Академический Документы

Профессиональный Документы

Культура Документы

Optical Hydrogen Sensor Based On Etched Fiber Bragg Grating Sputtered

Загружено:

Iwan de AngeloОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Optical Hydrogen Sensor Based On Etched Fiber Bragg Grating Sputtered

Загружено:

Iwan de AngeloАвторское право:

Доступные форматы

Optical Fiber Technology 19 (2013) 2630

Contents lists available at SciVerse ScienceDirect

Optical Fiber Technology

www.elsevier.com/locate/yofte

Regular Articles

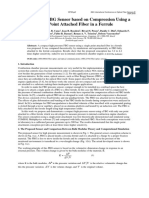

Optical hydrogen sensor based on etched ber Bragg grating sputtered with Pd/Ag composite lm

Jixiang Dai a,, Minghong Yang a, Xun Yu b, Hong Lu b

a b

National Engineering Laboratory of Optical Fiber Sensing Technology, Wuhan University of Technology, Wuhan 430070, China Department of Control Science & Engineering, Huazhong University of Science & Technology, Wuhan 430074, China

a r t i c l e

i n f o

a b s t r a c t

A novel ber optical ber hydrogen sensor based on etched ber Bragg grating coated with Pd/Ag composite lm is proposed in this paper. Pd/Ag composite lms were deposited on the side-face of etched ber Bragg grating (FBG) as sensing elements by magnetron sputtering process. The atomic ratio of the two metals in Pd/Ag composite lm is controlled at Pd:Ag = 76:24. Compared to standard FBG coated with same hydrogen sensitive lm, etched FBG can signicantly increase the sensors sensitivity. When hydrogen concentrations are 4% in volume percentage, the wavelength shifts of FBG-125 lm, FBG38 lm and FBG-20.6 lm are 8, 23 and 40 pm respectively. The experimental results show the sensors hydrogen response is reversible, and the hydrogen sensor has great potential in hydrogens measurement. 2012 Elsevier Inc. All rights reserved.

Article history: Received 9 April 2012 Revised 17 September 2012 Available online 25 October 2012 Keywords: Etched FBG Pd/Ag composite lm Magnetron sputtering Hydrogen sensor

1. Introduction Optical ber hydrogen sensor has attracted intensive research interests due to its potential as next generation of hydrogen sensor. At present there are several kinds of optical ber hydrogen sensors, such as evanescent sensor [17], micro-mirror sensor [8,9], surface plasmon resonance (SPR) sensor [10], acoustic resonator sensor [11] and ber Bragg grating sensor [1216]. Among these sensors, FBG hydrogen sensor is more suitable for distributed measurement due to its wavelength multipliable capability. Another advantage of FBG is that it is easy for temperature compensation [1619] which can reduce the inuence of optical sources intensity so as to improve the sensors accuracy. Therefore, it is very meaningful to utilize FBG hydrogen sensor for hydrogen leakage detection. At present the most sensitive FBG hydrogen sensor is based on WO3 doped with Pt layer on which hydrogen can undergo an exothermic reaction [15]. The sensor has fast response and high sensitivity, but it still has the potential to explode in high hydrogen concentrations. FBG hydrogen sensors based on pure Pd lm has nature safety, however these sensors are easily suffered from Pd lms fatal fracture caused by its ab phase transition [6,20]. Moreover pure Pd lm has a poor adhesion towards optic ber, and it may peel off when it is exposed to hydrogen [14]. These defects can cause the hydrogen sensors irreversible response, leading to the hysteretic effect during the hydrogen adsorption and desorption process. In our previous work, side polished FBG coated with WO3Pd com Corresponding author. Fax: +86 27 87665287.

E-mail address: djx409081947@163.com (J. Dai). 1068-5200/$ - see front matter 2012 Elsevier Inc. All rights reserved. http://dx.doi.org/10.1016/j.yofte.2012.09.006

posite lm shows high sensitivity to hydrogen, but the hydrogen sensor still has hysteretic effect [16] due to its lattice defects. Therefore, selecting proper hydrogen sensitive lm is very important for FBG hydrogen sensor. It has been reported that Pd75/Ag25 composite lm has certain plasticity to tense strength [2123] during hydrogen response; therefore it has been widely used in hydrogen separating industry. To improve the sensors repeatability, Pd/Ag composite lm is chosen as hydrogen sensitive lm to overcome hysteretic effect during hydrogen absorption and desorption process. Cr lm is selected as the basal layer to improve the adhesion between Pd/Ag composite lm and FBG. In order to improve the hydrogen sensors sensitivity, FBG is etched by HF solution to reduce its diameter. Generally, etched FBG is very fragile it is not suitable for practical application. However, etched FBG still can be used for application if it is properly protected. With the aim to prepare hydrogen sensor with good performance, etched FBG hydrogen sensors based on Pd/Ag composite lm are proposed and their sensing characteristics have been investigated in this paper. 2. Principle As it is well known, the reected wavelength (kB) of FBG has correlation with its effective refractive index (neff) and grating pitch (K). The equation can be expressed as [24]:

kB 2neff K

In order to increase the hydrogen sensors sensitivity, FBG was etched in our experiments. Pd/Ag coating can expand when it absorbs hydrogen, which will induce strain in the underlying FBG.

J. Dai et al. / Optical Fiber Technology 19 (2013) 2630

27

The grating pitch of FBG will be changed by the volume expansion of Pd/Ag composite lm, which can cause the wavelength shift of FBG. Since the volume expansion induced by the formation of PdHx [6] depends on the hydrogen concentration, FBG wavelength shift has correlation with hydrogen concentration. Therefore, hydrogen concentration can be deduced by measuring the wavelength shift of FBG. 3. Experiment The polyimide coating around signal mode ber was removed by ber stripper before UV exposure. A Lambda Physik excimer laser (COMPex-150T) operating at 248 nm was used as laser source to write FBG in single mode ber by phase mask method [25]. The FBGs used in our experiments were fabricated on a single mode 125 lm ber with 910 lm diameter core region. The length of optical ber exposed to UV light is about 8 mm. FBG with central wavelength of 1302.685 nm were prepared by UV light through an 898.51 nm period phase mask. The refractive index modulation of ber core is about 46 106, yielding to a reectivity approaching 90% at the Bragg wavelength. After UV exposure, FBG was xed on polyvinyl chloride polymer sheet for the etching process. Then single mode FBG ber was dipped in 50% HF solution for tens of minutes to remove cladding layer. In our experiment, FBGs with diameters of 38 and 20.6 lm were prepared by dipping in HF solution for 37 and 46 min respectively. After the etching process, the etched FBG was baked by infrared light for next process. 100 nm Pd76/Ag24 composite thin lms were deposited on the etched FBG ber by using a BESTECH sputtering system. To ensure the selectivity of hydrogen sensitive lm, 10 nm pure Pd lm is set as the protective layer outside the Pd76/Ag24 composite lm. Before preparing hydrogen sensitive lm, 10 nm Cr lm was deposited on side face of FBG by RF sputtering process. On the one hand, Cr lm can stop H2O penetrating into optical ber so that it can be used as protective layer. On the other hand, Cr lm has good adhesion toward optical ber; therefore it can be employed as a basal layer to overcome the material mismatch of SiO2 and Pd/Ag composite lm so as to improve the sensors stability. Under 0.5 Pa sputtering pressure of Ar, the deposition power for Pd and Ag targets are 100 and 55 W respectively, which corresponds to deposition rate of 0.14 and 0.05 nm/s respectively. With this sputtering process, the atomic ratio of Pd and Ag is about 76:24. During the sputtering process, the thickness of the hydrogen sensitive was monitored by quartz crystal method. Meanwhile coatings on several 10 mm 10 mm Si pieces were also prepared in the same

run for further characterization. After sputtering process, etched FBG coated with Pd/Ag composite lm was sealed in porous stainless steel tube for hydrogen test. Fig. 1 shows the schematic diagram of ber-hydrogen sensor characterization system. The hydrogen sensing performance was measured at room temperature of 15.4 C using air as carrier gas. The relative humidity of the atmosphere is about 61.7%. During hydrogen concentration characterization, the reected wavelength is collected with a BCD-100 FBG demodulator. The BCD-100 FBG demodulator is equipped with a Fiber FabryPerot Tunable Filter (FFP-TF) from Micron Optics Inc., USA, which can provide high precision (1 pm) to detect a slight wavelength shift of FBG. The varying hydrogen concentrations are provided by changing owing rate of H2. A commercially available MIC-500 hydrogen concentration meter (Yiyuntian Company, solid polymer electrode type) based on chemical electrics principle is connected to the gas room for calibration. A standard non-coated FBG with the similar wavelength is used as the temperature compensating element. The measured data is recorded by a computer connecting with the FBG demodulator for further data treatment. 4. Results and discussions Fig. 2a shows etched FBG enlarged by 1000 times in length. Obtained by VHX-100 digital microscope, the diameter of etched FBG is about 20.6 lm. Fig. 2b is the morphology of etched FBG sputtered with 110 nm Pd/Ag composite lms. After deposited with Pd/Ag composite lm, the etched FBG looks not as transparent as before. The reective spectrum of etched FBG coated with Pd/Ag composite lms was measured by optical spectrum analyzer (AQ6370B, YOKOGAWA). As it is shown in Fig. 2c, the etched FBG still has good reective spectrum after the etching and sputtering process, which can provide reliable optical single for hydrogen test. The advantage of FBG hydrogen sensor is its wavelength multipliable capability, which can reduce the inuence of optical sources intensity so as to improve the sensors accuracy. In our previous work [7], optical hydrogen sensor based on modulation of optical power intensity has baseline shift during the hydrogen response. The FBG amplitude spectrum is also easily suffered from the uctuation of optical intensity. The light source used in our experiment is a common superluminescent light emitting diode, and its intensity may have a little uctuation during the hydrogen test. Generally, the change of central wavelength of FBG is much more credible than that of amplitude spectrum when the light source is not stable. Therefore in this paper our research is focused on

Fig. 1. Conguration of optical ber hydrogen sensor characterization.

28

J. Dai et al. / Optical Fiber Technology 19 (2013) 2630

Fig. 2. Microphotography of chemically-etched FBG-20.6 lm (a) before and (b) after sputtered with 110 nm Pd/Ag composite lms; (c) reective spectrum of etched FBG20.6 lm sputtered with 110 nm Pd/Ag composite lms.

Fig. 4. SEM images of 110 nm Pd/Ag composite lm (a) before and (b) after hydrogen response. Fig. 3. (a) EDAX pattern and (b) X-ray diffraction of 110 nm Pd/Ag composite lm.

FBG hydrogen sensors wavelength shift during the hydrogen response. Fig. 3 shows the elemental analysis and phase pattern results of 110 nm Pd/Ag composite lm coated on Si piece. The elemental analysis of Pd/Ag composite lm deposited on Si piece was carried out by energy dispersive X-ray analysis (EDAX) using an X-ray detector attached to the eld emission scanning electron microscope (FE-SEM S-4800, Hitachi, Japan). The EDAX result shows

the atom ratio of Pd:Ag is about 78:22, which is consistent with the actual Pd:Ag of 100 nm Pd76/Ag24 composite lm and 10 nm pure Pd lm. X-ray diffraction pattern of Pd/Ag composite lm was obtained on a X-ray diffractometer (XRD D8 Advance, Brucker, German) using Cu Ka radiation source operating at 40 kV and 30 mA. The relatively weak peak at 2h = 29 is the characteristic peak of monocrystalline silicon. The Pd/Ag peaks can be found at 2h = 40, 46.7, 68.2, 82.4 and 86.6 corresponding to the cubic phase (1 1 1), (2 0 0), (2 2 0), (3 1 1) and (2 2 2) crystal planes (JCPDS

J. Dai et al. / Optical Fiber Technology 19 (2013) 2630

29

Fig. 5. Three cycles of hydrogen response of (a) FBG-125 lm, (b) FBG-38 lm and (c) FBG-20.6 lm coated with 110 nm Pd/Ag composite lm; (d) central wavelength shift FBG-125 lm, FBG-38 lm and FBG-20.6 lm coated with 110 nm Pd/Ag composite lm under different hydrogen concentrations.

65-6174). The XRD result demonstrates the atoms in Pd/Ag composite lm are in orderly arrangement. Fig. 4 displays the microphotography of Si pieces coated with 110 nm Pd/Ag composite lm (a) before and (b) after exposing to hydrogen. The white particles are Ag atoms, but Ag particles look much less than Pd particles due to 10 nm pure Pd lm on the surface of Pd76/Ag24 composite lm. It can be seen that Pd/Ag composite lm looks uniform and dense. Moreover, there is no crack on the surface of the hydrogen sensitive lm. These results demonstrate that Pd/Ag composite lm has good mechanical performance during hydrogen response. Fig. 5ac illustrate the repeatability of FBG-125 lm, FBG-38 lm and FBG-20.6 lm coated with 110 nm Pd/Ag composite lm in the three hydrogen response cycles. The relative wavelength is derived by subtracting the center wavelength of reference FBG from that of sensing FBG. During the three cycles response, the sensor has good repeatability to 4% hydrogen concentration. There is little hysteretic effect during the hydrogen response due to the good mechanical strength of Pd/Ag composite lm, which is corresponding with the good appearance of hydrogen sensitive lm as shown in Fig. 4. Compared to amorphous WO3Pd composite lm [16], cubic phase Pd/Ag composite lm has less sensitivity but better repeatability. Ag is not sensitive to hydrogen, so the ab phase transition of Pd/Ag composite lm can be suppressed by alloying with Ag [21]. Therefore, the FBG hydrogen sensors reversibility can be improved by using Pd/Ag composite lm. As it is depicted in Fig. 5ac the response time of FBG coated with 110 nm Pd/Ag composite lm is about 280300 s. Compared

to our previous work [16], it can be observed a retardation in the response rate for hydrogen sensors tested under humidied air atmosphere. Furthermore, lower ambient temperature can reduce hydrogen atoms diffusion rate, which led to the increase of the hydrogen sensors response time. The ambient temperature can affect the FBG hydrogen sensor sensitivity in two ways. On one hand, the change of ambient temperature can cause the wavelength shift of sensing FBG, leading to the reduction of the sensors accuracy, which may has a bad effect on the sensor sensitivity. However, this adverse effect can be greatly reduced by using a reference FBG [16,24,26,27]. On the other hand, lower ambient temperature can decrease the diffusion speed of hydrogen molecular [12,13], which increase the response time of FBG hydrogen sensor. As it is reported FBG coated with 350 nm Pd lm without laser heating has no response to 10% H2 at 25 C ambient temperature [13]. Under high humidity atmosphere, the adsorbed H2O on the surface hydrogen sensitive lm can reduce the formation of PdHx, desensitizing the hydrogen sensitive lm towards the detection of hydrogen [28]. Moreover, the adsorbed H2O reduce hydrogen atoms diffusion rate so that the hydrogen sensors response time will be increased. High ambient humidity has a bad effect on the sensors sensitivity and response rate. In our experiment, the longer response time may be mainly attributed to 61.7% ambient humidity and relatively low temperature. Fig. 5d shows the central wavelength shift of FBG coated with 110 nm Pd/Ag composite lm under different concentrations hydrogen. All FBGs coated with hydrogen sensitive lm shift to longer wavelength with the increase of the hydrogen concentra-

30

J. Dai et al. / Optical Fiber Technology 19 (2013) 2630 [6] M. Yang, H. Liu, D. Zhang, X. Tong, Hydrogen sensing performance comparison of Pd layer and Pd/WO3 thin lm coated on side-polished single- and multimode bers, Sens. Actuators B 149 (2010) 161164. [7] M. Yang, Y. Sun, D. Zhang, D. Jiang, Using Pd/WO3 composite thin lms as sensing materials for optical ber hydrogen sensors, Sens. Actuators B 143 (2010) 750753. [8] M.A. Butler, Micromirror optical-ber hydrogen sensor, Sens. Actuators B 22 (1994) 155163. [9] X. B venot, A. Trouillet, C. Veillas, H. Gagnaire, M. Clment, Hydrogen leak detection using an optical bre sensor for aerospace applications, Sens. Actuators B 67 (2000) 5767. [10] K. Lin, Y. Lu, J. Chen, R. Zheng, P. Wang, H. Ming, Surface plasmon resonance hydrogen sensor based on metallic grating with high sensitivity, Opt. Express 16 (2008) 1859918604. [11] C. Ma, A. Wang, Optical ber tip acoustic resonator for hydrogen sensing, Opt. Lett. 35 (2010) 20432045. [12] M. Buric, T. Chen, M. Maklad, P.R. Swinehart, K.P. Chen, Multiplexable lowtemperature ber bragg grating hydrogen sensors, IEEE Photon. Technol. Lett. 21 (2009) 15941596. [13] M. Buric, K.P. Chen, M. Bhattarai, P.R. Swinehart, M. Maklad, Active bre Bragg grating hydrogen sensor for all-temperature operation, IEEE Photon. Technol. Lett. 19 (2007) 255257. [14] B. Sutapun, M. Tabib-Azar, A. Kazemi, Pd-coated elastooptic ber optic Bragg grating sensors for multiplexed hydrogen sensing, Sens. Actuators B 60 (1999) 2734. [15] C. Caucheteur, M. Debliquy, D. Lahem, P. Mgret, Hybrid ber gratings coated with a catalytic sensitive layer for hydrogen sensing in air, Opt. Express 16 (2008) 1685416859. [16] J. Dai, M. Yang, Y. Chen, K. Cao, H. Liao, P. Zhang, Side-polished ber Bragg grating sensor with WO3Pd composite lm as sensing materials, Opt. Express 19 (2011) 61416148. [17] J.H. Lee, J.H. Kim, Y.G. Han, S.H. Kim, S.B. Lee, Investigation of Raman ber laser temperature probe based on ber Bragg gratings for long-distance remote sensing applications, Opt. Express 12 (2004) 17471752. [18] G.T. Kanellos, G. Papaioannou, D. Tsiokos, C. Mitrogiannics, G. Nianios, N. Pleros, Two dimensional polymer-embedded quasi-distributed FBG pressure sensor for biomedical applications, Opt. Express 18 (2010) 179186. [19] D. Lin, X. Jiang, F. Xie, W. Zhang, Z. Lin, I. Bennion, High stability multiplexed bre interferometer and its application on absolute displacement measurement and on-line surface metrology, Opt. Express 12 (2004) 5729 5734. [20] M. Armgarth, C. Nylander, Blister formation in Pd gate MIS hydrogen sensors, IEEE Electron Device Lett. 3 (1982) 384386. [21] B. McCool, G. Xomeritakis, Y.S. Lin, Composition control and hydrogen permeation characteristics of sputter deposited palladiumsilver membranes, J. Membr. Sci. 161 (1999) 6776. [22] J. Shu, A. Adnot, B.P.A. Grandjean, S. Kaliaguine, Structurally stable composite PdAg alloy membranes: introduction of a diffusion barrier, Thin Solid Films 286 (1996) 7279. [23] S. Uemiya, T. Matsuda, E. Kikuchi, Hydrogen permeable palladiumsilver alloy membrane supported on porous ceramics, J. Membr. Sci. 56 (1991) 315325. [24] A.D. Kersey, M.A. Davis, H.J. Patrick, M. LeBlac, K.P. Koo, C.G. Askins, M.A. Putnam, E.J. Friebele, Fiber grating sensors, J. Lightw. Technol. 15 (1997) 1442 1463. [25] K.O. Hill, B. Malo, F. Bilodeau, D.C. Johnson, J. Albert, Bragg gratings using fabricated in monomode photosensitive optical ber by UV exposure thorough a phase mask, Appl. Phys. Lett. 62 (1993) 10351037. [26] K.S. Chiang, R. Kancheti, V. Rastogi, Temperature-compensated ber-Bragggratings for DC and AC currents, Opt. Eng. 42 (2003) 19061909. [27] M. Yang, J. Dai, C. Zhou, D. Jiang, Optical ber magnetic eld sensors with TbDyFe magnetostrictive thin lms as sensing materials, Opt. Express 17 (2009) 2077720782. [28] Z. Zhao, M. Knight, S. Kumar, E.T. Eisenbraun, M.A. Carpenter, Humidity effects on Pd/Au-based all-optical hydrogen sensors, Sens. Actuators B 129 (2008) 726733.

tion. FBG hydrogen sensors show linearity response for 1.54% hydrogen concentrations. However, FBG-125 lm coated with Pd/ Ag composite lm almost has no wavelength shift during 1% hydrogen exposure. When the hydrogen concentration is 4% in volume percentage, the wavelength shifts of FBG-125 lm, FBG-38 lm and FBG-20.6 lm are 8, 23 and 40 pm respectively. Because of the different etching content of the ber, FBG-125 lm, FBG-38 lm and FBG-20.6 lm have different sensitivity to hydrogen. FBG with fewer diameters has more sensitivity. Compared to FBG-125 lm, FBG20.6 lm can increase the sensitivity by 400%, the FBG hydrogen sensitivity can be signicantly improved by etching FBG to a proper content. 5. Conclusion Optical hydrogen sensor based on etched FBG sputtered with Pd/Ag composite lm has been developed in this paper. The sensor has good reversibility in the hydrogen response. XRD results demonstrate the Pd/Ag composite lms are mainly cubic phase. The results show that the FBG with fewer diameters has more wavelength shift under same hydrogen concentration. When the hydrogen concentration is 4% in volume ratio, the wavelength shifts of FBG-125 lm, FBG-38 lm and FBG-20.6 lm are 8, 23 and 40 pm respectively. And FBG hydrogen sensors show linearity response for 1.54% hydrogen concentrations. As a new solution, etched FBG combined Pd/Ag composite lm as hydrogen sensitive element could be very promising for distributed measurement of hydrogen concentration. Acknowledgments This work is nically supported by the Project of National Science Foundation of China, NSFC (Number: 60908020) and the Program for New Century Excellent Talents in University (NCET-100664). References

[1] M. Tabib-Azar, B. Sutapun, R. Petrick, A. Kazemi, Highly sensitive hydrogen sensors using palladium coated ber optics with exposed cores and evanescent eld interactions, Sens. Actuators B 56 (1999) 158163. [2] S.K. Khijwania, B.D. Gupta, Fiber optic evanescent eld absorption sensor: effect of ber parameters and geometry of the probe, Opt. Quantum Electron. 31 (1999) 625636. [3] S. Sekimoto, H. Nakagawa, S. Okazaki, K. Fukuda, S. Asakura, T. Shigemori, S. Takahashi, A ber-optic evanescent-wave hydrogen gas sensor using palladium-supported tungsten oxide, Sens. Actuators B 66 (2000) 142145. [4] J. Villatoro, D. Monzn-Hernndea, Fast detection of hydrogen with nano ber tapers coated with ultra thin palladium layers, Opt. Express 13 (2005) 5087 5092. [5] D. Monzn-Hernndez, D. Luna-Moreno, D. Martnez-Escobar, Fast response ber optic hydrogen sensor based on palladium and gold nano-layers, Sens. Actuators B 136 (2009) 562566.

Вам также может понравиться

- Sound Insulation TheoryДокумент2 страницыSound Insulation TheorySarinОценок пока нет

- AFS Thermal Analysis of CupsДокумент10 страницAFS Thermal Analysis of Cupsyash_ganatraОценок пока нет

- AFS Thermal Analysis of CupsДокумент12 страницAFS Thermal Analysis of Cupsyash_ganatraОценок пока нет

- EN# EN Name SAE UNS DIN BS 970 UNI JIS Carbon SteelsДокумент3 страницыEN# EN Name SAE UNS DIN BS 970 UNI JIS Carbon Steelspm StarkeonОценок пока нет

- Phenolic Resin - BrosurДокумент53 страницыPhenolic Resin - BrosurpaimannОценок пока нет

- Sputtering 1Документ64 страницыSputtering 1.. ..Оценок пока нет

- Build Your Own DS-1 DistortionДокумент32 страницыBuild Your Own DS-1 Distortionsebapunk-leiva-arias-9956100% (1)

- MUFF GUTS - The Big Muff Circuit, Wiring Diagrams, Schematics, Replacement PartsДокумент7 страницMUFF GUTS - The Big Muff Circuit, Wiring Diagrams, Schematics, Replacement PartsgianmarcoОценок пока нет

- Investment Casting Ductile Iron ReviewДокумент5 страницInvestment Casting Ductile Iron ReviewSteve GreenОценок пока нет

- Everyday Electronics 1974 10.CV01Документ6 страницEveryday Electronics 1974 10.CV01marcosscarato0% (1)

- Fiber Optic Sensor Technology: An OverviewДокумент22 страницыFiber Optic Sensor Technology: An OverviewNadia F Mohammad Al-RoshdeeОценок пока нет

- Computer Music 252 February 2018Документ116 страницComputer Music 252 February 2018Oleksii SurskovОценок пока нет

- Temperature PyrometerДокумент60 страницTemperature PyrometerBhargav ShuklaОценок пока нет

- CS3 Mods PDFДокумент6 страницCS3 Mods PDFAnonymous LgJH9UE2jОценок пока нет

- CGA C-6-2019Документ5 страницCGA C-6-2019Y L YewОценок пока нет

- Hot Rod Deville Service Manual GuideДокумент8 страницHot Rod Deville Service Manual GuideFrank L. BaumОценок пока нет

- True Bypass To Big MuffДокумент8 страницTrue Bypass To Big MuffJuan Ignacio SalvucciОценок пока нет

- L Series acoustic guitars deliver time-honored craftsmanship and inspirationДокумент29 страницL Series acoustic guitars deliver time-honored craftsmanship and inspirationRonОценок пока нет

- Andromeda A6Документ37 страницAndromeda A6Zoeloe_2Оценок пока нет

- Boss DD-20 Service NotesДокумент29 страницBoss DD-20 Service NotesFernando GómezОценок пока нет

- Cost Comparison Between Foundry ProcessesДокумент1 страницаCost Comparison Between Foundry ProcessesSiraj PatelОценок пока нет

- Boss OD1 ModificationДокумент2 страницыBoss OD1 ModificationIlya FuksmanОценок пока нет

- Building Analog in The 2010sДокумент67 страницBuilding Analog in The 2010slgl1100% (1)

- Hot Rod Deluxe - Service Manual (1996)Документ8 страницHot Rod Deluxe - Service Manual (1996)Ludwig_AОценок пока нет

- Repair Crackling MIC Potmeters Motu 828 MKII 02Документ7 страницRepair Crackling MIC Potmeters Motu 828 MKII 02maxibandoОценок пока нет

- PDC0097/98 BoM With Preferred VendorsДокумент18 страницPDC0097/98 BoM With Preferred VendorsenergiculОценок пока нет

- Audio Circuits Using The NE5532/34Документ11 страницAudio Circuits Using The NE5532/34Jose Simon Bolivar MoranОценок пока нет

- Dec 2307Документ1 страницаDec 2307rmcelligОценок пока нет

- Guitar (Dadgad) Chords C Minor7thДокумент2 страницыGuitar (Dadgad) Chords C Minor7thAndre Oliveira MendonçaОценок пока нет

- Yamaha Pacifica 904Документ2 страницыYamaha Pacifica 904mikletОценок пока нет

- Keeley ModsДокумент3 страницыKeeley ModsBob StampОценок пока нет

- Boss Cs3 Mods Factory SchemДокумент2 страницыBoss Cs3 Mods Factory Schemprimus2Оценок пока нет

- Guitar (Dadgad) Chords C MinorДокумент1 страницаGuitar (Dadgad) Chords C MinorAndre Oliveira MendonçaОценок пока нет

- FENDER-PRO-SONIC Custom Shop Designed Pro-Sonic DiagramsicДокумент8 страницFENDER-PRO-SONIC Custom Shop Designed Pro-Sonic Diagramsicfecalma100Оценок пока нет

- 117 Section 6 Types of BrassДокумент10 страниц117 Section 6 Types of Brassrozanedeghat8942Оценок пока нет

- RECHUPEДокумент7 страницRECHUPEmarcotulio123Оценок пока нет

- Research On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesДокумент7 страницResearch On Strip Deformation in The Cage Roll-Forming Process of ERW Round PipesJames PhillipsОценок пока нет

- Transparent Conducting Oxides.Документ8 страницTransparent Conducting Oxides.ladycharlotОценок пока нет

- Vacuum Carburizing Using Acetylene GasДокумент6 страницVacuum Carburizing Using Acetylene GasRamesh JakkanagoudarОценок пока нет

- Instr PDFДокумент23 страницыInstr PDFsf39armyОценок пока нет

- Stairville LED Bar 252 ManualДокумент12 страницStairville LED Bar 252 ManualBlaize110Оценок пока нет

- 990 Discrete Op-AmpДокумент8 страниц990 Discrete Op-AmpAnonymous kdqf49qbОценок пока нет

- Dumb Le NotesДокумент7 страницDumb Le NotesFrank Puchi100% (1)

- By: Kory Lutes Moises Garcia Jason Fox: Monday, July 30, 2012Документ17 страницBy: Kory Lutes Moises Garcia Jason Fox: Monday, July 30, 2012m_ignaciogarciaОценок пока нет

- King Slayer Effect PedalДокумент10 страницKing Slayer Effect PedalPablo RagoОценок пока нет

- 2020 Custom Guitar: Design GuideДокумент34 страницы2020 Custom Guitar: Design Guide王斌Оценок пока нет

- Heavy Duty Standby Switch Installation for Billm Blues Junior AmplifierДокумент9 страницHeavy Duty Standby Switch Installation for Billm Blues Junior AmplifierAndrea CeciniОценок пока нет

- 3 SmawДокумент55 страниц3 SmawPutra Daha PratamaОценок пока нет

- Mxr90 To EvhДокумент7 страницMxr90 To EvhCristianОценок пока нет

- Reclamation of Used Green Sand in Small Scale FoundriesДокумент11 страницReclamation of Used Green Sand in Small Scale FoundriesSofi LopezОценок пока нет

- Corrosion Resistence Using Epoxy CoatingДокумент23 страницыCorrosion Resistence Using Epoxy Coatingultra instinctОценок пока нет

- Microarc Oxidation - KeroniteДокумент23 страницыMicroarc Oxidation - Keronitefeni4kaОценок пока нет

- How To Paint Swirl A GuitarsДокумент4 страницыHow To Paint Swirl A Guitarstoneskupang100% (1)

- Peavey Valveking 100 212Документ12 страницPeavey Valveking 100 212whitestratОценок пока нет

- Publicação 1Документ4 страницыPublicação 1rpenzeSОценок пока нет

- An Optimum Design of High Sensitivity PMMA-coated FBG Sensor For Temperature MeasurementДокумент8 страницAn Optimum Design of High Sensitivity PMMA-coated FBG Sensor For Temperature MeasurementTELKOMNIKAОценок пока нет

- Fiber-Optic H2S SensorДокумент5 страницFiber-Optic H2S SensorShauvik BhattacharyaОценок пока нет

- Fiber Bragg Grating Sensor Detects Hydrogen in Power TransformersДокумент6 страницFiber Bragg Grating Sensor Detects Hydrogen in Power TransformersNika ThaiОценок пока нет

- 18 Sep 2021 MitaДокумент10 страниц18 Sep 2021 MitaDedi IrawanОценок пока нет

- 溫度、濕度Документ5 страниц溫度、濕度JОценок пока нет

- Single-Stub Matching ExamplesДокумент9 страницSingle-Stub Matching ExamplesIwan de AngeloОценок пока нет

- Comparison of Optical Back Propagation Schemes For Fiber-Optic Communications - ELSEVIERДокумент6 страницComparison of Optical Back Propagation Schemes For Fiber-Optic Communications - ELSEVIERIwan de AngeloОценок пока нет

- A New Feedback Control Method To Stabilize Fiber-Optical Parametric OscillatorsДокумент3 страницыA New Feedback Control Method To Stabilize Fiber-Optical Parametric OscillatorsIwan de AngeloОценок пока нет

- Circuit Diagrams and Component Drawings: EMCH 367 Fundamentals of Microcontrollers 367pck S01Документ11 страницCircuit Diagrams and Component Drawings: EMCH 367 Fundamentals of Microcontrollers 367pck S01Iwan de AngeloОценок пока нет

- Table of The Erlang Loss Formula PDFДокумент50 страницTable of The Erlang Loss Formula PDFulfar uulОценок пока нет

- Refresher 3 PipeДокумент11 страницRefresher 3 PipeKira YagamiОценок пока нет

- HW1 Solution PDFДокумент6 страницHW1 Solution PDFZuhair AliОценок пока нет

- 22 Metallic Glass: Aggregated Diamond or Hyper DiamondДокумент3 страницы22 Metallic Glass: Aggregated Diamond or Hyper DiamondMariam AbdulkariamОценок пока нет

- Chemistry Multiple Choice Questions Covering Moles, Bonding, and ThermochemistryДокумент7 страницChemistry Multiple Choice Questions Covering Moles, Bonding, and Thermochemistry20Y3G HONG JIN KAIОценок пока нет

- Nuclear ReactionsДокумент3 страницыNuclear ReactionsErica Alviyanti BastiandОценок пока нет

- How Oxygen and Acids in Uence The Aging of TransformersДокумент12 страницHow Oxygen and Acids in Uence The Aging of TransformersRajesh MadapatiОценок пока нет

- Summative Test in Science 6 No.3 1Документ2 страницыSummative Test in Science 6 No.3 1Yram Ecarg OudiserОценок пока нет

- Ikpeka Et Al-2018-Journal of Petroleum Exploration and Production TechnologyДокумент24 страницыIkpeka Et Al-2018-Journal of Petroleum Exploration and Production TechnologyNwakile ChukwuebukaОценок пока нет

- Grade 7 Science Chapter 6 NotesДокумент54 страницыGrade 7 Science Chapter 6 Notesapi-238589602Оценок пока нет

- Determination of Peracetic Acid by Potentiometric Titration: Sample Preparation and ProceduresДокумент6 страницDetermination of Peracetic Acid by Potentiometric Titration: Sample Preparation and ProceduresHasan Zeki BayrakОценок пока нет

- Lab Report Isomerisation of Chromium (III) CoplexesДокумент9 страницLab Report Isomerisation of Chromium (III) CoplexesHDОценок пока нет

- Ultraviolet Spectroscopy and Uv Lasers - Compress PDFДокумент566 страницUltraviolet Spectroscopy and Uv Lasers - Compress PDFmagsОценок пока нет

- ME 63 Syllabus For MEДокумент2 страницыME 63 Syllabus For MEGab MercadoОценок пока нет

- Dalton's Law of Partial PressureДокумент19 страницDalton's Law of Partial PressureAbdur RehmanОценок пока нет

- Tutorial 5 Steam GeneratorsДокумент2 страницыTutorial 5 Steam GeneratorsSherif El-soudyОценок пока нет

- Chapter 15Документ50 страницChapter 15陈希尧Оценок пока нет

- Effect of Narrow vs Broad Particle Size DistributionsДокумент6 страницEffect of Narrow vs Broad Particle Size DistributionsMajd M. KhalilОценок пока нет

- Fuels and CombustionДокумент63 страницыFuels and CombustionKenneth DilancoОценок пока нет

- Emulsion Stability Determination From TurbidityДокумент4 страницыEmulsion Stability Determination From TurbidityalinerhcОценок пока нет

- Acids and BasesДокумент8 страницAcids and BasesJoric MagusaraОценок пока нет

- Calorimetry and Household Circuits Icse TestДокумент1 страницаCalorimetry and Household Circuits Icse Testtarun aroraОценок пока нет

- Paper Class 2021AL Tute 34 A3 DsДокумент4 страницыPaper Class 2021AL Tute 34 A3 DsBlueОценок пока нет

- Operation Distilation Tools OkeДокумент75 страницOperation Distilation Tools Okeali budiantoОценок пока нет

- Lab 11Документ11 страницLab 11jutkiewiczОценок пока нет

- Ce Doped ZnO 9Документ13 страницCe Doped ZnO 9SAHIL SONIОценок пока нет

- Selection: Semi-Hermetic Reciprocating Compressors: Input ValuesДокумент8 страницSelection: Semi-Hermetic Reciprocating Compressors: Input ValuesLoucel Jan Martinez AnibongОценок пока нет

- The Use of Nanoclay in Preparation of Epoxy Anticorrosive CoatingsДокумент10 страницThe Use of Nanoclay in Preparation of Epoxy Anticorrosive Coatingsbelgacem hafidaОценок пока нет

- Chem Process Evaporator Brochure CompressedДокумент4 страницыChem Process Evaporator Brochure CompressedAnonymous O0lyGOShYGОценок пока нет