Академический Документы

Профессиональный Документы

Культура Документы

PTC Thermistors For Degaussing

Загружено:

metaldeathИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PTC Thermistors For Degaussing

Загружено:

metaldeathАвторское право:

Доступные форматы

2322 662 96...

Vishay BCcomponents

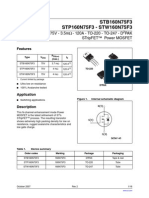

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

FEATURES

a. Dual or double mono PTC degaussing.

Residual currents as low as 2 mA (p-p), ideal for high-resolution displays Long decay time Stable performance over a long time (>20000 operations) Self-extinguishing white plastic case (UL 94.V.0 )

MBB633

Design-in support available.

APPLICATIONS

Colour televisions

b. Mono PTC degaussing.

Colour monitors.

DESCRIPTION

For good picture definition, colour televisions and monitors must be degaussed by a strong alternating magnetic field which gradually and symmetrically decays to a small value of residual current. This can be achieved by connecting a PTC thermistor in the degaussing circuit. The new generation of flat-screen, high-definition colour televisions and monitors require an excellent picture quality with high colour purity. This can only be achieved by a dual PTC device housing two PTC thermistors in intimate thermal contact, one being used to heat the other and so further reduce the residual current.

CCB442

QUICK REFERENCE DATA

PARAMETER Resistance of degaussing PTC (Rs) at 25 C Standard tolerance on resistance of degaussing PTC (Rs) at 25 C Resistance of heater PTC (Rp) at 25 C Standard tolerance on resistance of heater PTC (Rp) at 25 C Maximum AC voltage (RMS value) Minimum inrush current (peak-to-peak value) Temperature range (at maximum voltage) Available pitch: 4e/1e 4e/2e Standard pin length Detailed specications based on 10.16 to 2.54 10.16 to 5.08 4.2 mm mm mm VALUE 3 to 30 20 and 25 3000 75 145 to 276 10 to 30 0 to 60 UNIT % % V A C

CECC 44000/ IEC 60738

www.vishay.com 184

For technical questions contact: nlr.europe@vishay.com

Document Number: 29077 Revision: 10-Oct-03

2322 662 96...

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

DUAL RANGE ELECTRICAL DATA AND ORDERING INFORMATION

MINIMUM PEAK-TO-PEAK(2)(6) INRUSH CURRENT (A) MAXIMUM PEAK-TO-PEAK(2) RESIDUAL CURRENT (mA) after 5s after 30 s after 180 s 2 2 4 2 2 2 4 4 5 5 5 10 10 10 14 10 10 R25(3) ( ) Rcoil(4)(6) () TYPICAL DECAY PERFORMANCE TYPE(8) Rs % MIN. TYP. DECAY TIME(5)(6) (ms) 60 40 40 65 50 75 40 45 70 80 95 115 110 80 85 85 115 ALPHA MAX.(6) (%) 36 43 44 33 38 29 45 40 36 30 33 26 33 31 30 31 29 LD LD LD LT LD/LT LT LD/LT LD/LT LT LD/LT LD 4e/1e pitch 4e/2e pitch CATALOG NUMBER(9) 2322 662 .....

Vishay BCcomponents

UR = 220 to 240 VRMS (Umax = 276 VRMS) 11 50 5 14 50 5 16 80 8 16 80 8 20 80 8 18 80 15 25 80 10 25 80 10 21 80 10 21 100 20 20 100 40 20 100 25 21 100 40 UR = 100 to 120 VRMS (Umax = 145 VRMS) 19 200 20 27 200 50 30 200 20 30 200 20

30 26 22 22 18 18 14 14 12 12 9 9 7 7 5 5 3

25 25 25 25 25 25 25 25 20 20 20 20 20 20 30/15 20 30/15

17 14 14 10 10 10 10 10 10 10 13 13 20 5 5 4 4

25 17 17 17 13 17 10 10 17 17 20 20 20 7 6 5 6

96209 96211 96216 96616 96624 96626 96602 96642 96606 96646 96608 96648 96213 96605 96645 96643

96309 96311 96316 96716 96724 96726 96702 96742 96706 96746 96708 96748 96709 96313 96705 96745 96743

MONO CASED RANGE ELECTRICAL DATA AND ORDERING INFORMATION

MINIMUM PEAK-TO-PEAK(2) INRUSH CURRENT (A) MAXIMUM PEAK-TO-PEAK(2) RESIDUAL CURRENT (mA) R25(3) ( ) Rcoil(4)(7) () TYPICAL DECAY PERFORMANCE CATALOG NUMBER(9) 2322 662 .....

TYPE(8)

after after after DECAY ALPHA % MIN. TYP. 4e pitch Rs 5s 30 s 180 s TIME(5)(7) (ms) MAX.(6) (%) UR = 220 to 240 VRMS (Umax = 276 VRMS) 11 100 40 20 30 25 17 25 75 30 96281 12 50 30 20 26 25 14 25 90 30 96688 16 80 40 20 22 25 14 17 40 44 96286 20 100 50 25 18 25 10 13 50 38 96682 25 200 50 30 14 25 10 10 40 45 96683 25 200 80 30 14 25 10 10 45 40 LD 96692 21 200 80 30 12 20 10 17 70 36 96684 21 200 80 30 12 20 10 17 80 30 LD 96696 20 100 50 30 9 20 13 20 95 33 LT 96687 20 200 50 25 9 20 13 20 115 26 LD/LT 96698 21 100 50 30 7 20 20 20 110 33 LD/LT 96681 UR = 100 to 120 VRMS (Umax = 145 VRMS) 19 200 70 40 7 20 5 7 80 31 96285 27 200 70 40 5 30/1 5 6 85 30 96686 30 200 70 40 5 20 4 5 85 31 LD 96695 30 200 70 40 3 30/1 4 6 115 29 LD 96693 Notes 1. Electrical data and catalog numbers. The shading indicates preferred types. 2. All peak-to-peak currents are measured at typical resistance of the coil, at 50 Hz (AC), at 25C and at 220 Vrms for the 276V types, and 110Vrms for the 145V types. 3. Lower tolerances on resistance of degaussing PTC are available on request. 4. Lower minimum coil resistance is available on request. 5. Decay time is the time from the moment of maximum peak current until the half of the maximum peak inrush current. 6. Alpha maximum is the maximum decrease in current expressed in percent between two successive peaks. 7. Inrush currents and decay times at other voltage coil combinations can be derived from Figures 7 to 13, see section Introduction, PTC thermistors for degaussing. 8. LT = low tolerance; LD = long decay. 9. Smallest packaging quantity (SPQ) = 600 units. Document Number: 29077 Revision: 10-Oct-03 For technical questions contact: nlr.europe@vishay.com www.vishay.com 185

2322 662 96...

Vishay BCcomponents

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

DOUBLE MONO CASED RANGE ELECTRICAL DATA AND ORDERING INFORMATION

MINIMUM PEAK-TO-PEAK(1) INRUSH CURRENT (A) MAXIMUM PEAK-TO-PEAK(1) RESIDUAL CURRENT (mA) after 5s after 30 s after 180 s R25(3) () Rcoil(2)(6) () TYPICAL DECAY PERFORMANCE TYPE(7) Rs % MIN. TYP. DECAY TIME(4)(6) (ms) ALPHA MAX.(5) (%) 4e/2e pitch CATALOG NUMBER(8) 2322 662 .....

UR = 220 to 240 VRMS (Umax = 276 Vrms) 33 34 36 33 35 200 200 200 200 200 35 35 40 45 50 25 25 30 35 40 9.0 (18 2) 7.0 (14 2) 6.0 (12 2) 4.5 (9 2) 3.5 (7 2) 25 25 20 20 20 7 7 7 10 13 10 10 10 13 13 80 80 85 130 135 31 31 31 27 27 LD LD LD/LT LD/LT LD/LT 96754 96752 96756 96758 96759

UR = 100 to 120 VRMS (Umax = 145 Vrms) 27 34 39 Notes 1. 2. 3. 4. 5. 6. All peak-to-peak currents are measured at typical resistance of the coil, at 50 Hz (AC), at 25C and at 220 Vrms for the 276V types, and 110Vrms for the 145V types. Lower minimum coil resistance is available on request. The indicated resistance value is the parallel combination of two degaussing PTCs. Decay time is the time from the moment of maximum peak current until the half of the maximum peak inrush current. Alpha maximum is the maximum decrease in current expressed in percent between two successive peaks. Inrush currents and decay times at other voltage coil combinations can be derived from Figures 7 to 13 in the section, Introduction, PTC thermistors for degaussing. 7. LT = low tolerance; LD = long decay. 8. Smallest packaging quantity (SPQ) = 600 units. 250 250 250 80 80 80 45 45 45 3.5 (7 2) 2.5 (5 2) 1.5 (3 2) 20 20 20 3 3 4 7 6 6 255 200 250 16 19 21 LD/LT LD/LT LD/LT 96757 96755 96753

INRUSH CURRENT

Minimum inrush current as a percentage of mains voltage.

IINR (%)

CCB447

100 80 60 40 20 0 90 110 220 300 V (VRMS)

APPLICATION SPECIFIC DATA

The data shown in the above tables is obtained from measurements at reference parameters. If these parameters do not correspond to the application parameters required, refer to Figures 7 to 13 in theIntroduction, PTC thermistors for degaussing, datasheet.

www.vishay.com 186 For technical questions contact: nlr.europe@vishay.com Document Number: 29077 Revision: 10-Oct-03

2322 662 96...

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

DIMENSIONS AND PIN CONFIGURATION(1)

PRODUCT TYPE MONO 4e 2322 662 9628. 2322 662 9668. 2322 662 9669. Note 1. See Mono, Dual and Dual and Double drawings below. 4e/1e 2322 662 962.. 2322 662 966.. DUAL 4e/2e 2322 662 963.. 2322 662 967.. DOUBLE MONO 4e/2e 2322 662 9675.

Vishay BCcomponents

DIMENSIONS in millimeters

Dual PTC pin configuration 4e/1e pitch.

16.5 0.5 14.1 0.5 4e/1e pitch

B A 20.5 0.4 0.9 0.1 10.16 0.508 0.25 0.05 1.1 max. 2.54 0.3 5.08 0.3 5.08 0.3 C

2.54 0.3 (1e)

4.2 0.3

CCB303

For electrical data and ordering information, see Dual Range table.

Dual and Double mono PTC pin configuration 4e/2e pitch.

16.5 0.5 14.1 0.5 4e/2e pitch B A 20.5 0.4 0.9 0.1 10.16 0.508 0.25 0.05 1.1 max. 5.08 0.3 5.08 0.6 5.08 0.6

CCB304

5.08 0.3 (2e)

4.2 0.3

For electrical data and ordering information, see Dual Range and Double Mono Range tables.

Mono PTC pin configuration 4e pitch.

16.5 0.5 14.1 0.5 4e pitch

20.5 0.4 0.9 0.1 10.16 0.508

4.2 0.3 1.1 max. 10.16 0.3

0.25 0.05

CCB305

For electrical data and ordering information, see Mono Cased Range table.

Document Number: 29077 Revision: 10-Oct-03

For technical questions contact: nlr.europe@vishay.com

www.vishay.com 187

2322 662 96...

Vishay BCcomponents

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

PIN CONFIGURATIONS

PRODUCT TYPE CONNECTION MONO Mains Coil(s) point A point B DUAL points A and B points A and B DOUBLE MONO point B points A and C

MEASURING CIRCUITS

B Rs +T Vmains Rc 2% V

Vmains +T Rp

Rs +T

Rc 2%

CCB456

CCB457

a. Mono cased PTC degaussing.

B Rs1 +T Rs2 Vmains +T A Rc 2% V C

b. Dual cased PTC degaussing. V = A/D converter or oscilloscope. Rs = resistance of series PTC or degaussing PTC. Rp = resistance of parallel PTC or heater PTC. Rc = replaces the degaussing coil. Vmains = AC power source with high output current capability; frequency = 50 Hz 1%; total harmonic distortion < 2%. For residual current measurement the Rc resistor can be increased to 100 1%, 30 s after inrush.

CCB458

c. Double mono cased PTC degaussing.

CONSTRUCTION

The dimensions of the ceramic are just for reference and might vary according to the PTC degaussing type.

DUAL CASED PTC DEGAUSSING

2 5 4 Pitch 4e/1e 3 6 2 5 4 3 6

MONO CASED PTC DEGAUSSING

2 3 5 Pitch 4e 2 5 3

1

CCB449

4 2

3 4 5 3 6 1

1

CCB448

Pitch 4e/2e 3

Mono cased PTC degaussing.

CCB450

Dual cased PTC degaussing.

DOUBLE MONO CASED PTC DEGAUSSING

2 3 5 Pitch 4e/2e 1

CCB452

Double mono cased PTC degaussing. www.vishay.com 188 For technical questions contact: nlr.europe@vishay.com Document Number: 29077 Revision: 10-Oct-03

2322 662 96...

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

MATERIAL INFORMATION(1)

NUMBER 1 2 3 4 5 6 DESCRIPTION base cap spring contact (outer) central contact degaussing PTC thermistor (Rs) heater PTC thermistor (Rp) MATERIAL AND REMARKS glass bre reinforced polybutyleneteraphtalate (PBTP); self-extinguishing according to UL 94 V-0, UL number E69578(M) or equivalent corrosion resisting steel with nickel/silver ash; pin termination in Sn60Pb40 coated BaTiO3 doped

Vishay BCcomponents

Note 1. See Mono, Dual and Double mono cased PTC Degaussing drawings.

MASS

MASS PTC DEGAUSSING PER UNIT (g) 5.0 4.2 PER BOX OF 600 units (kg) 3.6 3.0

PACKAGE MARKING

The package containing the thermistors marked as shown in the barcode label below.

DUAL OR DOUBLE MONO MONO CASED

MARKING PRODUCT MARKING

The thermistors are manufactured in Belgium and assembly is either in Belgium or Indonesia (Batam). The products are marked on the top with the last five digits of the catalogue number, code of manufacturer and the date code (year, week, day and batch of manufacture).

ASSEMBLED IN BELGIUM

MARKING 96724 BC 1141A DESCRIPTION last 5-digits of code number code of manufacturer manufacturing date (YWWDx)

JW90

MARKING EXAMPLE

96724 BC1141A Barcode label.

BARCODE LABEL MARKING ASSEMBLED IN INDONESIA (BATAM)

MARKING BC 96724 SP 1141A DESCRIPTION code of manufacturer last 5-digits of code number code of assembler manufacturing date (YWWDx) 4 5 6 LINE 1 2 3 MARKING EXPLANATION Name of manufacturer; country of origin Batch number Preference origin code: A Country of origin in code: 170 (Belgium) Responsible production centre: VS Quantity and production period, year, week day and batch code Product type description Product code (12NC)

MARKING EXAMPLE BC96724 SP1141A

Document Number: 29077 Revision: 10-Oct-03

For technical questions contact: nlr.europe@vishay.com

www.vishay.com 189

2322 662 96...

Vishay BCcomponents

PACKAGING in millimeters

The thermistors are supplied in cardboard boxes containing 5 trays of 120 items per tray; each box containing 600 units.

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

182

CCB240

288 212

Outer box dimensions.

GENERAL OVERVIEW OF PRODUCTION AND QUALITY CONTROL FLOWCHART

RAW MATERIALS INCOMING INSPECTION

POWDER PREPARATION

POWDER TEST

35

CCB298

PRESSING

CONTROL OF PRESSING PARAMETERS

282 208

FIRING ELECTRICAL CHECKS

CONTACTING

CONTROL OF CONTACT LAYER THICKNESS

Tray dimensions.

INSPECTION PARAMETERS

AUTOMATED RESISTANCE CHECK AND VISUAL CHECK

MOUNTING

AUTOMATED INSPECTION ON MOUNTING MACHINE

PACKING

PACKAGING

PRODUCT AUDIT

SAMPLE BASED TESTING

WAREHOUSE

DISPATCH AUDIT

Process steps Main process control activities

www.vishay.com 190

For technical questions contact: nlr.europe@vishay.com

Document Number: 29077 Revision: 10-Oct-03

2322 662 96...

PTC Thermistors For Degaussing, Dual, Mono And Double Mono Cased

TEST AND REQUIREMENTS STANDARD TEST SCHEDULE

CECC 44003 CLAUSE TEST D* or ND CONDITIONS PERFORMANCE REQUIREMENTS

Vishay BCcomponents

Outgoing inspection (lot-by-lot) 4.3.1 4.3.2 4.3.3 4.4 visual examination marking dimensions (gauging) zero power resistance: degaussing PTC (Rs) heater PTC (Rp) 4.27 minimum peak to peak inrush current maximum peak to peak current after: 5s 30 s 180 s 4.13.1 solderability D solder bath method: 235 5 C the terminations shall be evenly tinned; 95% covered ND ND at 220/110 VRMS and reference coil at 220/110 VRMS and reference coil as specied ND at 25 C ND no visible damage legible as detailed specications as specied

* D = Destructive, ND = Non-destructive.

LIFE TESTS

IEC 60738 TEST METHOD TEST endurance cycling: maximum voltage at low temperature endurance cycling: maximum voltage at 25 C endurance at maximum rated temperature and maximum voltage endurance cycling at maximum voltage in humidity PROCEDURE maximum voltage with minimum coil: see detailed specications; temperature: 0 5 C; duration, 100 cycles maximum voltage with minimum coil: see detailed specications; temperature: 25 5 C; duration, 40000 cycles maximum voltage: see detailed specications; temperature: 60 5 C; duration, 2000 hours maximum voltage with minimum coil: see detailed specications; conditions: 40 C, 95% RH; cycle; 30 on 60 off; duration, 56 days (900 cycles) REQUIREMENTS no visible damage Rs/Rs (25 C) max.: 20% Rp/Rp (25 C) max.: 50% inrush current at 25 C: Iinrush > 95%; Iinrush specied nal current at 25 C: Inal < 105%; Inal specied Inal = I after 3 minutes

Other tests in accordance with IEC 60068-2 3 (Ca) 2 (Ba) 6 (Fc) damp heat (steady state) dry heat vibration (mounted state) 56 days; 40 C; 95% RH 1000 hours; 125 C frequency: 10 to 55 Hz; displacement 0.75 mm or acceleration 10 g; 3 directions; total 6 hours 10 s; 260 5 C vertical severity; duration 10 s ammability: ame 5 s max.

20 (Tb)

resistance to soldering heat

Other test in accordance with IEC 60695.2 2 ammability needle ame test

Document Number: 29077 Revision: 10-Oct-03

For technical questions contact: nlr.europe@vishay.com

www.vishay.com 191

This datasheet has been download from: www.datasheetcatalog.com Datasheets for electronics components.

Вам также может понравиться

- TDA2008Документ10 страницTDA2008miusayОценок пока нет

- 2.0" DM Dotmatrix 5X7: Kwality Photonics Private LimitedДокумент1 страница2.0" DM Dotmatrix 5X7: Kwality Photonics Private LimitedKike GutierrezОценок пока нет

- STW21NM50N MosfetДокумент16 страницSTW21NM50N MosfetrigowОценок пока нет

- 2N6027Документ9 страниц2N6027mariogizziОценок пока нет

- MH 182 Multi-Purpose Hall Effect Latch Technical SpecificationДокумент11 страницMH 182 Multi-Purpose Hall Effect Latch Technical SpecificationharshalvikasОценок пока нет

- A 1102Документ11 страницA 1102l461870Оценок пока нет

- CTX 400Документ5 страницCTX 400Brzata PticaОценок пока нет

- Electronic Timer CT-VBS.17+18: OFF-delayed Without Auxiliary Voltage, For DC Contactors Data SheetДокумент7 страницElectronic Timer CT-VBS.17+18: OFF-delayed Without Auxiliary Voltage, For DC Contactors Data SheetRoga29Оценок пока нет

- Vepppalodai Power VerДокумент27 страницVepppalodai Power VerRajaDurai RamakrishnanОценок пока нет

- Siemens - Tyco V23084 C2001 A303Документ5 страницSiemens - Tyco V23084 C2001 A303meda меда100% (1)

- BLF244Документ16 страницBLF244Luis AlfredoОценок пока нет

- ABB T1maxДокумент6 страницABB T1maxharrisvasОценок пока нет

- Relee Din Gama 38Документ6 страницRelee Din Gama 38andy175Оценок пока нет

- Tda7266sa PDFДокумент11 страницTda7266sa PDFerju10Оценок пока нет

- UKFLR300Документ8 страницUKFLR300Ginanjar PranathaОценок пока нет

- BTA/BTB24, BTA25, BTA26 and T25 Series: 25A TriacДокумент9 страницBTA/BTB24, BTA25, BTA26 and T25 Series: 25A TriacCristiano BruschiniОценок пока нет

- Metal Film Resistors MRS16S/25: Philips Components Product SpecificationДокумент12 страницMetal Film Resistors MRS16S/25: Philips Components Product SpecificationnrsaranОценок пока нет

- TY616Документ8 страницTY616Anupam AshokОценок пока нет

- TDA7262Документ9 страницTDA7262Nelson PereiraОценок пока нет

- 159 Pul-Si: Vishay BccomponentsДокумент8 страниц159 Pul-Si: Vishay BccomponentsteomondoОценок пока нет

- Thyristor Power ElectronicsДокумент14 страницThyristor Power ElectronicssayedtafseerОценок пока нет

- STK404 070SДокумент5 страницSTK404 070SJuan Carlos BarrantesОценок пока нет

- Stb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetДокумент16 страницStb160N75F3 Stp160N75F3 - Stw160N75F3: N-Channel 75V - 3.5M - 120A - To-220 - To-247 - D Pak Stripfet™ Power MosfetmoabdolyОценок пока нет

- Ca3306 (A, C)Документ17 страницCa3306 (A, C)notaden1849Оценок пока нет

- Bta 24800 BДокумент9 страницBta 24800 BIulia CalinОценок пока нет

- Tesys Contactors DДокумент6 страницTesys Contactors DJabir QuadriОценок пока нет

- Datasheet mc14584Документ8 страницDatasheet mc14584Heriberto Flores AmpieОценок пока нет

- CA3059, CA3079: Description FeaturesДокумент12 страницCA3059, CA3079: Description FeaturesMiltongrimi GrimilОценок пока нет

- ZVP4525GДокумент8 страницZVP4525GAlexander AnotherSituation MartinsonОценок пока нет

- Go P20NM60FP PDFДокумент15 страницGo P20NM60FP PDFHenry HenriquezОценок пока нет

- MR758Документ7 страницMR758Bruno NascimentoОценок пока нет

- ACPL312TДокумент18 страницACPL312Tcms_saОценок пока нет

- Datasheet Capacitor YAGEOДокумент10 страницDatasheet Capacitor YAGEOrafaelfernandes183Оценок пока нет

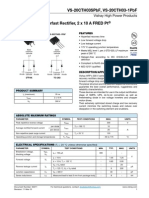

- Vs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsДокумент9 страницVs-20Cth03Spbf, Vs-20Cth03-1Pbf: Vishay High Power ProductsrrebollarОценок пока нет

- Ca 3083Документ4 страницыCa 3083tabassam7801Оценок пока нет

- ST3232 Data SheetДокумент12 страницST3232 Data SheetcredioОценок пока нет

- TSL257S DatasheetДокумент9 страницTSL257S DatasheetAndresPalaciosОценок пока нет

- Tda 7294Документ17 страницTda 7294Abubakar SidikОценок пока нет

- LC0406FC3.3C LC0406FC36C: ApplicationsДокумент6 страницLC0406FC3.3C LC0406FC36C: ApplicationsselocaОценок пока нет

- LT 3693Документ24 страницыLT 3693Zoltán BaranyaiОценок пока нет

- 2 DIGIT LED DISPLAY SPECSДокумент5 страниц2 DIGIT LED DISPLAY SPECSBima Richardo SihombingОценок пока нет

- HS-1840ARH: Rad-Hard 16 Channel CMOS Analog Multiplexer With High-Z Analog Input Protection FeaturesДокумент7 страницHS-1840ARH: Rad-Hard 16 Channel CMOS Analog Multiplexer With High-Z Analog Input Protection FeaturesDeepa DevarajОценок пока нет

- D D D D D D D D: DescriptionДокумент10 страницD D D D D D D D: DescriptionVíctor LópezОценок пока нет

- 200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CДокумент9 страниц200W Low Capacitance Flip Chip Tvs Array Description: Lc0408Fc3.3C - Lc0408Fc36CselocaОценок пока нет

- 60528Документ23 страницы60528Andres CaminoОценок пока нет

- 3 SF 21Документ15 страниц3 SF 21vohoncoiОценок пока нет

- NPN BRT Dtc143tm3t5g (Sot-723) RohsДокумент10 страницNPN BRT Dtc143tm3t5g (Sot-723) RohsBLUEE009Оценок пока нет

- STTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeДокумент9 страницSTTA1206D/DI/G: Turboswitch Ultra-Fast High Voltage DiodeMarcos AndréОценок пока нет

- CA3102Документ11 страницCA3102bonaparteCWBОценок пока нет

- Eng DS 1308242 T92 1112 PDFДокумент4 страницыEng DS 1308242 T92 1112 PDFYashiro AlvaradoОценок пока нет

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОт EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsОценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1От EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- Ohm's LawДокумент16 страницOhm's LawSamuel Matthew AlfonsoОценок пока нет

- Discussion - Ohm - S LawДокумент2 страницыDiscussion - Ohm - S LawChrisEmilsonHernaez50% (4)

- Technical Aptitude SetДокумент15 страницTechnical Aptitude SetSelva RajОценок пока нет

- Physics P3 EDEXCEL IGCSE MAY 2010Документ16 страницPhysics P3 EDEXCEL IGCSE MAY 2010aqua05Оценок пока нет

- pH/ORP Transmitter Operating ManualДокумент70 страницpH/ORP Transmitter Operating ManualDaniel Andres Silva AlvaradoОценок пока нет

- A6 Voltage Variations in Capacitors (NEW FILE)Документ7 страницA6 Voltage Variations in Capacitors (NEW FILE)Andrei NicolasОценок пока нет

- Basics of Sonars & Underwater Acoustics PDFДокумент108 страницBasics of Sonars & Underwater Acoustics PDFSrinivasanОценок пока нет

- FTR F3aa012e PDFДокумент5 страницFTR F3aa012e PDFAhmad Noor HasanОценок пока нет

- Electrical Fundamentals: Aircraft Maintenance LicenceДокумент271 страницаElectrical Fundamentals: Aircraft Maintenance Licenceram rijhan yadavОценок пока нет

- Fundamentals of Electric Circuits, Second Edition - Alexander/SadikuДокумент18 страницFundamentals of Electric Circuits, Second Edition - Alexander/SadikuSuttarat Yonying100% (1)

- EE131.1 LabДокумент40 страницEE131.1 LabMarc MontillaОценок пока нет

- Homework HW11 - P16-P19 ReviewДокумент12 страницHomework HW11 - P16-P19 Reviewaargaw55Оценок пока нет

- MV March2018 EsasДокумент9 страницMV March2018 EsasMargo Isay EriveОценок пока нет

- Invertec Cc400-S Export Wiring Schematic: CODE: 76115Документ1 страницаInvertec Cc400-S Export Wiring Schematic: CODE: 76115Suryana MamanОценок пока нет

- Ronda 8040 N Complete Technical DocumentationДокумент35 страницRonda 8040 N Complete Technical DocumentationBraulioОценок пока нет

- ICSE Board Class X Physics Gold Series Sample Paper - 4: Time: 1 Hrs Total Marks: 80 General InstructionsДокумент16 страницICSE Board Class X Physics Gold Series Sample Paper - 4: Time: 1 Hrs Total Marks: 80 General InstructionsArijit Das GuptaОценок пока нет

- Chemical Process Calculations: Sweta C Balchandani Faculty, SOT-Chemical, PdpuДокумент32 страницыChemical Process Calculations: Sweta C Balchandani Faculty, SOT-Chemical, PdpuParikh DhruvОценок пока нет

- FatДокумент31 страницаFatgourishankar2Оценок пока нет

- 6ES72315PF320XB0 Datasheet en PDFДокумент4 страницы6ES72315PF320XB0 Datasheet en PDFahmad 58parsОценок пока нет

- 1401 - Enthusiast & Leader - (AIOT) - Paper - (E) - JMДокумент20 страниц1401 - Enthusiast & Leader - (AIOT) - Paper - (E) - JMDhairya KumarОценок пока нет

- IAPT Physics Exam QuestionsДокумент18 страницIAPT Physics Exam Questionssudhir_kumar_33Оценок пока нет

- Math 115 HW #9 Solutions PDFДокумент7 страницMath 115 HW #9 Solutions PDFHyan Gontijo0% (1)

- Physical Sciences: (Physics) P1 Preparatory Examination: September 2017Документ18 страницPhysical Sciences: (Physics) P1 Preparatory Examination: September 2017KristianОценок пока нет

- Physics Lab Report 8Документ6 страницPhysics Lab Report 8Grace UrbanoОценок пока нет

- Ad5220 0Документ11 страницAd5220 0el mehdi harrasОценок пока нет

- An 1378Документ8 страницAn 1378accxerОценок пока нет

- New Holland 160HP - Electronical Component TestingДокумент52 страницыNew Holland 160HP - Electronical Component TestingDrag TrakОценок пока нет

- CAAB 2008 EEE Question BankДокумент2 страницыCAAB 2008 EEE Question Bankrajshahieee100% (10)

- A6V12027144 - Automation Station PXC4.E16 - enДокумент14 страницA6V12027144 - Automation Station PXC4.E16 - enMahammad SathalyaОценок пока нет