Академический Документы

Профессиональный Документы

Культура Документы

Boat Landing Systems-2

Загружено:

Guilherme Leal0 оценок0% нашли этот документ полезным (0 голосов)

317 просмотров6 страницTrelleborg offshore products Boat Landing Systems provide a cost effective and reliable protection for offshore platforms. Every unit is load tested prior to delivery and the customer can choose from a complete range of sizes to suit their needs. The Shock Cells and Eccentric Bumper Rings are proven in absorbing and safely defecting almost all axial and lateral loads.

Исходное описание:

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTrelleborg offshore products Boat Landing Systems provide a cost effective and reliable protection for offshore platforms. Every unit is load tested prior to delivery and the customer can choose from a complete range of sizes to suit their needs. The Shock Cells and Eccentric Bumper Rings are proven in absorbing and safely defecting almost all axial and lateral loads.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

317 просмотров6 страницBoat Landing Systems-2

Загружено:

Guilherme LealTrelleborg offshore products Boat Landing Systems provide a cost effective and reliable protection for offshore platforms. Every unit is load tested prior to delivery and the customer can choose from a complete range of sizes to suit their needs. The Shock Cells and Eccentric Bumper Rings are proven in absorbing and safely defecting almost all axial and lateral loads.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 6

Trelleborg Offshore Products

Boat Landing and Fendering Systems

Boat Landing

Eccentric Bumper Ring

Boat Landing Systems by Trelleborg provide a cost effective and

reliable protection for offshore platforms. Building on our experience

in manufacturing specialized rubber products for the marine industry, the

Boat Landing Systems can withstand the most hostile climates and operate in

even the most severe weather.

It is durable, easy to install and requires no maintenance. Every unit is load tested prior

to delivery and the customer can choose from a complete range of sizes to suit their

needs. Our Shock Cells and Eccentric Bumper Rings are proven in absorbing and safely

defecting almost all axial and lateral loads so that you can have peace of mind that your

platform will always be protected.

How it works

The Boat Landing System consists primarily of the Shock Cells, Eccentric Bumper Rings

(EBR) and a steel contact surface. On impact by a berthing vessel, the steel surface transfers

the load to the EBRs and the Shock Cells. Kinetic energy is absorbed and dissipated as heat

and a smaller reaction force against the vessel by the rubber as it undergoes shear and

tension. The load is therefore reduced and the vessel can berth without damaging

the platform structure. The strong bonding achieved between the rubber and the

steel during the manufacturing process ensures that this arrangement will safely

dissipate and reduce the external load without damaging the platform.

We essentially utilize rubber`s unique ability in defecting

normal and lateral impact to withstand the design stresses

that is imposed on a platform during barge and vessel

operations. Rubber, with its internal damping effect, can

resist high overloads without damage.

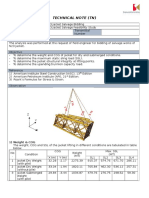

Shock CeII Specications (AII dimensions in mm)

Type

TH1424

TH1630

TH1830

TH1636

TH1836

TH2036

A

356

406

457

406

457

508

B

19

26

19

26

24

21

C

610

762

762

914

914

914

D

17

19

19

25

25

25

E

216

406

406

610

610

610

F

435

679

610

800

746

660

D

B

All dimensions act as a guide only. Please refer to us for details.

Shock Cell

E

F

C

A

Boat Landing

Boat Landing

TH-RS-100

Rubstrips

Rubstrips

TH-RS-400 TH-RS-200

We also manufacture rubstrips of several different profles. Our profles can be solid or hollow and

come with many ftting options to the jacket leg/structure.

Our rubstrips are made of high quality rubber that provide the necessary protection to offshore

structures while ensuring that the vessel is not damaged. It consists of a simple but robust design

that is free from maintenance and have excellent weather resistance. Please contact us for more

details.

GeneraI ProIes

TH-RS-300

TH-RS-BB1 TH-RS-700 TH-RS-400 TH-RS-BB2

Models and sizes are for reference only.

Rubber & plate size can vary according to customer`s specifcation.

ModeI

TH-RS-100

TH-RS-200

TH-RS-300

TH-RS-400

TH-RS-700

TH-RS-BB1

TH-RS-BB2

305mm(W) x 229mm(H)

216mm(W) x 143mm(H)

203mm(W) x 154mm(H)

229mm(W) x 57mm(H)

229mm(W) x 57mm(H)

276mm(W) x 136mm(H)

276mm(W) x 136mm(H)

Rubber Size OveraII Size

356mm(W) x 248mm(H)

216mm(W) x 255mm(H)

254mm(W) x 173mm(H)

229mm(W) x 130mm(H)

229mm(W) x 159mm(H)

305mm(W) x 355mm(H)

305mm(W) x 355mm(H)

ExxonMobiI EAST AREA Arch Fender & Frame

BTE SAUDI ARAMCO Shock Cell

Petronas ABU-A Rubstrips

Amerada Hess UJUNG PANGKAH Rubstrips

ConocoPhiIIips KERISI Shock Cell, EBR & Rubstrips

Premier OiI WEST LOBE Rubstrips

Murphy OiI WEST PATRICIA WPPA & 1A Fenders

PTTEP ERAWAN FIELD TTP Shock Cell & EBR

BG & CIough PANNA FIELD Shock Cell, EBR & Rubstrips

Petronas Vietnam RUBY B Rubstrips

TOTAL Myanmar WP3 FIELD Shock Cell & EBR

JVPC C1, CLPP & S1 FIELD Shock Cell, EBR & Rubstrips

CIough HAZIRA DEVELOPMENT Shock Cell, EBR & Rubstrips

Sandra SOUTH PARS 4 & 5 Shock Cell & EBR

I.O.E.C SOUTH PARS 1 & 2 Shock Cell & EBR

McDermott Dubai AMOCO P15/18 Shock Cell & EBR

IHC Gusto UNOCAL L11-B Shock Cell & EBR

Heerema MOBIL P-6B & C Shock Cell & EBR

Grootint CONOCO L16 Shock Cell & EBR

T

E

S

-

O

B

L

0

1

-

R

e

v

1

Certifcate No. 190037

Certifcate No. 403030

Boat Landing

Project Reference List

Research & DeveIopment

At Trelleborg, we continue to further refne and

improve our product line through R & D activities

utilizing the latest tools like FEA modelling (shown

above), rapid prototyping/testing and a more

selective mixture of raw materials that combine

to give our customers products that perform at

the highest standard. These initiatives ultimately

translate to cost savings that will be passed on

to our customers. We are able to offer the fastest

and most cost competitive customization to meet

every offshore fendering requirement. Contact us

to learn more about what we can offer in terms of

product improvements/ customizations.

PhysicaI Properties of Rubber

Property Test Standard Specication

Tensile Strength (MPa) ASTM D412 18 min

Elongation @ Break ASTM D412 450 min

Tear Resistance (kN/m) ASTM D624 (B) 80 min

Compression Set (%) ASTM D395 (B) 25 max

Ozone Resistance ASTM D1149 No cracks

Вам также может понравиться

- Trelleborg Offshore Boat Landing SystemsДокумент6 страницTrelleborg Offshore Boat Landing SystemswaleedyehiaОценок пока нет

- Leg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251Документ8 страницLeg Penetration Analysis AD-G34-1041-R2658 - Seafox 8 LPA at Zulf 246-251SinojKumarMalipronОценок пока нет

- JEE309 Assignment3 OnBottomStabilityДокумент2 страницыJEE309 Assignment3 OnBottomStabilityAnwarul Shafiq AwalludinОценок пока нет

- Static Analysis Report Rev-A PDFДокумент16 страницStatic Analysis Report Rev-A PDFbee4manuОценок пока нет

- KOM Loadout InterfaceДокумент49 страницKOM Loadout InterfaceNguyen Dinh Ngoc Duy100% (1)

- Existing Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3Документ8 страницExisting Pipeline Cable Under Crossings - ADDENDUM To PROCEDURE - RO3MitchellgranyОценок пока нет

- Calculation Note Rev.0Документ8 страницCalculation Note Rev.0Riandi HartartoОценок пока нет

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsДокумент2 страницыEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaОценок пока нет

- Redefining Riser-Guard System For Fixed Offshore PlatformsДокумент5 страницRedefining Riser-Guard System For Fixed Offshore PlatformsJACKОценок пока нет

- Cable Laying Equipment: CCC (Underwater Engineering) SalДокумент5 страницCable Laying Equipment: CCC (Underwater Engineering) Sallaleye_olumideОценок пока нет

- J-Tube Pull-In Simulation SetupДокумент4 страницыJ-Tube Pull-In Simulation SetupArie Indra MasudiОценок пока нет

- Erection and Installation Procedure for Marine Loading Arm Package Doc. 9754Документ48 страницErection and Installation Procedure for Marine Loading Arm Package Doc. 9754Arie Reza RizaldyОценок пока нет

- Engineering data for SPM buoyДокумент4 страницыEngineering data for SPM buoyRomawi Stevyandi100% (3)

- Concrete Mattresses FlysheetДокумент3 страницыConcrete Mattresses FlysheetDave M MichaelОценок пока нет

- Bonga Pipe in Pipe LayДокумент66 страницBonga Pipe in Pipe LayWilliam O OkolotuОценок пока нет

- Sea TransportationДокумент8 страницSea TransportationMark Samsel RohanОценок пока нет

- Above Water Tie inДокумент2 страницыAbove Water Tie inZadeh NormanОценок пока нет

- PLEM Pile Drivability PDFДокумент49 страницPLEM Pile Drivability PDFTharach JanesuapasaereeОценок пока нет

- OBS InstallationДокумент6 страницOBS InstallationFaridah ZahraОценок пока нет

- Underwater Submarine Pipe LineДокумент30 страницUnderwater Submarine Pipe LinevillanuevamarkdОценок пока нет

- Steel Pipe Stacking Analysis on Wooden SleepersДокумент2 страницыSteel Pipe Stacking Analysis on Wooden Sleeperslive4sankarОценок пока нет

- TBDP-A-S-RPT-1020 - Substructure Inplace AnalysisДокумент45 страницTBDP-A-S-RPT-1020 - Substructure Inplace AnalysisViktor DươngОценок пока нет

- Collapse Analysis 1Документ13 страницCollapse Analysis 1samiransmitaОценок пока нет

- MaxTeff OrcaFlex SpreadsheetДокумент10 страницMaxTeff OrcaFlex SpreadsheetNaeem NematiОценок пока нет

- Etame Pipeline Fabrication PlanДокумент25 страницEtame Pipeline Fabrication PlanWilliam O OkolotuОценок пока нет

- Jacket Weighing ProcedureДокумент14 страницJacket Weighing ProcedureBolarinwaОценок пока нет

- 286 Oral WED 1B 04Документ6 страниц286 Oral WED 1B 04Guomin JiОценок пока нет

- Input Data: Trench - CoverДокумент20 страницInput Data: Trench - CoverEl riza annamlОценок пока нет

- 14 - NRG - Pipe Installation - Davit LiftДокумент16 страниц14 - NRG - Pipe Installation - Davit LiftBalanОценок пока нет

- Offshore Pipeline Landfall PDFДокумент112 страницOffshore Pipeline Landfall PDFangga fajarОценок пока нет

- Flexible Jumper Design PremiseДокумент12 страницFlexible Jumper Design PremiseAgus BudionoОценок пока нет

- Principia DeepLines PresentationДокумент45 страницPrincipia DeepLines Presentationbello imamОценок пока нет

- FatFree User ManualДокумент41 страницаFatFree User ManualLava Sat100% (1)

- Pipeline INSTALLATIONДокумент4 страницыPipeline INSTALLATIONJemar Lim100% (1)

- Equipment List Including Long Lead ItemsДокумент6 страницEquipment List Including Long Lead Itemspapilolo2008Оценок пока нет

- Lifting Analysis Preview)Документ4 страницыLifting Analysis Preview)Faisal AjaОценок пока нет

- Wind Turbine Foundation Design StepsДокумент9 страницWind Turbine Foundation Design StepsRamachandran Sundararaman100% (1)

- FatFREE 10.1Документ1 страницаFatFREE 10.1jesusgameboyОценок пока нет

- CN Scrubber Dn3500 Rev04Документ58 страницCN Scrubber Dn3500 Rev04becemОценок пока нет

- 7234 M RP 1002 Ver C0100 PDFДокумент601 страница7234 M RP 1002 Ver C0100 PDFbaskaran ayyapparaj100% (1)

- Section A: 2.1. Sling Design Load and SelectionДокумент30 страницSection A: 2.1. Sling Design Load and SelectionThomas StephenОценок пока нет

- Lateral BucklingДокумент36 страницLateral Bucklingrsb72Оценок пока нет

- Mathcad - DevelopmentДокумент4 страницыMathcad - Developmenttheo lucasОценок пока нет

- MS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabДокумент19 страницMS002-UZ-PRO-0B1-50220 - B01 Welding Qualification Plan For Riser FabPuspita LerianaОценок пока нет

- Jacket AppurtenancesДокумент50 страницJacket AppurtenancesAanbualagan ChelvanathanОценок пока нет

- Section 4: Specifications Specifications For Quick Release HookДокумент17 страницSection 4: Specifications Specifications For Quick Release HookAnonymous iM2totBrОценок пока нет

- Tender Documents For Procurement For Coated PipeДокумент56 страницTender Documents For Procurement For Coated PipeVeena S V0% (1)

- PT - Mcci Document Register List Rev.B 110811Документ3 страницыPT - Mcci Document Register List Rev.B 110811adityadhОценок пока нет

- OPT98 Fatigue Design-DNV-Guideline-Free Spanning PipelinesДокумент24 страницыOPT98 Fatigue Design-DNV-Guideline-Free Spanning PipelinesYemi LawalОценок пока нет

- LOTOS SIWZ A1-3 Z12 112996-EnG-RPT-00003 R02 IFC Pipeline Installation AnalysisДокумент33 страницыLOTOS SIWZ A1-3 Z12 112996-EnG-RPT-00003 R02 IFC Pipeline Installation AnalysisJP EDSОценок пока нет

- Lazy AssignmentДокумент5 страницLazy Assignmentthefoot39Оценок пока нет

- DANA-Technical Note (TN)Документ8 страницDANA-Technical Note (TN)Samsul Imran BahromОценок пока нет

- PLEM Design Methodology: StructureДокумент4 страницыPLEM Design Methodology: StructureErik AlfiandyОценок пока нет

- Guide Document For Itemized Spring Hangers and Tie-Rod Data SheetsДокумент19 страницGuide Document For Itemized Spring Hangers and Tie-Rod Data SheetsAHMED AMIRAОценок пока нет

- Ageing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityОт EverandAgeing and Life Extension of Offshore Structures: The Challenge of Managing Structural IntegrityОценок пока нет

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОт EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsОценок пока нет

- Bearing Pad - 2007Документ4 страницыBearing Pad - 2007Kumar JbsОценок пока нет

- Defensas Maritimas - Complete FlotationДокумент32 страницыDefensas Maritimas - Complete FlotationFelipe FernandesОценок пока нет

- Seals For Water Lubricated Propeller ShaftsДокумент4 страницыSeals For Water Lubricated Propeller ShaftsAndrea NaranjoОценок пока нет

- Brochure Ej BeanДокумент5 страницBrochure Ej Beanipman99Оценок пока нет

- Batista - Stresses in A Circular Ring Under Two Forces Acting Along A DiameterДокумент4 страницыBatista - Stresses in A Circular Ring Under Two Forces Acting Along A DiameterGuilherme LealОценок пока нет

- Best Practice Report Mooring of Floating Marine Renewable Energy DevicesДокумент30 страницBest Practice Report Mooring of Floating Marine Renewable Energy DevicesGuilherme LealОценок пока нет

- Gte 2012 PDFДокумент92 страницыGte 2012 PDFGuilherme LealОценок пока нет

- Postresp UmДокумент328 страницPostresp UmGuilherme LealОценок пока нет

- Xtract Report Builder User ManualДокумент64 страницыXtract Report Builder User ManualGuilherme LealОценок пока нет

- Monitoring VIV DamageДокумент12 страницMonitoring VIV DamageGuilherme LealОценок пока нет

- WhitePaper Fatigue 0510 - tcm4-79704Документ23 страницыWhitePaper Fatigue 0510 - tcm4-79704Mario TirabassiОценок пока нет

- WhitePaper Fatigue 0510 - tcm4-79704Документ23 страницыWhitePaper Fatigue 0510 - tcm4-79704Mario TirabassiОценок пока нет

- Introduction To FT N 95Документ45 страницIntroduction To FT N 95Guilherme Leal0% (1)

- 04 1santalaДокумент13 страниц04 1santalaGuilherme LealОценок пока нет

- NR13 em InglesДокумент16 страницNR13 em InglesTaniucha1100% (5)

- Non-Destructive Radiography ProcedureДокумент16 страницNon-Destructive Radiography ProcedureGuilherme LealОценок пока нет

- Genie User Manual Volume 2Документ121 страницаGenie User Manual Volume 2Guilherme LealОценок пока нет

- Office VBA Macros You Can Use Today-Over 100 Amazing Ways To Automate Word - Excel - PowerPoint - Outlook and AccessДокумент594 страницыOffice VBA Macros You Can Use Today-Over 100 Amazing Ways To Automate Word - Excel - PowerPoint - Outlook and Accessaitt59Оценок пока нет

- Timoshenko. Strength of Materials. Parts I - II (2nd Ed, 1947) - Print - ScannedДокумент7 страницTimoshenko. Strength of Materials. Parts I - II (2nd Ed, 1947) - Print - ScannedRavinder SinghОценок пока нет

- CFEExam Prep CourseДокумент28 страницCFEExam Prep CourseM50% (4)

- ABBBAДокумент151 страницаABBBAJeremy MaraveОценок пока нет

- Wind EnergyДокумент6 страницWind Energyshadan ameenОценок пока нет

- CORE Education Bags Rs. 120 Cr. Order From Gujarat Govt.Документ2 страницыCORE Education Bags Rs. 120 Cr. Order From Gujarat Govt.Sanjeev MansotraОценок пока нет

- Elaspeed Cold Shrink Splices 2010Документ3 страницыElaspeed Cold Shrink Splices 2010moisesramosОценок пока нет

- Marketing ManagementДокумент14 страницMarketing ManagementShaurya RathourОценок пока нет

- Law of TortsДокумент22 страницыLaw of TortsRadha KrishanОценок пока нет

- Installing and Registering FSUIPCДокумент7 страницInstalling and Registering FSUIPCKAPTAN XОценок пока нет

- ASME Y14.6-2001 (R2007), Screw Thread RepresentationДокумент27 страницASME Y14.6-2001 (R2007), Screw Thread RepresentationDerekОценок пока нет

- Dell 1000W UPS Spec SheetДокумент1 страницаDell 1000W UPS Spec SheetbobОценок пока нет

- QSK45 60 oil change intervalДокумент35 страницQSK45 60 oil change intervalHingga Setiawan Bin SuhadiОценок пока нет

- Elementary School: Cash Disbursements RegisterДокумент1 страницаElementary School: Cash Disbursements RegisterRonilo DagumampanОценок пока нет

- AE383LectureNotes PDFДокумент105 страницAE383LectureNotes PDFPoyraz BulutОценок пока нет

- An Overview of Tensorflow + Deep learning 沒一村Документ31 страницаAn Overview of Tensorflow + Deep learning 沒一村Syed AdeelОценок пока нет

- Royalty-Free License AgreementДокумент4 страницыRoyalty-Free License AgreementListia TriasОценок пока нет

- Applicants at Huye Campus SiteДокумент4 страницыApplicants at Huye Campus SiteHIRWA Cyuzuzo CedricОценок пока нет

- Top Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Документ1 страницаTop Brand Story Bar Supervisor Jobs Chennai Apply Now Latest Fresher Experienced Bar Supervisor Jobs in Various Location July 18 2021Surya JamesОценок пока нет

- Fundamentals of Real Estate ManagementДокумент1 страницаFundamentals of Real Estate ManagementCharles Jiang100% (4)

- Aci 207.1Документ38 страницAci 207.1safak kahraman100% (7)

- Bentone 30 Msds (Eu-Be)Документ6 страницBentone 30 Msds (Eu-Be)Amir Ososs0% (1)

- Dissolved Oxygen Primary Prod Activity1Документ7 страницDissolved Oxygen Primary Prod Activity1api-235617848Оценок пока нет

- Econometrics Chapter 1 7 2d AgEc 1Документ89 страницEconometrics Chapter 1 7 2d AgEc 1Neway AlemОценок пока нет

- EWAIRДокумент1 страницаEWAIRKissy AndarzaОценок пока нет

- Bank Statement AnalysisДокумент26 страницBank Statement AnalysisAishwarya ManoharОценок пока нет

- Distribution of Laptop (Ha-Meem Textiles Zone)Документ3 страницыDistribution of Laptop (Ha-Meem Textiles Zone)Begum Nazmun Nahar Juthi MozumderОценок пока нет

- Impact of Coronavirus On Livelihoods of RMG Workers in Urban DhakaДокумент11 страницImpact of Coronavirus On Livelihoods of RMG Workers in Urban Dhakaanon_4822610110% (1)

- Bill of ConveyanceДокумент3 страницыBill of Conveyance:Lawiy-Zodok:Shamu:-El80% (5)

- Leg Wri FInal ExamДокумент15 страницLeg Wri FInal ExamGillian CalpitoОценок пока нет

- Part E EvaluationДокумент9 страницPart E EvaluationManny VasquezОценок пока нет

- Group 4 HR201 Last Case StudyДокумент3 страницыGroup 4 HR201 Last Case StudyMatt Tejada100% (2)