Академический Документы

Профессиональный Документы

Культура Документы

SPE 89394 Improve Injection Profile by Combining Plugging Agent Treatment and Acid Stimulation

Загружено:

msmsoftОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SPE 89394 Improve Injection Profile by Combining Plugging Agent Treatment and Acid Stimulation

Загружено:

msmsoftАвторское право:

Доступные форматы

SPE 89394 Improve Injection Profile by Combining Plugging Agent Treatment and Acid Stimulation

Puchun Zhao, Huating Zhao, Zhongyuan Petroleum Exploration Bureau, SINOPEC, Baojun Bai, SPE, New Mexico Institute of Mining and Technology, Xinming Yang, Zhongyuan Petroleum Exploration Bureau, SINOPEC

Copyright 2004, Society of Petroleum Engineers Inc. This paper was prepared for presentation at the 2004 SPE/DOE Fourteenth Symposium on Improved Oil Recovery held in Tulsa, Oklahoma, U.S.A., 17-21 April 2004. This paper was selected for presentation by an SPE Program Committee following review of information contained in a proposal submitted by the author(s). Contents of the paper, as presented, have not been reviewed by the Society of Petroleum Engineers and are subject to correction by the author(s). The material, as presented, does not necessarily reflect any position of the Society of Petroleum Engineers, its officers, or members. Papers presented at SPE meetings are subject to publication review by Editorial Committees of the Society of Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper for commercial purposes without the written consent of the Society of Petroleum Engineers is prohibited. Permission to reproduce in print is restricted to a proposal of not more than 300 words; illustrations may not be copied. The proposal must contain conspicuous acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P. O. Box 833836, Richardson, TX 75083-3836, U.S.A. fax 01-972-952-9435.

Introduction Statistics suggests that, in water flooding reservoirs, the water-entering thickness is only one third of the perforated height[1]. The injection profile is extremely inhomogeneous because of the intensity of water flooding and the existence of initial permeability contrast. At present, plugging agent treatment and acid stimulation are the main ways to improve injection profile[2-3]. Plugging agent treatment is to start-up the zones with low and medium permeability by shutting off the high permeability zones, but it can't directly increase the starting pressure of the former. On the contrary, during the plugging operation, damage occurs do the low and medium permeable zones since the plugging operation pressure is usually higher than regular injecting pressure[4]. Although acid stimulation can improve the water receptivity of low and medium permeability zone, part of the acid acts with high permeability zone and makes the water receptivity of high permeability zone become much more stronger[5]. So, injection profile improvement is not ideal by either of the two techniques mentioned above. A process, which can block high permeability zones while reducing the starting pressure of low and medium permeability zones, is needed urgently.

Abstract Plugging agent treatment and acid stimulation has completely different mechanisms for improving injection profiles. In this paper, a hybrid procedure is introduced to reduce the damage of plugging agent to low and medium permeability zones and the penetration radius of acid into high permeability zones. The procedure is: first inject plugging agent to block high permeability zones, and then inject acid to remove plugging agent damage from the low and medium permeability zones and stimulate them. For performing this procedure successfully, three kinds of plugging agents were screened out for using in different reservoirs: Strong strength plugging agent for the wells with fractures or high permeability streaks; Weak gel for those with thick layer in which serious heterogeneity exists; Temporary plugging agent for those in which the absorption ability of high permeability zones needs maintaining. Several acid systems were evaluated to be compatible with the three kinds of plugging agents. The objectives of this paper are: (1) To show the screen results about the compatible plugging agent and acid; (2) To show how to optimize the operation process; (3) To tell some experiences learnt from the oilfield applications of this technique. From Jan. 2001 to Dec. 2002, 46 operations using this procedure were carried out in Weicheng and Mazhai Oilfields of SINOPEC. Results show that the average benefit/cost ratio is over 3.5. Experience learnt from these applications was summarized in the paper.

Theory The following described process is a combination of plugging agent treatment and acid stimulation. First, it is to reduce the permeability of high permeable zone by using profile control method for increasing the starting pressure and reducing the relative water absorption of the high permeability zones. At the same time, the starting pressure of the target well becomes higher than before, making the well ready for preventing acid from acting with the high permeability zones. Then better the low and medium permeability zone by acid stimulation, which removes the plugging agent damage from the low permeable zones and increases the water receptivity the low permeable zones. The input profile is improved greatly and pressure difference among zones is reduced strongly by this hybrid procedure. The technological process is displayed in Figure-1.

www.petroman.ir

SPE 89394

In Figure-1, PL , PM and PH indicate the starting pressure of three sorts of zones; and QL, QM and QH indicate relative water absorption. The starting pressure of high permeability zone is increased and the relative water absorption becomes lower after plugging agent treatment. For the low and medium permeability zone, the starting pressure is dropped and water absorption becomes higher after acid stimulation. In one word, the starting pressure difference is reduced and the injection profile tends to be more homogeneous. Three advanced characteristics of this technique are clearly shown in Figure-1. The first one is that the water intake of high permeability zone is controlled but increased for low and medium permeability zone, improving the injection profile greatly. The second is that the process is continuous, there is no residual acid drain and easy to operate. The last one is that there is little change of injection pressure after the acid stimulation, which gives no additional burden to the surface equipment.

Research on Proper Plugging Agents and Acids for the Hybrid Procedure In accordance with the state of injection profile and the permeability contrast among reservoirs and target wells, strong strength plugging agent, weak gel and temporary plugging agent were screened out by laboratory tests. BL-D Strong Strength Plugging Agent. This kind of plugging agent is selected to block zones with macropores. It consists of particle fly ash, modified resin, oil well cement, polyacrylamide (PAM), dispersant and so on. Modified resin which is oil-soluble and melted in the formation is used to enhance the adhesion of the plugging agent. Polyacrylamide has shielding action to acid. The dispersant with water wettability aids the other components to dispel in water easily. Particularly it is helpful for the plugging agent entering the pores. Particle fly ash can strengthen the acid-resistance and the blocking strength of the plugging agent. The oil well cement and the particle fly ash are the main component of the plugging agent. Curing time: Initial and final setting time and final strength of the BL-D plugging agent of 30% were tested under different temperatures. The test results are showed in Table 1. The test data show that there is a long initial setting time that can meet the need of long time injection, and the strong strength gives a better efficiency to block the high permeability zones. Acid resistance. Two pieces of cured plugging agent which have the same shape and size were used in this test . One of them was kept in the multiple acid for thirty minutes, then flushed by water, dried in an oven at 80 . A comparison of mass and compression strength between the samples before and after acid immersion was made. The average values of three groups of such test are displayed in Table 2.

Weak gel. To meet the need of blocking high and medium permeability zones, weak gel is selected as its property is between gel and polymer solution. It contains little polymer and possesses better heat and divalent ion resistance. The main component of the weak gel is sodium-based bentonite and HPAM. It can migrate in the formation and enhance the water sweeping volume by changing water flowing direction . Blocking mechanism. Two blocking mechanisms of floc unit and accumulated film were found in the tests. Floc unit blocking. When sodium-based bentonite meets with HPAM solution, bridging forms between the hydrophilic group of HPAM and the hydroxide radical of the bentonite by hydrogen bond. In this process, bigger floc unit shapes, which blocks the high permeability zone. The process is shown in Figure 2. Accumulated film blocking. As the mixture of bentonite and HPAM is injected into the target well, firstly the hydroxide radical on the surface of sand combines with HPAM by hydrogen bond, and then the hydrophilic group of HPAM combines with the surface hydroxide radical of bentonite by hydrogen bond. This process occurs repeatedly in macropores. So, an accumulated bentonite film bridged by HPAM forms on the surface of macropores and reduces its permeability. Laboratory evaluation. Tests were carried out on porous pressure measuring flow installation. Determination of the entering and retaining diameter of clay grains. In order to increase the treatment radius, it is necessary to know the entering and retaining diameter of clay grains, which is the dimension that the clay grain can enter into the pores and can't be flushed out of it. The connection of the permeability reduction percentage and the ratio of pore and grain diameters is described in Figure 3. The curve shows that the greatest permeability reduction is achieved as the ratio of pore and grain diameters reaches six, which indicates that the clay has a good blocking effectiveness. On the assumption of a 50% permeability reduction, a good blocking effectiveness can be gotten when the ratio is between three and nine. This curve gives a method how to select formations that are suitable and/or optimum for using clay as its plugging agent. Mercury injection and tracer tests indicate that secondary pores with an average diameter from 20 to 200m may exist in maturing formation. Therefore, clay with proper grain diameter should be selected to obtain the best improvement of injection profile. Test in porous pressure measuring flow installation. Test results are displayed in Table 3 and two conclusions can be obtained from Table 3. a) Dual solution plugging is better than single one on the condition of the same injection sequence. b) Multiple stage injection is better than single one. According to the test results, the determined formula of weak gel is 5~7% sodium-based bentonite + isolating water (about 1~2 m3) + 0.06% ~ 0.1% HPAM . Generally, dual solutions are injected in 10~20 stages.

www.petroman.ir

SPE 89394

Temporary plugging agent. The grained temporary plugging agent of watersoluble is screened out for plugging low and medium permeability zones. Its breaking time can be controlled from 24 to 36 hours on the conditions of 90 and the film thickness is within the range of 0.2~0.4m. Under a temperature range of 100~120 its breaking time can be equal or over 16 hours and the film thickness is over 0.5 m . The property of the temporary plugging agent is shown in Table 4. Core test. Two groups of parallel cores are used in the test and the Experimental procedures are performed as follows: (1) Inject temporary plugging agent into the paralleled high and low and medium permeability cores under a high pressure, record the injection volume separately and test the permeability changes in the two cores. (2) Inject temporary plugging agent into the paralleled high and low and medium permeability cores under a low pressure, record the injection volume separately and test the permeability changes in the two cores. (3) Wait the temporary plugging agent to break; and (4) Test the permeability changes of the high and low and medium permeability cores. The results of the test is summarized in Table 5. By 80% permeability of the cores is reduced after injecting the temporary plugging agent. However, the permeability of low permeable zones is increased to 94% after plugging agent breakdown. Dissolution property. Put samples of the temporary plugging agent of the same weight separately into the injected water and the acid of the same volume, results shown in Table 6 indicate that the dissolution time in the former is 5 hours, but no dissolution occurred in the latter. Strength. A sandpack of 25mm 150mm was prepared and saturated with 5% NH4Cl. Then injected the 5% NH4Cl into the sandpack at a constant flow rate till the pressure became stable. Then 0.4 PV of 15% temporary plugging agent was injected. After that, 0.1PV of acid and 0.4PV of 5% NH4Cl were injected successively. See Figure 4 for the results. From Figure 4 it can be seen that the pressure increases clearly during the injection of the temporary plugging agent. The pressure is stabilized at 4.3MPa after the injection of acid. A filter cake with a thickness of 2 mm was found on the injection end of the sandpack. Property of the unblocking acid. Acid stimulation is an important method for removing the damage from near wellbore area in sand reservoirs. But the regular inorganic acid will lead to a secondary precipitation of ferro hydroxide and give damage to the formation once more. The treatment radius and the valid period are limited. The acidic system selected for the combination technology is composed of 1-15% hydrochloric acid (HCl) + 1-15% hydrofluoric acid(HF) + 1-15% mixture of gelled acid (PAC851), multiple inorganic acid and surfactant + 1-15% mixture of micelle acid (JS841) , impurity alcohol

acid ,ethane and inorganic acid + 0.01-5% clay stabilizer (NH4Cl) + 0.01-5% corrosion inhibitor of the compound of quinoline quaternary ammonium salts + 0.01~5% ferric ion stabilizer of the phosphate compound and 25-95.97% water . The system possesses the characteristics of longer treatment radius, more effective ferric ion stabilization and a remarkable effect of acid stimulations. Compatibility with formation water. Separately mix the multiple acidic system in different proportions with the formation water from 9 oilfields, such as Weicheng, Pucheng, Wennan, Wenliu and so on. Then keep the mixtures in a constant temperature cabinet set at 90 for 24 hours to check any precipitation. The result of no precipitation is shown in Table 7. It indicates that the acidic system selected has a good compatibility with the formation water. Antiswelling property of the acid. First soak the core samples with the mixtures of formation water and the multiple acidic system in different proportions. Then keep the mixtures with core samples in a constant temperature cabinet set at 80 for 24 hours. Then measure the volume changes of the cores and make a comparison with the volume changing results of the cores soaked with 3% KCl. The test results are displayed in Table 8. A conclusion can be drawn from Table 8 that the swelling ratio of all cores in different mixtures are less than 105% whether the core sample is loose or tight, which is within the range of non-swelling. So, the multiple acid can prevent plugging agent from swelling to failure. Corrosion rate. In order to reduce the corrosion to injection equipment, surface and subsurface pip, the acidic system must be better in anticorrosion. Its static corrosion inhibiting rate to N80 Steel sheet is over 98% under the conditions of 90 and barometric pressure. A corrosion rate of 3.1 g/m2 per hour is measured, which is less than the standard (10 g/ m2 per hour). It can be seen that the acidic system selected has a better corrosion inhibiting performance and can penetrate into low and medium permeability zones and remove the contaminants from deep reservoir. Thermostability. Heated the acid to 90 and held for 4 hours. The color of the multiple acid has no obvious change and there is no flocculus, precipitation and laying, and no difference in interfacial tension and corrosivity. Simulation tests on sandpacks. Sandpacks of 25mm 150mm was prepared and saturated with 5% NH4Cl solution. Then inject the 5% NH4Cl solution into the sandpacks at a constant flow rate until the injecting pressure become stable. Then separately inject BL-D strong strength plugging agent, weak gel and temporary plugging agent into different sandpacks. The multiple acid is injected into each sandpack after plugging, and finally, the 5% NH4Cl. The experimental data are presented in Table 9. It shows that different plugging agents have different blocking capacities and the multiple acid has the effect of unblocking, especially in the case of sandpack blocked by temporary plugging agent.

www.petroman.ir

SPE 89394

After the acid stimulation, the permeability reduction of the sandpacks treated with weak gel and temporary plugging agent is due to the harden reaction of the acid with each of the plugging agent. After the injection of the 5% NH4Cl solution, there is almost no further change in the permeability of the sandpacks treated with strong strength and weak gels, but a big change in the permeability of the sandpack treated with temporary plugging agent. It is because of the water-soluble property of the temporary plugging agent, which leads to the dissolution of the temporary plugging agent and the permeability restoration of the sandpack.

The max. operating pressure can be calculated by the empirical formula in equation (2) if no recent injection profile data or a poor injection profile can be based on for an optimum injection pressure. Then the max. injection rate can be determined by equation (1). Pmax=Pinjection (2)

Acid injection pressure is decided by the starting pressure shown on the injectivity index curve. Try to raise the acid injection pressure above the starting pressure of low and medium permeability zone, for it is good for acid to enter low permeable zones and the zones contaminated by plugging agent. Volumes of blocking agent & multiple acid. The volume of plugging agent can be calculated by equation (3) and the volume of multiple acid can be gained from equation (4). Qplugging agent =hr2hh Qacid =lr2hl (3) (4)

Operational Procedure Selection of the candidates. Whereas the dual functions of plugging and acidization of the combination technique mentioned in this paper, and on the basis of the analysis in lab and field tests, the criteria of selecting a candidate well can be described as follows: a) With a wide permeability contrast in vertical, extremely uneven injection profile and a zone or zones with a relative water absorption of more than 30%. b) With a great reduction in absorbing height or in the number of water intaking layers, in comparison with the best injection profile in history, i.e. with a serious contamination. And the absorption height of the well is less than 1/3 of the perforated height. c) With zones not actuated before or of poor water absorption, which are interconnected with producing wells. d) With good wellbore conditions of no casing failure and channeling. Operating pressure. Optimizing the injection pressure and rate can reduce the damage to and increase the acid stimulation effectiveness of low and medium permeability zones. Currently, the widely used max. operating pressure is 70 to 80% of the formation breakdown pressure. But this pressure may probably actuate all the perforated zones and lead to a contamination of plugging agent to low and medium permeability zones. For solving this problem, operating pressure and injection rate can be determined as below. a) Make a comparison of the injection profiles under different injecting pressures, determine the injection pressure and rate according to the starting pressures of the target and nontarget zones. b) Calculate the rate under the highest operating pressure according to the injectivity index curve of the target well. q max=(Q2-Q1)/(P2-P1)P max c) 1

Operating tool string. Usually a simple pumping string is satisfactory in the performance of the combination technique. But when wells are found with wide permeability contrast in vertical and the thickness of a gap zone can meet the need of setting a packer, a multi-zone separating pumping string, as shown in Figure 5, will be used for performing this technique. Operating sequence. After any of the strong strength plugging agent, weak gel and temporary plugging agent is selected in accordance with the conditions and requirements of target well, all of them can be employed if macropores, high and medium permeability zones existing in the same target well. Their blocking strength is determined by the conditions of injection profile. But the pumping sequence of plugging agents should be from the strong to the weak, to guarantee the need of various shutting off. According to the injection sequence, the operation process can be classified into two kinds. One is to plug first and then acid stimulation; the other is the combination of acid stimulation, plugging and acid stimulation again. Generally, the former injection sequence is preferred. The latter one is mainly used in the wells with the following conditions. a) Of high injection pressure, leading to a too high injection pressure to guarantee a smooth operation. b) Serious contamination existing in the near wellbore area by water injection or by job operation.

Application Forty-six operations using the combination technique are carried out on 41 injectors in Weicheng and Mazhai Oilfields of SINOPEC. There is no failure in the 46 operations and the effectiveness reaches to 100%. Totally 11,623 m3 plugging

Determine the operation equipment on the basis of the calculated operation rate.

www.petroman.ir

SPE 89394

agent 2,936 m3 multiple acid were injected; 118 layers of high permeability with a total thickness of 178.9 m were blocked. 179 formations of low and medium permeability with a total thickness of 342.7 m were stimulated by acid. The highest operating pressure is 21.4 MPa, the average starting and stop pressures are 15.5MPa and 18.8 MPa respectively. Table 10 presents the classified operations. Geologic background of the reservoirs. The third Production Company of Zhongyuan Petroleum Exploration Bureau of SINOPEC administrates two small oilfields named Weicheng and Mazhai. The whole anticipated recovery is 36.25%. By the end of 2001, the composite water cut and the rate of oil production of the two oilfields are 83.12% and 1. 21%, while the geologic and industrial recovery is 26.66% and 73.34% respectively. All the two oilfields have reached the high water-cut decline stage. Weicheng Oilfield. It is a transoid mono-anticline controlled by east and west fracture belts of Weicheng. The cutting of many subfaults forms multi small blocks. The anticipated recovery is 34.92%. The reservoir depth is 1500~3100 m, containing oil bearings in all the sections from the first to the forth. Reservoir temperature is 67~116 , and the salinity is 3.17~8.5210-4 mg/l. According to the geological features, Weicheng Oilfield is sorted into shallow and deep reservoirs. The shallow reservoir contains formations from the first to the third middle section. Its depth is 1500~2500 m and the anticipated recovery is 28.9%. It has three characteristics, firstly, its oil-bearing series is simple with an average effective thickness of 7.2 m; secondly the formation physical properties are sound, but with serious heterogeneity and a permeability contrast of more than 15. The third one is its poor crude properties , with a viscosity of more than 100 mPa s and a surface density of 0.9042g/cm3 The pay zones of deep reservoir are spaced from the third down to the forth section, with a depth range of 2,700~3,000 m and the anticipated recovery is 37.18%. It has four main geological features, the first one is its low and medium permeability which is less than 50 10-3m 2, particularly in W81 block of the forth section that has a permeability of only 11.910-3m 2, with a great change in sand body, serious heterogeneity and a permeability contrast of 0.67~0.89. Secondly there are gas caps existing in the reservoir. The third one is the big stratigraphic dip, which is over 25 for the main pay zones. The last one is the high salinity of 28.310-4 mg/l on the average. Mazhai Oilfield. It is a horst block controlled by two faults trending to northeast with opposite dip directions. Its anticipated recovery is 36.06%, reservoir temperature is 60~83. The formation water salinity is 3.17~8.5210-4 mg/l . It covers the two blocks named W95 and W305. The former is a shallow reservoir, the latter is a deep reservoir. The depth of W95 is 1,770 m with an effective zone thickness of 23 m. It is a medium porosity and low and medium permeability reservoir with an average porosity of 20.35% and a permeability of 71.410-3m2. In horizontal,

the sand body changes greatly and presents a finger interdistribution. In W95 block, the permeability variation coefficient is 0.67 and interlayer permeability contrast is over 20, with the reservoir characteristic of better from south to north. In the block of W305, the pay zones distribute from the middle third to the forth sand section with a depth of 2500 ~ 2900 m. The permeability of the third and forth sand sections are 38~41.210-3m 2 and 3.9 10-3m 2 respectively. The two oilfields are different in porosity, permeability and saturation. But they have the same reservoir characteristics of serious heterogeneity. So, to improve injection profile should be a effective way for enhancing water flooding efficiency. Effectiveness of water injection. The average injection pressure of the treated wells increased from 7.2 to 9.3 MPa, and the average starting pressure increased from 6.6 to 9.4 MPa. The average water absorption of each well increased from 50 m3 to 55 m3 per day , and the average valid period was 176 days. The average PI of the 46wells increased from 5.2 MPa to 7.6 MPa[7], and the injectivity index increased 1 m3/MPa per day. The water injection effectiveness is presented in Table 11. Improvement of injection profile. Comparative injection profile data of thirteen wells indicated that the thickness of water absorption increased from 74.4 m to 118.3 m, the number of water absorption zones increased from 42 to 62, and another 32 new zones with a thickness of 61.6 m were developed. The average thickness of high permeability zone with a relative water absorption of more than 30% reduced from 3.2 m to 1.9 m, and the average thickness of low and medium permeability zone with a relative water absorption of less than 10% increased from 5.2 m to 6.7 m, as shown in Table 12. It can be seen in Table 12 that the number of zones shut off by a single plugging agent treatment is increased by 4 zones with a totalized thickness of 6.4 m, by compared with the number of zones newly started up. The number of the total intake zones is decreased by 3 layers with a total thickness of 9.6 m. After a single acid treatment, the thickness of intake layers is 8 m out of 2 zones. However, the intake profile plot shows that some of the strong water intaking zones are not controlled effectively. The water intake profile of 13 wells can be compared after the combination treatment of plugging and acidization, with an average thickness of 4.7 m per well newly started and an increase of water intaking zones by 3.4 m out of 1.4 zones. The changes in water absorption of Well W22-39 in Weicheng oilfield before and after the three different treatments are shown in Figure 6. After the single plugging agent treatment in March, 1998, the strong absorbing zone with a relative water absorption of 82.8% was blocked and did not absorb water again, which led to a reduction in water absorbing height by 5.6 m of one zone. The total water absorbing thickness increased by 9.4 m of 4 zones after the acid stimulation in May, 1999. However, a zone

www.petroman.ir

SPE 89394

with a thickness of 2 m was stimulated by the acid, which was blocked in March, 1998. and the water absorption of strong water absorbing zones was still higher than the others. Six new zones with a total thickness of 12.5 m were actuated by the combination treatments in Feb. 2001. The highest and lowest relative water absorption was 19.3% and 2.2% respectively with a difference of only 8.8. Results of producing wells. 79 producing wells interconnect with the 41 injectors treated by the combination technique, of which 68 producing wells presented responses in production rate increase. The effectiveness of the producing wells is 86%. By the time of Dec., 2002, the total increment of oil production obtained by the combination technique is 10,519 tons, and the average effective period is 143 days. The 229 tons of oil increment per group of wells is 47 and 84 tons higher than that of the wells treated by single plugging agent treatment and single acid stimulation, separately. Table 13 summarizes the effectiveness of the wells responding to the injectors treated by different operation procedures. By the time the paper is presented, 39 producing wells are still actively responding the combination treatments, with an oil increase of 47.8 t per day and a daily water reduction of 121 m3. Economic Analysis The total cost of the 46 operations which includes material and operating expenses is 328.2104 (RMB), from which a total increase of 40,480 m3 water injection with a benefit of 40.48104 (RMB) has been achieved. A total increase of 10,519 tons oil rate is gained with a benefit of 1,100.3 104 (RMB). A benefit of 7.87104 (RMB) is obtained from the reduction of water production. The total benefit /cost ratio is 3.5.

Multiple acid can remove the damage caused by plugging agent from low and medium permeability and non-target zones. Field operations suggest that the hybrid procedure can give a better injection profile improvement and a better oil increase in responding wells, by comparison to that from each of the single plugging and acidization procedure.

Nomenclature correction factor, which depends on permeability contrast and water absorbing thickness and so on. Generally, it is 1.1-1.5. volume of plugging agent, m3 volume of multiple acid, m3 porosity of high permeable zones or zones to be blocked, % porosity of low and medium permeability zones penetration radius, m (1.0-1.5 m for acid resistance plugging agent, 2.0-5.0 m for weak gel and 0.5 m for temporary plugging agent ) thickness of the zones to be blocked, m thickness of zones to be acid stimulated, m pressure index pore volume

Qplugging agent Qacid h l r

hh hl PI PV

References

Xiange Liu, et at.: Translation Collection of Field Profile Control through Plugging, Petroleum Industry Press, Beijing, 1995. 2. Editorial Committee of Technical Papers on Block Profile Control through Plugging: Symposium on Bock Profile Control through Plugging, Petroleum Industry Press, Beijing, 1994. 3. Xiange Liu, et al.: Performance and Results of Field Water Plugging, Journal of Oil Drilling and Production Technology(Oct. 1898). 4. Xigane Liu, Yuxiang Li: A Summary of China Oilfield Water Plugging Technology, Oilfield Chemistry(Sept. 1992). 5. Development and Production Bureau of CNPC: Monograph of Profile Control for Stabilizing Oil Production, Petroleum Industry Press, Beijing, 1995. 6. Puchun Zhao, et al.: Study and Application of Diverting and Profile Control Agent, Oil & Gas Recovery Technology (April, 2000)56. 7. Yikun Li, et al.: Study and Application of PI Tests in Cores, Fault-Block Oil & Gas Field (May 1996)53. 1.

Discussion and conclusion The hybrid procedure mentioned in this paper is a combination of plugging and acid stimulation. It remedies the defects of each of the single process and it can improve injection profile greatly. Three kinds of plugging agents are selected for different reservoir conditions. They are: a) Strong strength plugging agent for the wells with fractures or high permeability streaks; b) Weak gel for those with thick layer in which serious heterogeneity exists; and c) Temporary plugging agent for those in which the absorption ability of high permeability zones needs maintaining.

www.petroman.ir

SPE 89394

Table 1 - Curing property of BL-D strong strength plugging agent

Temperature 25 60 80 95 Initial setting* h 48 24 16 16 Final setting* h 96 32 28 28 Final strength** Mpa 10 15 16 16

* Initial setting means the setting time when the hand of strength tester can enter the sample of the plugging agent, but cant get through to its bottom; final setting is the time when the hand of strength tester cant break into the cured sample. **The strength of cured plugging agent is calculated from the weight divided by the cross sectional area of the testers hand.

Table 2 - Acid Resistance of Cured BL-D Plugging Agent

Change of quality (g) Before test After test Difference 178.6 169.7 8.9 Compression strength (MPa) Before test After test Difference 8.3 7.1 1.2

Table 3 Plugging Results of 10% Sodium-based Bentonite (A) and 400 mg/L HPAM(B)

Single solution Method 20gA Initial Permeability (m ) Permeability after 10 PV plugging agent (m2) Permeability Reduction percentage (%)

2

Dual solution 10gA+10gB 601.5 264.0 56.1 10gA+10gB 622.9 272.7 56.2 5gB+5gA+5gB+5gA 656.4 174.8 73.4

20gB 612.7 608.7 0.7

601.5 446.5 25.8

Table 4 - Property of water soluble temporary plugging agent

Grain Items Technical index Remarks appearance Red and brown liquid Density 1.05-1.1 (g/cm3) pH value diameter 5-7 100-10000 (m) content >20% >72h >36h 90-120 >98% Solid Melting time Water solubility

Change with Ambient porosity temperature

www.petroman.ir

SPE 89394

Table 5 - Property evaluation data of water soluble temporary plugging agent

Core group Initial permeability to water (10-3m2) 684 1 102 426 2 98 19 18 26 6 7.8 9 Porosity (%) 28 6 6.4 12.2 18 85 3 0 95 High injecting pressure (MPa) Plugging agent into cores (ml) 13.6 Permeability after plugging (10-3m2) 116 3 0.1 20 96 45 Low injecting pressure (MPa) Plugging agent into cores (ml) 19.9 Permeability after gel breakdown (10-3m2) 64

Table 6 - Dissolution property of temporary plugging agent

Media Injected water Multiple acid Solubility (%) 95 15

Table 7 - Compatibility test of multiple acidic system with formation water

Formation water : multiple acid Results 0:5 Transparent 1:4 Transparent 2:3 Transparent 5:0 Transparent

Table 8 - Swelling analysis of different rocks in different mixtures

Incoherent rock Rock samples Volume (ml) 3% KCl Formation water : multiple acid=5 : 0 Formation water : multiple acid=4 : 1 Formation water : multiple acid=1 : 1 Formation water : multiple acid=1 : 4 Formation water : multiple acid=0 : 5 1.58 1.58 1.61 1.00 1.58 1.60 Rate of change( %) 100 100 102 101 100 101 Volume (ml) 1.85 1.95 1.92 1.90 1.90 1.85 Rate of change( %) 100 105 103 102 102 100 Tight rock

www.petroman.ir

SPE 89394

Table 9 - Simulation test of hybrid procedure on sandpacks

Permeability 10-3m2 Before plugging After plugging After acid stimulation After injecting 5% NH4Cl Strong strength plugging agent treatment 223 9 12 11 Weak gel treatment 296 87 75 76 Temporary plugging agent treatment 247 11 8 229

Table 10 Site Operations of the hybrid procedure

Operation mode Strong blocking acid stimulation Weak gel - acid stimulation Strong blocking Weak gel - acid stimulation Total Number of operations 28 11 7 46 710 8560 2713 Volume of the fluids injected, m3 Strong strength Weak gel plugging agent 7850 2713 350 350 Temporary plugging agent Acid solution 845 1581 510 2936 Marks

Table 11 - Effectiveness of water injection achieved by the hybrid procedure

Number of operation PI value (MPa) Before 4.6 6.8 Starting pressure (MPa) After 8.7 10.6 Change 3.4 0.6 Injection pressure (MPa) Before 5.5 11.5 After 7.9 11.8 Change 2.4 0.3 Injection capacity (m3/d) Before 44 67 Valid period (d) After Change 53 64 9 -3 186 170

Operation mode

After Change Before 7.1 7.8 2.5 1.0 5.3 10

Strong blocking acid stimulation Weak gel acid stimulation Strong blocking Weak gel - acid stimulation Total

28 11 7

5.3 46 5.2

9.5 7.6

4.2 2.4

6.4 6.6

10.3 9.4

3.9 2.8

7.1 7.2

10.9 9.3

3.8 2.1

49 50

49 55

0 5

145 176

www.petroman.ir

10

SPE 89394

Table 12 - Water injection profile improvement comparison between single and hybrid procedure

Before treatment (m/n) No. of operations Treatment Water absorption No. of layers Thickness Water receptivity level Water absorption No. of layers Thickness After treatment (m/n) Blocked zones 10 10-5 5 No absorption (m/n) Newly actuated zones (m/n) Water receptivity level

10

10~5

No absorption

Plugging agent (1) Acid stimulation (2) Combination of (1)& (2)

11 101.1 56 7 13 45.7 74.4 37 44

34.5/19 26.2/4 40.7/15 303.7/152 18.7/5 13.6/3 20.8/9 61.8/42

90.5 53.7

53 39 62

33.6/16 31.2/14 55.9/33 14.6/10 17.8/4 21.7/9 48.2/21 18.6/12 51.5/29

308.3/149 54.3/38 507.5/216

52.8/28 35.4/16 33.9/18

46.4/24 32.4/15 61.6/32

29.8/17 28.4/15 16.5/12 551.4/235 118.3

Table 13 Results of responding producing wells

Operation mode Strong blocking acid stimulation Weak gel acid stimulation Strong blocking Weak gel - acid stimulation Total Number of operations 28 11 Number of interconnected producing wells 38 27 Number of responding producers 32 24 Ratio of response (%) 84 89 annual oil increment (t) 6860 2343 Average oil increment (t) 245 213 annual water reduction (m3) 9853 3432

7 46

14 79

12 68

85 86

1316 10519

188 229

2457 15742

www.petroman.ir

SPE 89394

11

Figure 1 - Principle Schematic of the Hybrid Procedure

Figure 2 Flocculation of HPAM with bentonite

Figure 3 - Plugging capacity

www.petroman.ir

12

SPE 89394

Figure 4 - Blocking strength of temporary plugging agent

Figure 5 - Multi-zone separating pumping string

www.petroman.ir

SPE 89394

13

Figure 6 Injection profile data of Well W22-39

www.petroman.ir

Вам также может понравиться

- Formation Strengthening Via Wellbore Cooling Description and ModelingДокумент13 страницFormation Strengthening Via Wellbore Cooling Description and ModelingmsmsoftОценок пока нет

- MsmsoftДокумент11 страницMsmsoftmsmsoftОценок пока нет

- MsmsoftДокумент14 страницMsmsoftmsmsoftОценок пока нет

- Object XMLDocumentДокумент6 страницObject XMLDocumentmsmsoftОценок пока нет

- SPE/IADC 91356 Pressure Stability Analysis For Aerated Mud Drilling Using An Analytical Hydraulics ModelДокумент8 страницSPE/IADC 91356 Pressure Stability Analysis For Aerated Mud Drilling Using An Analytical Hydraulics ModelmsmsoftОценок пока нет

- 2 PDFДокумент13 страниц2 PDFmsmsoftОценок пока нет

- MSMДокумент11 страницMSMmsmsoftОценок пока нет

- Object XMLDocumentДокумент8 страницObject XMLDocumentmsmsoftОценок пока нет

- MsmsoftДокумент12 страницMsmsoftmsmsoftОценок пока нет

- MSMДокумент10 страницMSMmsmsoftОценок пока нет

- Object XMLDocumentДокумент11 страницObject XMLDocumentmsmsoftОценок пока нет

- Object XMLDocumentДокумент7 страницObject XMLDocumentmsmsoftОценок пока нет

- SPE 87468 Measurment and Prediction of Salt Formation in The Presence of Hydrate Organic InhibitorsДокумент7 страницSPE 87468 Measurment and Prediction of Salt Formation in The Presence of Hydrate Organic InhibitorsmsmsoftОценок пока нет

- SPE 90580 Productivity of Selectively Perforated Horizontal WellsДокумент7 страницSPE 90580 Productivity of Selectively Perforated Horizontal WellsmsmsoftОценок пока нет

- 2 PDFДокумент13 страниц2 PDFmsmsoftОценок пока нет

- IADC/SPE 87170 A Pressure Activated Deployment System For Openhole Memory Logging Tools and Its Application in Directional WellsДокумент7 страницIADC/SPE 87170 A Pressure Activated Deployment System For Openhole Memory Logging Tools and Its Application in Directional WellsmsmsoftОценок пока нет

- SPE 91789 Variation of Fracture Opening With Pressure - Key To Well Productivity in Naturally Fractured ReservoirsДокумент5 страницSPE 91789 Variation of Fracture Opening With Pressure - Key To Well Productivity in Naturally Fractured ReservoirsmsmsoftОценок пока нет

- SPE 87472 Groet 1 Scale Study: Analysis, Diagnosis & Solution ImplementationДокумент8 страницSPE 87472 Groet 1 Scale Study: Analysis, Diagnosis & Solution ImplementationmsmsoftОценок пока нет

- SPE 87437 Inhibition of Barite Scale in The Presence of Hydrate InhibitorsДокумент10 страницSPE 87437 Inhibition of Barite Scale in The Presence of Hydrate InhibitorsmsmsoftОценок пока нет

- SPE 90798 Solvent / Acid Blend Provides Economic Single Step Matrix Acidizing Success For Fines and Organic Damage Removal in Sandstone Reservoirs: A Niger - Delta Case StudyДокумент11 страницSPE 90798 Solvent / Acid Blend Provides Economic Single Step Matrix Acidizing Success For Fines and Organic Damage Removal in Sandstone Reservoirs: A Niger - Delta Case StudymsmsoftОценок пока нет

- SPE 89518 Predicting Coiled-Tubing Failure Below Injector: WWW - Petroman.irДокумент5 страницSPE 89518 Predicting Coiled-Tubing Failure Below Injector: WWW - Petroman.irmsmsoftОценок пока нет

- SPE 87471 Soap Sludges: Aggravating Factors and Mitigation MeasuresДокумент4 страницыSPE 87471 Soap Sludges: Aggravating Factors and Mitigation MeasuresmsmsoftОценок пока нет

- SPE 89334 Analysis of The Effects of Major Drilling Parameters On Cuttings Transport Efficiency For High-Angle Wells in Coiled Tubing Drilling OperationsДокумент8 страницSPE 89334 Analysis of The Effects of Major Drilling Parameters On Cuttings Transport Efficiency For High-Angle Wells in Coiled Tubing Drilling OperationsmsmsoftОценок пока нет

- IADC/SPE 87158 Taut Leg Moorings Using Polyester and VLA AnchorsДокумент6 страницIADC/SPE 87158 Taut Leg Moorings Using Polyester and VLA AnchorsmsmsoftОценок пока нет

- SPE 88767 Near Wellbore Stimulation by Acoustic Waves: WWW - Petroman.irДокумент6 страницSPE 88767 Near Wellbore Stimulation by Acoustic Waves: WWW - Petroman.irmsmsoftОценок пока нет

- SPE 89529 Inflatable Packers in Extreme Environments: WWW - Petroman.irДокумент6 страницSPE 89529 Inflatable Packers in Extreme Environments: WWW - Petroman.irmsmsoftОценок пока нет

- SPE 87461 Scale Management of Production Wells Via Inhibitor Application in Supporting Injection WellsДокумент8 страницSPE 87461 Scale Management of Production Wells Via Inhibitor Application in Supporting Injection WellsmsmsoftОценок пока нет

- IADC/SPE 87102 Specialized Rig-Crew Training Produces Results For New Technology Drilling RigsДокумент12 страницIADC/SPE 87102 Specialized Rig-Crew Training Produces Results For New Technology Drilling RigsmsmsoftОценок пока нет

- IADC/SPE 88030 Window Exit Sidetrack Enhancements Through The Use of Solid Expandable CasingДокумент7 страницIADC/SPE 88030 Window Exit Sidetrack Enhancements Through The Use of Solid Expandable CasingmsmsoftОценок пока нет

- IADC/SPE 87178 Offshore Rig Sharing Improves Exploration Drilling Performance: A Case HistoryДокумент9 страницIADC/SPE 87178 Offshore Rig Sharing Improves Exploration Drilling Performance: A Case HistorymsmsoftОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- 2014 PTQ q1Документ156 страниц2014 PTQ q1coolvishal2003100% (1)

- PAT KIMIA 12 GENAP 2023 (Jawaban)Документ37 страницPAT KIMIA 12 GENAP 2023 (Jawaban)elikОценок пока нет

- 3-P 7 29 PDFДокумент263 страницы3-P 7 29 PDFsorinamotocОценок пока нет

- Phytochemical and Antioxidant Activity of Avocado Leaf Extract (Persea Americana Mill.)Документ1 страницаPhytochemical and Antioxidant Activity of Avocado Leaf Extract (Persea Americana Mill.)Jeff AlbaОценок пока нет

- Original PDF Fundamentals of General Organic and Biological Chemistry 8th Edition PDFДокумент41 страницаOriginal PDF Fundamentals of General Organic and Biological Chemistry 8th Edition PDFgwen.garcia161100% (33)

- Shampoo Selsun Untuk Ketombe Dan Rontok - Google PenelusuranДокумент1 страницаShampoo Selsun Untuk Ketombe Dan Rontok - Google PenelusuranRezky AnОценок пока нет

- Chapter 2 RRLДокумент31 страницаChapter 2 RRLIkamuzu OturanОценок пока нет

- SKF Industrial Shaft Seals (5300 EN) - CATALOGUE PDFДокумент379 страницSKF Industrial Shaft Seals (5300 EN) - CATALOGUE PDFLily VyОценок пока нет

- VSEPR Worksheet: 1) What Is The Main Idea Behind VSEPR Theory?Документ3 страницыVSEPR Worksheet: 1) What Is The Main Idea Behind VSEPR Theory?Johanna LipioОценок пока нет

- Cidox Chlorine Dioxide Disinfection Tablets BrochureДокумент6 страницCidox Chlorine Dioxide Disinfection Tablets BrochureOso Casa50% (2)

- Titalon 6800GF-HT: Charpy Impact Strength (Notched)Документ1 страницаTitalon 6800GF-HT: Charpy Impact Strength (Notched)katolokchokОценок пока нет

- Biomolecules Activity 1.1Документ1 страницаBiomolecules Activity 1.1Kimberly Ann Castro VitugОценок пока нет

- Spec of Medium Chain Triglycerides Powder-S SeriesДокумент2 страницыSpec of Medium Chain Triglycerides Powder-S SerieswefdeОценок пока нет

- Post-critical heat flux heat transfer survey correlations applicabilityДокумент2 страницыPost-critical heat flux heat transfer survey correlations applicabilityJoana Marie ManaloОценок пока нет

- Ethylene Polymers LLDPE PDFДокумент42 страницыEthylene Polymers LLDPE PDFDadadaОценок пока нет

- Deicing Salt - Recognizing The Corrosion ThreatДокумент11 страницDeicing Salt - Recognizing The Corrosion ThreatMilanОценок пока нет

- Chemistry Lab - 15 - Solubility Curve For KNO3Документ4 страницыChemistry Lab - 15 - Solubility Curve For KNO3Nader AwadОценок пока нет

- Katalog Hdpe 2019Документ51 страницаKatalog Hdpe 2019DianWidodoОценок пока нет

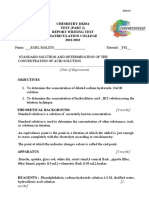

- Earl's Practical Test Part 2 (Lab Report Template) - Dk014Документ5 страницEarl's Practical Test Part 2 (Lab Report Template) - Dk014MALIUS BIN SUNGGI MoeОценок пока нет

- Ferrous Alloys: Author: KattusДокумент19 страницFerrous Alloys: Author: KattussunsirОценок пока нет

- Chapter 3 - Concept of Acid-Base NeutralisationДокумент58 страницChapter 3 - Concept of Acid-Base NeutralisationIkmal FikriОценок пока нет

- Wrought Iron Properties ApplicationsДокумент2 страницыWrought Iron Properties ApplicationsRaymond LiewОценок пока нет

- PolyacetalДокумент16 страницPolyacetalChakma SHIMULОценок пока нет

- Kar 2018Документ7 страницKar 2018andrianexcelОценок пока нет

- Thermocouple Connector Selection GuideДокумент21 страницаThermocouple Connector Selection GuideRAVIRAJ DATTATRAYA PADOLОценок пока нет

- Water Desalination Using Electrodialysis (EDДокумент18 страницWater Desalination Using Electrodialysis (EDibrahimawad06Оценок пока нет

- Coagulation / FlocculationДокумент1 страницаCoagulation / FlocculationElmaeen BagiohanonОценок пока нет

- Uv VisДокумент28 страницUv VisVictor AristizabalОценок пока нет

- Technip Germany Coke Calcining ExpertiseДокумент17 страницTechnip Germany Coke Calcining ExpertiseSimin Coke Co.Оценок пока нет

- Vapor Pressures: Appendix HДокумент1 страницаVapor Pressures: Appendix HMeetu KaurОценок пока нет