Академический Документы

Профессиональный Документы

Культура Документы

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT To optimise economiser design for better performance

Загружено:

Martin CorkeryИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT To optimise economiser design for better performance

Загружено:

Martin CorkeryАвторское право:

Доступные форматы

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

To optimise economiser design for better performance

A.D. PATIL,P.R.BAVISKAR, M.J.SABLE, S.B.BARVE Department Of Mechanical Engineering, Rajarshi Shahu College of Engg, Pune. University Of Pune Tathwade -411033, Maharashtra, India (e-mail:amol_patil77@rediffmail.com) ___________________________________________________________________

This paper presents an approach for the optimisation of economiser design with finned & bare tube economiser.The aim of this work is to develop methodology which finds optimisation of economiser design.CFD analysis is used to compare the new economiser design with traditional strategies.A brief historical overview on economiser design & optimisation is given.Main economiser design methodologies available in literature are described and their advantages and disadvantages.The main advantage of the proposed method is that it permits a better understanding of influence of the design parameters on the cycle performance.

________________________________________________________________________________

1 Introduction:

Economiser performs a key function in providing high overall boiler thermal efficiency by recovering the low level energy from the flue gas before it is exhausted to the atmosphere. Economiser recovers the energy by heating the boiler feedwater.Economiser are basically tubular heat transfer surfaces used to preheat boiler feed water before it enters the steam drum or furnace surfaces. Economiser reduces operating costs or economise on fuel by recovering extra energy from the flue gas. Economisers also reduce the potential of thermal shock and strong water temperature fluctuations as the feed water enters the drum or waterwalls. Increasingly stringent environmental regulations limiting nitrogen oxides and sulfur dioxide emission can also affect economizer design. The gas-side heat transfer coefficient is much less than water side heat transfer coefficient. To compensate this, outer surface of the tubes may be finned to increase the surface area of heat transfer.The ultimate goal of economizer design is to achieve the necessary heat transfer at

minimum cost. A key design criterion for economizer is maximum allowable flue gas velocity. Higher velocity provide better heat transfer and reduce capital cost.[4] Economiser tubes are employed in fossil fuel power plants to preheat the boiler feed water before it is introduced into the boiler drum and to recover some of the heat from the flue gas leaving the boiler. The economiser is located in the boiler rear gas pass below the rear horizontal superheater. Each section is composed of a number of parallel tube circuits. Feed water is supplied to the economiser inlet via feed stop and check valves from the outer header. Feed water is pumped to the drum via economised links. Steaming in the economiser is prevented by controlling the economiser outlet feed water temperature.The operating temperature of the economiser tubes lies below 399 C, suggesting that the occurence of creep of the tube material which is generally mild steel is not expected. Therefore tensile properties at the operating temperature range rather than stress rupture properties have much importance in predicting the remaining life of these tubes.

ISSN: 1792-4596

70

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

Generally premature failures of economiser tubes take place due to several reasons mainly flue gas erosion, low temperature water corrosion, fatigue, oxygen pitting.

2 Traditional strategies economiser design

for

Economiser surface types Bare tube: The most common and reliable economiser design is the bare tube, in-line, crossflow type. When coal is fired, the flyash creates a high fouling and erosive environment. The bare tube, in-line arrangement minimizes the likelihood of erosion and trapping of ash as compared to a staggered arrangement . It is also the easiest geometry to be kept clean by sootblowers. However, these benefits must be evaluated against the possible larger weight, volume and cost of this arrangement. Extended surfaces : To reduce capital costs, most boiler manufacturers have built economisers with a variety of fin types to enhance the controlling gas-side heat transfer rate. Fins are inexpensive parts which can reduce the overall size and cost of an economiser. However, successful application is very sensitive to the flue gas environment. Surface cleanability is a key concern. In selected boilers, such as coal-fired units, extended surface economisers are not recommended because of the peculiar fly ash characteristics.[1] Stud fins : Stud fins have worked reasonably well in gas-fired boilers. However, stud finned economisers can have higher gas-side pressure drop than a comparable unit with helically-finned tubes. Studded fins have performed poorly in coal-fired boilers because of high erosion, loss of heat transfer, increased pressure loss and plugging resulting from flyash deposits. Longitudinal fins : Longitudinally-finned tubes in staggered crossflow arrangements,have also not performed well over long operating pe-

riods. Excessive plugging and erosion in coal-fired boilers have resulted in the replacement of many of these economisers. In oil- and gas-fired boilers, cracks have occurred at the points where the fins terminate. These cracks have propagated into the tube wall and caused tube failures in some applications. Plugging with flyash can also be a problem (tight spaces). Rectangular fins : The square or rectangular fins, arranged perpendicular to the tube axis on inline tubes have been used occasionally in retrofits. The fin spacing typically varies between 13 and 25 mm and the fins are usually 3.18 mm thick. There is a vertical slot down the middle because the two halves of the fin are welded to either side of the tube. Most designs are for gas velocities below 15.2 m/s. However, because of the narrow, deep spaces, plugging with fly ash is a danger with such designs. Velocity limits: The ultimate goal of economiser design is to achieve the necessary heat transfer at minimum cost. A key design criterion for economisers is the maximum allowable flue gas velocity (defined at the minimum cross-sectional free flow area in the tube bundle). Higher velocities provide better heat transfer and reduce capital cost. For clean burning fuels, such as gas and low ash oil, velocities are typically set by the maximum economical pressure loss. For high ash oil and coal, gas-side velocities are limited by the erosion potential of the fly ash. This erosion potential is primarily determined by the percentage of A1203, and SiO2 in the ash, the total ash in the fuel and the gas maximum velocity.

Performance

analysis

of

Economiser

Economiser heat transfer rate is calculated as per following formula

ISSN: 1792-4596

71

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

q = U x A x (LMTD) [5] (1) q = mg x cp x Tg = mg x cp x ( T- T) (2) q=mxH (3) where, q = heat transfer rate, Kcal/hr U = overall heat transfer coefficient LMTD = log mean temperature difference, C mg = gas mass flow rate, Kg/hr cp = mean specific heat of gas, KJ/Kg K T = gas temperature leaving economizer, C T = gas temperature entering economizer, C T = economiser water outlet temp, C T1 = economiser water inlet temp, C The heat transfer by convection and intertube radiation is: qci = q - qr (4) where, q = total heat transfer rate. Kcal/hr qr = cavity radiation Kcal/hr Gas temperature leaving the economiser can be determined by : T = T - ((qci)/(mg x cp) (5) Counter flow heat exchanger, the log mean temp difference is : LMTD = (( T - T) - ( T- T1)) / (ln((T T)/ (T-T1))) (6) Average gas temperature can be determined by: Tf = (( T1 + T)/2 +(LMTD/2)) (7) Gas mass flux : Gg = mg / Ag (8) Reynolds number: Re = Kre x Gg (9) K Re = Gas properties factor, m2 hr/ Kg Gas film heat transfer coefficient: hcg = hc x Fpp x Fd x Fc (10) Fpp = Physical properties factor Fd = Heat transfer depth factor Fc = Arrangement factor hc = Geometry factor Gas side radiation heat transfer coefficient: hrg = hrx K x Fs (11) Fs = (A Ap)/A (12) hr = Radiation heat transfer coefficient K = Effect of fuel on radiation heat transfer coefficient

Overall heat transfer coefficient: U = hcg + hrg

(13)

Finned tubes: As a general guideline, the overall heat transfer coefficient can be approximated by the following relationship for most types of economiser fins: U = 0.95(hg x kf) (14) Kf = surface effectiveness factor hg = gas-side heat transfer coefficient for the heat transfer across finned tube bundles.. Gas-side resistance: The gas-side pressure loss across the economiser tube bank can be evaluated using the crossflow correlations . The pressure loss should be adjusted for the number of tube rows using the correction factors provided. The gas-side resistance across the in-line finned tube banks is approximately 1.5 times the resistance of the underlying bare tubes. Water-side pressure drop: If the calculated water-side pressure drop is excessive, the number of parallel flow paths must be increased. If the flue gas velocity can be increased, the water-side pressure drop can also be reduced by increasing the tube size, usually in increments of 3 mm. The dynamic pressure drop is inversely proportional to the fifth power of the inside tube diameter. Total pressure loss is calculated (Pt): Pt = Pf + P l + Pz (15) Where, Pf = friction pressure loss Pl = sum of local losses Pz = static head loss Pf = f x L/De x v (G/105)2 (16) where, Pf = fluid pressure drop,kg/cm2 f = friction factor L = length,m De = equivalent dia of flow channel,m v = specific volume.m3/kg G = mass flux of fluid,Kg/hr m2 Pl = Nv x (30/B) x ((T+460)/(1.73 x 105)) x (G/103)2 (17) Where, Nv = number of equivalent velocity heads

ISSN: 1792-4596

72

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

dimensionless Pl = pressure drop in wg B = barometric pressure, mm Hg T = air temp. C

Pz = (g/gc)L sin g = acceleration of gravity (m/s2) gc = 1 kg m/ N s2

(18)

Fig.1 Basic radiation heat transfer coefficient

ISSN: 1792-4596

73

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

Fig. 2 Effect of fuel, partial pressure and mean radiating length on radiation heat transfer coefficient

Fig. 3. Heat transfer depth factor for number of tube rows

ISSN: 1792-4596

74

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

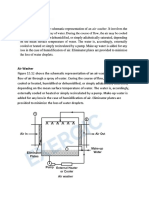

4 CFD analysis of Economiser

Input parameter:

Air inlet mass flow rate = 160 Kg/s Flue gas inlet Temperature = 800 0C Back pressure at outlet = -150 mmWC Gas composition (volume fractions) H2O 13.81 % N2 68.65 % CO2 11.45 % O2 5.09 %

Plane after CRH

Plane before ECO

Plane 2 Plane 1

Fig. 4 Plane location

ISSN: 1792-4596

75

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

Fig. 5. Velocity vector on plane

Fig. 6. Velocity streamlines on plane

ISSN: 1792-4596

76

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

Fig. 7. Velocity contours on plane before eco

Fig. 8. Velocity contours on plane before eco

ISSN: 1792-4596

77

ISBN: 978-960-474-215-8

NEW ASPECTS of FLUID MECHANICS, HEAT TRANSFER and ENVIRONMENT

Conclusion

References For journal papers: [1] Eduard Eitelberg & Edward Boje, Water circulation control during oncethrough boiler start-up, 10 July 2003, University of Natal, Durban, South Africa. [2] Young Sun & Lin Ma, Optimisation of economiser tubing system renewal decisions, 10 March 2008, Queensland University of Technology, Australia. [3] R.K.Sinha & S. Chaudhuri, Remaining life estimation of service exposed economizer tubes, 14 Sept.1998, National Metallurgical Laboratory, Jamshedpur. For books: [4] P. K . NAG , Power Plant Engineering,2006 Tata McGraw-Hill Publication, pp. 363. [5] Steam Book, 2006 The Babcock & Wilcox Company, pp.20-1.

The most common and reliable economiser design is the bare tube, in-line, cross flow type. When coal is fired, the flyash creates a fouling and erosive environment. The bare tube, in-line arrangement minimizes the likelihood of erosion and trapping of ash as compared to staggered arrangement.It is also easiest geometry to be kept clean by sootblowers. To reduce capital costs, most boiler manufacturers have built economizers with a variety of fin types to enhance the controlling gas-side heat transfer rate. Fins are inexpensive parts which can reduce the overall size and cost of an economiser. However, successful application is very sensitive to the flue gas environment.Surface cleanability is key concern. In selected boilers, such as coal-fired units, extended surface economisers are not recommended because of the peculiar flyash characteristics. Stud fins have worked reasonably well in gas- fired boilers. However, stud finned economisers have higher gas side pressure drop than a comparable unit with helically-finned tubes. Studded fins have performd poorly in coalfired boilers because of high erosion, loss of heat transfer, increased pressure loss and plugging resulting from flyash deposits

ISSN: 1792-4596

78

ISBN: 978-960-474-215-8

Вам также может понравиться

- Prelim Yearly Kiss NotesДокумент83 страницыPrelim Yearly Kiss NotesPercy Jack100% (1)

- Part (2-A) - Fundamentals of Open Hole Logging-Abbas Radhi 2020Документ223 страницыPart (2-A) - Fundamentals of Open Hole Logging-Abbas Radhi 2020Ali ElayawiОценок пока нет

- C.O.P Derivation and Thermodynamic Calculation of Ammonia-Water Vapor Absorption Refrigeration System-2 PDFДокумент10 страницC.O.P Derivation and Thermodynamic Calculation of Ammonia-Water Vapor Absorption Refrigeration System-2 PDFErGiteshAroraОценок пока нет

- DR ApichitДокумент139 страницDR ApichitMuh. Yousuf KhanОценок пока нет

- Blowdown Economizer CalculationДокумент2 страницыBlowdown Economizer CalculationSajjad AhmedОценок пока нет

- Guntner CO2 PDFДокумент20 страницGuntner CO2 PDFerreagaaОценок пока нет

- Double Pipe Heat Exchanger - Excel CalculationsДокумент4 страницыDouble Pipe Heat Exchanger - Excel CalculationsMmmmohОценок пока нет

- Table 8 3 1 Properties of Mixture Water/Glycol: Extract From Vdi Warmeatlas DD 17 Vdi Verlag GMBH, Dusseldorf 1991Документ2 страницыTable 8 3 1 Properties of Mixture Water/Glycol: Extract From Vdi Warmeatlas DD 17 Vdi Verlag GMBH, Dusseldorf 1991Santiago MolinaОценок пока нет

- APH PerformanceДокумент9 страницAPH PerformanceSiva SubramaniyanОценок пока нет

- Hvac Rpoblems NewДокумент20 страницHvac Rpoblems NewGrace Joy CariОценок пока нет

- eArt-Performance Analysis of Spiral Tube Heat ExchangerДокумент4 страницыeArt-Performance Analysis of Spiral Tube Heat ExchangerMoly69xОценок пока нет

- Mollie ChartДокумент15 страницMollie ChartKriz EarnestОценок пока нет

- Air WasherДокумент5 страницAir WasherManral SaurabhОценок пока нет

- From Wikipedia, The Free Encyclopedia: Process Duct WorkДокумент17 страницFrom Wikipedia, The Free Encyclopedia: Process Duct WorkB DASОценок пока нет

- Energy Management Tutorial SolutionsДокумент9 страницEnergy Management Tutorial SolutionsLucas LentzОценок пока нет

- Heat Rate of Thermal Power PlantДокумент15 страницHeat Rate of Thermal Power Plantsameer betal100% (1)

- DuctДокумент3 страницыDuctRamalingam PrabhakaranОценок пока нет

- Overcurrent Protection in Electric Arc FurnacesДокумент8 страницOvercurrent Protection in Electric Arc FurnacesgigatrixОценок пока нет

- Line SizingДокумент20 страницLine SizingAhmed HassanОценок пока нет

- PH102 LabДокумент10 страницPH102 LabPeggy CockerОценок пока нет

- Cycle of Concentration in Cooling Tower PDFДокумент1 страницаCycle of Concentration in Cooling Tower PDFNgoc Vũ TrầnОценок пока нет

- EconomiserДокумент19 страницEconomiserGaurav KumarОценок пока нет

- Scroll-Chillers Catalog High-ResДокумент12 страницScroll-Chillers Catalog High-ResubaidОценок пока нет

- Refrigeration COP CalculationДокумент17 страницRefrigeration COP CalculationibrahimОценок пока нет

- Tube Wire Vs Wall Condenser PDFДокумент15 страницTube Wire Vs Wall Condenser PDFHimanshu100% (1)

- Delivering Excellence in Combustion and Process Heating SystemsДокумент11 страницDelivering Excellence in Combustion and Process Heating SystemssajjadyasinОценок пока нет

- Continuum Mechanics For EngineersДокумент53 страницыContinuum Mechanics For Engineersshushant kumarОценок пока нет

- Precise Temperature Control for Reactor ApplicationsДокумент22 страницыPrecise Temperature Control for Reactor ApplicationsFernando Stuar Campos MendozaОценок пока нет

- 12 Chapter08 Heat ExchangerДокумент58 страниц12 Chapter08 Heat Exchangerกล้าณรงค์ บริคุตОценок пока нет

- Cryogenic CoolingДокумент17 страницCryogenic CoolingmaheshwaranОценок пока нет

- Waste Heat Recovery (Mech-31)Документ18 страницWaste Heat Recovery (Mech-31)shammiОценок пока нет

- Air PropertiesДокумент19 страницAir PropertiesVanbiervlietОценок пока нет

- Cooling Tower IntroductionДокумент27 страницCooling Tower Introductiondinesh babuОценок пока нет

- Cooling Tower 434Документ15 страницCooling Tower 434arslan MaqboolОценок пока нет

- Regenerative Heat ExchangerДокумент4 страницыRegenerative Heat ExchangerSalehAfadlehОценок пока нет

- 12-Design Fundamentals of BoilerДокумент12 страниц12-Design Fundamentals of BoilerVishalVaishОценок пока нет

- Gas Turbine Power Plant: By: Ms. Monika DeshwalДокумент19 страницGas Turbine Power Plant: By: Ms. Monika DeshwalKeshantSharma100% (1)

- Indian Railway, JaipurДокумент20 страницIndian Railway, JaipurHarish GirdharОценок пока нет

- Mechanical Heat Pump-2 PDFДокумент9 страницMechanical Heat Pump-2 PDFRushikesh PatilОценок пока нет

- Chapter 11 Refrigeration CyclesДокумент20 страницChapter 11 Refrigeration Cycleskalite123Оценок пока нет

- HVAC AcroymnsДокумент6 страницHVAC AcroymnsglenlcyОценок пока нет

- Distillation Column Reboiler DesignДокумент13 страницDistillation Column Reboiler DesignLouie GresulaОценок пока нет

- Transfer of Liquefied Natural Gas On Long Insulated Lines PDFДокумент6 страницTransfer of Liquefied Natural Gas On Long Insulated Lines PDFIgnacio ChaparroОценок пока нет

- Heat Exchangers DesignДокумент58 страницHeat Exchangers DesignShubhamОценок пока нет

- Troubleshooting A Plate Heat Exchanger - CPE Systems IncДокумент7 страницTroubleshooting A Plate Heat Exchanger - CPE Systems Incrajmohan_kОценок пока нет

- 8-2. Heat Ex ChangersДокумент6 страниц8-2. Heat Ex ChangersBambang HermawanОценок пока нет

- Si - f13 - ch33 (Physical Properties of Materials)Документ4 страницыSi - f13 - ch33 (Physical Properties of Materials)Delian KurniawanОценок пока нет

- Physics 06-Temperature, Heat, and Thermodynamics (2018)Документ113 страницPhysics 06-Temperature, Heat, and Thermodynamics (2018)Kiyu ImanОценок пока нет

- Cycle of Absorption MachineДокумент4 страницыCycle of Absorption MachineMajid SattarОценок пока нет

- Vapour Absorption Machine Basics PresentationДокумент16 страницVapour Absorption Machine Basics PresentationAyub GNОценок пока нет

- Training ReportPDF PDFДокумент42 страницыTraining ReportPDF PDFAman RajОценок пока нет

- Glutaraldehyde Bulk HandlingДокумент4 страницыGlutaraldehyde Bulk HandlingnubblerОценок пока нет

- Crossflow Heat Exchanger Ex PDFДокумент5 страницCrossflow Heat Exchanger Ex PDFprinesst0% (1)

- Stonel Limit Switch InstructionsДокумент2 страницыStonel Limit Switch InstructionsgenibraОценок пока нет

- TEWI AnalysisДокумент63 страницыTEWI Analysismirali74Оценок пока нет

- At AssignmentДокумент3 страницыAt AssignmentYogesh PatilОценок пока нет

- Mech3005 Lab1112 Fancoil PDFДокумент5 страницMech3005 Lab1112 Fancoil PDFbilal almelegy100% (1)

- Internship On HVACДокумент11 страницInternship On HVACPrince AB100% (1)

- MEE 515 - HVAC - Lecture 3Документ28 страницMEE 515 - HVAC - Lecture 3Charbel KhouryОценок пока нет

- Burner Management System BMSДокумент38 страницBurner Management System BMSمحمد مصطفيОценок пока нет

- FH-08gf234 2fsdДокумент9 страницFH-08gf234 2fsdBorisvukic89Оценок пока нет

- Optimization of Air Preheater Design For The Enhancement of Heat Transfer CoefficientДокумент10 страницOptimization of Air Preheater Design For The Enhancement of Heat Transfer CoefficientVijay KumarОценок пока нет

- Heat TransferДокумент9 страницHeat TransferAjinkya MoreОценок пока нет

- Kathmandu University Presentation on CSTR Simulation and Process ControlДокумент19 страницKathmandu University Presentation on CSTR Simulation and Process Controlramesh pokhrelОценок пока нет

- Eng201 ch7 Accuracy Clarity Conciseness CoherenceДокумент2 страницыEng201 ch7 Accuracy Clarity Conciseness CoherenceAyesha MughalОценок пока нет

- Workshop 5.1: Global Mesh Controls: Introduction To ANSYS MeshingДокумент31 страницаWorkshop 5.1: Global Mesh Controls: Introduction To ANSYS MeshingDaniloCardenasОценок пока нет

- राजनीति सिद्धांत के अध्ययन के उपागम - Political Theory ApproachesДокумент20 страницराजनीति सिद्धांत के अध्ययन के उपागम - Political Theory ApproachesAyan BordoloiОценок пока нет

- Naoroj Muntashir: Curriculum Vitae ofДокумент3 страницыNaoroj Muntashir: Curriculum Vitae ofMizanul HoqueОценок пока нет

- Microsoft's Corporate Social ResponsibilityДокумент15 страницMicrosoft's Corporate Social ResponsibilityYusrie AbinalОценок пока нет

- Self Evaluation Rubric ShadowingДокумент1 страницаSelf Evaluation Rubric ShadowingJoaquín LaraОценок пока нет

- Feeding The Positive WolfДокумент4 страницыFeeding The Positive WolfJenelle FerrerОценок пока нет

- SEO-optimized title for English exam documentДокумент5 страницSEO-optimized title for English exam documentAyu PermataОценок пока нет

- Agile Coaching Is Dead Long Live Agile PracticingДокумент20 страницAgile Coaching Is Dead Long Live Agile Practicingb_prabhusankarОценок пока нет

- Nathaniel Lichfield - Community Impact Evaluation - Principles and Practice-Routledge (1996)Документ342 страницыNathaniel Lichfield - Community Impact Evaluation - Principles and Practice-Routledge (1996)Michael González VásquezОценок пока нет

- Changes in AATCC Manual 2011Документ3 страницыChanges in AATCC Manual 2011rajeshpatkar39Оценок пока нет

- Midpoint Subdivision Line Clipping AlgorithmДокумент2 страницыMidpoint Subdivision Line Clipping AlgorithmAnsuman MahantyОценок пока нет

- Proportional-Integral-Derivative and Linear Quadratic Regulator Control of Direct Current Motor Position Using Multi-Turn Based On LabviewДокумент5 страницProportional-Integral-Derivative and Linear Quadratic Regulator Control of Direct Current Motor Position Using Multi-Turn Based On LabviewGERARDO CABRERAОценок пока нет

- Startup BoilerДокумент51 страницаStartup BoilerSahariar Bin ShafiqueОценок пока нет

- Real Time Sign Language DetectionДокумент6 страницReal Time Sign Language DetectionIJRASETPublicationsОценок пока нет

- Advances in Water Polllution Monitoring and ControlДокумент185 страницAdvances in Water Polllution Monitoring and Controlantonioheredia100% (1)

- Japanese Civil Service ReformДокумент6 страницJapanese Civil Service ReformJake345678Оценок пока нет

- Final Draft of Academic WritingДокумент4 страницыFinal Draft of Academic Writingvwandah0Оценок пока нет

- Sound Propagation p.11-p.13Документ2 страницыSound Propagation p.11-p.13Antonio BarónОценок пока нет

- IodinДокумент7 страницIodinnovi lianaОценок пока нет

- Alix HansonДокумент1 страницаAlix HansonAlix HinesОценок пока нет

- Master Umk CourseworkДокумент4 страницыMaster Umk Courseworkzgctgvvcf100% (2)

- Mt271 Lecture Notes 1Документ13 страницMt271 Lecture Notes 1Ahmed MasoudОценок пока нет

- WKS 5 Cutting and Welding Drums and TanksДокумент3 страницыWKS 5 Cutting and Welding Drums and TanksKishor KoshyОценок пока нет

- Line Out Building SettingДокумент1 страницаLine Out Building SettingvkОценок пока нет