Академический Документы

Профессиональный Документы

Культура Документы

Thermodynamics of Surfaces

Загружено:

cuongtran_siegenАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Thermodynamics of Surfaces

Загружено:

cuongtran_siegenАвторское право:

Доступные форматы

1

Thermodynamics of Surfaces

Surface atoms are very different from atoms in the bulk.

The fewer neighbors of the surface cause it to have a very

different and anisotropic chemical environment compared with

the bulk.

The thermodynamics of the surface is most likely to be quite

different from the thermodynamic properties of the bulk.

Often certain atoms in multicomponent systems selectively

accumulate on the surface as a result of these properties and

impart rather different surface properties compared with the

bulk.

The balance of energies at the surface is the reason why small

drops are curved and why liquid interfaces may rise when

placed in capillaries

Surface Thermodynamic Functions

Consider a large crystalline solid containing a total of N atoms,

which is bounded by surface planes. We can determine

various thermodynamic properties by including a term that

accounts for excesses from the surface properties.

Let E

o

, S

o

be the energy and entropy of the solid per atom,

respectively. Also, E

s

= specific surface energy (energy per

unit area):

E = NE

o

+ E

s

where

N = # of atoms in the solid;

E = total energy of the solid and

= surface area

Similarly, for entropy the total entropy is

S = NS

o

+ S

s

Total free energy is: G = NG

o

+ G

s

Surface work content is: A

s

= E

s

TS

s

Surface free energy is: G

s

= H

s

TS

s

2

Work Needed to Create A Surface of one

Component: Surface Tension

Surface area is increased by moving atoms from the bulk to

the surface and then to move surface atoms out of the way

to make room for the new surface atoms.

At const. T and P, the reversible surface work, W, required

to increase the surface area, , by an amount d of a one

component system is

where = called surface tension and is two dimensional

equivalent of pressure. Note volume change is

replaced with change in the surface area.

Units:

Pressure, P = force per unit area = N/m

2

;

Surface tension, = force per unit length = N/m = J/m

2

Rough estimate of surface tension can be obtained by

assuming the work is of the same magnitude as heat of

sublimation

The H

sub

is about 4x10

5

J/mol = 7x10

24

J/atom and the

typical concentration of atoms on a surface is 10

15

atoms/cm

2

= 10

19

atoms/m

2

Experimentally the equation is best described as

Small coefficient that metal metal bonds in the bulk are not

all broken when the surface is created.

Also due to a relaxation where surface atoms move their

equilibrium positions to maximize their bonding with the

remaining neighbors.

d W

s

P T

,

7

10 10 7

2

2 19 24

J/m

atoms/m J/atom x x

est

sub est

H 16 . 0

3

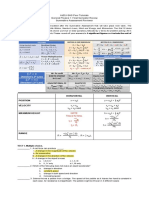

Surface Tension and Work2

Experimental values of surface tensions of a few metals and

other substances are shown below.

Estimation of three dimensional pressure, P, for a solid

surface.

Divide by the thickness of the interaction assuming a

few atomic layers (d 1 nm)

For W: = 2.900 J/m

2

Conclusion metal surface experiences very large

compressive forces.

20 0.07275 Water

20 0.02275 Ethanol (liquid)

25 0.227 NaCl

1027 1.410 Au(solid)

1727 2.900 W (solid)

T,C , J/m

2

Material

atm x

J

atm L x

L

cm

cm

m x

m x

m J

d

P

4

3 3

3

2

9

2

10 9 . 2

10 9 . 9

1

1000 10 1

10 1

/ 900 . 2

,

_

4

Surface Free Energy: Positive

Total free energy change dG of a one component system can

include the contribution from surface work:

At constant T and P:

Two ways of increasing the surface area:

Adding new atoms from the bulk and

Stretching the already existing surface so that the number

of atoms is fixed and only the state of strain changes

(changes ).

Earlier we said that G = NG

o

+ G

s

, but when any change

free energy is due only to a change in the surface free energy,

this equation becomes: dG

T,P

= d(G

s

). This can be rewritten

in terms of the total differential at constant T, P:

When changing the surface are by addition of atoms to the

surface from the bulk, the specific surface free energy, G

s

is

independent upon the surface are:

Simplify:

Combine with above to get:

Or

Thus, for a one component system the surface tension is

equal to the specific surface free energy. Only true when

surface area changes as a result of the movement of atoms to

the surface from the bulk.

Since surface tension is always positive, the surface free

energy is always positive.

d VdP SdT dG + +

d dG

P T

,

d

G

G d

G

dG

P T

s

s

P T

s

P T

1

1

]

1

,

_

,

_

, ,

,

) (

0

,

,

_

P T

s

G

d G dG

s

P T

,

s

G

d d G dG

s

P T

,

5

Surface Free Energy (2)

G

s

is positive; this means that there is reluctance of a surface

to form and is the cause of many interfacial properties of

condensed phases.

Surface free energy is minimized by keeping the surface

tension to a minimum closest packing of atoms is preferred.

If at all possible, a high surface tension surface will be covered

with a coating of reduced surface tension.

Metals are covered with oxides when the metal gas

interfacial energy,

m-g

>

ox-g

+

ox-m

Water will adsorb on and cover the oxide if

ox-g

>

H2O-g

+

H2O-ox

Adsorbed water can be displaced or covered by organic

molecules of even lower surface tension

Liquids tend to assume a spherical shape to minimize

their surface area and surface tension.

Metal

Oxide

Organic

Water

Surface coating will develop when

new surface

+

interface

<

old surface

6

Temperature Dependence of Specific Surface Free

Energy

For the temperature range that are typically used in the

studies of surface-tension, G

s

= . Temperature

dependence can be determined by differentiating with

respect to temperature.

Thus, temperature dependence of surface tension leads to

the specific surface entropy.

Temperature dependence of predicting by a semi -empirical

equation (van der Waals and Guggenheim:

where

o

= at T = 0 K, T

c

= critical temperature

(temperature at which condensed phase no longer can

exist) and n is a constant that varies from 11/9 for organic

substances to 1 for metals.

Notice = 0 when T T

c

.

Another empirical relationship for metals:

where m = melting point of the metal; is in dynes per

centimeter.

Specific surface enthalpy can be determined from the

specific free energy and entropy (eq. 1):

n

o

o

T T ) / 1 ( 2

s

P

P

s

S

T T

G

,

_

,

_

1

P

s

s s s

T

T H

TS G H

,

_

4

3 / 2

6 . 3

m

m

m

V

T

3

7

Specific Surface Energy and Heat Capacity

At constant pressure the heat absorbed upon creation of unit

surface area is given by Eq. 4. If volume is constant, then we

can immediately see that the specific surface energy and

specific surface enthalpy are equal to each other:

Specific Heat Capacity

Remember the heat capacity, C, is defined as C = dq/dt. This

leads to:

Take derivative with respect to temperature of equation 4 to

find the heat capacity at constant pressure.

Also, using H = G + TS and taking the derivative of both sides

with respect to T leads to

Surface heat capacity is equal to T times temperature

derivative of entropy at constant pressure.

On metal surfaces C

v

and C

P

are usually consider

approximately equal to each other.

Accurate surface tension measurements should lead to

accurate estimates of surface heat capacity.

P

s

T

T E

,

_

5

P P

P

v v

v

T

H

T

q

C

T

E

T

q

C

,

_

,

_

,

_

,

_

6

P

s

P

P

P P p

p

P

P

s

s

P

T

T C

T

T

T T

T

T T

T

T T

H

C

,

_

,

_

,

_

,

_

,

_

1

]

1

,

_

,

_

2

2

2

2

7

( )

,

_

,

_

,

_

+ +

,

_

+

,

_

+

,

_

,

_

P P

P P P P

P

P

T

S

T

T

H

T

S

T S S

T

S

T S

T

T

T

G

TS G

T T

H

8

Surface Heat Capacity 2

Direct Surface Heat capacities are often not reliable since the

data is often not accurate enough.

Better results are obtained from direct measurements of

surface heat capacity measurements on finely divided

powders with large surface to volume ratio.

Difference between this and heat capacity of large crystallites

of the same material yield the surface heat capacity.

Theoretical Estimation of Surface Heat Capacity

Bulk heat capacities: C

P

varies in a regular fashion with

temperature. At low temperatures, it is often estimated using

Debye extrapolation, which

assumes a T

3

dependence,

fits the data to the expression: C

P

= aT

3

uses the value of a obtained above to determine heat

capacities where they could not be measured.

Surface heat capacities: Frequencies of vibration is given by

where = surface area, = frequency and C

2

= velocity of

sound in two dimensions, n = number of frequencies.

If N surface atoms still have 3N vibrational modes, we have

(after integration of eq 8):

where

D

is the limiting Debye frequency.

2

2

) (

C

v

v f

dv

dn

8

2

2

0

2

3

0

3

2

C

v

N

dv

C

v

dn

D

D

v

N

9

9

Surface Heat Capacity: Theoretical

In 9 solve for C

2

and substitute into 8 to get:

The total surface energy is given by

Use the approximation for high temperatures

where kT >> h

and

so that C

V

(T ) = 3Nk

These limiting values at high temperature are the same as is

seen for 3-dimensional solids.

We do the same for low temperatures. First use the following

substitutions

2

2

2

2

6

) (

3

2

) (

3

D

D

D

v

Nv

v f

N

v

v

v f

N

v

C

10

D

v

D

dv

kT hv

v

v

Nh

E

0

2

2

1 ) / exp(

6

11

kT

hv

kT

hv

+

,

_

1 exp

12

NkT E

v

v

NkT

kTvdv

v

N

dv

kT hv

v

v

Nh

E

D

D

D

v

D

D

v

D

3

2

6 6

1 / 1

6

2

2

0

2

0

2

2

13

Nk

T

E

C

T

E

V

V

V

3

,

_

,

_

14

h

k

v

kT

hv

x

kT

hv

x

D

D

D

max

10

Surface Heat Capacity: Theoretical (2)

Find a substitute for variables

Substitute into eq 11

It can be shown that

Substitution into eq 12

Heat capacity is then determined

Thus at low temperature C

P

s

is proportional to T

2

instead of

T

3

as is the case in the bulk.

k

h v

x

h

kT

v dx

h

kT

dv

D

D

2 2

dx

e

x

T k

N

E

dx

e

x

h

kT

v

Nh

dx

h

kT

e

x

h

kT

v

Nh

E

x

x

D

D

v x

x

D

D

v x

x

D

,

_

,

_

,

_

max

0

2

3

2

max

0

2

3

2

max

0

2

2

2

1

6

1

6

1

6

15

404 . 2

1

0

2

dx

e

x

x

3

2

3

2

4 . 14

404 . 2 6

T

k N

E

T

Nk

E

D

D

16

2

2

2

2

2 . 43

4 . 14

3

T

Nk

T

E

C

T

Nk

T

E

C

D

V

s

P

D

V

s

P

,

_

,

_

17

11

Surface Energy and Surface Composition of Two

Component Systems

A metal B dissolved in low concentatrions in metal A will

have a tendency to segregate to the surface of A, if it forms

a strong surface bond.

At all bulk concentrations of B, some of the B atoms will be

at the surface of A as a result of the surface bulk

equilibrium.

Formation of a strong surface chemical bond between A

and B, greatly enhances concentration of B.

Enhancement in concentration of B occurs when heat of

desorption of B from the surface of A > heat of

vaporization of pure B

If B atoms form weaker chemical bonds with A surface

atoms compared to the bulk, B atoms will be repelled from

the surface and the surface concentration; surface

concentration will be less than predicted by bulk

concentrations.

Strength of A B bond strongly depends upon the

reactivity of the surface, which strongly depends upon the

crystal orientation.

Concentration of B in the surface region is compared to its

concentration in the bulk. The surface excess is

where n

B

= number of moles of B in the surface above the

number of moles in the bulk region what would contain the

same number of moles of atoms as that part of the

surface.

B on Surface A

B in pure B

B in A

B vapor

Energy of

Solution

Energy of

Adsorption

Energy of

Vaporization

Energy of

Segregation

B

B

n

12

Surface Segregation in Binary Alloys

Dilute binary system exhibiting ideal solution behavior

Since the mole fraction < 1, the natural log term is negative

and the chemical potential of this component in the bulk is

less than in pure solid.

Driving force of surface segregation is difference in bonding

energies between the two metal atoms, A B, compared to

bonds, A A and B B, for the pure metals.

Change in chemical bonding is also responsible to a change

in surface tension in solution compared to the surfaces of the

pure substances.

At equilibrium chemical potentials of bulk and surface must

be equal

where a

2

= surface area covered by 1 mole of the

component 2 of the binary system.

For pure component 2 and eq 19 produces:

Substitute eq 20 into eq 19 and assume a

1

= a

2

= a

b b b

x RT

2

, 0

2 2

ln +

18

bulk. in the component second the of fraction mole

is and component pure and solution bulk in the component

second the of potentials chemical the are and where

2

, 0

2 2

b

b b

x

2

2

, 0

2 2

, 0

2

2 2

ln ln a x RT x RT

s s b b

s b

+ +

19

1

2 2

b b

x x

2 2

, 0

2

, 0

2

a

b s

20

s b

s b b s

x RT x RT a a

a

a x RT x RT

2 2

2

2 2

2

2 2

, 0

2

, 0

2

ln ln

ln ln

+

21

13

Surface Segregation in Binary Alloy Systems (2)

Using the same logic for the first component

Combining 21 and 22 gives equation for the monolayer ideal-

solution model.

where

2

and

1

are surface tensions of pure 2 and 1.

When

2

<

1

, the surface fraction of 2 will by greater than 1.

Component 2 will be concentrated on the surface.

Whichever component has the lowest surface tension, will

segregate to the surface.

One way of determining the surface tension is from H

subl

; a

strong correlation exists between surface tension and H

subl

.

As discussed earlier for metals,

m

0.16 H

subl

Substitute into 23 to get:

Surface segregation is exponentially dependent upon the

temperature.

Many metal alloys not ideal solutions, because of finite H

mix

.

When including this the ratio in Eq. 24 becomes

l = fraction of nearest neighbors to an atom in the plane;

m = fraction of nearest neighbors below the plane.

= regular solution parameter containing H

mix

s b

x RT x RT a a

1 1

1

ln ln + 22

( )

1

]

1

RT

a

x

x

x

x

b

b

s

s

2 1

1

2

1

2

exp

23

( )

1

]

1

RT

H H

x

x

x

x

sub sub

b

b

s

s

2 1

1

2

1

2

16 . 0

exp

24

( )

( ) ( ) ( ) ( )

1

]

1

'

'

1

]

1

2

1

2

2

2

1

2

2

2 1

1

2

1

2

) (

exp exp

s s b b

b

b

s

s

x x

RT

l

x x

RT

m l

RT

a

x

x

x

x

25

14

Curved Surfaces

Solids and liquids tend to minimize their surface area to

decrease the excess surface free energy.

Liquids, equilibrium surface is curved and the radius of

curvature depends upon the pressure difference on the two

sides of the interface and on the surface tension.

Let r = radius of surface;

The change in volume when the bubble changes size will

be

The force acting on the surface will be given by

Any change in pressure must be balanced by the surface

energy to give

Pressure inside the bubble is greater than external

pressure, because of surface tension.

Smaller droplets large pressure difference possible

(required).

3

3

4

r V

P

ext

P

int

dr r dV

2

4

dr P P r

ext

) ( 4

int

2

rdr d 8

r

P P

dr r dr P P r

ext

ext

2

) (

8 ) ( 4

int

int

2

26

15

Capillary Rise and Vapor Pressure of Curved

Surfaces

Capillary Rise: A liquid contained in a tube with a small radius

develops a large pressure difference between internal and

external pressures.

liquid level rises up the tube until the hydrostatic pressure

of the rising liquid column balances the internal pressure

where

= density difference between liquid and gas phases,

g = gravitational constant,

h is the height of the capillary column.

Vapor pressure of curved surfaces: vapor pressure of a

droplet depends upon the radius of curvature, r.

At equilibrium, pressure difference across the droplet is

given by Eq. 26.

Transferring molecules (atoms) for one phase (e.g. liquid

phase) to the other is exactly matched by transferring

molecules from the other phase to the liquid phase

At constant temperature, the free-energy change

accompanying transfer across the interface is

At equilibrium free-energy changes are equal; leads to

r

gh P

2

27

,

_

r

d dP dP

r

P P

ext

ext

2

2

) (

int

int

28

ext ext ext

dP V dG dP V dG

int int int

ext

ext

ext ext

dP

V

V

dP

dP V dP V

int

int

int int

29

16

Vapor Pressure of Curved Surfaces 2

Substitute Eq 29 into Eq 28:

But molar volume of gas is much larger than the molar

volume of the liquid

Assuming gas behaves ideally, molar volume is

Substitute into Eq 30

Integrate 31 from zero curvature (r = , P = P

o

) to some

other surface.

Eq 32 called the Kelvin equation gives the relationship

between vapor pressure of a spherical particle and its size.

Vapor pressure increases with decreases in particle size.

,

_

r

d dP

V

V V

ext

in

in ext

2

30

t V V

in ext

>>

ext

ext

P

RT

V

,

_

,

_

r

d

RT

V

P

dP

r

d

V

dP

P

RT

ext

ext

ext

ext

1 2

2

int

int

31

RTr

V

P

P

r

d

RT

V

P

dP

o

r

r P

o

P

ext

ext

int

int

2

ln

1 2

,

_

,

_

32

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- High School Chemistry Grade 10-12Документ486 страницHigh School Chemistry Grade 10-12Todd95% (39)

- HFC-125 Thermodynamic PropertiesДокумент30 страницHFC-125 Thermodynamic Propertiesdario delmoralОценок пока нет

- Heat Load CalculationДокумент3 страницыHeat Load Calculationapi-3728508100% (2)

- PMMAДокумент7 страницPMMAcuongtran_siegenОценок пока нет

- Novel Silicone-Based Polymers for Biomedical ApplicationsДокумент139 страницNovel Silicone-Based Polymers for Biomedical Applicationscuongtran_siegenОценок пока нет

- LPG Tanker WoolcottДокумент80 страницLPG Tanker WoolcottnickurfriendОценок пока нет

- Final Review Document TitleДокумент152 страницыFinal Review Document TitledaskhagoОценок пока нет

- Paper 2. Funct. SiO2-NP. 5.jan.2014Документ52 страницыPaper 2. Funct. SiO2-NP. 5.jan.2014cuongtran_siegenОценок пока нет

- Paper 3. Funct. SiO2-NP. 5.jan.2014Документ8 страницPaper 3. Funct. SiO2-NP. 5.jan.2014cuongtran_siegenОценок пока нет

- Paper 1. Funct. SiO2-NP. 5.jan.2014Документ4 страницыPaper 1. Funct. SiO2-NP. 5.jan.2014cuongtran_siegenОценок пока нет

- DLS Terms Defined MalvernДокумент6 страницDLS Terms Defined Malverncuongtran_siegenОценок пока нет

- Light Microscopy HandoutДокумент24 страницыLight Microscopy HandoutDevaprakasam DeivasagayamОценок пока нет

- Light Microscopy HandoutДокумент24 страницыLight Microscopy HandoutDevaprakasam DeivasagayamОценок пока нет

- Sem 4Документ29 страницSem 4Raluca CristacheОценок пока нет

- Lecture 3 Conventional-MicroscopeДокумент45 страницLecture 3 Conventional-Microscopearul1987Оценок пока нет

- Sem 4Документ29 страницSem 4Raluca CristacheОценок пока нет

- CaSO4 Mass LossДокумент0 страницCaSO4 Mass Losscuongtran_siegenОценок пока нет

- Light Microscopy HandoutДокумент24 страницыLight Microscopy HandoutDevaprakasam DeivasagayamОценок пока нет

- OrganicChemistryAbout 1H-NMRДокумент25 страницOrganicChemistryAbout 1H-NMRcuongtran_siegenОценок пока нет

- XrayДокумент8 страницXraycuongtran_siegenОценок пока нет

- Mma PmmaДокумент14 страницMma Pmmacuongtran_siegenОценок пока нет

- PMMA - SynthesisДокумент8 страницPMMA - Synthesiscuongtran_siegenОценок пока нет

- P 2006nanotechnologyДокумент6 страницP 2006nanotechnologycuongtran_siegenОценок пока нет

- EDX Course NotesДокумент13 страницEDX Course Notescuongtran_siegenОценок пока нет

- Pmma - 3Документ5 страницPmma - 3cuongtran_siegenОценок пока нет

- MDW QCM Web StuffДокумент19 страницMDW QCM Web Stuffcuongtran_siegenОценок пока нет

- Pmma - 2Документ20 страницPmma - 2cuongtran_siegenОценок пока нет

- Versatile Calorimeter for Studying Physics, Chemistry and BiologyДокумент7 страницVersatile Calorimeter for Studying Physics, Chemistry and Biologycuongtran_siegenОценок пока нет

- A Simple Way For Synthesis of Alkyne-Telechelic Poly (Methyl Methacrylate) Via Single Electron Transfer Radical Coupling ReactionДокумент4 страницыA Simple Way For Synthesis of Alkyne-Telechelic Poly (Methyl Methacrylate) Via Single Electron Transfer Radical Coupling Reactioncuongtran_siegenОценок пока нет

- QCMДокумент2 страницыQCMmanish_keswani01Оценок пока нет

- ICHO07Документ18 страницICHO07MacxsimusОценок пока нет

- Instructions for QCM Setup and Data CollectionДокумент9 страницInstructions for QCM Setup and Data Collectioncuongtran_siegenОценок пока нет

- Photon Scanning Tunneling Microscope: Detection of Evanescent WavesДокумент5 страницPhoton Scanning Tunneling Microscope: Detection of Evanescent Wavescuongtran_siegenОценок пока нет

- EDX Course NotesДокумент13 страницEDX Course Notescuongtran_siegenОценок пока нет

- Energy Dissipation in StructuresДокумент20 страницEnergy Dissipation in StructuresTommy SidebottomОценок пока нет

- Topic 2.0 B.heating and Cooling Load Calculation 2Документ25 страницTopic 2.0 B.heating and Cooling Load Calculation 2siti nasuhaОценок пока нет

- SVT Collge of Engg. Structure II Lecture Notes..1245Документ38 страницSVT Collge of Engg. Structure II Lecture Notes..1245Shams KhattakОценок пока нет

- UPVC Technical Data SheetДокумент1 страницаUPVC Technical Data SheetRND KencanaОценок пока нет

- Churchill 1977Документ7 страницChurchill 1977weonОценок пока нет

- Equivalent Tensile Stress - (CSA-Z662 - 2007)Документ2 страницыEquivalent Tensile Stress - (CSA-Z662 - 2007)live4sankarОценок пока нет

- Hoval DocumentationДокумент7 страницHoval DocumentationLUSS4UОценок пока нет

- The Ductility of Coupeld Shear WallsДокумент414 страницThe Ductility of Coupeld Shear WallsJorgeLuisSeguraОценок пока нет

- FVM - CFDДокумент44 страницыFVM - CFDgrkguptaОценок пока нет

- Physical Properties of Liquid & Gas MixturesДокумент2 страницыPhysical Properties of Liquid & Gas MixturesGhost Rider100% (1)

- IS 13920 - 1993vs2016Документ14 страницIS 13920 - 1993vs2016RonakShahОценок пока нет

- One-Dimensional Site Response AnalysisДокумент85 страницOne-Dimensional Site Response AnalysisesscindiaОценок пока нет

- ME-503 Assignment Design ElementsДокумент2 страницыME-503 Assignment Design ElementsSupratim Bhattacharjee100% (1)

- Preparation and Characterization of Starch/carrageenan Edible FilmsДокумент6 страницPreparation and Characterization of Starch/carrageenan Edible FilmskiaraОценок пока нет

- Molecular Dynamics Simulation of Crack Propagation in AluminumДокумент40 страницMolecular Dynamics Simulation of Crack Propagation in AluminumodoalawayeОценок пока нет

- BCR02 - Brochure - EN Sample Gas PumpДокумент2 страницыBCR02 - Brochure - EN Sample Gas PumptenggarayОценок пока нет

- Term Project Report CFDДокумент20 страницTerm Project Report CFDAbu AliОценок пока нет

- Elasticity Imp QuestionsДокумент2 страницыElasticity Imp QuestionsShubh PatiyatОценок пока нет

- 5-Eigenvalue Buckling PredictionДокумент4 страницы5-Eigenvalue Buckling PredictionMaurizio FalconieriОценок пока нет

- Gen. Physics 1 Summative ReviewerДокумент3 страницыGen. Physics 1 Summative ReviewerMARIELLE ANDREA ZAMORASОценок пока нет

- Phychem2 Simple MixturesДокумент65 страницPhychem2 Simple Mixturesnoel sabarilloОценок пока нет

- L Shaped ColumnДокумент18 страницL Shaped ColumnMahmood Mufti100% (1)

- CE 302 - Conc - Lecture 1 - Wk1 PDFДокумент18 страницCE 302 - Conc - Lecture 1 - Wk1 PDFIsraelОценок пока нет

- Helical SpringsДокумент20 страницHelical SpringsVINAYAK SHARMAОценок пока нет

- Psychrometric Chart - Us and Si UnitsДокумент1 страницаPsychrometric Chart - Us and Si UnitsRaden_Rici_Abi_1914Оценок пока нет

- The Perfect Gas Expansion Experiment Similar BT TH 11Документ69 страницThe Perfect Gas Expansion Experiment Similar BT TH 11Irshad KhokharОценок пока нет