Академический Документы

Профессиональный Документы

Культура Документы

Ferric and Ferrous

Загружено:

MwemeziАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ferric and Ferrous

Загружено:

MwemeziАвторское право:

Доступные форматы

Forms of Iron Found in Water Iron will cause an orange stain and will many times be accompanied by manganese

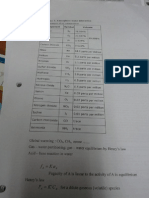

and hydrogen sulfide gas odor. In combination with manganese, Iron staining will sometimes be chocolate or brown. At high concentration (> .3ppm ) the iron will cause the water to have a metallic taste and metallic odor. The iron itself can exist in four forms: 1. Ferrous iron (often referred to as clear-water iron) - This form of iron is invisible in the water just like dissolved sugar is. Just like sugar water, the iron can not be mechanically filtered from the water. 2. Ferric (often referred to as red-water iron) - It is called red water iron because it gives the water a cloudy colored appearance. The iron has precipitated and formed a solid that is no longer in solution - it has turned to rust - "oxidized". This form of iron can be mechanically filtered. An easy way to remember which kind of iron is visible (ferrous or ferric) is to remember that the "i" and the "c" at the end of the word ferric say the same thing as "I see" it. 3. Organic iron (sometimes called heme-iron or pink water iron)- This form is actually iron combined with the dissolved organic matter (tannins) in the water and is held solution with the organic materials. The water will appear clear but may or may not have color. Sometimes this iron will begin to oxidize and form a suspension in the water. We refer to this as colloidal iron. 4. Colloidal iron - This will look like red-water iron but can not be easily filtered. The iron has precipitated (turned to ferric iron) but the molecules formed do not stick together in large enough pieces to settle to the bottom of a container or be trapped with normal filtration. This water/solid combination is called a colloid. To test if you have this type of water, collect a sample in a clear glass container. Shine a flashlight beam through the water and see if you can see the light (tyndall effect) in the water. Then, let the water set overnight. If you can see the beam of light as it passes through the water and there was no settling of material on the bottom of the container, the chances are very good that you have colloidal iron. Treatment Ferrous iron can be treated two ways. The most common way is to use a water conditioner or softener to remove the iron by ion exchange. This method can be used on almost any level of iron. We have treated iron concentrations in excess of 100ppm successfully with a water conditioner. This method will only be successful by itself if all the iron is in the ferrous form, the TDS is relatively low (generally <500ppm), the pH is low ( generally <7) and there is very little oxygen in the water. The TDS has to be low to assure that there is no bleed through due to the iron being removed from the resin once attached. High TDS indicates there

are other minerals in the water competing for the sites on the resin (media) the iron has attached to. The low pH and low oxygen assure that the iron will not oxidize to ferric iron while attached to the media (resin). If the iron oxidizes once attached to the media, it can not be removed during regeneration. A second method to remove iron, is a two step process called oxidation filtration. The iron is first oxidized by the use of either oxygen, chlorine or potassium permanganate. The oxidation causes the ferrous iron to form ferric iron. The ferric iron is then removed by filtration. This method is not typically used on very high concentrations (> 8 or 10ppm) of iron because the filter beds will require more frequent backwashing (automatic cleaning) then is reasonably possible. This method may also require the use of some kind of pH correction because iron will not oxidize below a pH of 6.8. There are several types of oxidation filtration systems used today. They are1. Air Injection (our preferred method) - Oxygen in the air is used to oxidize the iron. The system requires the use of a venturi to inject the air. The system is therefore called an air injection system. There are many brand names for this type of system but they all require a minimum flow (usually at least 5 gpm) from the well pump to make the venturi work. This flow must be tested (see pump flow test instructions) before this type of system can be used. Good systems will consist of 3 parts- venturi, air release tank, and filter tank. The air release tank removes any undissolved air and allows for the retention of the water. If the air is not released, severe spitting will result at the faucet. The retention allows time for the oxidation reaction to take place. The filter tank removes the precipitated (ferric) iron that was formed by the oxidation process. 2. Chlorination Systems (our second choice) - Chlorine is introduced into the water by one of two methods. The chlorine can be pumped in with a solution feed pump or it can be dropped in tablet form directly into the well. The water is then either sent to a retention tank and then to a filter or it can be sent directly to a filter. The choice of methods will be determined by the severity of the iron problem and the type of media chosen for the filter tank. If chorine is used, it may be desirable to remove it with carbon. If the iron levels are low (<2ppm), the carbon can also be used as the filter that removes the ferric iron that is formed. If the iron is greater than this (2ppm) than a separate filter with filter AG should be used to remove the ferric iron so the carbon will not be fouled. Some customers will opt to use filter AG as the filter and only use carbon at a sink as a P.O.U (point of use) treatment to remove the chlorine from the drinking water. If this is done, there will still be chlorine in the water at all other faucets and showers. The chlorine should be able to be regulated so that it is of no higher a concentration than that found in city water. CARBON IS NOT TO BE USED UNTIL THE WATER IS CHECKED FOR RADON BECAUSE THE CARBON CAN BECOME A RADIOACTIVE SOURCE.

3. Greensand Systems (NOT USED BY US)- This method uses a catalytic media (called greensand) coated with manganese that is treated periodically (like the salt regeneration of a softener) with potassium permanganate. The potassium permanganate acts as an oxidant (like the chlorine or air). When the iron in the water comes in contact with the surface of media it oxidizes and the ferric iron is then filtered out by sticking to the media before it finds it way through the filter. We do not use this method because these systems can easily bleed manganese into the water and the potassium permanganate is not only poisonous, but, if spilled, stains badly. The manganese that bleeds into the water can get to levels high enough to be toxic. You will hear these filters referred to as iron filters, greensand filters or potassium permanganate filters. Catalytic Media (NOT USED BY US)- This method uses a media similar to greensand. The media has many different trade names but is usually a naturally occurring mineral called pyrolucite (manganese dioxide). This method of treatment counts on there being enough air in the water to provide the oxygen necessary to turn the ferrous iron into ferric iron. This media can also bleed manganese into the water. It doesn't work to remove iron in the water we find locally because there is not enough naturally dissolved oxygen. A second major draw back is that the media is so heavy it is very difficult to back wash properly with the flows available from most residential pumps. Ferric iron can be removed by any of the backwashing filter commonly used. Since the iron is already oxidized the water, only needs to be filtered. Generally the iron will be filtered with AG or Calcite filter media. Organic iron is usually treated with an anion resin in a tank that uses salt like a water conditioner or softener. The resin usually is very expensive and has a short life( 1-2 years). At the end of the resins life, the resin must be replaced at a cost $400 or more dollars. Colloidal Iron is probably the most difficult form of iron to deal with and usually comes with many other water problems. The treatment usually requires two solution feed systems, static mixers, retention tanks and filters. The goal is to floc the iron (make the particles grow large enough to filter) and then filter it. These are very expensive systems (typically $4000-$5000). There are no water treatment companies that want to deal with this type of iron, very few that will and even less know how. We have had very good success and will continue to provide our solution to those who want it.

Вам также может понравиться

- PB RemovalДокумент7 страницPB RemovalMwemeziОценок пока нет

- Rice Husk PretreatmentДокумент4 страницыRice Husk PretreatmentMwemeziОценок пока нет

- Normality TestДокумент15 страницNormality TestMwemeziОценок пока нет

- DW Standards 2012Документ20 страницDW Standards 2012Rangga BarmanaОценок пока нет

- Biosorption of Heavy Metals: An OverviewДокумент11 страницBiosorption of Heavy Metals: An OverviewH15H4MОценок пока нет

- Organic Molecules: Presenter NameДокумент18 страницOrganic Molecules: Presenter NameAudith AudithkumarОценок пока нет

- Soil and Sediment ExtractionДокумент7 страницSoil and Sediment ExtractionMwemeziОценок пока нет

- P Aerosol Meas SureshДокумент41 страницаP Aerosol Meas SureshMwemeziОценок пока нет

- Use of PhytoremediationДокумент17 страницUse of PhytoremediationMwemeziОценок пока нет

- Removal ScienceДокумент7 страницRemoval ScienceMwemeziОценок пока нет

- Influence of Sea Breeze - BC, PM2.5, PM10Документ12 страницInfluence of Sea Breeze - BC, PM2.5, PM10MwemeziОценок пока нет

- Water Quality ReviewДокумент4 страницыWater Quality ReviewMwemeziОценок пока нет

- WWT DisinfectionДокумент49 страницWWT DisinfectionMwemeziОценок пока нет

- BIOAVAILABILITY Physical, Chemical, and Biological InteractionsДокумент11 страницBIOAVAILABILITY Physical, Chemical, and Biological InteractionsMwemeziОценок пока нет

- Chi Square TableДокумент1 страницаChi Square TableMwemeziОценок пока нет

- 8.lee Willingham - Improved Smallholder Pig ProductionДокумент18 страниц8.lee Willingham - Improved Smallholder Pig ProductionMwemeziОценок пока нет

- Aquatic Chemistry Assignment 2Документ1 страницаAquatic Chemistry Assignment 2MwemeziОценок пока нет

- ICP-MS Book ManualДокумент408 страницICP-MS Book ManualMwemezi100% (2)

- City of Malmö 2006Документ8 страницCity of Malmö 2006MwemeziОценок пока нет

- A Mathematics Powerpoint by Eric ZhaoДокумент24 страницыA Mathematics Powerpoint by Eric ZhaomousypusaОценок пока нет

- Gsa 2003BДокумент2 страницыGsa 2003BMwemeziОценок пока нет

- Energy QuestionsДокумент3 страницыEnergy QuestionsMwemeziОценок пока нет

- E S, MES S09, Autumn 2008: Date Time ActivityДокумент1 страницаE S, MES S09, Autumn 2008: Date Time ActivityMwemeziОценок пока нет

- Canon Software Guide enДокумент91 страницаCanon Software Guide enMwemeziОценок пока нет

- IpTIME Manual RouterДокумент6 страницIpTIME Manual RouterMwemeziОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Djj3053 Engineering MechanicsДокумент18 страницDjj3053 Engineering MechanicslyenaОценок пока нет

- Stem 006 Day 3Документ10 страницStem 006 Day 3Caryl Ann C. SernadillaОценок пока нет

- Engineering Mechanics Statics and Dynamics Irving H Shames PDFДокумент2 страницыEngineering Mechanics Statics and Dynamics Irving H Shames PDFNeci CardenoОценок пока нет

- Steel Fabrication UnitДокумент62 страницыSteel Fabrication UnitKhan kingОценок пока нет

- Te-Metals and Non Metal Final Revisor (2022-23)Документ85 страницTe-Metals and Non Metal Final Revisor (2022-23)Gautam SharrmaОценок пока нет

- Universe Question Bank (Introduction) : Physics PhysicsДокумент2 страницыUniverse Question Bank (Introduction) : Physics Physicsanon_50109362Оценок пока нет

- Chemistry-2nd Semester Exam Practice TestДокумент21 страницаChemistry-2nd Semester Exam Practice TestGerick Dave Monencillo Vender100% (1)

- Chap 16 No 1Документ2 страницыChap 16 No 1blackwellbert0% (1)

- OsmosisДокумент4 страницыOsmosisWalica DeokinananОценок пока нет

- Slamet AbdullahДокумент14 страницSlamet AbdullahStanindo ArthalanggengОценок пока нет

- Specialty Chemcials Lab FinalДокумент9 страницSpecialty Chemcials Lab FinalSharath BalachandraОценок пока нет

- A. Velocity B. Length C. Density D. Temperature E. AreaДокумент3 страницыA. Velocity B. Length C. Density D. Temperature E. AreaFitria Istikomah DewiОценок пока нет

- NGДокумент23 страницыNGEngr. Md. Tipu SultanОценок пока нет

- CruДокумент33 страницыCruRenanОценок пока нет

- CATALISEДокумент13 страницCATALISEANTONIO RAUL MANUELОценок пока нет

- Licowax S FlakesДокумент1 страницаLicowax S Flakes王偉仲Оценок пока нет

- Will An Object Float or Sink in Water?Документ3 страницыWill An Object Float or Sink in Water?Isabella Betances-PerezОценок пока нет

- Lasers and Coherent Light SourcesДокумент354 страницыLasers and Coherent Light SourcesDenhell100% (1)

- Chemical Kinetics LabsДокумент14 страницChemical Kinetics Labssukhkaran.dhaliwal82% (11)

- Nonlinear Analysis of Pre Stressed Concrete FramesДокумент18 страницNonlinear Analysis of Pre Stressed Concrete FramesLauОценок пока нет

- Silt Density IndexДокумент11 страницSilt Density IndexWilfredo Suarez Torres100% (1)

- Answer KEY of Nature of Light Online TestДокумент12 страницAnswer KEY of Nature of Light Online TestKhanОценок пока нет

- PetrographyДокумент13 страницPetrographyMI ChoudharyОценок пока нет

- Textile TechnologyДокумент5 страницTextile TechnologyKaye NicolasОценок пока нет

- Thermodynamics (SI Units) Sie 6E - CengelДокумент157 страницThermodynamics (SI Units) Sie 6E - CengelMatt HarrisОценок пока нет

- Science Class X Sample Paper Test 06 For Board Exam 2023 1 PDFДокумент7 страницScience Class X Sample Paper Test 06 For Board Exam 2023 1 PDFSahasra YeruvaОценок пока нет

- Biochemistry Practical 1Документ9 страницBiochemistry Practical 1Ramziya KaleelОценок пока нет

- Experimental Investigation of CI Engine Performance by Nano Additive in BiofuelДокумент5 страницExperimental Investigation of CI Engine Performance by Nano Additive in BiofuelThiruvasagamoorthy KaОценок пока нет

- CombustionДокумент3 страницыCombustionJeancy SenosinОценок пока нет