Академический Документы

Профессиональный Документы

Культура Документы

82 Ultraflex s2 Quick GB NoRestriction

Загружено:

FloorkitОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

82 Ultraflex s2 Quick GB NoRestriction

Загружено:

FloorkitАвторское право:

Доступные форматы

x e l f k a c r i t u l U2Q S

TH EUROPEA E WI N NC EN 12004 S

OU ER SA DHESIVE FOR C

AM IC T ILES

EN 12004

IN COM PLI A

C2FT S2

RDS NDA TA

One component, highlyflexible, high performance, quick-setting and hydrating cementitious adhesive, which is easy to trowel with no vertical slip and an extremely high yield, for ceramic tiles and stone material

CLASSIFICATION IN COMPLIANCE WITH EN 12004 Ultraflex S2 Quick is highly deformable (S2) cementitious (C) improved (2) fast-setting (F) slip-resistant (T) adhesive of class C2FTS2. Ultraflex S2 Quick is CE marked, as declared in ITT certificate n 25070199/Gi (TUM) issued by the Technische Universitt Mnchen laboratory (Germany). WHERE TO USE Bonding of all types (double-fired, single-fired, porcelain, klinker, etc.) and sizes of ceramic tiles on internal and external surfaces. Bonding of natural stone, which is not sensitive to moisture, to interior or exterior. Some application examples Bonding of ceramic tiles (double-fired, single-fired, porcelain, klinker, etc.) and stone material (if not particularly sensitive to humidity) on traditional substrates such as: cementitious and anhydrite screeds; heated screeds; cementitious render or lime-mortar render; plasterboard, pre-fabricated and cement-fibre panels. Laying on flexible substrates or substrates subject to vibration: marine plywood, wooden agglomerates (if sufficiently stable in the presence of water), old wooden floors, etc. Quick refurbishment work where immediate installation is required (public buildings, transport cafes, supermarkets, airports and pedestrian areas). Laying ceramic and stone material on faades, balconies, terraces and slab floors exposed to direct sunlight and temperature gradients. Laying on pre-fabricated concrete walls and concrete substrates. Laying in environments (such as hospital entrance halls, school corridors, public buildings, etc.) where impact noise caused by footsteps needs to be reduced, especially if used in conjunction with the Mapefonic System. Laying ceramic and stone material directly on top of old floors (in ceramic, marble, etc.). Laying floors and coatings on MAPEI waterproofing and anti-fracture membranes. TECHNICAL CHARACTERISTICS Ultraflex S2 Quick is a grey-coloured powder made up of a blend of special cements, graded sand, a high quantity of synthetic resins and micronised elastomers, according to a formula developed in MAPEIs own Research Laboratories. When mixed with water, it forms a mortar with the following characteristics: The innovative Ultralite TechnologyTM provides a low density product which results in two key advantages:

ITI NT CEME

exk l f ra uic t l U2 Q S

1) weight advantage: 15 kg of Ultraflex S2 Quick weighs less than traditional cementitious adhesives of the same volume. Easier handling and lower transport costs apply; 2) increased yield: yield is approximately 30% more compared with MAPEIs traditional cementitious adhesives; low viscosity and, therefore, good workability; highly thixotropic: Ultraflex S2 Quick may be applied on vertical surfaces without sagging and there is no risk of the tiles slipping. It is also possible to lay the tiles from the top working downwards and diagonally without using spacer pegs. excellent capacity for following deformation in the substrate and tiles; bonds perfectly to all materials normally used in the building industry. Ultraflex S2 Quick develops high bonding strength after only 2-3 hours at +23C (after 8 hours at +10C); therefore, floors finishes laid using this product may be used after a very short period of time. RECOMMENDATIONS Do not use Ultraflex S2 Quick in the following cases: on metallic, rubber, PVC or linoleum surfaces; with marble or artificial composite material subject to considerable movement in the presence of humidity. Do not embed electric radiating heating elements in the layer of adhesive. Do not add more water to the mix once it has started to set. APPLICATION PROCEDURE Preparing the substrates The substrates must be mechanically strong, dry and free from crumbling parts, grease, oil, paint and wax. Generally, cementitious substrates used for laying ceramic must not be subject to shrinkage once the tiles have been laid. Since Ultraflex S2 Quick is particularly flexible, however, it is also able to compensate for micro-cracks which form in the substrate if it is not sufficiently cured. Gypsum substrates and anhydrite screeds must be perfectly dry, sufficiently hard, free from dust and, in all cases, treated with Primer G or Mapeprim SP. Areas which are subject to high humidity must be treated with Primer S. Preparing the mix Blend Ultraflex S2 Quick with clean water until a smooth, lump-free paste is obtained. Leave the mix standing for 5 minutes, then re-mix.

The amount of water to use is approx. 5.4 l of water for every 15 kg sack. The mix prepared as above lasts approx. 30 minutes. Applying the mix Apply Ultraflex S2 Quick on the substrate using a notched trowel. Use a trowel which guarantees perfect buttering of the back of the tile. To obtain a good bond, spread a thin layer of Ultraflex S2 Quick on the substrate using the smooth side of the trowel. Immediately spread a further layer of Ultraflex S2 Quick to the thickness required using a suitable notched trowel, according to the size and type of the tiles. When laying floors and coatings on external surfaces, or for tiles larger than 900 cm2 and floors subject to heavy loads, spread the adhesive on the back of the tile to guarantee total buttering. Laying the tiles It is not necessary to wet the tiles before they are laid. Only in the case of tile backs which are very dusty do we recommend washing them by dipping them into clean water. The tiles must be applied with a slight pressure to guarantee that they are well buttered. At normal temperatures and humidity conditions, the open time of Ultraflex S2 Quick is ca. 15-20 minutes. Unfavourable conditions (direct sunlight, dry wind and high temperatures), or if the substrate is very absorbent, may reduce this time to only a few minutes. Continuously check the adhesive to make sure that a skin does not form on the surface and that it is still fresh. If a skin forms, respread the adhesive using the notched trowel. It is unadvisable to wet the adhesive when a surface skin forms, because the water forms a film which prevents bonding instead of dissolving it. Finishes laid with Ultraflex S2 Quick must not be washed down or exposed to rain for at least 3-4 hours, and must be protected against freezing weather or direct sunlight for at least 24 hours after laying. Grouting and sealing The tile joints may be grouted after 2-3 hours when laid on walls and after 5-6 hours when laid on floors using a special MAPEI cementitious or epoxy grout, which are available in a variety of colours. Expansion joints must be sealed using the special MAPEI sealants. SET TO LIGHT FOOT TRAFFIC Floors are ready for foot traffic after approx. 5-6 hours. READY FOR USE The surfaces may be put into service after approx. 24 hours. Cleaning Tools and containers may be cleaned using plenty of water while Ultraflex S2 Quick is

Example of porcelain gres laid on Mapelastic using Ultraflex S2 Quick

TECHNICAL DATA (typical values)

Conforms to the following standards: European EN 12004 as C2FTS2 ISO 13007-1 as C2FTS2 American ANSI A 118.4 - 1999 Canadian 71 GP 30 M type 2

PRODUCT IDENTITY Consistency: Colour: Bulk density (kg/m3): Dry solids content (%): Storage: Hazard classification according to EC 1999/45: powder grey 870 100 12 months in its original packaging in a dry place none. Before using refer to the Safety instructions for preparation and application paragraph and the information on the packaging and Safety Data Sheet 3824 50 90

Customs class: APPLICATION DATA (at +23C and 50% R.H.) Mixing ratio:

100 parts of Ultraflex S2 Quick with 35-37 parts of water by weight creamy 1,200 > 12 > 30 mins from +5C to +35C 15-20 mins 2-3 hours 5-6 hours 5-6 hours 24 hours

Consistency of the mix: Density of mix (kg/m3): pH of mix: Pot life of mix: Application temperature range: Open time (according to EN 1346): Grouting of wall tile joints: Grouting of floor tile joints: Set to light foot traffic: Ready for use: FINAL PERFORMANCE Adhesion strength according to EN 1348 (N/mm2): initial (after 28 days): after application of heat source: after immersion in water: after freeze-thaw cycles: Resistance to alkalis: Resistance to oils: Resistance to solvents: Temperature in service: Deformability according to EN 12002:

1.90 1.80 1.30 1.40 excellent excellent (poor to vegetable oils) excellent from -30C to +90C S2 - highly flexible (> 5 mm)

CONSUMPTION 0.9 kg/m2 per mm of thickness, equal to 1.5-2.5 kg/m2. STORAGE Ultraflex S2 Quick may be stored for up to 12 months in its original packaging in a dry place. The product conforms to the requirements of Directive 2003/53/CE. SAFETY INSTRUCTIONS FOR PREPARATION AND APPLICATION Ultraflex S2 Quick contains cement that, when in contact with sweat or other bodily fluids, produces a slightly irritant reaction. Wear protective clothing, gloves and eye/face protection. For further information, please refer to the Safety Data Sheet. FOR PROFESSIONAL USE.

Please refer to the current version of the Technical Data Sheet, available from our web site www.mapei.com

Our Commitment To The Environment More than 150 MAPEI products assist Project Designers and Contractors create innovative LEED (The Leadership in Energy and Environmental Design) certified projects, in compliance with the U.S. Green Building Council.

Contains more than 20% of recycled material

BUILDING THE FUTURE

82-4-2010

Any reproduction of texts, photos and illustrations published here is prohibited and subject to prosecution

All relevant references for the product are available upon request and from www.mapei.com

(GB) A.G. BETA

exk l f ra uic t l U2 Q S

still fresh. Surfaces must be cleaned with a damp cloth before the adhesive sets. PACKAGING Ultraflex S2 Quick is available in 15 kg paper sacks.

WARNING Although the technical details and recommendations contained in this product data sheet correspond to the best of our knowledge and experience, all the above information must, in every case, be taken as merely indicative and subject to confirmation after long-term practical application: for this reason, anyone who intends to use the product must ensure beforehand that it is suitable for the envisaged application: in every case, the user alone is fully responsible for any consequences deriving from the use of the product.

Вам также может понравиться

- 9235 Waterproofing Membrane: Advantages and CertificationsДокумент5 страниц9235 Waterproofing Membrane: Advantages and CertificationsatharkОценок пока нет

- Altro Sample Card Altro PVC Weld RodДокумент1 страницаAltro Sample Card Altro PVC Weld RodFloorkitОценок пока нет

- Str. Design Calc of Boundary WallДокумент7 страницStr. Design Calc of Boundary WallAnonymous NBGW6fj8Yl100% (2)

- Hydraulic Jacking SystemДокумент21 страницаHydraulic Jacking SystemGan Chee SienОценок пока нет

- 2703 UltramasticIIIsuperwhite GB NoRestrictionДокумент4 страницы2703 UltramasticIIIsuperwhite GB NoRestrictionFloorkitОценок пока нет

- 2608 Planitop Fast 330 Uk NoRestrictionДокумент4 страницы2608 Planitop Fast 330 Uk NoRestrictionFloorkitОценок пока нет

- Basf Masterflow 9200 DB EngДокумент4 страницыBasf Masterflow 9200 DB Engapi-283891975Оценок пока нет

- MYK Aquafin 2CДокумент2 страницыMYK Aquafin 2Cnarmad_anil100% (1)

- 2801 Ultracolor Plus GB NoRestrictionДокумент6 страниц2801 Ultracolor Plus GB NoRestrictionFloorkitОценок пока нет

- Rapid Set Tds - NoRestrictionДокумент4 страницыRapid Set Tds - NoRestrictionFloorkitОценок пока нет

- TDS - Mastertop 200Документ2 страницыTDS - Mastertop 200Venkata RaoОценок пока нет

- S1 NoRestrictionДокумент4 страницыS1 NoRestrictionFloorkitОценок пока нет

- Cmci Cmci: Euco-Weather GuardДокумент2 страницыCmci Cmci: Euco-Weather Guardpravi3434Оценок пока нет

- 100 Keraflex Maxi Uk NoRestrictionДокумент4 страницы100 Keraflex Maxi Uk NoRestrictionFloorkitОценок пока нет

- Sikacem Gunit 133Документ2 страницыSikacem Gunit 133the pilotОценок пока нет

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringДокумент4 страницыUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitОценок пока нет

- 2069 Mapelastic Foundation GB NoRestrictionДокумент4 страницы2069 Mapelastic Foundation GB NoRestrictionFloorkitОценок пока нет

- 4005 Ultraplan Eco 20 UaeДокумент0 страниц4005 Ultraplan Eco 20 UaeJohn SarthouОценок пока нет

- Ul Tra Co Lor: UltracolorДокумент6 страницUl Tra Co Lor: UltracolorKim ChanthanОценок пока нет

- Emaco Fast FibreДокумент4 страницыEmaco Fast FibreSandro MendesОценок пока нет

- Master Emaco S5400Документ2 страницыMaster Emaco S5400WahyudiBlueghostОценок пока нет

- Brochure GammaONE PANTONE BassaДокумент16 страницBrochure GammaONE PANTONE BassaEmran MiaОценок пока нет

- Mapelastic SmartДокумент7 страницMapelastic SmarttamukachiromoОценок пока нет

- Fevicol PurДокумент3 страницыFevicol PurVenkata ChadaОценок пока нет

- 1 DT 2.8 Preparation FillercoatДокумент4 страницы1 DT 2.8 Preparation Fillercoatyoxan25808Оценок пока нет

- Sikafloor - 2530 W: 2-Part Water Based Epoxy CoatingДокумент5 страницSikafloor - 2530 W: 2-Part Water Based Epoxy Coatingthe pilotОценок пока нет

- Fugabella Epoxy enДокумент6 страницFugabella Epoxy enKiran Kumar JhaОценок пока нет

- Non-Shrink / Tixothropic Grouting Mortar: Ünka-Hgt Ünka-HgtДокумент1 страницаNon-Shrink / Tixothropic Grouting Mortar: Ünka-Hgt Ünka-HgtKrm ChariОценок пока нет

- BASF MasterSeal M 790 TdsДокумент9 страницBASF MasterSeal M 790 TdsAmar WadoodОценок пока нет

- Ardex WPM 155 DatasheetДокумент2 страницыArdex WPM 155 DatasheetGiriPrasathОценок пока нет

- Gallery 0768498605 Sika Level 100TДокумент5 страницGallery 0768498605 Sika Level 100TRobert EshwerОценок пока нет

- MoyaProof WS2 PDFДокумент2 страницыMoyaProof WS2 PDFChristian Nicolaus Mbise100% (4)

- FF NoRestrictionДокумент4 страницыFF NoRestrictionFloorkitОценок пока нет

- (PDS) Conbextra EP300Документ4 страницы(PDS) Conbextra EP300Faizal HaziziОценок пока нет

- Sikafloor 2530 W-LP, 18kg (Ab)Документ4 страницыSikafloor 2530 W-LP, 18kg (Ab)azheminОценок пока нет

- Shower Waterproofing SystemДокумент2 страницыShower Waterproofing SystemLoz101Оценок пока нет

- The Anydron Manual - Working With PU Waterproof CoatingsДокумент5 страницThe Anydron Manual - Working With PU Waterproof Coatingsakis5375Оценок пока нет

- TDS - Emaco S88 PlusДокумент2 страницыTDS - Emaco S88 PlusVenkata RaoОценок пока нет

- Sikafloor® Proseal-22: Product Data SheetДокумент3 страницыSikafloor® Proseal-22: Product Data SheetLIDER BAHTERAОценок пока нет

- Underlay Ment Waterproofing InstructionsДокумент2 страницыUnderlay Ment Waterproofing InstructionsjacksonliОценок пока нет

- Ceresit Global Ce40 Aquastatic TdsДокумент3 страницыCeresit Global Ce40 Aquastatic TdsSurush ZikrilobekovОценок пока нет

- Water ProofingДокумент5 страницWater ProofingMalith De SilvaОценок пока нет

- 232 Ultrabond Eco 380 UkДокумент4 страницы232 Ultrabond Eco 380 UkFloorkitОценок пока нет

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingДокумент4 страницыSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaОценок пока нет

- Pds Sikaceram flx23Документ5 страницPds Sikaceram flx23mertelululalalolo23Оценок пока нет

- TDS - Masterkure 161Документ2 страницыTDS - Masterkure 161Venkata Rao0% (1)

- TDS Euco Diamond HardДокумент2 страницыTDS Euco Diamond HardJim HaigОценок пока нет

- TDS - Mastertop 1730Документ2 страницыTDS - Mastertop 1730Venkata RaoОценок пока нет

- Sikagrout - 295: Cement-Base Fluid Expanding Mortar, With High Mechanical ResistanceДокумент2 страницыSikagrout - 295: Cement-Base Fluid Expanding Mortar, With High Mechanical Resistancethe pilotОценок пока нет

- Waterproofing - Sikafloor - Proseal-22Документ3 страницыWaterproofing - Sikafloor - Proseal-22CC Cost AdvisoryОценок пока нет

- TDS - Mastertop 230Документ2 страницыTDS - Mastertop 230Venkata RaoОценок пока нет

- Florgard SLДокумент3 страницыFlorgard SLcharibackupОценок пока нет

- Seal&dry PDFДокумент4 страницыSeal&dry PDFAnySikaОценок пока нет

- TDS Pattex BondsealfillДокумент5 страницTDS Pattex BondsealfilldknisОценок пока нет

- SikaTop Armatec 110 EpoCemДокумент3 страницыSikaTop Armatec 110 EpoCemseagull70Оценок пока нет

- Nitoseal 290Документ4 страницыNitoseal 290Venkata RaoОценок пока нет

- K10 GRS 2000Документ2 страницыK10 GRS 2000Dilon FernandoОценок пока нет

- Mapecem Pronto Data - BakДокумент4 страницыMapecem Pronto Data - BakFloorkitОценок пока нет

- Tds - Emaco s88c TДокумент2 страницыTds - Emaco s88c TVenkata RaoОценок пока нет

- 8.T-ProofCrete 709 13-03-28Документ2 страницы8.T-ProofCrete 709 13-03-28Shamsul IslamОценок пока нет

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionОт EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionОценок пока нет

- No. 110 Inside Cove Corner KitДокумент1 страницаNo. 110 Inside Cove Corner KitFloorkitОценок пока нет

- Crain 247 Multi Purpose Wall TrimmerДокумент2 страницыCrain 247 Multi Purpose Wall TrimmerFloorkitОценок пока нет

- L3 Gold System Primer GB 01Документ2 страницыL3 Gold System Primer GB 01FloorkitОценок пока нет

- Invisiweld Installation GuidelinesДокумент2 страницыInvisiweld Installation GuidelinesFloorkitОценок пока нет

- Mastic Sample BoardДокумент1 страницаMastic Sample BoardFloorkitОценок пока нет

- Avenue Installation and MaintenanceДокумент8 страницAvenue Installation and MaintenanceFloorkitОценок пока нет

- Uzin Ke 2000 S: Product Data SheetДокумент4 страницыUzin Ke 2000 S: Product Data SheetFloorkitОценок пока нет

- Leoline Installation and MaintenanceДокумент8 страницLeoline Installation and MaintenanceFloorkitОценок пока нет

- Uzin KE 603Документ2 страницыUzin KE 603FloorkitОценок пока нет

- Uzin NC 110Документ4 страницыUzin NC 110FloorkitОценок пока нет

- Uzin KE 2428Документ2 страницыUzin KE 2428FloorkitОценок пока нет

- Uzin PE 360Документ2 страницыUzin PE 360FloorkitОценок пока нет

- Uzin PE 260Документ2 страницыUzin PE 260FloorkitОценок пока нет

- Ultrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringДокумент4 страницыUltrabond P902 2K Ultrabond P902 2K: Two-Component Epoxy-Polyurethane Adhesive For Wooden FlooringFloorkitОценок пока нет

- Uzin NC 145: Product Data SheetДокумент2 страницыUzin NC 145: Product Data SheetFloorkitОценок пока нет

- Uzin L 3 Gold: Product Data SheetДокумент2 страницыUzin L 3 Gold: Product Data SheetFloorkitОценок пока нет

- Uzin NC 152Документ2 страницыUzin NC 152FloorkitОценок пока нет

- 231 Ultrabond Eco Vs90 UkДокумент4 страницы231 Ultrabond Eco Vs90 UkFloorkitОценок пока нет

- Uzin NC 150 New: Product Data SheetДокумент2 страницыUzin NC 150 New: Product Data SheetFloorkitОценок пока нет

- 219 Ultrabond Eco Fix UkДокумент4 страницы219 Ultrabond Eco Fix UkFloorkitОценок пока нет

- Uzin NC 150 New: Product Data SheetДокумент2 страницыUzin NC 150 New: Product Data SheetFloorkitОценок пока нет

- Mapei MapelayДокумент4 страницыMapei MapelayFloorkitОценок пока нет

- 2504 Ultrabond Eco s945 1k GBДокумент4 страницы2504 Ultrabond Eco s945 1k GBFloorkitОценок пока нет

- 232 Ultrabond Eco 380 UkДокумент4 страницы232 Ultrabond Eco 380 UkFloorkitОценок пока нет

- 2918 Mapeproof 1k Turbo UkДокумент4 страницы2918 Mapeproof 1k Turbo UkFloorkitОценок пока нет

- A Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionДокумент4 страницыA Solvent-Free Non-Staining Acrylic-Adhesive in Water DispersionFloorkitОценок пока нет

- 270 Ultrabondecos9551k GBДокумент4 страницы270 Ultrabondecos9551k GBFloorkitОценок пока нет

- 220 Ultrabond Eco 170 UkДокумент4 страницы220 Ultrabond Eco 170 UkFloorkitОценок пока нет

- Mapei FibreplanДокумент4 страницыMapei FibreplanFloorkitОценок пока нет

- Installation Procedure EQOBRUSH For Heat Exchangers and CondensersДокумент16 страницInstallation Procedure EQOBRUSH For Heat Exchangers and CondensersWatco GroupОценок пока нет

- The Role of The Construction Sector in Influencing Natural Resource Use, Structural Change, and Industrial Development in ZambiaДокумент31 страницаThe Role of The Construction Sector in Influencing Natural Resource Use, Structural Change, and Industrial Development in ZambiabrianОценок пока нет

- Obe Reports Hec - Report Section OutlineДокумент2 страницыObe Reports Hec - Report Section OutlineDanish EjazОценок пока нет

- Testing & Commissioning of Domestic Water PumpsДокумент5 страницTesting & Commissioning of Domestic Water PumpsHishamGharbiahОценок пока нет

- The Paombong Public MarketДокумент2 страницыThe Paombong Public MarketJeonAsistin100% (1)

- ContinueДокумент2 страницыContinuePramod RaghuОценок пока нет

- Ship LaddersДокумент5 страницShip LaddersPatrick GuoОценок пока нет

- Buildingguide - Co.nz-Construction ChecklistsДокумент16 страницBuildingguide - Co.nz-Construction ChecklistsElla CelineОценок пока нет

- Iare E&c Lecture Notes PDFДокумент110 страницIare E&c Lecture Notes PDFRichik MondalОценок пока нет

- Studor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)Документ1 страницаStudor Tec-Vent: Product Information/Specification Sheet (Air Admittance Valve For Plumbing Ventilation)sijilОценок пока нет

- Mohd Faiz Mohammad Zaki Afizah Ayob and Tee Chin FangДокумент4 страницыMohd Faiz Mohammad Zaki Afizah Ayob and Tee Chin FangDenis Dwayne DizzleОценок пока нет

- Linear Bushing MetricДокумент256 страницLinear Bushing MetricsandchiОценок пока нет

- Piled Foundation ReportДокумент7 страницPiled Foundation ReportDijo Mathews100% (1)

- AMEC Coating Specification 01Документ35 страницAMEC Coating Specification 01cenkturker100% (1)

- Metric Hex Bolt ChartsДокумент1 страницаMetric Hex Bolt ChartsPraburamОценок пока нет

- Durability of Concrete Exposed To Marine Environment-A Fresh LookДокумент30 страницDurability of Concrete Exposed To Marine Environment-A Fresh LookElizabeth CruzОценок пока нет

- Ghansali Pumping Water Supply SchemeДокумент43 страницыGhansali Pumping Water Supply SchemeProject ManagerStructuresОценок пока нет

- Proposal For Verification of In-Situ Concrete StrengthДокумент36 страницProposal For Verification of In-Situ Concrete StrengthYF NОценок пока нет

- Multiline-Stone Coated Roofing Balinese ShakesДокумент2 страницыMultiline-Stone Coated Roofing Balinese ShakesjbonvierОценок пока нет

- Connection PDFДокумент59 страницConnection PDFsachin.meenaОценок пока нет

- Paling BillДокумент5 страницPaling Billanon_b186Оценок пока нет

- DS 4HH-CCДокумент2 страницыDS 4HH-CCeduardo mata gamezОценок пока нет

- VE5C VE Commodore Hard Lid ManualДокумент13 страницVE5C VE Commodore Hard Lid ManualmathewОценок пока нет

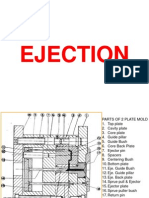

- K EjectionДокумент21 страницаK EjectionAmolPagdalОценок пока нет

- 20 THДокумент2 страницы20 THdohamateОценок пока нет

- Review PaperДокумент21 страницаReview PaperShar KhanОценок пока нет

- Forging AluminiumДокумент3 страницыForging Aluminiumnadeem_mechОценок пока нет

- Testing: II.1. Limitations On PressureДокумент10 страницTesting: II.1. Limitations On Pressureகோகுல் இராОценок пока нет