 24.7.1 24.7.2 24.7.3

kN kN kN

~176 ~825 During detailed engg ~825 During load rejection J value J value Relief pipes considered.

24.8 24.9 24.10 24.11

Maximum unbalanced hydraulic thrust during worst operating condition (specify condition also) Fly wheel effect of turbine rotating parts Fly wheel effect required from the generator Specific speed of unit at rated net head of 176.47 m with 100% guide vane opening

kN kg m kg m

2

~ 5000 423000 134.14

Rpm kW-m

Section 2 Sheet 18

24.12

Critical speed of turbine

rpm

Refere 2.6 c above.

24.13 24.13.1

Weights Weight and designation of heaviest part or assembly of the turbine as prepared for shipment Heaviest turbine assembly to be handled by powerhouse crane during installation Heaviest embedded part for erection to be handled by EOT Crane Recommended additional spare parts List hereunder the spare parts which are recommended by the Contractor for purchase in addition to the specified spare parts. The purchase of any or all of the recommended spare parts will be at the option of Employer. The prices for recommended additional spare parts for five (5) years shall therefore not be included in the bid prices. kg 14000, Stay ring If transported in single piece.

30000 kg

24.13.2

Distributor assembly

24.13.3 2.3.

Kg

ITEM 1. 2. 3. 4. 5. 6. 7. 8. 9. 10.

DESCRIPTION

UNIT

PRICE/ UNIT

Section 2 Sheet 19

11. 12. 13. 14. 15. 16. Note: Use additional sheet, if required ** Single point efficiencies, corresponding guide vane openings and discharge values are for information purpose only. However mean weighted efficiency(Hydraulic) is guaranteed. Water temperature of 23 degree C is considered for efficiency calculation. 2.4. Information to be supplied together with the bid At least the information listed hereunder shall be given by the Bidder. The Bidder may submit additional documents /descriptions to describe special technical features of offered equipments / system: 1 Computation pressure rise at turbine inlet under the most unfavorable conditions (load acceptance and rejection) as requested in Technical specification. Conditions considered as well as governor acting times to be clearly indicated in the computations.

Reply :Refer attached Transient calculations report 2 Computation turbine speed rise under conditions as above and for following load rejection parameters. From 110 % rated output to zero Reply :Refer attached Transient calculations report From100 % rated output to zero From 75 % rated output to zero From 50 % rated output to zero From 25 % rated output to zero Reply : During detail engg 3 Expected flow characteristics during closing and opening of guide vanes as

Section 2 Sheet 20

function of time. Reply : During detail engg. 4 Expected performance curves for the maximum, rated and minimum net heads. The curves shall also show the overload output at maximum possible guide vane opening extending beyond the guarantee points.

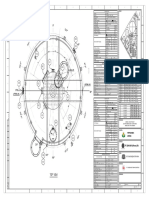

Reply : Find attached prototype hill curve. 5 Dimensional drawing (cross section) of turbine and associated equipment showing main dimensions. Reply :During detail engg. Refer power house cross section drawing no. 2734510225 for overall dimension. 6 Describe proposed shaft seal systems, preferably illustrated by schematic diagram. Reply : Refer Turbine Technical Description 7 Applicable methods and types of vibration monitoring system. Reply : During detail engg 8 Provide information on model or field performance tests performed on a turbine which is hydraulically similar to the proposed turbine. Indicate at least the following: Reply: Xi Luo du(China) Place of model or field tests : Lausanne + Heidenheim Year of model or field tests : 2008 Designed rated turbine output : 784 MW Rated net head : 197 m Rated speed : 125 rpm Efficiency achieved : Yes 9 Calculation sheet for dimensions of turbine, generator and power house. Reply : Refer power house layout drawings. Calculation sheet of various heads like, rated net head, maximum net head and minimum net head. Reply : Net heads are already provided by employer. The same has been used. 10

Section 2 Sheet 21

Вам также может понравиться

- Annexure 9.7 - Head Loss in Water Conductor SystemДокумент2 страницыAnnexure 9.7 - Head Loss in Water Conductor SystemKshitij ThakurОценок пока нет

- Water HammerДокумент3 страницыWater HammerSrinivas ReddyОценок пока нет

- Design of Intake, Orifice&CanalДокумент1 страницаDesign of Intake, Orifice&CanalHutendra SilwalОценок пока нет

- Salient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Документ3 страницыSalient Features of Lower Ankhu Khola Hydropower Project (Lakhep)Bidur GautamОценок пока нет

- Actividad3 2Документ8 страницActividad3 2Darleen Ariana Serruto AlarconОценок пока нет

- Salient Features CombinedДокумент4 страницыSalient Features CombinedkrishbistОценок пока нет

- Energy CalculationДокумент4 страницыEnergy CalculationRanjan ParajuliОценок пока нет

- Project Location: Diversion StructureДокумент5 страницProject Location: Diversion Structureelec310Оценок пока нет

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018Документ3 страницыReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018unconformistОценок пока нет

- Design of Outlets - JaboriДокумент7 страницDesign of Outlets - JaboriHaji Ahmad BhattiОценок пока нет

- Contoh Desain SaluranДокумент2 страницыContoh Desain Saluranghost46Оценок пока нет

- Bab Iv Hasil Pengamatan Dan PerhitunganДокумент9 страницBab Iv Hasil Pengamatan Dan PerhitunganAhmad NurilОценок пока нет

- Dykewall CalculationДокумент4 страницыDykewall CalculationVipul GandhiОценок пока нет

- Jumdi S HEP HM 12FEB13Документ32 страницыJumdi S HEP HM 12FEB13modest_dhuОценок пока нет

- VOCATOMAДокумент4 страницыVOCATOMAErick GTОценок пока нет

- Gerwia Dam Lay Out PointsДокумент36 страницGerwia Dam Lay Out PointsahmedОценок пока нет

- Economic Diameter CalДокумент28 страницEconomic Diameter CaldsdeshpandeОценок пока нет

- RE - BOQ of Chilli IIДокумент17 страницRE - BOQ of Chilli IIAnonymous AV90SAXa5VОценок пока нет

- (EDITED-FINAL) Sludge - Storage CalculationДокумент16 страниц(EDITED-FINAL) Sludge - Storage CalculationAmro Ahmad AliОценок пока нет

- Paddle FlocculatorsДокумент12 страницPaddle FlocculatorsBinyam KebedeОценок пока нет

- Recovery PhosphateДокумент4 страницыRecovery PhosphateYuni HapsariОценок пока нет

- Pressure Loss - SwitchyardДокумент1 страницаPressure Loss - Switchyardkarthikraja21Оценок пока нет

- Reinforced Line Canal Project CostДокумент4 страницыReinforced Line Canal Project CostJoefel BessatОценок пока нет

- TrapezoidДокумент11 страницTrapezoidPrisoner SparrowОценок пока нет

- Flow Trajectory at End of Spillway (At Bottom)Документ5 страницFlow Trajectory at End of Spillway (At Bottom)Dinesh SharmaОценок пока нет

- Lodhama-II Design CivilДокумент68 страницLodhama-II Design Civilnira365Оценок пока нет

- Bandhu Rs.3694 CrsДокумент12 страницBandhu Rs.3694 Crsnira365Оценок пока нет

- CO2 Condenser 02-03-2023-15 PMДокумент37 страницCO2 Condenser 02-03-2023-15 PMahmad santosoОценок пока нет

- Hydraulic Level Calculations For Revised Layout Dated March 8, 2013.Документ10 страницHydraulic Level Calculations For Revised Layout Dated March 8, 2013.SEPC Anta100% (1)

- Zero Water DischargeДокумент5 страницZero Water Dischargehemendra499Оценок пока нет

- Headloss FormulaДокумент2 страницыHeadloss FormulaDenBagoesОценок пока нет

- Brushbond TGPДокумент2 страницыBrushbond TGPBalasubramanian AnanthОценок пока нет

- Line Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsДокумент2 страницыLine Sizing Single Phase Fluid Flow: Chemical Engineering CalculationsRawlinson TolentinoОценок пока нет

- Industrial VillageДокумент35 страницIndustrial VillageRajani jirelОценок пока нет

- Pumpstation Input DataДокумент31 страницаPumpstation Input DataTahirJabbarОценок пока нет

- Hyd - Cal. WTP BaggiДокумент27 страницHyd - Cal. WTP BaggiChief Engineer PMUОценок пока нет

- M S Pipe Weight CalculationДокумент3 страницыM S Pipe Weight CalculationArun NandaОценок пока нет

- SurgeДокумент3 страницыSurgeSrinivas ReddyОценок пока нет

- Pipe Network Analysis: Chemical Engineer's GuideДокумент12 страницPipe Network Analysis: Chemical Engineer's GuideRio BuiОценок пока нет

- Intake DesignДокумент3 страницыIntake Designyam adhikariОценок пока нет

- Input For Trashrack Details: M /s M /s M /sДокумент2 страницыInput For Trashrack Details: M /s M /s M /sPRAVEEN CHAUDHARYОценок пока нет

- Final Bop TDДокумент79 страницFinal Bop TDsuleman247Оценок пока нет

- Data Solution: C F L DДокумент27 страницData Solution: C F L DJMVОценок пока нет

- Partially Full Pipe Flow Calculations - S.I. Units: Workbook ContentsДокумент29 страницPartially Full Pipe Flow Calculations - S.I. Units: Workbook ContentsdiegoОценок пока нет

- Boat & Adit Tunnel Comparision at TailraceДокумент4 страницыBoat & Adit Tunnel Comparision at Tailracepawan paudelОценок пока нет

- Istaru-Booni Hydropower Project (72 MW) : Calculation Sheet Rev:0 Contract:Feasibilty Study ofДокумент3 страницыIstaru-Booni Hydropower Project (72 MW) : Calculation Sheet Rev:0 Contract:Feasibilty Study ofguildkeyОценок пока нет

- Salient Features of Super Ankhu Khola Hydropower ProjectДокумент4 страницыSalient Features of Super Ankhu Khola Hydropower ProjectSarojkumar PoudelОценок пока нет

- Design of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Документ20 страницDesign of Anchor Block 4 (As Per Penstock L Section Drawing No. Lodhama-II/Civil/GA/3/Rev-1)Souvik DasОценок пока нет

- Hydraulic Design o F Feeder ChanelДокумент1 страницаHydraulic Design o F Feeder ChanelbalashardaОценок пока нет

- Conical Tank Design For OSCARДокумент2 страницыConical Tank Design For OSCARArie Emmanuel ListonОценок пока нет

- ALL - Purpose - Worksheet (Conversions)Документ28 страницALL - Purpose - Worksheet (Conversions)Mokr AchourОценок пока нет

- Basic Control Valve Sizing and SelectionДокумент38 страницBasic Control Valve Sizing and SelectionmohamedОценок пока нет

- Degasifier 18-02-2017 Sheet 1Документ1 страницаDegasifier 18-02-2017 Sheet 1Abu SuraisyОценок пока нет

- Design of Pro. WTP (6.8 MLD) For BasavkalyanДокумент27 страницDesign of Pro. WTP (6.8 MLD) For BasavkalyanPradeep Kumar SharmaОценок пока нет

- Design of PumpДокумент4 страницыDesign of PumpTajamul HussainОценок пока нет

- Hydraulic CalculationsДокумент16 страницHydraulic CalculationsForam ParekhОценок пока нет

- Exhaust System CalculationДокумент2 страницыExhaust System CalculationZa YonОценок пока нет

- Screening Equipments TrainingДокумент74 страницыScreening Equipments TrainingSindhuja RaghunathanОценок пока нет

- Technical Data Sheets - TurbineДокумент19 страницTechnical Data Sheets - Turbinepavankumar001Оценок пока нет

- Alak - MIV 1500 WeightДокумент1 страницаAlak - MIV 1500 Weightpavankumar001Оценок пока нет

- MIV Technical Data SheetДокумент3 страницыMIV Technical Data Sheetpavankumar001Оценок пока нет

- 4 MivДокумент19 страниц4 Mivpavankumar001Оценок пока нет

- Alak Description Pelton TurbineДокумент12 страницAlak Description Pelton Turbinepavankumar001Оценок пока нет

- DIBN TFV00 0000 PRS Technical Description TurbineДокумент21 страницаDIBN TFV00 0000 PRS Technical Description Turbinepavankumar001Оценок пока нет

- DIBN HC BR SR TransportationДокумент4 страницыDIBN HC BR SR Transportationpavankumar001Оценок пока нет

- Dibn Tfv00 0000 Bom Turbine RevДокумент15 страницDibn Tfv00 0000 Bom Turbine Revpavankumar001Оценок пока нет

- MIV Seal Area For CoatingДокумент2 страницыMIV Seal Area For Coatingpavankumar001Оценок пока нет

- BJHL TFV00 0000 PRS Turbine Technical DescriptionДокумент23 страницыBJHL TFV00 0000 PRS Turbine Technical Descriptionpavankumar001Оценок пока нет

- Technical Data Sheets - TurbineДокумент19 страницTechnical Data Sheets - Turbinepavankumar001Оценок пока нет

- NAFR-TFV00-0000-TR Technical Description MIV Spherical ValveДокумент10 страницNAFR-TFV00-0000-TR Technical Description MIV Spherical Valvepavankumar001100% (1)

- NAFRA Guaranteed Technical Perticulars Spherical ValveДокумент8 страницNAFRA Guaranteed Technical Perticulars Spherical Valvepavankumar001Оценок пока нет

- Spherical Valve Technical DescriptionДокумент12 страницSpherical Valve Technical Descriptionpavankumar001100% (6)

- 3-Digital Governor GTP SainjДокумент5 страниц3-Digital Governor GTP Sainjpavankumar001Оценок пока нет

- 8 Penstock BFV and AccessoriesДокумент6 страниц8 Penstock BFV and Accessoriespavankumar001Оценок пока нет

- 4 Main Inlet ValveДокумент6 страниц4 Main Inlet Valvepavankumar001Оценок пока нет

- Equipment and System Dehydrating, Charging, and Testing: Related Commercial ResourcesДокумент7 страницEquipment and System Dehydrating, Charging, and Testing: Related Commercial Resourcesalialavi2Оценок пока нет

- Activity Sheets For Chem With NamesДокумент6 страницActivity Sheets For Chem With Namesapi-283862617100% (1)

- SSG Manual: Dow Performance SiliconesДокумент59 страницSSG Manual: Dow Performance SiliconesAditya KОценок пока нет

- Pile Capacity PrecastДокумент38 страницPile Capacity Precastbasum matОценок пока нет

- Nidek GYC-1000 Photocoagulator - Technical TrainingДокумент85 страницNidek GYC-1000 Photocoagulator - Technical TrainingAngela RoblesОценок пока нет

- wch13 01 Que 20220524Документ16 страницwch13 01 Que 20220524vintu pvОценок пока нет

- IGCSE Biology: Practice CORMS QuestionsДокумент12 страницIGCSE Biology: Practice CORMS QuestionsDaniel Conway63% (8)

- Animikh Ray ResumeДокумент4 страницыAnimikh Ray ResumeAnimikh RayОценок пока нет

- SN1 V SN2 (Nucleophilic Substitution Again) (A2)Документ3 страницыSN1 V SN2 (Nucleophilic Substitution Again) (A2)Kevin The Chemistry TutorОценок пока нет

- Food ProcessingДокумент52 страницыFood ProcessingAtanacia IlaganОценок пока нет

- Aluminium Sheet Grade 65032 SuppliersДокумент17 страницAluminium Sheet Grade 65032 Supplierssanghvi overseas incОценок пока нет

- CronogramaДокумент101 страницаCronogramaeddyronaldycОценок пока нет

- Class 6 NSO Sample Paper (2017-18)Документ2 страницыClass 6 NSO Sample Paper (2017-18)ZaraОценок пока нет

- Magic Cleaner - FroniusДокумент4 страницыMagic Cleaner - FroniusKristy DavisОценок пока нет

- Cebu City Department of ChemistryДокумент7 страницCebu City Department of ChemistryGeorgette RepunteОценок пока нет

- ColaTeric CBSДокумент1 страницаColaTeric CBSmndmattОценок пока нет

- Semiconductor ElectronicsДокумент46 страницSemiconductor Electronicspraveen2910Оценок пока нет

- Masterfill™ 300: Semi - Flexible Epoxy Joint SealantДокумент2 страницыMasterfill™ 300: Semi - Flexible Epoxy Joint SealantDoby YuniardiОценок пока нет

- Rheology of Drilling MudДокумент20 страницRheology of Drilling MudAnonymous bFVPpQjwj0% (1)

- Presentation On Modern Trends in PackagingДокумент24 страницыPresentation On Modern Trends in PackagingBhupendra Singh100% (1)

- VukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedДокумент19 страницVukcevicEtAl GhostFluidMethodInPolyhedralFV AnnotatedputhenkulamОценок пока нет

- Tutorial On Scale UpДокумент18 страницTutorial On Scale Uphafizi naim IsmailОценок пока нет

- IntegralДокумент4 страницыIntegralprasenjitsayantanОценок пока нет

- 03 FIRE BOOST Aftertreatment UsersGuideДокумент318 страниц03 FIRE BOOST Aftertreatment UsersGuidehenevil0% (1)

- 10 ST Chapter 01Документ12 страниц10 ST Chapter 01Amit TripathiОценок пока нет

- Phast ManualДокумент122 страницыPhast ManualMojtabaОценок пока нет

- Demulsification Kinetics of W/O Emulsion in An A.C. Electric FieldДокумент7 страницDemulsification Kinetics of W/O Emulsion in An A.C. Electric FieldajostosОценок пока нет

- Netzash BrochureДокумент24 страницыNetzash BrochureYasin GençОценок пока нет

- B.SC Physiscs 5th 6th SemДокумент24 страницыB.SC Physiscs 5th 6th SemYashaswiniОценок пока нет