Академический Документы

Профессиональный Документы

Культура Документы

Hydrostatic Test of Pressure Vessels

Загружено:

عزت عبد المنعمИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hydrostatic Test of Pressure Vessels

Загружено:

عزت عبد المنعمАвторское право:

Доступные форматы

Hydrostatic Test of Pressure Vessels

As per ASME VIII div 1 UG-99 STANDARD HYDROSTATIC TEST (a) A hydrostatic test shall be conducted on all vessels afte r:(1) all fabrication has been completed, except for operations which could not be performed prior to the test such as weld end preparation [see U-1(e)(1)(a)], cosmetic grinding on the base material which does not affect the required thickness; and(2) all examinations have been performed, except those required after the test .The completed vessels, except those tested in accordance with the requirements of UG-100 and UG-101, shall have satisfactorily passed the hydrostatic test prescribed in this paragraph.(b) Except as otherwise permitted in (a) above and 27-4, vessels designed for internal pressure shall be subjected to a hydrostatic test pressure which at every point in the vessel is at least equal to 1.3 times the maximum allowable working pressure 34 to be marked on the vessel multiplied by the lowest ratio (for the materials of which the vessels constructed) of the stress value S for the test temperature on the vessel to the stress value S for the design temperature(see UG-21). All loadings that may exist during this test shall be given consideration.(c) A hydrostatic test based on a calculated pressure may be used by agreement between the user and the Manufacturer. The hydrostatic test pressure at the top of the vessel shall be the minimum of the test pressures calculated by multiplying the basis for calculated test pressure as defined in 3-2 for each pressure element by 1.3 and reducing this value by the hydrostatic head on that element. When this pressure is used, the Inspector shall reserve the right to require the Manufacturer or the designer to furnish the calculations used for determining the hydrostatic test pressure for any part of the vessel.(d) The requirements of (b) above represent the minimum standard hydrostatic test pressure required by this Division. The requirements of (c) above represent a special test based on calculations. Any intermediate value of pressure may be used. This Division does not specify an upper limit for hydrostatic test pressure. However, if the hydrostatic test pressure is allowed to exceed, either intentionally or accidentally, the value determined as prescribed in (c)above to the degree that the vessel is subjected to visible permanent distortion, the Inspector shall reserve the right to reject the vessel.(e) Combination units [see UG-19(a) and UG-21] shall be tested by one of the following methods.(1) Pressure chambers of combination units that have been designed to operate independently shall be hydrostatically tested as separate vessels, that is, each chamber shall be tested without pressure in the adjacent chamber. If the common elements of a combination unit are designed for a larger differential pressure than the higher maximum allowable working pressure to be marked on the adjacent chambers, the hydrostatic test shall subject the common elements to at least their design differential pressure, corrected for temperature as in (b) above, as well as meet the requirements of (b) or (c) above for each independent chamber.(2) When pressure chambers of combination units have their common elements designed for the maximum differential pressure that can possibly occur during start up ,operation, and shutdown, and the differential pressure is less than the higher pressure in the adjacent chambers, the common elements shall be subjected to a hydrostatic test pressure of at least 1.3 times the differential pressure To be marked on the unit, corrected for temperature as inUG99(b).Following the test of the common elements and their inspection as required by (g) below, the adjacent chambers shall be hydrostatically tested simultaneously [see (b) or(c) above]. Care must be taken to limit the differential pressure between the chambers to the pressure used when testing the

common elements .The vessel stamping and the vessel Data Report must describe the common elements and their limiting differential pressure. See UG-116(j) and UG-120(b).(f) Single-wall vessels designed for a vacuum or partial vacuum only, and chambers of multi chamber vessels designed for a vacuum or partial vacuum only, shall be subjected to an internal hydrostatic test or when a hydrostatic test is not practicable, to a pneumatic test in accordance with the provisions of UG-100. Either type of test shall be made at a pressure not less than 1.3 times the difference between normal atmospheric pressure and the minimum design internal absolute pressure.(g) Following the application of the hydrostatic test pressure, an inspection shall be made of all joints and connections. This inspection shall be made at a pressure not less than the test pressure divided by 1.3. Except for leakage that might occur at temporary test closures for those openings intended for welded connections, leakage is not allowed at the time of the required visual inspection . Leakage from temporary seals shall be directed away so as to avoid masking leaks from other joints. The visual inspection of joints and connections for leaks at the test pressure divided by 1.3 may be waived provided:(1) a suitable gas leak test is applied;(2) substitution of the gas leak test is by agreement reached between Manufacturer and Inspector;(3) all welded seams which will be hidden by assembly be given a visual examination for workmanship prior to assembly;(4) the vessel will not contain a "lethal" substance.(h) Any nonhazardous liquid at any temperature may be used for the hydrostatic test if below its boiling point. Combustible liquids having a flash point less than 110F(43C), such as petroleum distillates, may be used only for near atmospheric temperature tests. It is recommended that the metal temperature during hydrostatic test be maintained at least 30F (17C) above the minimum design metal temperature, but need not exceed 120F (48C), to minimize the risk of brittle fracture. [See UG-20 and General Note (6) to Fig. UCS-66.2.] The test pressure shall not be applied until the vessel and its contents are at about the same temperature. If the test temperature exceeds 120F(48C), it is recommended that inspection of the vessel required by (g) above be delayed until the temperature is reduced to 120F (48C) or less. CAUTION: A small liquid relief valve set to 113 times the test pressure is recommended for the pressure test system, in case a vessel, while under test, is likely to be warmed up materially with personnel absent.(i) Vents shall be provided at all high points of the vessel in the position in which it is to be tested to purge possible air pockets while the vessel is filling.(j) Before applying pressure, the test equipment shall be examined to see that it is tight and that all low-pressure filling lines and other appurtenances that should not be subjected to the test pressure have been disconnected.(k) Vessels, except for those in lethal service, may be painted or otherwise coated either internally or externally, and may be lined internally, prior to the pressure test. However, the user is cautioned that such painting /coating /lining may mask leaks that would otherwise have been detected during the pressure test.

Вам также может понравиться

- Safe Work Method StatementДокумент176 страницSafe Work Method StatementMohamed Rizwan100% (2)

- PFI - ES - 48 - 2008 - Random ExaminationsДокумент5 страницPFI - ES - 48 - 2008 - Random Examinationsespluisjavier100% (1)

- Underground Piping SystemsДокумент5 страницUnderground Piping SystemsBinodh DanielОценок пока нет

- Corrosion Above Ground Brochure EnglishДокумент6 страницCorrosion Above Ground Brochure EnglishsyammohansОценок пока нет

- Rtaa Svd01a en - 01012004Документ10 страницRtaa Svd01a en - 01012004alcomech100% (3)

- Inspection and Test Plan For Reciprocating CompressorДокумент21 страницаInspection and Test Plan For Reciprocating CompressorNorman Morales100% (1)

- Air Leak TestДокумент2 страницыAir Leak TestWaqas Waqas100% (1)

- Hydrotest ProcedureДокумент12 страницHydrotest Procedurealex_feryando42100% (1)

- Pneumatic Test ProcedureДокумент2 страницыPneumatic Test Proceduredyke_engg67% (3)

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3017042Документ40 страницPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3017042Panca XpОценок пока нет

- ASME VIII Div. 1 - 6 Pressure TestingДокумент11 страницASME VIII Div. 1 - 6 Pressure TestingYoucef ChorfaОценок пока нет

- Sample - Template - Itp For Piping Fabrication and InstallationДокумент2 страницыSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriОценок пока нет

- Jacobs: Equipment Inspection Code: AДокумент2 страницыJacobs: Equipment Inspection Code: ASigit BintanОценок пока нет

- F.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselДокумент7 страницF.sq-p.003 Rev. 0 Procedure For Repair, Alteration, and Modification Pressure VesselIksan Adityo MulyoОценок пока нет

- Pipeline Integrity ManagementДокумент122 страницыPipeline Integrity Managementعزت عبد المنعم100% (11)

- Pressure Test - Hydrostatic and Pneumatic Test RequirementsДокумент6 страницPressure Test - Hydrostatic and Pneumatic Test RequirementslorenzoОценок пока нет

- Deaerator CorrosionДокумент7 страницDeaerator Corrosionanindya1986Оценок пока нет

- CHAPTER 11 GIs, Letters and ReferencesДокумент12 страницCHAPTER 11 GIs, Letters and ReferencesMahrouz MadoОценок пока нет

- SPC-0804.02-96.58 Rev D2 Hydrostatic Pressure Testing of PipingДокумент23 страницыSPC-0804.02-96.58 Rev D2 Hydrostatic Pressure Testing of Pipingsdb91Оценок пока нет

- Job Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptДокумент13 страницJob Procedure For Tanks Radiography Test: 10 of Ramadan City, Industrial Area A1, EgyptShubham ShuklaОценок пока нет

- Pneumatic Testing Procedure For PipelinesДокумент3 страницыPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinОценок пока нет

- Hydrostatic Test ProcedureДокумент3 страницыHydrostatic Test Proceduregstketut100% (6)

- Dokumen - Tips Bobcat 553 Skid Steer Loader Service Repair Manual InstantДокумент22 страницыDokumen - Tips Bobcat 553 Skid Steer Loader Service Repair Manual InstantGienek KotОценок пока нет

- Lecture - 1 Steel Structures Design PhilosophiesДокумент67 страницLecture - 1 Steel Structures Design Philosophiesعزت عبد المنعم60% (5)

- Hydrostatic Test Procedure: 1. ScopeДокумент5 страницHydrostatic Test Procedure: 1. ScopeHassan SleemОценок пока нет

- Pressure VesselДокумент85 страницPressure VesselAsad Abbas100% (1)

- Asme Ccase - 2046Документ2 страницыAsme Ccase - 2046ADAMJSRAOОценок пока нет

- Standard Procedure For Hydrotest As Per Asme?Документ4 страницыStandard Procedure For Hydrotest As Per Asme?Faraz ArshadОценок пока нет

- Designing of Air Cooled Heat Exchangers: by Mehaboob Basha N.BДокумент28 страницDesigning of Air Cooled Heat Exchangers: by Mehaboob Basha N.Bgerty1818100% (2)

- Ansi Isa-75.19.01-2013Документ34 страницыAnsi Isa-75.19.01-2013Carlos Anibal OrtizОценок пока нет

- Air Release ValveДокумент17 страницAir Release Valvevikaskatheria100% (1)

- Mobile Equipment Inspection SOPДокумент12 страницMobile Equipment Inspection SOPSimranjit100% (1)

- Api 653 Report-Hydrolic Test PDFДокумент12 страницApi 653 Report-Hydrolic Test PDFnaoufel1706Оценок пока нет

- F.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselДокумент6 страницF.sq-p.002 Rev. 0 Procedure For Existing Pressure VesselIksan Adityo MulyoОценок пока нет

- ISO 8501 Photo ReferДокумент5 страницISO 8501 Photo Referapi-386436191% (11)

- Safety System - Emergency Shutdown System P1Документ41 страницаSafety System - Emergency Shutdown System P1عزت عبد المنعم100% (2)

- ASME VIII Div. 1 - 6 Pressure TestingДокумент26 страницASME VIII Div. 1 - 6 Pressure Testingعصمت ضيف الله75% (4)

- ASME Pressure and Leak TestingДокумент4 страницыASME Pressure and Leak TestingBohdan100% (1)

- Commissioning Report For Bag House Filter Unit 1Документ10 страницCommissioning Report For Bag House Filter Unit 1Arif Febrianto0% (1)

- Pressure TestingДокумент14 страницPressure TestingWeld Bro Sandeep100% (2)

- TDI41 Tank Inspection Repair & Alteration API 653 Sec 9Документ13 страницTDI41 Tank Inspection Repair & Alteration API 653 Sec 9Faizal Sattu100% (2)

- Safety System - Emergency Shutdown System P2Документ15 страницSafety System - Emergency Shutdown System P2عزت عبد المنعم100% (3)

- Pressure Form Test RecordДокумент1 страницаPressure Form Test Recordphyo7799Оценок пока нет

- Hydro Vs PneumaticДокумент4 страницыHydro Vs PneumaticAnonymous rYZyQQot55Оценок пока нет

- ONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCДокумент34 страницыONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCshankarmech04@gmail.comОценок пока нет

- API 510 VesselsДокумент11 страницAPI 510 Vesselsmoonstar_dmeОценок пока нет

- Agenda Item: 650-2024: Coating Prior To Hydrostatic TestingДокумент4 страницыAgenda Item: 650-2024: Coating Prior To Hydrostatic Testinggigiphi1Оценок пока нет

- Rubber Gasket (Full Face in Flat Face Flanges) Installation & TorqueДокумент4 страницыRubber Gasket (Full Face in Flat Face Flanges) Installation & Torquecavillalobosb8167Оценок пока нет

- R057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor PackageДокумент10 страницR057-Ac-It-001 (C) - Inspection and Test Plan For Instrument Air Compressor Packagedharwin100% (1)

- Characteristics of Residual StressДокумент61 страницаCharacteristics of Residual Stressعزت عبد المنعمОценок пока нет

- Fireproofing For Petrochemical FacilityДокумент12 страницFireproofing For Petrochemical FacilityJames Murray100% (4)

- Material Properties Requirements For Metallic MaterialsДокумент70 страницMaterial Properties Requirements For Metallic Materialsعزت عبد المنعمОценок пока нет

- A System Approach To SO3 Mitigation PDFДокумент8 страницA System Approach To SO3 Mitigation PDFعزت عبد المنعمОценок пока нет

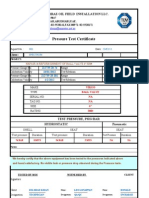

- Pressure Test CertificateДокумент10 страницPressure Test CertificateDav LalОценок пока нет

- K2S-CW230907-BA6008-00006 - A01 - Nitrogen Leak Test & Purging ProcedureДокумент21 страницаK2S-CW230907-BA6008-00006 - A01 - Nitrogen Leak Test & Purging ProcedureAzeta Robert100% (3)

- Pneumatic Test ProcedureДокумент3 страницыPneumatic Test Procedurevijay padale50% (2)

- QAP TanksДокумент3 страницыQAP TanksAnonymous zejWt17100% (2)

- To Commissioning Manual: Appendix No. 1Документ7 страницTo Commissioning Manual: Appendix No. 1Bassem BalghouthiОценок пока нет

- Aiche 26 009 PDFДокумент7 страницAiche 26 009 PDFImmanuelОценок пока нет

- API 650 12th Edition 2013 - NDT RequirementДокумент1 страницаAPI 650 12th Edition 2013 - NDT Requirementfarjadulhaq100% (2)

- Lesson Learnt From Aiche Paper'sДокумент49 страницLesson Learnt From Aiche Paper'sSyed Sheraz Hussain100% (1)

- Ger 3751a Understanding Diagnosing Repairing Leaks h20 Gen Stator WindingsДокумент28 страницGer 3751a Understanding Diagnosing Repairing Leaks h20 Gen Stator Windingsnareshvkkd100% (1)

- UG-100 Pneumatic TestДокумент2 страницыUG-100 Pneumatic TestInaamОценок пока нет

- Procedure Fabrikasi TankiДокумент10 страницProcedure Fabrikasi TankiMuhammad Yunus NurdinОценок пока нет

- Inspection & Test Plan For Nozzle Replacement On VS ShellДокумент1 страницаInspection & Test Plan For Nozzle Replacement On VS ShellQC Taner 453100% (2)

- Chemical Resistance (LLDPE) PDFДокумент24 страницыChemical Resistance (LLDPE) PDFrubyshreeОценок пока нет

- Tank Inspection NotesДокумент5 страницTank Inspection Notesaneeshjose013Оценок пока нет

- Alvaer DNV2.7-3 PDFДокумент23 страницыAlvaer DNV2.7-3 PDFThanhdong Do100% (1)

- API 650 PageДокумент2 страницыAPI 650 PageGerry Dan ChanliongcoОценок пока нет

- Storage Tank Test & Inspection Report enДокумент10 страницStorage Tank Test & Inspection Report enMarketing CTNОценок пока нет

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartДокумент1 страницаMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanОценок пока нет

- Reverse Engineering Pressure Vessel ChecklistДокумент5 страницReverse Engineering Pressure Vessel ChecklistES RouzaОценок пока нет

- UL-142 R912 Installation InstructionsДокумент4 страницыUL-142 R912 Installation InstructionsRodrigoОценок пока нет

- Qap 8000ce Reactor - Repat - 1Документ2 страницыQap 8000ce Reactor - Repat - 1AliasgarОценок пока нет

- Pttep Painitng of Offshore FacilitiesДокумент66 страницPttep Painitng of Offshore FacilitiesSufianОценок пока нет

- BS 1414-1975 PDFДокумент27 страницBS 1414-1975 PDF윤규섭Оценок пока нет

- ITP For Hydraulic BarrierДокумент4 страницыITP For Hydraulic Barriermoytabura96Оценок пока нет

- Conduit Installation GuideДокумент10 страницConduit Installation GuidelaxmandohanОценок пока нет

- Valve Testing & Seat Leakage Comparism PDFДокумент6 страницValve Testing & Seat Leakage Comparism PDFAnupmaОценок пока нет

- Manufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsДокумент4 страницыManufacturing Quality Plan For Tank: FGD Sysyem, 2X550 MW TpsBhanu Pratap ChoudhuryОценок пока нет

- Standard Procedure For Hydrotest As Per Asme?Документ4 страницыStandard Procedure For Hydrotest As Per Asme?Faraz ArshadОценок пока нет

- Ug-99 Standard Hydrostatic TestДокумент7 страницUg-99 Standard Hydrostatic TestNícoli GaloОценок пока нет

- OKITP01 - PruebaPresión Rev.1Документ13 страницOKITP01 - PruebaPresión Rev.1Hugo Fiusa AlvarezОценок пока нет

- Article T-3 Hydrostatic Tests: Licensed by Information Handling Services Licensed by Information Handling ServicesДокумент2 страницыArticle T-3 Hydrostatic Tests: Licensed by Information Handling Services Licensed by Information Handling Servicesbgonzalez1981Оценок пока нет

- Inspection and Tests: ASME Section VIII, Division 1Документ16 страницInspection and Tests: ASME Section VIII, Division 1Muhamed MahmoudОценок пока нет

- 1 - Differences Between API 600 & API 6DДокумент9 страниц1 - Differences Between API 600 & API 6Dعزت عبد المنعمОценок пока нет

- Gate Valve Standard FeaturesДокумент3 страницыGate Valve Standard Featuresعزت عبد المنعمОценок пока нет

- Day 14 Heat Treatments of SteelДокумент20 страницDay 14 Heat Treatments of Steelعزت عبد المنعمОценок пока нет

- Shielded Metal Arc WeldingДокумент39 страницShielded Metal Arc Weldingعزت عبد المنعم100% (1)

- High Temperature Corrosion Guide Line 7 (1) .0Документ20 страницHigh Temperature Corrosion Guide Line 7 (1) .0عزت عبد المنعم100% (2)

- Correct Expansion of Heat Exchanger - Boiler Tubes PDFДокумент4 страницыCorrect Expansion of Heat Exchanger - Boiler Tubes PDFعزت عبد المنعمОценок пока нет

- Comparison Material Specs. Table PDFДокумент41 страницаComparison Material Specs. Table PDFعزت عبد المنعمОценок пока нет

- Kia Crt-3500 User Manual - EngДокумент22 страницыKia Crt-3500 User Manual - Engkuzyakuzovenko7Оценок пока нет

- Fuel Pro® 382 Technical ManualДокумент20 страницFuel Pro® 382 Technical ManualSudar MonoОценок пока нет

- F4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFДокумент19 страницF4281-GEDI-M-SS-ITP-1039-3 ITP For Equipment and Pipe Installation in - Compressed Air System PDFDang Hieu NguyenОценок пока нет

- 1359-Trim Water Pressure Relief Valve 0.25 Inch To 2.5 Inch PDFДокумент15 страниц1359-Trim Water Pressure Relief Valve 0.25 Inch To 2.5 Inch PDFdgkmurti100% (1)

- Job Hazard Analysis (Jha) For Transformer Repair & Oil Filtration WorksДокумент2 страницыJob Hazard Analysis (Jha) For Transformer Repair & Oil Filtration WorksSathish PunniyanОценок пока нет

- KoelsystemenannexiiiДокумент6 страницKoelsystemenannexiiiSyed Abbu HurerahОценок пока нет

- 03 - Ussama Kaewpradap (PTTEP) - A Severe Top of The Line Corrosion Case StudyДокумент15 страниц03 - Ussama Kaewpradap (PTTEP) - A Severe Top of The Line Corrosion Case StudySamuel JohnОценок пока нет

- Service Manual AS26-35TB1HRAДокумент48 страницService Manual AS26-35TB1HRArao3farhat3masoodОценок пока нет

- Determination of Hazardous Zones: Case Study: Generic Hydrogen Refuelling StationДокумент15 страницDetermination of Hazardous Zones: Case Study: Generic Hydrogen Refuelling StationMahbub KhanОценок пока нет

- Cameron Ball ValvesДокумент26 страницCameron Ball ValvesJacobus CalvelageОценок пока нет

- Storage and Assy SpecДокумент14 страницStorage and Assy SpecGaurav DatarОценок пока нет

- In The Lands Tribunal of The Hong Kong Special Administrative RegionДокумент34 страницыIn The Lands Tribunal of The Hong Kong Special Administrative RegionDavidОценок пока нет

- MANEC5Документ18 страницMANEC5RC Villeda100% (1)

- Lees Loss Failure DataДокумент2 страницыLees Loss Failure DataRonak MotaОценок пока нет

- Terex Rubber Track Loader Pt70 80 Service ManualДокумент10 страницTerex Rubber Track Loader Pt70 80 Service Manualdelores100% (49)

- ECSS Q ST 70 15C (1may2021) Annex B (NDT Report)Документ5 страницECSS Q ST 70 15C (1may2021) Annex B (NDT Report)gooogaОценок пока нет